-

Posts

5,974 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by fredk

-

1. My timber yard had no 4 x 4 in stock when I visited. Largest was 2.5 x 3. But they had some 2 x 2 off-cuts and they cut it down and the blocks cost me all of £2 [$3] 2. I used standard water-proof woodworking PVA. Gluing to about 1/2" of each end of each block. That should take care of the punch hitting a glued joint. No way is the punch going to go in as much as 3/8", maybe 1/4" but no more 3. The boards around the outside are mostly decorative - to make it all look tidy. Very little chance of a block coming loose and breaking away. They also make a grip for easy lifting and moving of the block. I made my block to fit the top of a special stamping/punching table I built 4. The roughness of the end grain on mine can leave marks on the leather sometimes. I usually punch from grain to flesh, but some times I need to go flesh to grain. To prevent wood grain marks I just put a thin bit of waste leather between the two. A harder wood than mine would probably have a smoother end grain. My wood is cheap framing white-wood. The cheapest one can get

-

I have a few small blocks of lead which I used to use for punching into. I mainly used them when I was on-site at a history presentation and I was doing a leather work demo. When heavily marked I just melted it down and let it set again with a fresh surface. But I found it still dulled the punches as it is still metal. I still occasionally use one of the lead blocks when I'm too lazy to move over to the big block just for one small hole My block sits on a 6mm thick rubber slab on a special stamping/punching table I built. I do need to add extra rubber to the bottom of the table tho as it is still not quiet enough

-

I got a timber yard to cut me 3" lengths of 2x2, I then glued them side to side to make a punching block using the end grain of the blocks as the top surface. The advantages are; 1. You don't take a chunk of wood or rubber out of the surface. 2. punching on the side of wood the wood compresses either making it harder to cut a clean hole or giving you a distorted one, but not with this 3. You need to change your punching surface frequently but not with this. 4. I've found my punches stay sharper longer The black marks are my alignment marks; so that no two blocks have the end grain pattern running in the same direction. I've used this block for many years. The punches do leave circular ring marks in the end grain but have never removed any wood. This cost me just a few ££ to make

-

Mexican loop holster... And belt

fredk replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I'll be making to the pattern I suggested but it'll be fancy cos I'll do it as a holster for my new cell phone Off to sort out the leather now. . . . .- 23 replies

-

- mexican loop

- belt

-

(and 1 more)

Tagged with:

-

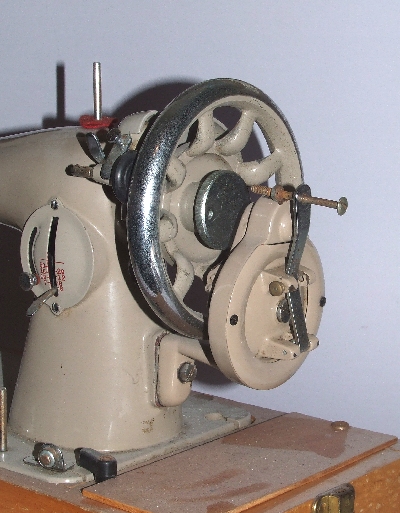

Question; the collar I've circled is spring loaded. When I press it the shaft for the foot-raising lever raises up. For Why?

-

Even tho the OP has cut his lines he can use those to guide a groover. A stitching groover would do the job too

-

I would use a groover to cut a, er. . . groove, rather than a cut line. I use woodcarver's V and U chisels for cutting certain grooves. I also sometimes, rarely, use the Tandy V gouge : https://www.tandyleather.eu/en/product/craftool-adjustable-v-gouge-2

-

Mexican loop holster... And belt

fredk replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Maybe use a slit and a big button or wood toggle - easier for wee hands. . . . and quicker cos yer cowboy haz gotta get to his ammo quick afore he's a deader edit; PS. I think I'll knock one up tonite or tomorrow, jus cos I wanna.- 23 replies

-

- mexican loop

- belt

-

(and 1 more)

Tagged with:

-

I forgive you This time

-

Thanks. I believe I have both roller and teflon feet which should fit this. I'll check later that I do still have them and that they fit. They were bought for the 15K

-

Mexican loop holster... And belt

fredk replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Up to you how far you wanna go; I'd make a simple one. One big back piece which includes the front flap. A bit of a welt and one front piece. The flap part of the back comes over the top and is held closed by a Sam Brown stud. One wide-ish bit on the back for the belt to slip thru. The belt loop can be riveted on. Using soft leather for the front it'll stretch enough to hold a whole bunch of 8 round caps.- 23 replies

-

- mexican loop

- belt

-

(and 1 more)

Tagged with:

-

Mexican loop holster... And belt

fredk replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Well no decent cowboy is gonna go around with only 8 shots. He's gonna need a lot more for those gunfights. Have you any conchos? put a star one on the pouch?- 23 replies

-

- mexican loop

- belt

-

(and 1 more)

Tagged with:

-

Got it. It was seized up a bit tho. A bit of brute force and oiling got the stop plate moving. Moves real smooth now. Did a little bit-by-bit dismantling and oiling - yup I'm using the proper oil. Had a stiff spot in the mechanism. Turned out to be mostly a big divot of fluff between the teeth bit and the case. As the teeth moved back they jammed a bit by the fluff. Once cleared and all oiled its moving like Fred Astaire on an ice rink The plastic handle for the handcrank was in the accessory box. Its all ok, but I might change the handle to a wooden one. The shaft and release parts of the bobbin winder were slightly seized up. Once again, oiled and worked and its working fine. I thought of leaving it off but then there is a big ugly gap there. Come 'ere, I'll tell ye a funny one. I said there was no serial number. There is. On the main casting, just under the front lip. Each time I'd opened it up to see under I'd been putting one of my hands right over the serial number plate! big Doh!

-

Mexican loop holster... And belt

fredk replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

umm, are ya gonna make an ammo pouch for them 8 shot cartyriges?- 23 replies

-

- mexican loop

- belt

-

(and 1 more)

Tagged with:

-

Mexican loop holster... And belt

fredk replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Lucky nephew with an Unc who just made him a real cowboy gun holster. He'll be all set up to catch those dastardly piggy-bank robbers- 23 replies

-

- mexican loop

- belt

-

(and 1 more)

Tagged with:

-

To cover the bases as it were; the belt strap just folds around that bar and the hook just hooks into the holes on the other end of the belt

-

Thanks guys

-

Righto - understand the first bit. ~Sorry, but not the bit I've embolden I have a singer 15K in my collection. Do you think this copy would take the same bobbin case? it needs a new one. And would the threading be about the same as I have the instructions for the 15K. Needles? same domestic Singer type? ~I can never get my head round to understanding thread sizes. I intend to use Gutterman 'Topstitch' thread with this, which needs a 100 or so needle.

-

My turn to ask questions. All help and advice gratefully received I picked this unknown machine up at Charity Shop [Thrift shop in USA] for a contribution of £10 Before I get stuck into sorting it out I'd like see if I can get some info on it. I'm guessing its a Japanese clone of a Singer. There is no serial number or maker's name on as far as first inspection can discern Front side: Rear side: Control knob on front of base: it reads; Embroidery, Silk, Normal Working end: I have the cover plate but it needs repaired; no screws to hold the spring in place. Nae prob fixin thon Stitch choice control; Question - Is the knob on the left to lock the choice lever or a reverse selection? This has a gearbox attachment on the fly wheel end. That bolt thats been fitted has a nut which restricts its turning to just under one revolution. It seems to be a 1:2 gear box, one turn of the gearbox turns the flywheel round by twice. Obviously that bolt needs changing to a handle and the gear box attachment to the main body needs fixing. The bolt and nut has been fitted and then bent to try and clear the gearbox but it shows its been rubbing on the gearbox housing for sometime use - daft, why not just back-off the nut?? All in all, it turns over freely and the mechanics underneath all look clean and oiled. PS: I'm aware this might not do much in my leatherwork, maybe manage very thin leather, however I do sew other materials as well TIA Fred

-

With chisel holes I prefer a 1mm thread and #17 Glover's needle or a #2 Saddler's needle

-

Working from the cow's backbone - spine - towards the belly; the back bone area is both the thickest, strongest and has virtually no stretch, round the sides a bit the leather is not as thick, still very strong and has a modest amount of stretch, the belly area has the most amount of stretch, not very great strength and tends to be thinner. The shoulders tend to be just slightly less than backbone and slightly more than sides of the cow. The backbone area is best for belts and straps. The sides for general purpose; wet moulding, wallet making. The belly area is good for women's purses/handbags where they like some stretch for the many things they like to carry or for back-packs. Shoulders are good for gun holsters; its strong and thick but can be modestly wet moulded As for thickness; most of the leather can be bought at many thickness - its up to the tannery how much they skive it to get to an even all over thickness. But generally backbone is 4.5 mm and thicker, sides are about 3.5mm to about 2.5mm and belly is 3mm to 0.8mm, shoulders are about 3 to 4.5mm

-

I just measured round my own hat; its a 56 cm head size. Around the outside of the crown is exactly 60 cm My hat bands I make are like belts with a buckle. The end with adjustment holes; 4cm to go thru the buckle and keeper is not too much. It allows a couple of extra holes at 1 cm intervals for a slightly larger diameter crown. 3 cm is too little and above 5cm looks too ungainly. On the other end for the buckle a fold around of 4cm is modest. It can be less, but at 4cm there is room for a keeper to be sandwiched Tandy sells ready cut hat-band straps. The straps are pre-punched for main fittings. They are 3/8" wide. 74 cm long and the fold around the buckle is 6cm [74 - 6 = 68cm nominal hat band]

-

A granite slab is of use other than stamping/tooling on. You can hold your leather on it to skive the edges - when the skive blade hits the granite neither it nor the surface are damaged. You can hold your leather on it to burnish the grain or the flesh side.

-

Average ladies head is about 56cm to 57 cm around; add about 4cm for hat sweat band and material thickness = 60 to 61cm. If doing a buckle joint add at least 4cm to go thru the buckle = 64 to 65cm plus your fold over for the buckle itself, maybe another 4cm = 68 to 69 cm, so around 70cm

-

I think; divide up your tools into similar types, eg all the punches, all the sewing items, then make tool rolls for them. Make simple drawstring bags for the rivets and tuck them into a pocket in the tool roll https://www.leathercraftlibrary.com/product/1760/making-a-leather-tool-roll-by-george-hurst