-

Posts

5,931 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by fredk

-

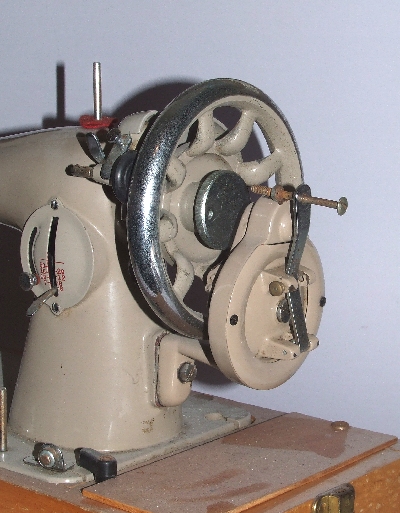

My turn to ask questions. All help and advice gratefully received I picked this unknown machine up at Charity Shop [Thrift shop in USA] for a contribution of £10 Before I get stuck into sorting it out I'd like see if I can get some info on it. I'm guessing its a Japanese clone of a Singer. There is no serial number or maker's name on as far as first inspection can discern Front side: Rear side: Control knob on front of base: it reads; Embroidery, Silk, Normal Working end: I have the cover plate but it needs repaired; no screws to hold the spring in place. Nae prob fixin thon Stitch choice control; Question - Is the knob on the left to lock the choice lever or a reverse selection? This has a gearbox attachment on the fly wheel end. That bolt thats been fitted has a nut which restricts its turning to just under one revolution. It seems to be a 1:2 gear box, one turn of the gearbox turns the flywheel round by twice. Obviously that bolt needs changing to a handle and the gear box attachment to the main body needs fixing. The bolt and nut has been fitted and then bent to try and clear the gearbox but it shows its been rubbing on the gearbox housing for sometime use - daft, why not just back-off the nut?? All in all, it turns over freely and the mechanics underneath all look clean and oiled. PS: I'm aware this might not do much in my leatherwork, maybe manage very thin leather, however I do sew other materials as well TIA Fred

-

With chisel holes I prefer a 1mm thread and #17 Glover's needle or a #2 Saddler's needle

-

Working from the cow's backbone - spine - towards the belly; the back bone area is both the thickest, strongest and has virtually no stretch, round the sides a bit the leather is not as thick, still very strong and has a modest amount of stretch, the belly area has the most amount of stretch, not very great strength and tends to be thinner. The shoulders tend to be just slightly less than backbone and slightly more than sides of the cow. The backbone area is best for belts and straps. The sides for general purpose; wet moulding, wallet making. The belly area is good for women's purses/handbags where they like some stretch for the many things they like to carry or for back-packs. Shoulders are good for gun holsters; its strong and thick but can be modestly wet moulded As for thickness; most of the leather can be bought at many thickness - its up to the tannery how much they skive it to get to an even all over thickness. But generally backbone is 4.5 mm and thicker, sides are about 3.5mm to about 2.5mm and belly is 3mm to 0.8mm, shoulders are about 3 to 4.5mm

-

I just measured round my own hat; its a 56 cm head size. Around the outside of the crown is exactly 60 cm My hat bands I make are like belts with a buckle. The end with adjustment holes; 4cm to go thru the buckle and keeper is not too much. It allows a couple of extra holes at 1 cm intervals for a slightly larger diameter crown. 3 cm is too little and above 5cm looks too ungainly. On the other end for the buckle a fold around of 4cm is modest. It can be less, but at 4cm there is room for a keeper to be sandwiched Tandy sells ready cut hat-band straps. The straps are pre-punched for main fittings. They are 3/8" wide. 74 cm long and the fold around the buckle is 6cm [74 - 6 = 68cm nominal hat band]

-

A granite slab is of use other than stamping/tooling on. You can hold your leather on it to skive the edges - when the skive blade hits the granite neither it nor the surface are damaged. You can hold your leather on it to burnish the grain or the flesh side.

-

Average ladies head is about 56cm to 57 cm around; add about 4cm for hat sweat band and material thickness = 60 to 61cm. If doing a buckle joint add at least 4cm to go thru the buckle = 64 to 65cm plus your fold over for the buckle itself, maybe another 4cm = 68 to 69 cm, so around 70cm

-

I think; divide up your tools into similar types, eg all the punches, all the sewing items, then make tool rolls for them. Make simple drawstring bags for the rivets and tuck them into a pocket in the tool roll https://www.leathercraftlibrary.com/product/1760/making-a-leather-tool-roll-by-george-hurst

-

Whilst many of us will do our own interpretations of many items I do not believe anyone on here, especially me, will actually make a full blown copy of an item produced by any company or individual

-

How to remove stickers from Tandy's leather straps

fredk replied to PappysLeather's topic in How Do I Do That?

If the surface is sealed WD40 will remove the label sticky -

There is no just right leather for anything. Thus to say 'you must use this leather for...' is wrong There is the best leather for a certain project and unsuitable leather for a certain project; it depends on that project. I've made knife sheaths [to order] out of soft 1.1mm upholstery leather, I've used 2mm, 4mm and even 6mm leather for knife sheaths, each to order, so to say 'you must only use 3.5mm leather for a knife sheath' is wrong If I'm asked by someone 'what leather should I use for this?' I'll advise according to the use of the item and what I want from the item and its finish

-

white specks on weaver dyed veg tan leather!

fredk replied to Hankhill11's topic in Leatherwork Conversation

Did you prep your leather before dyeing? It sounds like specks of contamination like greasy dirt preventing the leather from accepting the dye. A wipe over with Fiebings Dye Prep, IPA, Methylated spirits or sometimes I use cellulose thinners to remove anything which might be unseen on the leather surface -

I changed all my bulbs in my flat [apartment] to daylight LED bulbs. My power bill dropped to 35% roughly - not BY 35% but down TO 35%. I reckon the high power LED lights I use in my leather workroom are costing me about 12p [15c] per working day to run, old fashioned lights would cost 70p [85c]

-

Three of my son's car mechanics wear LED headlamps. Two mechanics wear them all day long, about 12 hours. They even leave them on over lunch break. The lamp units are expensive ones with a separate rechargeable battery pack. One battery pack is charging whilst the other is being worn. afaik the battery pack lasts almost a week before needing recharging I have a couple of cheapie ones out of a £1 shop [$ store]. These each take 3 AAA batteries. I don't use them a lot but at a guess I'd say they'd last about 2.5 working days, or about 20 hours work. [I'll do a test] I can buy alkaline AAA batteries 6 for £1. In my experience rechargeable batteries last only a few hours and need changing about every 6 hours. I just find it more convenient to have a few packs of fresh AAA batteries on hand, especially as I have other items which use the same batteries

-

Stitching horse from Springfield Leather?

fredk replied to Mungo's topic in Leatherwork Conversation

I've been thinking of buying this one; https://www.ebay.co.uk/itm/DIY-Leather-Craft-Lacing-Sewing-Leather-Table-Hand-Stitch-Pony-Horse-Clamp-Tool/202436849658 My old one is a basic home made one; have to loosen a wingnut to move item, uprights fixed in one position - this one has a lever clamp and the uprights can be rotated -

Most assuredly, especially if you took a tea/coffee break afterwards

-

Firstly; Le Prevo, Newcastle, UK does an an embossing plate service; http://www.leprevo.co.uk/embossing.htm The plates are done by photo etching and due to the nature of that process the edges of the image are not vertical as in the machined stamps but they widen out a bit as it gets near the backing Two of mine. Both machined in yellow brass by an ebay seller in China. These were actually done by two different sellers My makers mark. 3cm across by 1.8cm high One of the design stamps I had done. Stamp is 5cm across by 3.2cm high All the fine lines, eg in the grill, are nicely replicated

-

If only for a display piece; the only way I see of making that good is to cut away the ripped/broken bits and glue into the spaces freshly cut [& dyed[ sections of leather

-

That would come out ok with my stamp makers, but the landscape would be cut as deep as the sun and rays. To make it less deep I'd take a file over it and reduce it in height and maybe even leave file score marks in it for texture. At the price my maker charges I'd not fuss about doing it on a stamp from them

-

Won't help with your rounded edges but with the binary images like mine, simply make the background black and the image white. The machinest cuts away everything that is white

-

I got a stamp cut to my design by a seller in China. It cost £15 - about $16.50. Time from placing order till it dropped thru my letter box, about 10 days. Its cut in brass so it can be a. used as a hammer stamp b. heated in a pyrogravure for buning in I got my stamp made to 3cm x 2cm roughly. It has an M6 thread hole on the back so I can use a handle I've made up or under the ram of a press. Link to seller; https://www.ebay.co.uk/itm/Custom-Made-Design-Your-Logo-Leather-Seal-Wood-Stamp-Branding-Iron-Carving-Mold/382286790022?hash=item5902117d86:m:mxK2t0VgU1u9BQEIZjJLxxw I've had a few stamps made in China by different makers - they seem to go after a while. I've only ever got binary designs cut and they've managed to replicate the finest of lines

-

Have you guys considered trimming down?

fredk replied to OnePivot's topic in Feedback and Suggestions

mmmm, Topic bar, I might have one with my coffee later I keep four windows open. One for 'Unread Content' and one for 'All Activity', Two for 'How do I do that' - one working from the 1st page and one working from the oldest posting to the newest. Thats about all I need, anymore I just use the search function. This site is really not as bad as another I'm on where there are over 23,000 members, a lot of whom post similar questions within days of each other, post in the wrong section . . . . -

I'm not seeing an image

-

It looks like a longer version of a 'rabbiting* chisel' and he's using it in the way it should be used; to scrape away a thin layer of the surface *Rabbiting is the old name for 'rebate'. In wood work one used a rabbiting plane to shave down a groove in a piece of wood. The groove or shelf formed was to fit a panel flush. Look at the cross section of a picture frame; where the glass and back fit is the rebate. After using the rabbit plane one used a rabbiting chisel to go along the groove/shelf to even it up. If one did the rabbiting well the chisel only took off tiny scrapings. As the others have rightly pointed out he's removing some surface finish for adhesive, but it looks like he's actually skiving it a bit too

-

Dunno bout that. . . . . I believe there is a "special" area on this ere forum . . . . . . just sayin like

-

You asking me? You asking me!?! [in my best Robert de Niro impression] A beeswax mixture melts at around 65* The leather only needs to be slightly above that. I use a hair-dryer to warm the leather to just over hand-very-warm, my beeswax mix is soft and I apply it with a rag, then I play the hairdryer over it and the wax melts and flows into the leather. A couple of coats is enough, if you do more until the wax can no longer be seen disappearing into the leather, then when it cools you can buff that wax to a shine. If you add carnauba wax to a wax mix it will add hardness to the wax and thus stiffness to the leather item