-

Posts

5,262 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

I build steel lined belts . . . and I would have no doubt my steel lined belt would do your job . . . and do it quite well. I wear one often . . . carrying a 48 oz pistol . . . 2 magazines . . . and a cell phone. The steel lined one is the black one . . . the lining runs from the inside most screw down the length of the decoration. The brown belt is a simple double layer gun belt used for the same purpose. I have a friend who has worn one of my steel lined belts for several years now . . . and loves it. Honestly . . . I would hate to have someone take theirs off and use it on me in a skirmish. May God bless, Dwight

-

I got sick n tired of sewing belts with a Boss . . . started saving up for a 3200 . . . and long story short . . . a "blessing" came my way. I was easily able to buy the 4500 instead . . . and am seriously glad I could. Now if I could just get over this covid and get some work done. May God bless, Dwight

-

And there is the proof in the pudding . . . the cylinder is covered . . . triggerguard is covered . . . and even though there is not a lot of wet molding . . . it stays put. Thanks Pastor Bob . . . good lookin job there. May God bless, Dwight

-

Here in the US . . . everything Ikea sells . . . comes with screws that don't fit . . . and generally one broken piece. May God bless, Dwight

-

For revolvers like that . . . your front piece was way too small. It needs to go up to the back side of the cylinder and 3/8 to 1/2 inch above it . . . and the trigger needs to be covered. When you do that . . . the friction of the molding . . . will make it a really good holster Slick bald sold you a junk pattern. It should look a lot more like the image here. May God bless, Dwight

-

New belt for myself

Dwight replied to Ddat's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

A good belt is hard to come by these days . . . but it looks like you did it well. I'm wearing a double 7 oz that is nearly 20 years old . . . it is right at .220 inches thick . . . And I make a version like that which has a steel lining for those who need their britches not to sag. Thanks for sharing with us . . . May God bless, Dwight -

If y'all find something that works better than Weldwood . . . you will have just hit some kind of lottery. When I put it together with Weldwood . . . it rips the leather if I take two pairs of pliers and pull them apart. Don't use anything else other than the cheap rubber cement kids use at school . . . keep a bottle of it around for special projects. AND . . . I got a bottle of ol white glue for an occasional special project that needs it's special touch. Use it once a year maybe. May God bless, Dwight

-

If you have some really good ceiling lighting . . . rig up some mirrors on the back side of the machine . . . let the mirror pick up the ceiling light and toss it over to the sewing area. May God bless, Dwight

-

Actually . . . for my "1 1/2 inch" belts . . . they are actually 1 7/16 inches . . . because the cheap suckers running the pants industries the last few years . . . cut the length of the belt loops slightly. Found a number of britches where a full 1 1/2 is a tad tight going thru . . . but the 1 7/16 slips thru . . . and the missing 1/16 of an inch will not appreciably weaken the belt or make it look out of place. Bui that is just my way of doing things. And don't get me started on the stupidity of the US moving to MM . . . the rest of the stinking world needed to change to suit our inches, feet, yards . . . etc . . . or just get left out in the profit . . . but of course we let the politicians get involved . . . who with appropriate bribes . . . swung us the other way. May God bless, Dwight

-

I got the impression they were not making it any more . . . I used it for the last 15 or more years . . . had a black project last month . . . USMC was all they had. I'd probably give it to someone who drove over to pick it up. For now . . . I just might jump on the vinegaroon band wagon . . . still "contemplating" . . . but thanks . . . I'll check into Springfield Leather as well. May God bless, Dwight

-

I'm gonna get in here . . . simply because Tandy seems to have done away with their oil base dye . . . nothing but USMC black . . . which I'm going to throw away. WAYYYY to much buffing needed to make it work . . . Need someone to school me on vinegaroon . . . how is is made . . . how is it kept . . . how to apply it . . . what extra steps are necessary to make it work and not damage my leather???? Thanks, may God bless, Dwight

-

I've made really nice holsters out of back to back 7/8 and had no trouble . . . I'm wearing a double 8 oz belt sitting here . . . 16 oz total is not bad . . . in fact . . . once it is properly formed . . . the holster is really tough. This is my personal rig . . . almost 20 years old . . . double 7/8 for the holster and the belt. Still fits too . . . lol May God bless, Dwight

-

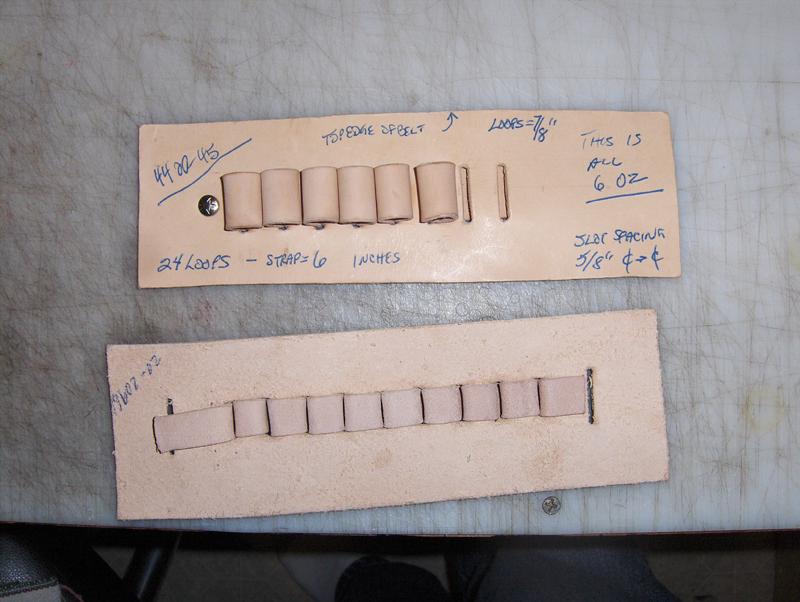

I don't recall where I first saw the design for my bullet loops . . . but I liked doing them this way . . . have sewn them on before . . . and really don't like it. I cannot tell you the space for .357 . . . but you can figure it out very easily . . . take a micrometer . . . measure the width of the casing . . . plus two thicknesses of your leather. I can tell you for sure that 3/4 of an inch is far to wide for that size cartridge . . . in my personal opinion . . . in order to make it really look right. That measurement is the distance center to center of your slots you punch in the leather belt. When you find the punch you want to use . . . cut your leather for the loops to be a fat 1/16 of an inch wider . . . and wet your leather. Rivet it at one end . . . start looping . . . pull each one tight . . . leave the bullet in there for at least 15 minutes . . . then take them all out and let the leather dry. Make sure you rivet the other end as well. Laying flat on a work bench or table . . . the sides of each round will touch . . . but when it gets slung on the human body . . . which is slightly rounded . . . they move slightly away from each other and it works out really well. The originator . . . said to use 5/6 oz calf leather if you could get it . . . I find it hard to come by so I just use veg tan leather. These are my note pieces I use to refresh my memory when I have another one to do. Oh . . . and yes . . . 2/3 oz for the lining is good . . . 4 or even 5 oz would work . . . just use which ever you have. I cut the outside piece . . . leaving it 1/8 to 1/4 inch too big all the way around . . . use it for the inside lining pattern . . . cut em both . . . cement them together with contact cement . . . . get it all right good and wet . . . and make the shape of the holster by putting the gun down on the leather and bringing them together and doing a rough wet forming. . . . let that dry . . . cement and sew the edge . . . viola . . . holster. May God bless, Dwight

-

I may be wrong . . . but from what I'm seeing . . . your needle is way too large . . . and if this is the top . . . your bobbin thread needs tightened . . . if this is the underside . . . your top thread is loose. May God bless, Dwight

-

Thanks, Guys . . . I did the saddle soap routine on it I think 3 times . . . hung it out in the sun . . . I'm thinking there is a smoker out there who would like a leather jacket cheap. It is absolutely nauseating in a closed up car with the heater on . . . May God bless, Dwight

-

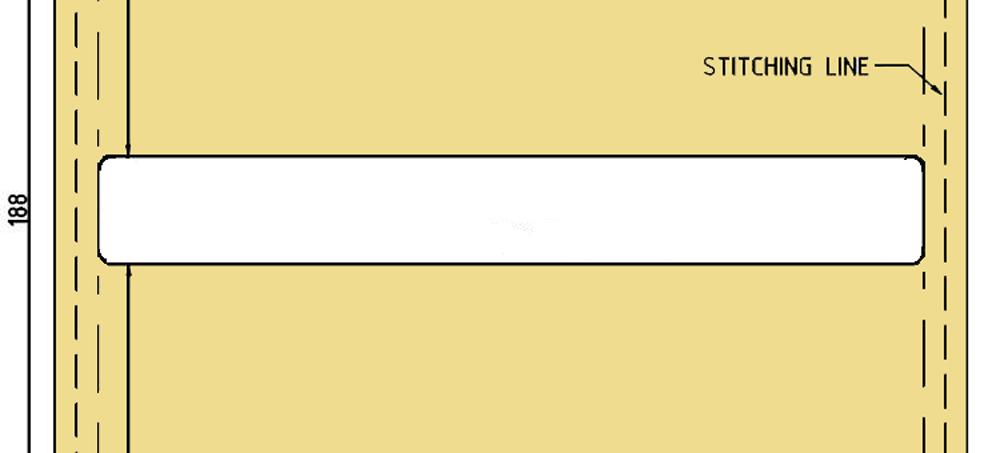

In answer to your "hole" question . . . yes . . . kinda sorta. What a lot of us do when making a "cut out" in a piece of leather . . . is first punch a hole . . . in this case I would use about a 1/4 inch hole. Those holes are punched in the corners of he cut out you want to make. Then starting at the top edge of the two holes at the top of this cut out . . . make straight cuts to the edges of each. Same for the two holes on the bottom . . . then cut the edges. You then wind up with a box that has 4 rounded corners for your cut out. Yes . . . that does definitely keep the corners from tearing better . . . makes for a cleaner look . . . I copied your drawing . . . stripped it down to the affected area . . . and here is what the finished product should resemble. May God bless, Dwight

-

Pictures and drawings do a lot to explain the chatter I read above . . . and could not decipher . . . May God bless, Dwight

-

Take a sponge . . . lightly dampen the flesh side . . . LIGHTLY . . . and use a wide putty knife . . . or something similar to flatten the fibers . . . then a light coat of resolene . . . cut 50/50 with water. Makes a nice finish . . . May God bless, Dwight

-

I didn't see where you considered a Tippmann Boss or one of it's clones . . . totally manual machine. I have used one since 2000 . . . picked up a Cowboy 4500 a year ago . . . that old one armed bandit made a lot of money for me . . . as well as made a lot of products. Looking at your list . . . it would fit very well for all of them . . . provided you are not sewing a lot of belts . . . then it becomes a bit of a pain. The rest are easy peasy for it. Tippmann is right down the road from you in Ft. Wayne . . . and they'll treat you like family . . . May God bless, Dwight

-

Actually . . . you didn't "yup" . . . so to speak. The pattern I sent you was for shooting an M1, and M14 or an M1A (or many other rifles) with iron sights . . . or could be adapted to a scope . . . depending on the scope's height. The cheek piece you made is from the pattern Littlef showed . . . and it was specifically created for the latter end of WW2 and the Korean war for our snipers who were using a scope on the M1 Garand. The cheek piece was made not to get your face in line with the iron sights . . . but was meant specifically to offset your face so you could make out the image in the offset scope that was used on the Garand. Just a little bit of history there. My cheek piece looks like this . . . May God bless, Dwight

-

Looks good . . . May God bless, Dwight

-

a tooled belt

Dwight replied to wolfago's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Beautiful . . . better than any I do . . . May God bless, Dwight -

You said you are interested in harness making. Assuming you want to dress and make your harness water resistant. Use 1 part (by weight) of neatsfoot oil to 1 part (by weight) of pure beeswax . . . heat in a double boiler type container. I use a glass jar set in water in an old small crock pot. It works wonders on all sorts of leather . . . belts, shoes, purses, harness, billfolds . . . the list is truly great. AND . . . it will not harm your leather. May God bless, Dwight

-

Welcome Wolfago . . . Agostino . . . glad to have you as part of the group . . . enjoy yourself while you are here. May God bless, Dwight