-

Posts

5,258 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

I make one of these every now and then, . . . just finished one for an HK USP .45, . . . These pictures don't tell the whole story, . . . but if you look close you can get an idea of my pattern. When I do a scope, . . . I cut a channel down where the sight track should be for the scope mount to go down in, . . . I would do the same for a red dot or anything else like that. In a wheel chair, . . . I would also opt for a thumb break rather than the strap over the gun butt, . . . with the thumb break, you do not have to mold it tight for retention, as the thumb break will provide security. May God bless, Dwight

-

I played the game trying to find something that works really well with those dyes, . . . ruined a couple of projects. Said to heck with it. Started back buying their reducer, . . . have not had ONE problem since that was dye related. I'm staying with their reducer, . . . there is not enough savings with anything else to make it worthwhile to ruin an otherwise completed project, . . . trying to save $.50 or a dollar on the dye. Once I did the $$$ calculation as to what I might save vs what I might lose, . . . it was an easy decision for me. Now when I need more dye, . . . I pour out of the bigger bottle, . . . the dye into a 4 oz container, . . . dump that in my dye container, . . . then rinse that bottle out with a 4 oz bottle of reducer, . . . pitch that bottle and keep the clean reducer bottle for the next batch I have to make. It has solved some of my dye problems. May God bless, Dwight

-

Don't let me assume to tell you how to run your railroad, . . . but the devil would be handing out ice cream cones before i would lift 3300 pounds with a 2 inch wide Walmart belt, . . . which is what you are advocating here: 1/16" by 2" wide, . . . is nothing more than a 4 oz strap. Scary !!!!!!!!!!! May God bless, Dwight

-

I've never had any real issues with Tandy snaps, . . . but they did change their supplier, . . . the backer pieces for the male part are differently shaped, . . . and the exterior piece that attaches to the female part seems to be made a bit thinner, . . . BUT, . . . they work, . . . May God bless, Dwight

-

Not to jump on anyone else, . . . but I've been messing with this leather stuff now on and off for 55+ years, . . . line 24 snaps have done everything I've ever asked of them, . . . and while I did one time buy some smaller ones, . . . have never used em. I only use regular line 24 snaps, . . . and some one way snaps (very rarely) that I got from Sailrite several years ago. And I honestly don't know if this tool will work on other sizes, . . . never tried. Oh, . . . and don't go to Walmart for the tool, . . . for some reason, they quit carrying it, . . . Hobby Lobby carries them. May God bless, Dwight

-

This is the tool I use 95% of the time, . . . had it for 12 or so years, . . . bought it at Walmart for $9.95 back then. Make sure you do not lose the little red piece in there, . . . goes around the male portion of the snap, . . . makes the tool work. You can use it without the cylinder but you mess up the snaps some times and that can be aggravating. I also have the Tandy tool set for snaps and rivets, . . . it does not hold as well as this tool in my opinion. The single bad part of it, . . . the throat is small, so the snaps have to be within a couple inches of the edge of whatever you are doing, . . . and for me that is the 95% of my work. May God bless, Dwight http://www.hobbylobby.com/Fabric-Sewing/Sewing-Quilting-Notions/Fasteners/5-8-Heavy-Duty-Fastener-Plier-Kit/p/109268

-

How many layers are you putting together, . . . or are you talking about sewing straps end for end to make a much longer one? May God bless, Dwight

-

If this dude is going to hold 10,000 pounds, . . . how wide and thick is it going to be? May God bless, Dwight

-

Yeldarb, . . . you can fight it, . . . or you can do it the easy way. Personally, . . . I'm all for easy. When I do a bag, . . . especially with an oval or a round bottom, . . . that bottom is stitched very early on in the process. I take a pair of dividers, . . . and lay off an area all around the bottom, . . . in this case it would be 3/8 of an inch. Lay off the same on the side material of the bag, . . . lay it off on the hair side of each piece of leather. Apply Weldwood contact cement up to each line, . . . on the hair side of each piece and allow it to dry. Then, . . . start putting it together, . . . both edges flush with each other, . . . flesh side of the bottom laying against your table, . . . flesh side of the bag's sides pointing up. Allow about a 1/2 inch strip for the overlap of the two sides, . . . and get started. Put together about 4 to 6 inches of the bag and bottom, . . . stitch that in place, . . . but make sure you stitch it at 1/2 inch in from the edge. That will make sure that all the contact cement is well inside the bag, . . . which is especially valuable if you are going to dye it. Contact cement will not allow the dye to penetrate. Work on it about 4 to 6 inches at a time, . . . and when you get around to your starting point, . . . you will then discover why you do this step first. The sides will then be either too short to touch, . . . or too long. Ideally, you want it too long, . . . so you can trim a 1/4 or 1/2 inch off one of the sides, . . . stitch the side up, . . . and have a beautiful and correctly proportioned bag. Sewing the seam first is a recipe for bag and purse disaster in my experience, . . . so I do just about everything else I can before I finally sew that line. Once the bottom and side seams are sewn, . . . you will have a bag that is sewn inside out, . . . simply turn it right side out, . . . voila, . . . beautiful should be the word. May God bless, Dwight

-

It would be tricky, . . . but turning it inside out, . . . would be the first thing I would do, . . . so you are like sewing inside a box. I did a really deep bag for a wedding gift some time back and that is how I did it. Worked out fine. I think this one could be done that way, . . . but it would depend on the dimensions. May God bless, Dwight

-

If a feller had a couple weeks he didn't know what else to do with, . . . I really think the boss could be changed over to a "air over oil" cylinder operation quite easily, . . . with a rocker pedal for the foot, . . . and a sliding air switch and second cylinder on the presser foot, . . . he could keep both hands on the leather, . . . and just as fast as he could rock that foot of his, . . . he could do stitches. BUT, . . . my way, . . . the arm gets tired, . . . it's time for Hershey's and coffee, . . . May God bless, Dwight

-

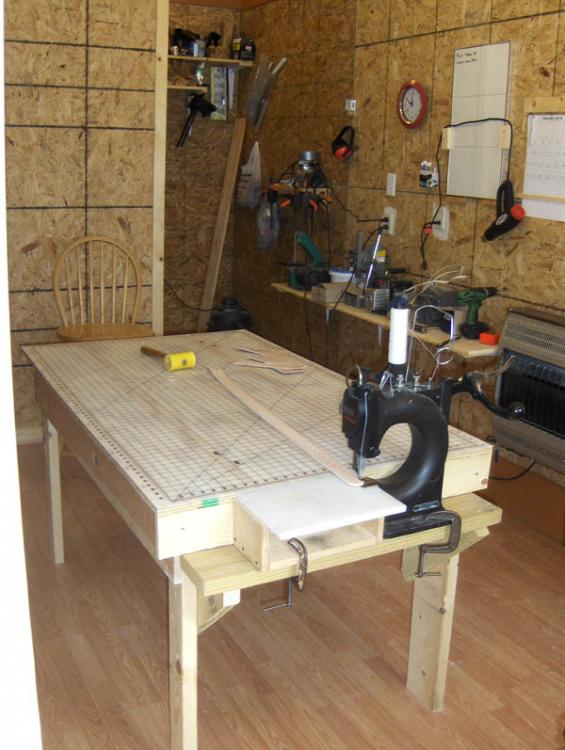

Mine is a Tippmann Boss, . . . love the thing, . . . my website shows some of my work, . . . all done with it. Picture shows the first belt I did in my new shop, . . . fixed a flat table I can slide on the machine, . . . or slip it off and not use the table. May God bless, Dwight

- 42 replies

-

- leather sewing machines

- what machine is used for leather

-

(and 13 more)

Tagged with:

- leather sewing machines

- what machine is used for leather

- professional leather sewing machine

- which leather sewing machine is best

- best machine for sewing leather

- sticky???

- sewing leather

- best antique leather sewing machine

- best new leather sewing machine

- leather sewing machines makes and models

- what machine do the pros use

- leather sewing machine reviews

- leather sewing machine opinions

- best sewing machine

- leather sewing machine question

-

I'll get in here, . . . mine has been a "new" aluminum, . . . from 2005 or 2006, . . . somewhere back there. I use it for whatever I make out of leather, . . . if it needs sewn, . . . except vests, . . . different machine for that. Look on my website for examples, . . . page 3 to be specific, . . . it sews everything up to and including 3/4 inch of dry veggie tanned leather, . . . although not too well on the 3/4 inch stuff. I use it to punch the holes in those things, . . . then hand stitch it. I live 2 hours from the factory, . . . whenever I have a problem (happened twice so far), . . . that I cannot fix myself, . . . I load it up, . . . call em and give em a heads up, . . . one of the mechanics cleans off a bench, . . . fixes my machine, . . . 2 hours later I am back home sewing again (or taking a nap). The Tippmann people are great people to work with. The other day I finished a belt that was darn near 3/8 of an inch thick, . . . for a feller that is in the 44 in waist area, . . . all in about 20 minutes, . . . at almost 6 stitches per inch, . . . total sewing was something over 100 inches. I use everything from 207 thread to 415, . . . but 346 is my mainstay, . . . very seldom use anything else. A happy customer??? Yessir, . . . I am, . . . and if I could go back and buy a different machine, . . . I most likely would not do it, . . . this one does what I want, where I want it, and the way I want it, . . . electrics do not always do that. May God bless, Dwight

-

1. Yes, you can paint the dye on the other pieces, . . . but will that not allow those pieces to be of a different color? I would at least dab them in a corner somewhere out of the way, . . . to see if maybe dabbing them with a sponge will color them without dunking them (the felt pieces). 2. When you say "regular" Feibing black dye, . . . I'm not sure there is any such thing. There is oil dye, . . . USMC dye, . . . water based dye, . . . and probably one or two I forgot to mention. I only use the professional oil dye, . . . so you'll have to check yours against that, . . . maybe talk to someone at the store. BE SURE to thin the black down half and half with their reducer though, . . . or you will be forever getting off the extra pigment. May God bless, Dwight

-

From the appearance, . . . it looks like an oiled leather, . . . no hard finish on it, . . . should not be a big deal to dye it. The one thing you are going to want to do, . . . as much as is possible, . . . take it apart. Get as much of the hardware off as you can. Go to a Tandy leather store, . . . buy 4 of their 4 oz bottles of pro oil black dye, . . . and 4 of their 4 oz bottles of dye reducer. Stop at Walmart and buy an aluminum pan for cooking a turkey, . . . or if you have one to spare at home, . . . a 8 x 14 cake pan works fine, . . . that is what I use. Get a pair of rubber gloves and a roll of paper towels. Mix all the dye and all the reducer together well, . . . pour it in the pan, . . . and one at a time, . . . snake each piece into and through the dye, . . . you don't need to linger any great time, . . . if it is black colored, . . . it is dyed. Hold it up over the pan until the drip-drip-drip stops, . . . then lay it face up on a piece of cardboard. DO NOT HANG it up to dry. Give it 10 to 15 minutes or so and then with the gloves still on, . . . holding the leather by the sides of the straps, . . . take paper towels and wipe off any dye that got on the metal. Sometimes the dye will stain the metal, . . . sometimes it will not, . . . you don't really want to take that chance. Leaving it on there may stain it. Allow the harness to dry for at least 24 hours, . . . then with another paper towel, . . . give it a coat of neatsfoot oil (if you can find it in a small bottle), . . . or olive oil, . . . just enough that you can honestly see that some oil is trying to soak in. Some black pigment will rub off on the towel, . . . don't worry about it. Allow that to dry for a couple of days, . . . then get a white tee shirt you don't like, . . . and laying each strap down on a hard surface that won't move, . . . buff the heck out of the whole harness. When black quits coming off the piece you are buffing, . . . you are done. Once the buffing is done, . . . you should be done. The obvious alternative, . . . is to take it to a local saddle shop, holster shop, or belt shop, . . . have the folks there do it for you, . . . it'll be twice the cost of doing it yourself, . . . but you only have to spill black oil dye on something ONE TIME, to know you don't ever want to do that again. Good luck. May God bless, Dwight

-

You can also contact Weaver Leather in Berlin, Ohio, . . . they will sell you the leather and for a small fee will cut it pretty much to the width's you want. (at least they used to do it, . . . don't know for certain today's details, . . . but contact them, . . . they are absolutely wonderful people to work with) May God bless, Dwight

-

I guess I must be doing something wrong, . . . I use the "flick your bic" type lighter, . . . have never burned a piece of leather yet. I leave about a 1/8 of an inch of thread when I cut it, . . . hit it with the edge of the yellow flame, . . . it melts / burns away, . . . I give it a little thumb rub, . . . done. May God bless, Dwight

-

Ya did good, . . . Springfield came to mind, . . . but when I saw Weaver had em, . . . I left Springfield off. I've actually been on the Weaver location, . . . wonderful people to deal with, . . . that's why I sent you there. Sorry it wasn't exactly what you wanted. Come to think of it, . . . it's about time to arrange another expedition to that area. May God bless, Dwight

- 3 replies

-

- horsehide

- horse butt

-

(and 1 more)

Tagged with:

-

Try Weaver Leather, . . . in I think Berlin, Ohio. http://products.weaverleathersupply.com/search?w=horse hide belt They should be able to help you. May God bless, Dwight

- 3 replies

-

- horsehide

- horse butt

-

(and 1 more)

Tagged with:

-

My latest holster

Dwight replied to hwhleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Hopefully they don't sit down in the dirt. A muzzle full of .45ACP dirt can get someone hurt bad. The reason I recognize it, . . . I'm only 72 and haven't completely grown up, . . . I still play in the dirt quite a bit. Just finished fixing a 10 inch field tile buried about 48 inches in the ground, . . . it blew out, . . . created a 6 foot diameter hole. Had to play in the dirt big time that day. Playing in the garden will get one dirty too, . . . and sometimes, . . . just sitting down next to a camp fire, . . . making memories or smores, . . . checkin' out my cast iron dutch oven, . . . and whatever is cookin in it. Seriously, . . . I would not own a slide, . . . and refuse to make em. They could be a cash item, . . . but I like my customers better than that. But, . . . anyway, . . . I still like your work, . . . keep it up. May God bless, Dwight -

My latest holster

Dwight replied to hwhleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I would say personally, that if you sent it to me, . . . I'd be more than willing to test wear it for you for a couple of years. Seriously, . . . really good looking, . . . the only thing I don't do for sure with my pancakes, . . . I never allow the muzzle to go below the holster, . . . sitting down on the ground "could" get a muzzle full of dirt, . . . which could be very dangerous. Other than that, . . . it's a good job. May God bless, Dwight -

Recent archaeological find: 5,500 year old shoe found in Armenia

Dwight replied to DJole's topic in Leather History

Thanks DJole, . . . wouldn't you love to sit down and have a conversation with the person that made that shoe?? May God bless, Dwight -

John Wayne Suede out belt.

Dwight replied to Forester's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Those pictures were the last one I did, . . . and it was indeed fun. If I had to choose making them or a regular Duke rig, . . . the money belt is probably a bit easier to do, . . . and because it is a bit "different" folks will pay a bit more for it than a normal Duke rig. May God bless, Dwight -

John Wayne Suede out belt.

Dwight replied to Forester's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Honestly, I don't know plinkercases, . . . snaps are probably not "period correct", . . . but then again, not much more than the leather is, . . . and even it has undergone many changes in the way it is created / finished, etc. I tend to go by the overall look, . . . Western?, . . . OK, . . . and I kind of drop it there. But that's just me, . . . and how I approach this stuff. May God bless, Dwight -

John Wayne Suede out belt.

Dwight replied to Forester's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I'm not the worlds best artist, . . . but here's a little drawing that may clear up some of the mud. May God bless, Dwight