Albob

Contributing Member-

Posts

118 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Albob

-

P320 Carry and P320 Compact

Albob replied to JLSleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks for the holster making lesson AGAIN! Fine looking hunks of leather. Off to your Etsy store again. Fredo, San Diego CA -

I'm sorry gents. I too quietly wish folks would show the knives and shooters when they post. Brain fart on my part. Here's the knife. It is made by WALSH but I have checked and it doesn't seem to have been made by the Walsh's in Alaska. If anyone might know of this maker please let me know I'd like to send them a love note. CORRECTION, it is a 10 inch blade, so a little bigger than a pocket knife with an over all length of 16 inches or pure sticky love.

-

Commander 1911 belt and holster

Albob replied to Albob's topic in Gun Holsters, Rifle Slings and Knife Sheathes

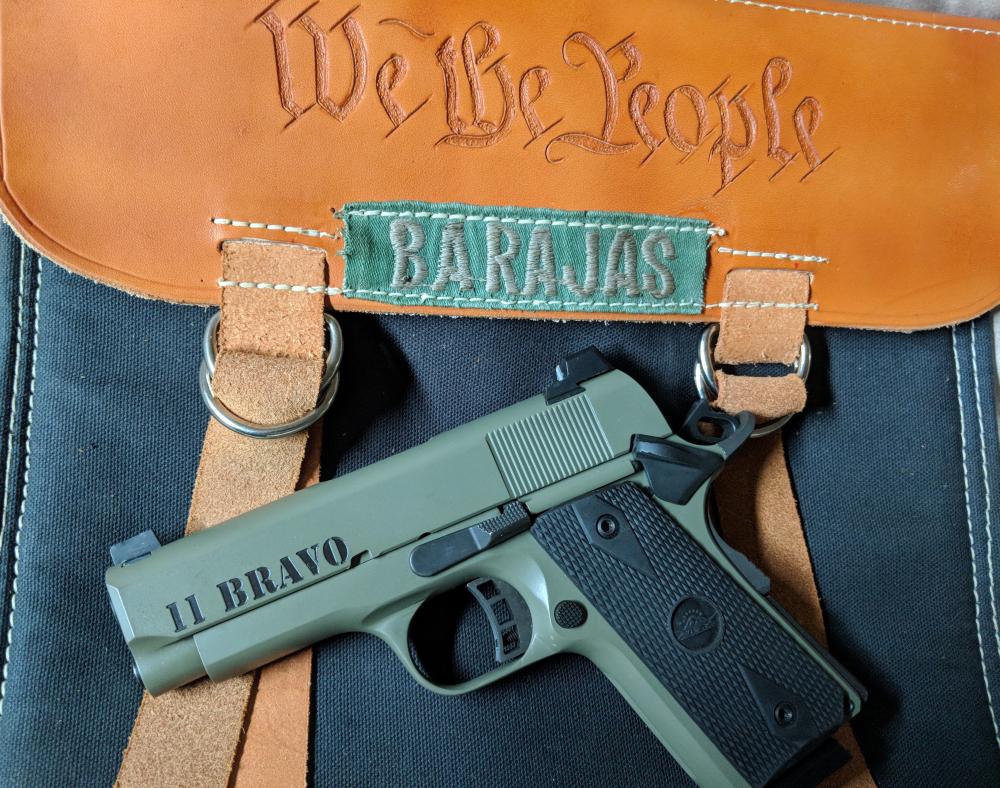

Thanks guys, I am a huge 1911 fan. 1911 is how you spell Freedom numerically. I own a Compact (officers model) that I recently took to the beauty shop for a color and cut. I guess I really should make a holster for it. They also added the trijicon/fiber optic sights for my old eyes to see better. Pic for attention, Army folks will recognize the 11 Bravo. -

I know Mr. Marsh through a mutual friend. I have never met him but hope to someday shake his hand. He is probably one of the nicest people you'll ever talk to. When I first started out working leather He spent over an hour with me on the phone just giving me advice and sharing a few secrets of the trade. Someday I hope to visit his shop and just absorb some knowledge.

-

Since I received my CB3200 I thought I'd post a pic of the last rig I sewed on my singer 111W155. This set up pushed the limits of the old singer which has now been regulated to wallets and other light weight items. You can see where the stitch line on the belt got a little (is that even a word). I can see my tooling still needs a lot of work. I've been reading Jeff's (JSL) input on a few tooling images and I think I have some good thoughts moving forward, all critiques and helpful input is welcome. I don't own a commander size1911 but I do have the blue gun so I figured why not. I can always use a good excuse to get another heater.

-

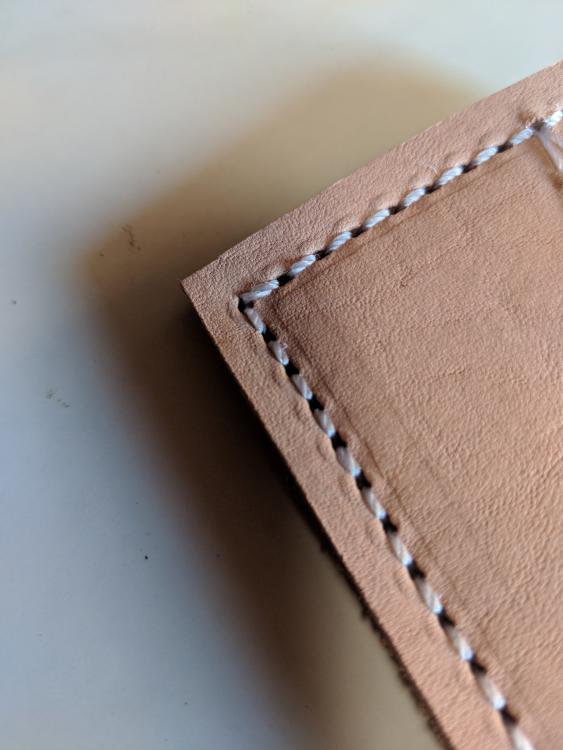

With the recent arrival of the CB3200 from Bob at Toledo Sewing I was able to sew up a little scrap I had laying around as a test. My carving is iffy at best and I didn't do a very good job of a clean stitch line, but it wont scratch anything in the safe for now. 2 layers of 10-12 oz . Veg tan, with same weight welt. The knife is hand made by someone named Walsh, but as far as I can find out it's not The Walsh knife maker from Alaska. 11 inch blade, natural horn handle.

-

I'm absolutely ready to buy a HD Leather sewing machine!

Albob replied to ComputerDoctor's topic in Leatherwork Conversation

I've had my CB3200 for about two days now and I have zero reason to second guess my choice to spend the money. Bob at Toledo Sewing is top notch in communication and helping you decide on which machine to buy. He can work with you to find the lest expensive mode of shipping too. Don't forget to order extra bobbins and a few different size threads. I am Making belts, holsters, knife sheaths etc. For lighter stuff like wallets I have my singer 111W155. -

Airplane, I tried racing for about a year, I never was able to really compete, those kids were just too good for me. I had about 1500 into a buggy and a short course truck, tools and repairs. I sold off both my race rigs and stuck with bashing and crawling just for kicks. I have a tarted up 2 WD slash that I change ties and suspension for street and a entry level crawler built from a box kit.

-

Thanks for the info Bob, again great customer service form you guys. I'll give you a call on Monday and get a few small items ordered. and talk about my phone call yesterday. Fredo San Diego CA

-

Well I got it all bolted up, checked over everything twice and decided to run a few test stitches. It ran pretty good, I still need to figure out why the top belt is so tight, The only adjustment I can find is from the servo motor to the speed reduction. The top belt doesn't seem to have an adjustment? I'll give Bob at Toledo Sewing and ask him about that. The learning curve on this machine is a lot less steep than I feared. In a matter of minutes I was sewing scrap pieces of 10 together. I played with the stitch length adjustment. I also changed the speed a little, but kept it pretty slow to make sure I didn't sew my fingers together. I'm looking forward to learning and using this bad boy. Fredo San Diego CA

-

A big thank's to Bob at Toledo Sewing for the outstanding customer service. He worked with me to get the shipping costs down and communication was/is top notch. Well now I have one, it's in my shed/shop and all I need to do is learn to use it. I'm looking forward to a few hours on it this evening just learning what does what and why it does it. No more sore fingers, no more stabbing myself with big needles when my work slips in the stitching horse. I'm feeling like a kid on Christmas, but I've always been giddy over new tools. Fredo San Diego CA

-

I would try a over loop with snaps. It will be easier for him to put on after he gets out of the truck, Easy on easy off for hanging out at camp too. If his mags are poly then no real issue, if old school metal mags you might want to make sure they are well oiled and put a way for them to drain metal or poly. Post up pics when you get them done. Fredo SAn Diego CA

-

After watching a few videos on leather workers one thing that hit me was they all wear a tool belt with the most common hand tools. Other than that I set mine up in areas of work, cutting area where I cut pieces out of the hides, this is also where I keep my bulk leather. Then the sewing area. I have both a table top Singer 111W155 there and will add the a Cowboy 3200 sometime today. Lastly I have my tooling bench, I do all of my final cuts there and tooling of the leather. If the work is small I cover the bench with a tarp n do gluing and dying there also, If its a large piece I'll dye right our side of the shop with an air brush. I'm in So Cal for weather is seldom an issue for working outside. One last thing is I set my shop up like an working kitchen, it is circular. So as I move through the shop I move in a clock wise circle.

-

How's he going to carry them, off a belt, MOLE compatible, slung over his shoulder?

-

I really enjoyed watching that

-

Thanks for the explanation Wiz. I'm ok with forum rules and guide lines. I've been on enough forums that went south real fast due to a lack. A small inconvenience isn't too bad a of a deal to maintain this forum functional.

-

That's a nice piece, do you have a price in mind? I don't know why I need to have these posts approved by an admin before you see them. Feel free to PM me and I'll send you my number?

-

Well you're asking a fellow not so good tool-er, so I not might be too helpful. I was thinking that you had the craft aid and it shows the number of the tool used and where. I don't have every tool they call out of course but once I figure out they mean beveler, or camo, vainer or whatever then I have a good idea what tool to reach for in my rack. Good luck and keep tapping away

- 5 replies

-

- tooling

- figure pattern

-

(and 2 more)

Tagged with:

-

My opinion and worth every penny you paid for it is since you're not sure if it's glazed pads or sticking pads the first step is take it apart and check it out. I'm not in the know on skivers but if the clutch motor hangs maybe a better option would be a servo conversion. I replaced clutch motor on my old Singer 111W155 and never looked back. I bought the motor from Bob over at Toledo Sewing, for 150 bones I was up and running smooth and quietly,

-

No but I go to Whittier all the time, I'm from the LA area and have family in Whittier. Do you have a pic of what you have and maybe a pic. Feel free to PM me.

-

Those are very nice, That knife is nothing to sneeze at either.

-

I'd guess that you can use the craft aid style as a guide or pint of reference to tool the image.

- 5 replies

-

- tooling

- figure pattern

-

(and 2 more)

Tagged with:

-

Where are you in So Cal, I might be interested in buying hat you have and you can buy what you need or want? I'm in San Diego Fredo

-

Well I guess I have the shop/shed ready to set up the new Cowboy 3200. Now it's all about hurry up and wait (Just like the Army in 73). I'm putting it right in the middle a little back of center. Did I just hear a truck pull up? No I didn't, still waiting but it isn't due till tomorrow. I just like getting new tools HA!

-

That is simply amazing work, thank you for sharing and motivating.