-

Posts

51 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by NCArcher

-

Nice pickup. You don't see those come up for sale very often around here.

-

I downloaded the manual even though I don't have this machine..........yet. Welcome to another Aussie on the forum

-

Press for Rivets and Snaps - So Confused!

NCArcher replied to NewfoundlandLaw's topic in Leather Tools

I bought two sets of dies to suit line 20 and line 24 snaps. https://www.aliexpress.com/item/32486314538.html?spm=a2g0s.9042311.0.0.4b214c4dqX59Nr Drilled and tapped an 8mm hole in my cheap arbor press. Works fantastically. I will pick up a few more sets of dies. They are pretty good quality and super cheap. I still need to make a rotating bottom holder so I can load different sets of dies. I'll post some photos once it's finished. -

I've got a needle positioner on my Consew/Efka servo machine. I love it and wouldn't want to sew without it now. I managed to find a manual for the positioner and it is very easy to set up so that it stops exactly where you want it to.

-

Just click on this @Techsew Ron

-

This might help https://www.manualslib.com/download/998200/Juki-Lu-562.html

-

No, it changed to World Archery Federation a few years ago. Federation Internationale Tir de la Arc. Is no more. I've always wanted to make my own quiver but haven't had the courage to commit to such a difficult project. One day.

-

I shoot FITA as well, although it's not called that any more, and it is anywhere from 20m to 90m for men. At 90m it is extremely hard to see where your arrows are hitting without a scope. The quiver looks great by the way. Nice work. Is it stamped on both sides or is it left hand only.

-

It may be poor quality rivets with the hole in the washer very slightly too large. Are you able to try a different source of rivets? I found that using anything other than a block of steel (or an actual anvil) didn't work very well with the copper rivets. You need to peen the post once it is set and cut to the correct length and I couldn't get it to work on anything other than a block of steel.

-

If this is occurring only when you lift the presser foot to turn the corner it may be a problem with the tension relief associated with the presser foot. I don't know if your machine has this but the tension should be relaxed as you lift the presser foot. If that is not happening it may be over-tensioning the top thread on the corners.

-

Aniline dyes are used for lots of things but 'Soluble in Alcohol' doesn't mean Vodka. You will have better results if you mix the dye with isopropyl alcohol or denatured alcohol. The Vodka contains other things, mainly water, that can affect the finish or the quality of the dye. Drink the rest of the Vodka and use a commercial alcohol with the dyes. Maybe finish the dye job before you drink the vodka though

-

Would love to see a video of the whole process Brian. I'm sure plenty of others would as well

-

Similar machines and capabilities. The 206 has a bigger bobbin I think. Both are compound feed. I have a 226 and it will sew what you need but I don't know that much about the 206. I had the impression that it was a bit lighter than the 226 but that may be wrong. For $200 each I would buy both and sell the one you don't need for $400. Still a good price for a solid machine.

-

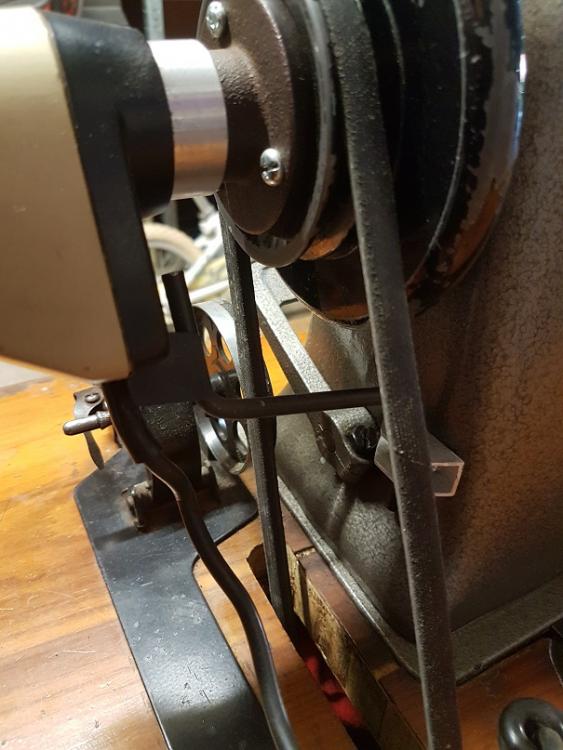

I mentioned in another thread that I had transplanted an Efka servo from one machine to another. I thought others may benefit from my experience. It was reasonably easy to do and took me a few hours all up. I purchased a Consew 226R for a really good price but it had the original clutch motor. I had a Juki 555, that I picked up for nothing, that I had been using for light work that had an Efka servo motor. As the Consew was going to be my main machine I decided to have a go at transplanting the servo from the Juki over to the Consew. Getting the old clutch motor off was no problem and was straight forward. Getting the Efka off the Juki was another matter. The Efka, while on the Juki, also controlled a number of other things like an automatic backtack and a thread cutter. Once I sorted out all the cabling it was OK. Just needed to work out what I needed to keep and what I could junk. The Efka is quite large and heavy and I struggled to get it onto the Consew table. With a bit of swearing, and a few ratchet straps to hold it in place while I bolted it in, I got it done. The Consew has a nice cast iron base, which I wanted to keep, but that meant that room was at a bit of a premium. It took a bit of fiddling to get the motor in so that it cleared the cross brace at the back and still allowed the knee lift to work. I had to tilt the motor a bit to make it fit which meant that I had to enlarge the belt slot in the table. I have plenty of woodworking tools so that was no problem. The motor also has a combined needle positioner and speed feedback encoder. I tried running the motor without it but it wouldn't even turn over. I then had the brilliant idea of just plugging the encoder in to get it to run and work it out later. I couldn't mount the encoder on the handwheel as the Juki had a special fitting for mounting the encoder and I couldn't swap the handwheels over. I turned the machine on and the motor immediately ramped up to full speed and stayed there no matter what I did. The motor had seen that the encoder was plugged in so was waiting for a speed feedback. When it didn't get any feedback it assumed that it wasn't going fast enough so went faster and faster and faster. So I needed to work out how to mount the encoder. The encoder was mounted on the Juki by way of a bracket that was fixed to an extension of the handwheel shaft. I removed the bracket and drilled and tapped holes in the Consew handwheel to fix it in place. It also need a way to prevent it from rotating. I initially drilled a hole in the table and fixed a piece of all thread in place (there's a slot in the encoder for this) but it meant that I had to disconnect it whenever I wanted to tilt the machine back. I changed that to a bent rod mounted on the machine so that it moves with the machine when I tilt it back. I had to drill and tap a couple more holes for this bracket as well. The last mod I had to make was to the foot pedal connection. The Efka is a lot bigger than the clutch motor and the rod was a lot further over the pedal connection. I made up a temporary clamp to hold the rod to the pedal. I will bend up a rod to suit sometime in the future. The motor works beautifully. No programming on these ones. A few switches and trim pots to set the min and max speed and the needle positioner settings. I have it set at a minimum of around 1 stitch/sec and a max of ......?? much faster. I can single stitch if I'm careful with the pedal. I had to recalibrate the needle positioner but that is a 2 sec job. All in all, very happy with how it turned out and how it performs.

-

Which servo motor should I buy in Australia?

NCArcher replied to Carrie88's topic in Leather Sewing Machines

It's a bit of a beast of a servo. Pretty heavy. No programming as such. It is set up with several switches and a few trim pots. The main mod I had to do was fit the position/speed sensor to the Consew hand wheel. I couldn't swap the hand wheels over so had to drill and tap the Consew handwheel to mount the sensor bracket. I then drilled and tapped another hole to mount the post that stops the sensor from rotating. I tried running it without the sensor and the motor took off at full speed with no speed adjustment. I then plugged the sensor in but the motor wouldn't run. It needs the feedback from the sensor. I had to modify the belt slot but that was nothing major. The belt was just at a different angle. You then have to set up the sensor for the correct needle position but that is also pretty straight forward. I'l take some photos and post in another thread. Sorry for the hijack Carrie -

Which servo motor should I buy in Australia?

NCArcher replied to Carrie88's topic in Leather Sewing Machines

http://www.ebay.com.au/itm/220V-Energy-Saving-Mute-Brushless-Servo-Motor-for-Industrial-Sewing-Machine-/162491283593?hash=item25d53c3889:g:Fn8AAOSwRUhZABCN This one comes in at less than $200. I would take a punt and give this a try but I am an electrician and comfortable with messing with it to get it to work if I had to. My Consew 226R has an Efka servo off a Juki 555 that I picked up for nothing. I had to modify the machine and the servo a bit to get it working. It wasn't a straight change over. -

Which servo motor should I buy in Australia?

NCArcher replied to Carrie88's topic in Leather Sewing Machines

The US one is the wrong voltage for Aus. $199 USD is $251 AUD atm. Postage from the US is horrendous. You may be looking at $100 postage even if you could get it in 220V.. I just checked the Reliable site and you can get it in 220V. I'll have a look at some of the EBay ones. -

Which servo motor should I buy in Australia?

NCArcher replied to Carrie88's topic in Leather Sewing Machines

Can you post a link to the motor you are looking at? It's a 2 minute job to change a plug. -

Great list Chain I'm in Sydney and have been buying from Birdsall. Quality is much better than Tandy and prices are pretty good.

- 4 replies

-

- australia

- where to buy leather?

- (and 4 more)

-

I think it might be a circular gasket cutter.

-

White paint and black antique... how is it done?

NCArcher replied to Northlift's topic in How Do I Do That?

Repaint it after you antique -

I've bought a few things from here. Good to deal with. http://www.sewingmachinesaustralia.com.au/shop/buy-accessories/motors

-

That needle seems to be making very large holes. Is it a leather needle? Back the top tension off a bit. It's now too high

-

I like this idea. Easy to implement as well