Webicons

Members-

Posts

250 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Webicons

-

Thanks Fred - Lol - I’ve been trying to get the screw heads to line up! I already ruined a screw trying to get it right. Yes. Will get some polish to clean it up before sending them out. Brass is great to work with but takes on scratches VERY easily.

-

Hello all - Just thought some of you might get a kick out of this. I'm making a few of these for gifts. I find that making tools is a fun way to pass the time between leather projects. If you get inspired to make one yourself make sure you wear eye protection and a respirator! Cutting metal is nasty work and brass dust will get everywhere. I wore a full face respirator for most of the work after losing a few years of my life breathing in some nasty metal dust. Also clamp the metal down whenever exposing the metal to any bit of torque when cutting, sanding, etc. Safety first! I started off with a piece of brass from the junkyard. 20 bucks for a nice long piece of 360 Brass. You can also buy some pre cut pieces from MSCDirect at a fair price. Note that most brass cannot be heat hardened only work hardened. I found this to be a blessing and a curse. On one hand it's an easy metal to work with but will scratch if you look at it wrong. Using a miter saw I cut the brass down to length using a 80 TPI carbide tipped saw blade. Slow and steady here. I then clamped a pneumatic cut off saw (Husky from Home Depot) perpendicular to a 6" cross slide vice (Harbor Freight with coupon) and was able to mill the piece down to the correct width. While I was at it, I also milled the channel that the blade will eventually sit in. At this point I was covered in brass dust and seriously thinking of buying a Bridgeport mill (added to the long list of equipment wanted but can't afford). I clamped the piece into a vice and heated the back spine of the brass handle with a propane torch. While heating, I slowly pinched the bottom of the brass handle together. No need to get it too hot. Its a soft metal and easy to work with. Using a file I shaped the handle to fit nicely in my hand and using sand paper from 320-1000 grit I smoothed everything out. I also had to use some small files to open up the hole in the front to accommodate the blade. From here I drilled and tapped the holes (1/4"x20) using a bottoming tap and secured the blade using slotted set screws purchased from Amazon. You will have to grind down the height of the screws to fit. Cuts like a champ using Blanchard blades from Rocky Mountain Leather Supply (I had to regrind and strop the cutting edge though). If anyone has questions on any part of the process let me know. Thanks!

-

Yang is officially off my list. A buddy had to file a PayPal claim after months of chasing him up through email and Instagram. I’ve seen other similar posts on Instagram. It’s too bad. He puts out a lot of nice stuff but I can’t be bothered with poor communication and aggravation. It’s just not worth it.

-

Interesting life experiences and those are some beautiful clips. It’s also nice to hear that your son is in the business and will carry on the making tradition. Can you provide a link to the finished sling?

-

I would put Yang Tools on probation for now. I hear nothing but poor communication and extremely slow delivery time (+90 days) recently. I would monitor his Instagram feed and ask around before placing an order. The rest of the list is solid.

-

That piece looks like cast iron. If you don’t have the pieces to braze together then I figure the best/easiest way to recreate this piece would be through a lost wax process. Using the piece that you have, you can build upon it with clay or similar, cast in 2 part RTV, make a wax positive, encase in fine sand and pour molten steel or brass. Refine shape with Dremel or files. Definitely a project.

-

Thank you for your insight @RockyAussie. I never really thought about the question of the shaft running true on these older models. Definitely going to rethink purchasing one of them and will not purchase one without running it first. I have heard of the issues with bell skiver without ejectors and I was hoping that I could live without it. Is it possible to just hook it up somehow into a dust collector system? Could you tell me what make and model you are running? Thanks again! You probably saved me a few bucks and a bunch of frustration.

-

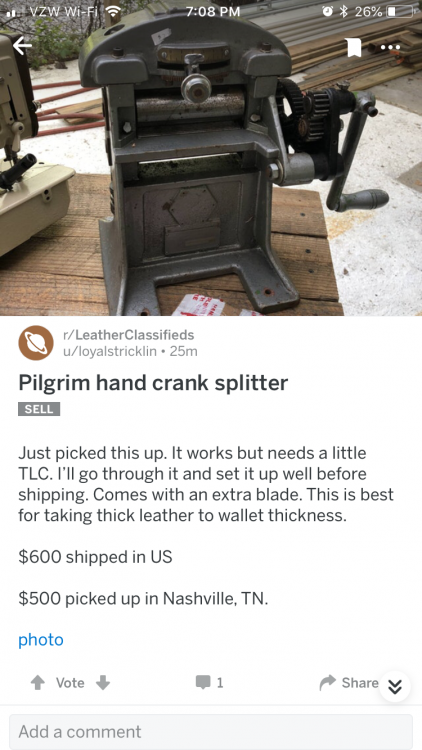

FYI - this crank splitter just came up on Reddit. Comes with an extra blade. Not a bad price. I would jump on this if I didn’t already have my LS440.

-

Which “handle” are you referring to? The crank handle on my American was definitely replaced with a home made one. Just looks like a flat stock of steel with a bolt welded onto one end (to fit on the body) with a set screw and a leather wrapped handle on the other end. Many machine shop could make one. If you’re taking about the adjustment handle then that’s going to be a tough one.

-

Hello All - I’ve been looking for a good quality bell skiver for a while now and one actually popped up a few minutes from me. It is described as a Fortschritt Skiving machine and seems like a Fortuna V50 clone. Can anyone tell me if the parts are typically interchangeable with Fortuna (bell, feet, feeder, etc)? Additionally, if anyone knows how much it would be if I were to purchase all the consumable parts for this unit. Thanks!

-

Lol! I have the same problem! I’m attracted to shiny objects. Thing is, all that looking had inspired me to make my own tools now so I have a second addiction just below leather. Lathe or sewing machine.....hmmm...

-

Try sending him a PM directly through Instagram. He responds pretty quickly through the platform (less the time difference).

-

I've been looking at this tool: https://factorysanta.thebase.in/items/8366986 It is used to evenly space out your stitches as you approach the end of a stitch line but it can be used to plan out and mark your stitch line in a variety of spacing. It can be a powerful tool when stitching wallet pockets.

-

Take a look at Nash Anonymous. I have two custom awls and both are excellent performers and the price is right. Only heard good things about his head knives. Good communication and about three week turn around.

-

Hello All - Hoping some bell skiver gurus can chime in here... I am looking at a few bell skiver units online: two fairly new chinese units and a Fortuna. Since I am a sucker for vintage fixer uppers I am more drawn to the Fortuna. The posting states that it's a V50. My questions are: Is this truely a V50 or perhaps a V50K or S or? Can this unit be converted to run full speed on the knife and vary speed on the feeder? Are the parts interchangeable with modern? Is there an argument to be made for choosing a modern chinese clone over an vintage Fortuna? I typically work with 1.5mm-3mm veg tan and chevre. Hoping to use the bell skiver to get down to ~0.5mm. Much appreciated - Ed

-

You can also try to contact some people who sells vintage Blanchard tools on Ebay France. You may get lucky. Depending on the damage to the screw you may be able to braze or TIG material onto the screw and shape to suit or perhaps have the shop machine just a threaded rod to match so you can cut and weld on a similar head. I am interested to know the price of two custom screws if you would share. Here in the US it would be very expensive. Good luck!

-

They used to be one of only a few companies that specialized in leather working tools but modern design and manufacturing techniques has put tool manufacture in the hands of craftsman and small companies who actually care if their tools are sharp out of the box. That being said, there will always be people who will buy Vergez Blanchard on name recognition, heritage and provenance but if they don't innovate or at the very least, improve the performance of their tools, they won't last another 100 years. As you said, the competition is just too stiff and the global market is too easy to access at a touch of a button. To be fair though, the scale is different. VB will sell more awls in one week than these small companies will sell in a year so who knows.

-

The Eagle HAS landed! (Finally!)

Webicons replied to YinTx's topic in Books, Journals and Photo Albums

Nice design and execution.- 17 replies

-

- 3 ring binder

- eagle

-

(and 1 more)

Tagged with:

-

Search for Bontex board (a.k.a. Texon outside the US). It is commonly available from sizes 0.6 mm - 2.0 mm thick. It is easy to cut, retains its shape and since it is commonly used in footwear, it is treated to resist odors.

-

Sewing machine with removable flat bed

Webicons replied to Rockoboy's topic in Leather Sewing Machines

I’ve always wondered why I don’t see this around more often. Very practical design. How does it perform? What would you do to improve on v2.0? -

I think @DreamFactory has every right to be concerned when this thread discusses making copies of his design. It's hard enough to make a living doing leather work without always having to worry about someone stealing either core aspects of your design or just a blatant copy. When people say "similar" all I can think about is Raphael's Lean wallet v. Craft&Lore's Port wallet (https://www.kickstarter.com/projects/jamesraphael/the-leantm-essentials-wallet-from-raphael-quality/posts/1286812). Everyone has a right to make their own, it's a free world, i'm just saying, put yourself in his shoes before being indignant and give this guy a break. With all this talk of reverse engineering, any self respecting maker would be concerned.

- 25 replies

-

- handstitched

- sewing

-

(and 3 more)

Tagged with:

-

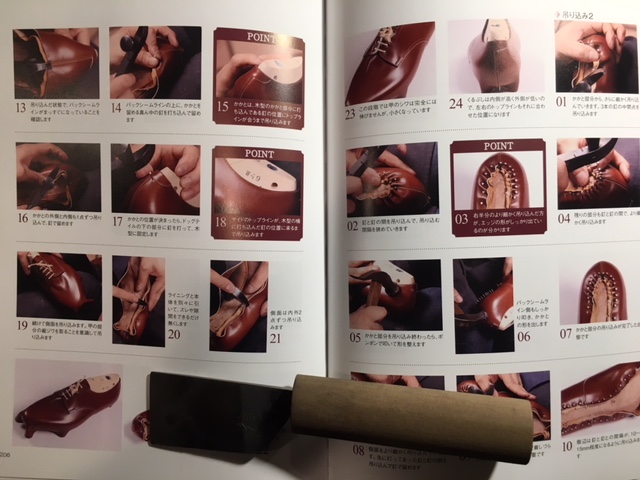

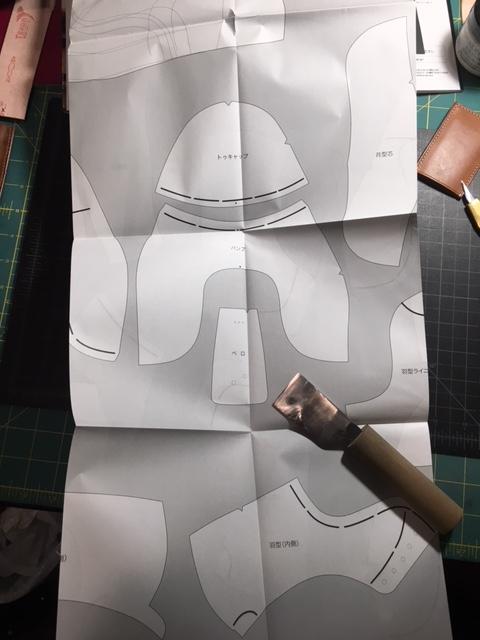

I highly recommend “The Book of Men’s Shoes Making” publishes by StudioTac. It’s totally written in Japanese but the photos are so detailed that you can easily understand it. Google translate on my iPhone also works well enough when I need it. Full step by step from lasting to hand welting. I am working on my first pair of Derby shoes in my spare time. It’s a fun hobby and cheaper than a therapist.

- 16 replies

-

- shoemaking

- education

-

(and 1 more)

Tagged with:

-

Can’t stress how important it is to have a well defined hole on the back side. When using your awl (I’m assuming you have a flat awl because you’re using French irons) make sure it goes through and way past your exit. Hammering your stitch line helps quite a bit when working with thin leathers. Lines that look strait will sometimes angle when hit. When pulling your thread tight lift your left hand up and away and your right hand down and towards you while pulling taut.

-

When using a fabric liner you need to finish the edges by either turning or painting. Both are less than ideal especially if you’re using Buttero but would prevent the edges fraying. On close examination of some of my wife’s wallets, it looks like they are not fully glued on (only the edges). The edges are turned on all of them. Have you tried to finish the flesh side with some wax or just burnish it with tokonole? It comes out better than raw and you may find it acceptable. It will, however, start to wrinkle and fray over time. Still think the best way is to buy an 818 from District split to 1mm. You can choose a neutral color so it can be used for other projects as well. You’re going to put in your precious time so might as well make the best product that you can. Life’s just too short for half-hearted attempts. Just sayin.