-

Posts

1,808 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by hidepounder

-

Thanks Marlon! That was sewn on an Artisan 797. The snap was used at the customers request.......

-

That's exactly right! It's a purely a matter of personal preference. I like to construct it this way because I can get more out of my leather, I don't have to groove and remove leather at the folds, it easier to handle the three pieces when tooling and I like the look of the binding sewn to the front and back. I think it dresses it up. Where it really makes a difference is when your doing a letter size or legal size folder...that's a big piece of leather to have to come up with and manage.

-

Jordan....what a great idea! I love it, that's thinking outside the box!

-

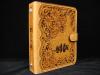

Here is a project just completed for a customer. It's a standard 5-1/2"x 8-1/2" organizer with a 1" three ring binder and a tab closure. It's constructed with 7/8 oz Herman Oak for the front and back, 2 oz for the interior and a piece of 7/8 was split down to 5/6 oz for the binder. Stiffeners were installed under the lining to give it more rigidity. After the tooling was completed and the background was dyed, it was oiled, antiqued and sealed with Neat-Lac. The interior is finger carved and sealed with Tan-Kote. I used a French edger to "let in" the tab to the back leaf so that it is sandwiched between the back and the lining and does not create an annnoying bump on the back of the organizer. I also buried the snap inside the tab for a little cleaner look. Everything was glued and then sewn with Rice #99 Nylon thread, top & bottom, at about 9 stitches per inch. I appreciate all critiques and comments!

-

Stitching with the Artisan Toro 3000

hidepounder replied to Randyc's topic in Leather Sewing Machines

I think it's supposed to Art, but I didn't think the one on my Adler was very effective. When I started grooving, the appearance of my stitiching improved about 300%. I'm still not good at sewing but I spent a lot less time aplogizing for it now! -

Stitching with the Artisan Toro 3000

hidepounder replied to Randyc's topic in Leather Sewing Machines

You can certainly remove the skeg with no negative results. You might want to call Steve at Artisan and see if Artisan offers a harness needle set-up, which has a much narrower and smooth inside and outside presser foot allowing you to get much closer to your molded work, while eliminateing the damage to your leather in the turns. In addition, I have to say that I can't imagine sewing and not using a stitch groover, anymore. I groove everything...I even groove 2/3 oz lining leather now. It protects, your stitches from abraision and makes them much, much prettier! -

Asking For Patterns: Opinions, Please

hidepounder replied to HARVEY's topic in Leatherwork Conversation

I don't think there is anything wrong with asking for help! We all need help at one time or another. Sharing our knowledge of techniques, methods and processes is what this forum is all about. But if the subject is proprietary, don't be surprised if the request is ignored! And you know what ?......no harm, no foul. I know that I'm willing to share what I've learned....I didn't learn everything all on my own....much was shared with me over the years. Sharing ones knowledge, however, is very different than sharing your work. If you want to copy something that I do....I'll help you....after all, imitation is the purest form of flattery. But please don't ask me to send you a pattern I spent hours or days drawing for a customers project! I don't draw very well....it's hard for me...and I'm trying to get paid for my efforts. You may as well ask me for my pants because you can't find yours! Asking for a freebe is not the same as asking for help...and that's inappropriate. Is it okay to ask someone to draw for you? Absolutely....perfectly acceptable...a mutual arrangement between two individuals. There's nothing wrong with that. However......if you really want to learn.......ask for a hand, not a hand-out! -

Bree....I've run into these chemical stains before and have had zero luck restoring the leather! I think it's time to go black! I hope there's not a texture change where the acetone is. Definitely deglaze everything first! The Major's idea may be worth a try...that's a really intersting approach! I would still be concerned that over time the original color and repaired color may not age the same. If there's no budget and no time.....I'd tell the customer how great it will look black!

-

Kustom & skipj, I will try to answer your questions regarding Porters style tooling. It is not as easy as one would think! As I'm sure you're aware, Porters was a very large saddle making company located in Phoenix, AZ., where it thrived for many years. Consequently hundreds of saddlemakers/toolers worked in their shop at one time or another, each perpetuating the Porter style of tooling. Old style Porter tooling is most represented by a large flower at the end of a stem which flows out of another flower or stem. There is a logical flow in the pattern where a stem starts, grows into a flower which is continued by another stem & flower, etc. Here are photos of Porter saddles from their 1931 catalog: As time evolved so did their tooling patterns. You will notice in the photo on the left, that the pattern now flows in interconnected circles, as opposed to the one on the right, which is flowing in a general circle. These photos were taken from their catalog which was being used in the early and mid 1960's: When considering Porter style tooling you must also recognize Bill Porters Saddle Shop where the Porter traditions were continued into the 1980's, long after Porters had closed their doors. In the next two photos you will see the Payson pattern (left), identical to one of the saddles from the 1965 photo and a Deer Valley pattern (right) which is very close to, and might even be confused with the Sheridan style. These two photo's came from a Bill Porters Saddle Shop catalog used in the 1960's, 70's and 80's: So here are six examples of Porter style tooling and you can see the evolution to what is now considered Sheridan sytle tooling. What I see published and called Porter style, today, mostly are those patterns as represented by the 1965 photo's, largely because of Ray Pohja's influence, as he is internationally known as a Porter style tooler. I find this particularly interesting because he was primarily responsible for reducing the size of the Porters patterns into what Bill Porters Saddle Shop, produced, as represented by the Deer Valley pattern. Ray designed a pattern known as the Small Payson, where the Payson flowers were the same size as the flowers in the Deer Valley pattern. I don't know, but suspect that Ray may also have designed the Deer Valley pattern. The Small Payson and the Deer Valley were Bill Porters most popular patterns! How do I know all of this you ask?...................Because I tooled for both Shops !.....................hope this helps to answer your questions!

-

Rawhide...thanks for posting these! Peter's work is always an inspiration. Do you know what value was placed on any of these pieces?

-

Wow Tina....that's beautiful! Your patterns are darn hard to carve....I'm impressed! I like the way you crossed outside the border...adds a lot of interst. Also like the way you used the pebble backgrounder around the pattern and then let it fade. Color is great too. What is the inside like? Please tell me about your lacing...is that an 8 platt braid? I'm asking because I have a couple of laced edge belts coming up and I want to use that braid (haven't laced anything in 20 years). Also...who makes the best kangaroo lace? I'm just not up to making it myself!

-

See minisaddlemaker...he just joined and that's his specialty.

-

Hi Ray...Good topic! I use Neat Lac and Tan Coat....more because that's what I have always used than for any other reason. It's kind of like fishing...you reach for the lure you have confidence in rather than the one that might catch more fish! 99% of what I do is western floral or Sheridan style tooling and I'm particularly interested in this topic because I am unhappy with every sealer I've used, when applying them over an antique finish. When I'm finished antiqueing and have buffed a piece out, the colors are terrific! But the"vibrant" look goes away when I apply a sealer. So much so, that I now photograph before applying the sealer coat. Maybe someone else has experienced this and has a solution. I have used other finishes in the past, but I use these two the most. I can't wait to see some of the responses here...might learn a new technique!

-

A kit purse

hidepounder replied to ClayB's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice purse Clay! I agree with your own critique...those were the things I noticed also. Not much else to do with the pre-punched holes. The pattern that Tina drew is beautiful (Great job Tina!) and very difficult to carve, but you handled it! Tools will make all the difference here. I like the bebble backgrounder, found it a little distracting because there is so much of it, but I think it is what I would have used also. When using that tool it's important to get really even impressions throughout the field, which is difficult here because there is so much area to cover. The other thing that is difficult with this pattern is the fine scroll like vines. I like the color, it's nice and even throughout and I like the contrast with the black leather. Good Job!!! -

Hi Tim Here in Arizona we have a ranch/rodeo association which emphasizes the old rodeo events. I think to join you must be part of a ranching family currently ranching here in Arizona. I don't think they sort or brand but I believe they still have a wild cow milking with adult range cows. Mostly an adult crowd...pretty entertaining...and they're real serious!

-

What style are you looking for Mike? There is a large variety of styles, roping, tripping, pleasure/show, etc. We need to know how it will be used...

-

I do both! When making a high end organizer or pad folio, etc., I custom build the interior to suit the client. The Chaylor Fenneli's size and layout often times does not meet my needs. In addition, building my own gives me the opportunity to "finger carve" the interior and place my makers stamp where I want it. Plus, completely "custom" commands higher prices. However, I often use the Chaylor Fenneli interiors to help keep my prices down...for instance, when the customer isn't so concerned about the layout of the interior, or cannot afford a completely custom piece, usig the manufactured interior often saves the "sale". I cannot build a high end interior for what I can buy theirs for and I think they do a very good job! Here's an example of a full size organizer with a Chaylor Fenneli interior: The photo really exagerates the color of the zipper, however, because the tan zippers do have a pink hue, I now replace them. Hope this helps! Keith Johstone 61-7 5520 7750 0418 751 711 cp

-

Really nice Brian....smooth, clean and nicely tooled!

-

Beautifully done! I assume you air brush, but do use dye?...it looks more like acrylics...but won't they crack or peel? Great job!

-

Beautiful work David!

-

Thanks Lippy....I'm sorry to say I don't...maybe this next year.

-

I'm not sure I should admit this................anyway, while using a draw knife to strip out a belt, I passed my palm thru the blade when the side of leather started to slip off the table......still don't understand how I did it....ended my tooling for a couple of weeks....

-

Evverything Bruce said!...here's Bob's number...I know him and sure recommend calling him! I don't have Keith's number.... Bob Douglas 307/737-2222 307/737-2248 fx Sheridan, WY

-

Thanks Locknut. I'm having a blast here....! Thanks Spencer..! Thanks Ben...!Thanks to all of you for all the kind words!

-

Time for a new and improved one Johanna....