-

Posts

489 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Rolandranch

-

Working Chaps (Bison)

Rolandranch replied to Rolandranch's topic in Clothing, Jackets, Vests and Chaps

Lol. If I'm not doing school or riding a horse, I'm doing leather work. It's work I enjoy so I make as much time for it as I can.- 30 replies

-

- chaps

- bison leather

-

(and 3 more)

Tagged with:

-

Working Chaps (Bison)

Rolandranch replied to Rolandranch's topic in Clothing, Jackets, Vests and Chaps

Thanks Gary! It took me 1 hour and 45 minutes to tool one yoke. Funny you noticed the belt. I hadn't oiled the belt and set it out in the sun like I did the yokes. So you can see the difference the sun does after you oil it. Anyways, it got oiled and sunned and matches the color very closely now. Thanks. I was wondering who would notice the initials first.- 30 replies

-

- chaps

- bison leather

-

(and 3 more)

Tagged with:

-

Working Chaps (Bison)

Rolandranch replied to Rolandranch's topic in Clothing, Jackets, Vests and Chaps

- 30 replies

-

- chaps

- bison leather

-

(and 3 more)

Tagged with:

-

Working Chaps (Bison)

Rolandranch replied to Rolandranch's topic in Clothing, Jackets, Vests and Chaps

- 30 replies

-

- chaps

- bison leather

-

(and 3 more)

Tagged with:

-

Here's something fresh off the bench. These are bison leather shotgun chaps for a cowboy friend of mine. We were rounding up cattle in heavy thickets and he needed chaps badly. Our shirts keep getting torn but I don't think I can fix that. This leather is great working chap leather because it is very tough but supple enough to be comfortable but it is a little scarred. He was very pleased with them. Let me know what you think. Comments/critique welcome.

- 30 replies

-

- chaps

- bison leather

-

(and 3 more)

Tagged with:

-

My take on the Dopp Kit

Rolandranch replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Stunning work, there! Like biker and rocky said, not everyone is a bargain hunter. There's a lot of people looking for superb quality and will pay high dollar for it. I also think $150 is reasonable for your work. The saddle maker I work under charges very high prices for his work but he still has customers galore because he is known for his quality work. I'm still bad at pricing but I'll get there one day. I bumped into a leather worker at Tandy one day and we started talking about prices. He told me when pricing to never think "I'd never pay that much for that" because if everyone thought that then everyone would do leather work. -Ryan -

I would say it is chrome tanned as well. I made some stuff with chrome tanned leather and it has a strong BB glove smell also.

-

You can dip-dye but that often uses a lot of dye which can get expensive. I had the same problem a year ago and this forum helped me fix it. Believe it or not, a cheap airbrush from Harbor Freight puts on the dye very evenly. That's what i would have used for what you are doing. For what you have already done, (if you have not already put the finish on) I would take a damp cloth and rub it in a circular pattern. That will help it blend in. The finish sometimes helps too. Apply neatsfoot and leave it in the sun until it turns the shade you want (10 hrs or so is usually long enough). The sun does miracles to leather color. I think it heats it up and helps the dye, oil, and finish blend evenly into the leather. However, for best results, it should be placed in the sun right after everything is applied. If it's already dry, another light coat of neatsfoot wouldn't hurt before placing it in the sun. Hope this helps. -Ryan

-

Messenger bag

Rolandranch replied to drexcess's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Those must have been some really good courses because that is a very nice bag. Welcome to the forum! -

380 iwb clip holster

Rolandranch replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice work. Great stitching, too. -

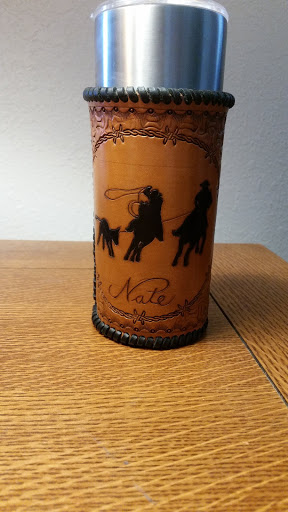

Coffee Koozie!

Rolandranch replied to Rolandranch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Wow. You guys are good at this. -

Coffee Koozie!

Rolandranch replied to Rolandranch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I'm trying to think of a clever reply to this... -

Coffee Koozie!

Rolandranch replied to Rolandranch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

The raven says "caw" (thank you) -

Holster and Gun Belt

Rolandranch replied to Rolandranch's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Oh, I already do...- 41 replies

-

Coffee Koozie!

Rolandranch replied to Rolandranch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

My dad feeds this curious Raven so he's the king of the front yard... or so he thinks. He seems to like my koozie, though. -

Coffee Koozie!

Rolandranch replied to Rolandranch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

-

Coffee Koozie!

Rolandranch replied to Rolandranch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks! It is not riveted on. Just sewn. I see what you mean now. At the moment it's not bad but I can see how time would make it worse. There is a rope inside the handle for stiffness and shape. I will post some pics soon. -

Holster and Gun Belt

Rolandranch replied to Rolandranch's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yes, it had a warranty. I've had it a little over a year now. I don't think it's the motor being servo, I think it's because it's an Enduro servo motor. I did some research and it seems that the Enduro motors are just plain cheap. Great machine but they give you a cheap motor. Also, I was told that if I got a surge protector my motor would last longer because it's power surges that kills them so easily. Maybe I should go Amish and hook up a peddle and power my machine myself. No worries of power surges there. It was funny when the board was shot because almost all my leather orders came to a stop for a few days because the next step involved sewing. My costumers asked me when I'd have their project done. I said, "depends on how fast shipping is." They threatened me to hand stitch it all. Don't get me wrong, I think hand stitching is much better quality than machine stitching and makes the product more hand made but it's not for me. I'll hand stitch if there's less than a foot of stitching to do and I have to, but hand stitching somewhat drains the money out of my work because of the time. Thank you! I'd love to see yours when you finish. Thank you!- 41 replies

-

Holster and Gun Belt

Rolandranch replied to Rolandranch's topic in Gun Holsters, Rifle Slings and Knife Sheathes

But I cried twice... my circuit board blew a few months ago. I replaced the board but will be getting a good motor when/if it happens again. The machine is great, though. It's just that these servo motors are a bit sensitive. They constantly need emotional support and you never know when they'll take a "mental health day."- 41 replies

-

Holster and Gun Belt

Rolandranch replied to Rolandranch's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you! You won't be sorry for buying a good sewing machine. When I started I was going to get a used $100 Singer that I didn't know if it worked or not. My dad said to just get a quality sewing machine that can do heavy work as well. So I ended up getting a cb 4500. Expensive? Yes. Worth it? Definitely. It paid itself off pretty fast. Ryan- 41 replies

-

Coffee Koozie!

Rolandranch replied to Rolandranch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Haha! Thanks, @YinTx! @TxLeather I go by whatever comes to mind first. I have 4 siblings whose names start with S so my mom often accidentally calls me Snate. I'm also known as Nate the Great. People who don't know me personally call me by my real name, Ryan. You can call me RolandRanch'sRowdyRangerRyan. Thanks! -

Holster and Gun Belt

Rolandranch replied to Rolandranch's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you, all!- 41 replies

-

Coffee... it's the secret to my leather work. Made this for myself in a little gap between some larger orders. (Nate is my nickname.) Also, this is my first time making a leather handle so please critique where needed. Let me know what you think. I'll try and get some better pics later. Pair of bison hide working chaps coming soon. -Ryan

-

Yup. Here in Tucson that's the southwest style everybody likes. Good work, Stewart!

-

Spur Straps and Breast Collar

Rolandranch replied to Rolandranch's topic in Saddle & Tack Maker Gallery

Thanks, Jeff! She already nipped me in the bud while I was shoeing her and my back was turned... Im 2 cool 4 scool. lol. No, I take online college courses that only take up a few hours a day so I usually get each week of school done in 3 days so I have time for leather and horses. Can't imagine going to a public school every week day all day. I'm very blessed. Can't leather work be enough though? Can't I just omit school and go full force into leather work? I mean, leather work is kinda school isn't it? I asked my parents those questions but they don't see things the way a leather worker does.... maybe that's a good thing. Anyways, I'll either major or minor in business so that would help my leather business. Lol! Thanks, Plinker! Don't forget very supportive and encouraging parents! Maybe one day, you'll have a great hat like mine. -Ryan- 12 replies

-

- spur straps

- breast collar

-

(and 4 more)

Tagged with: