-

Posts

286 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Pintodeluxe

-

It's called a "lifting lever" part # 91-010 606-45

-

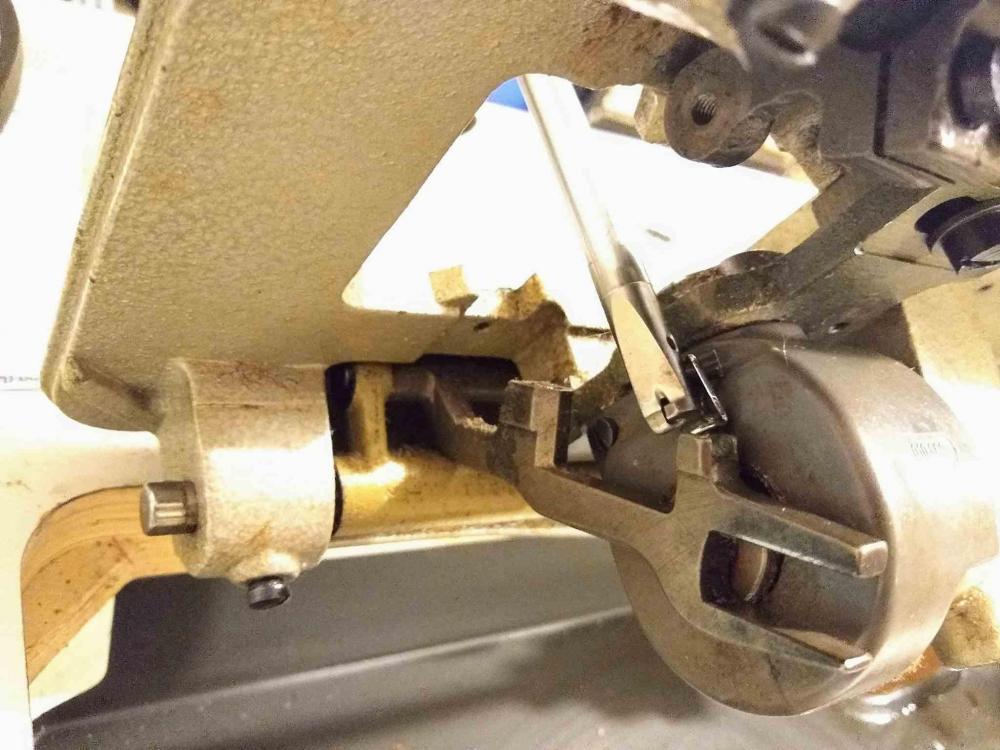

Does anyone have this spare part for a Pfaff 545? It's the linkage on the back of the machine that transfers knee lift movement to the head. I was using the knee lift and heard a sound like a wrench hitting the floor. Ugh, the linkage rod broke in two. It's a 545 H4 high lift model. Anyway, couldn't find one online. Anyone have one for sale?

-

Upholstery supply shops sell a thin backing for French seams. It kind of looks like a strip of canvas.

-

Single felled seam vs. french seam. Both can be great depending on the application. Usually the single felled seam is too bulky on one side for my applications.

-

I was sanding some upholstery leather on the belt sander to thin it a bit. I accidentally touched the top grain side to the belt sander and it gave it a cool antique look. Combined with dyes, I bet a belt sander would be one way to distress leather.

-

I'm not sure what you need the new machine to do, but if a big bobbin is your main requirement I'd recommend a Juki LU-563. It has an extra-large U style bobbin, and is a superbly built Japanese machine. They feel about 10 lbs. heavier than other industrial machines in the same class.

-

My Pfaff 545 H4 will sew about 20-24oz total of upholstery weight 2-3oz supple leather. Look to see if it is an H3 or H4 model. The H4 takes a longer 190 needle system, which can be an advantage with thick projects. If it's an H4, you may find it useful to use a slightly bigger needle than recommended to avoid breaking the needle. Longer needles are good, but can be prone to breaking if they're too thin.

-

The thread fraying I've personally experienced has been due to one of these problems... 1. Old thread / poor quality thread. 2. Sharp edge inside the eye of the needle / defective needle. 3. When threading the machine, if you miss the needle bar thread guide it is a recipe for shredded thread. Quite often a machine is supposed to be equipped with a needle bar thread guide, but it is missing. I would start with new thread in the size you need, 92 weight thread for instance. Then match the needle size to the thread. So 135x17 (135x16 for leather point) is the needle system, and use #19 or #20 needle for that thread. If you move up or down in thread size, change the needle size to match. Best of luck!

-

Deciding between 206RB-1 VS 206RB-5

Pintodeluxe replied to Teslabolt's topic in Leather Sewing Machines

I would take the 206rb-1 without hesitation. I've owned both these versions and while they look nearly identical, there is no comparison. The Rb-1 makes a smooth mechanical sound like a well oiled machine. The Rb-5 goes clackety-clack clackety-clack. No matter how much oil you add, it sounds like it still needs oil. Every RB-5 I've ever used sounds like that. I have to go in the other room to listen to nails on a chalkboard. It's more relaxing. Plus, you get a speed reducer with the Rb-1. That's worth $100-300 alone depending on what type of reducer. You could argue there are better deals on the the Rb-1, but I do believe it's hands down a better built machine. -

That's interesting about the minimum needle with different variants of the 545. I wasn't aware the minimum needle size was different from one 545 to the next. The difference might be something simple like the size of the needle hole in the feed dog. If it doesn't pucker your material, and sews well, it's probably fine. Maybe try a 16 or 18 needle and see if you can find a good middle ground.

- 26 replies

-

- thread size

- sewing machine

-

(and 1 more)

Tagged with:

-

You'd probably break a lot of needles with that small of a needle on a 545 (if it even fits). I have the H4 version which takes 190 system needles. I use #19 or #20 for 92 thread. I think the 545 will sew 138 fine, but I'm not sure about anything thicker.

- 26 replies

-

- thread size

- sewing machine

-

(and 1 more)

Tagged with:

-

Looks fairly similar to a Mitsubishi LY2-3300. Many other Asian brands have made similar machines like Techsew, Tacsew etc. Basically a non triple feed type of walking foot. But you're right, the short foot could be tricky to find. Add the Mitsubishi to your search, and see if anything pops up.

-

WorkPro Quantum 9000 for me. It's mesh seat and back keep you cool while you're working, and it's adjustable in every imaginable way. Super comfortable sewing chair.

-

I would take a class. I took one to learn leather upholstery, and it answered a lot of questions for me. The instructor had 30 years of experience and easily set me on the right path for my projects. Similar classes exist for leather crafting, and would help you tremendously. You may have to drive a bit to an area that offers classes, but it's worth it. There are machine concerns and project specific concerns, and you need to be aware of both to succeed with leather projects. I'm amazed how many machine operators (who are quite skilled at their craft) have very little mechanical knowledge of their machine. Start learning about upper and lower thread tension, matching needle size to thread size, machine oiling and maintenance etc. etc. etc. Then as you learn specific techniques, your machine will behave as expected. Good luck!

-

Mitsubishi YU-360 - looking for info

Pintodeluxe replied to Jooleus's topic in Leather Sewing Machines

I had trouble even finding a picture of this machine, let alone any technical info. Must not be as popular as some other brands. Maybe someone on the forum has some experience with one. Make sure parts are still available if you buy it. -

I can't speak to the Brother model, but the Juki is top shelf. The stitch length adjustment is easy, just push the button and turn the handwheel. It will click into position, then roll the handwheel forward to increase stitch length or backwards to decrease stitch length. The G style bobbin is adequate for some projects and too small for others. If I made belts and wallets, it would be fine. Since I do upholstery work, I went with the 563 with extra large U style bobbin. They are great machines.

- 4 replies

-

- brother ls2-b837

- juki lu-562

-

(and 1 more)

Tagged with:

-

I'd keep looking for a 563. Great machine. Another upholster's favorite is a Pfaff 545, especially the H4 variant. Those are the two machines I use, and they have comparable features like big top-loading bobbins and reverse. I've had Adler 67 and 167's in the past, and I was never that impressed with them for some reason. They are sturdy machines no doubt, I just like Juki and Pfaff a little better. Do you need a double needle machine, or is this just what you could find?

-

So I figured out what parts need to be removed, and successfully replaced the needle bar. It's sewing like new again. Thanks again for the help. A lot of the parts that need to be removed to get the needle bar frame out relate to the foot lifting mechanism. There is a secondary cover on the left side of the head. Once that comes off (with 2 screws) it exposes a flat head bolt. Remove the flat head bolt to start releasing linkage components for the lifter mechanism. Before long the needle bar frame will slide out sideways. Thanks again to those who messaged me and commented on this topic, it was very helpful.

- 6 replies

-

- needle bar

- pfaff 145

-

(and 1 more)

Tagged with:

-

The pictures and info have me on the right track. It looks like I need to remove the hand operated foot lifter to allow the needle bar frame to slide out. Just trying to figure out how the lifter mechanism comes out.

- 6 replies

-

- needle bar

- pfaff 145

-

(and 1 more)

Tagged with:

-

Thanks for the reply. I'd love to see the dismantling instructions for the 145 if you have them. Thanks!

- 6 replies

-

- needle bar

- pfaff 145

-

(and 1 more)

Tagged with:

-

I need to replace the needle bar on my Pfaff 545. The integral thread guide broke, so I ordered a new needle bar, and I have the new part. I removed the hook, and loosened the needle bar, but when I try to slide it down and out it hits other parts. It seems to contact the mechanism that drives the feed dogs. Do I continue disassembly of the feed dog mechanism, or is there an easier way? Remove the needle bar holder and slide it to the left? Thanks for any input you can offer.

- 6 replies

-

- needle bar

- pfaff 145

-

(and 1 more)

Tagged with:

-

On the Pfaff conversion, did you have to replace anything besides the hook assembly and bobbin case? On the Juki 562 to 563 conversion you have to replace the take up lever too. You probably used the same needle bar, and just switched to 190 needles correct? Thanks

-

One other little thing... looks like the bobbin might be in wrong. Hard to tell from the picture. Basically if you hold the bobbin in your left hand, it should unwind by pulling the thread to the right (unwind counterclockwise). It's kind of an anti-backlash feature with most sewing machines.

-

When you're timing and adjusting your machine, I would switch to #92 (tex90) thread size. My 563 doesn't love 138 thread in the bobbin unless the bobbin tension is backed way down. Pair the #90 thread with a #19 or #20 needle size. You have the needle system correct (135x17 or 135x16 for leather point). Swap out the worn and mismatched parts, and double check the timing is exact. As a rough gauge, the hook should pass the middle of the needle skarf. The hook should be as close to the needle as possible, without touching it. Good luck and keep us posted.

-

speed reducer using a servo...question..

Pintodeluxe replied to mixmkr's topic in Leather Sewing Machines

Yes it will. I recommend a box style speed reducer. It mounts where your motor would normally go, then the motor mounts underneath. It's a really slick setup that I use on my 563. Your machine will tip back normally If you go with a box style reducer.