kgg

Contributing Member-

Posts

3,378 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

My posts keep disappearing

kgg replied to DoubleKCustomLeathercraft's topic in Feedback and Suggestions

Post on the front page move down the list as new ones appear but are still in the sub Forum they were created in like a question related to a sewing machine would have been created in the Leather Sewing Machines sub forum but would also appear on the right side of the front forum page. As new topics appear it would move down the list and off the front page but be still listed in the Leather Sewing Machines sub forum. If someone posts a answer to your topic it would reappear on the front page of the forum and then move down the list once again. Your post: Questions on tooling English Bridle is still available in the "How do I do that?" sub forum on page 2 with one response from @TomE. kgg -

Most times it is not a problem but have a seniors moment, be distracted, tired or whatever and Murphy's Law is always at the ready to kick in. You screw up and you want to kick yourself in the butt as you just screwed up the work piece. Someone else my not notice but you will. @toxo I agree. Having a simple centre point ruler of any configuration is easier and correct everytime. Also the fractional measurements in the imperial system are not as easily divided in half as compared to the metric system. I did have a digital mic that read in both metric and imperial which is typical but this particular mic automatically showed half of the actual measurement. kgg

-

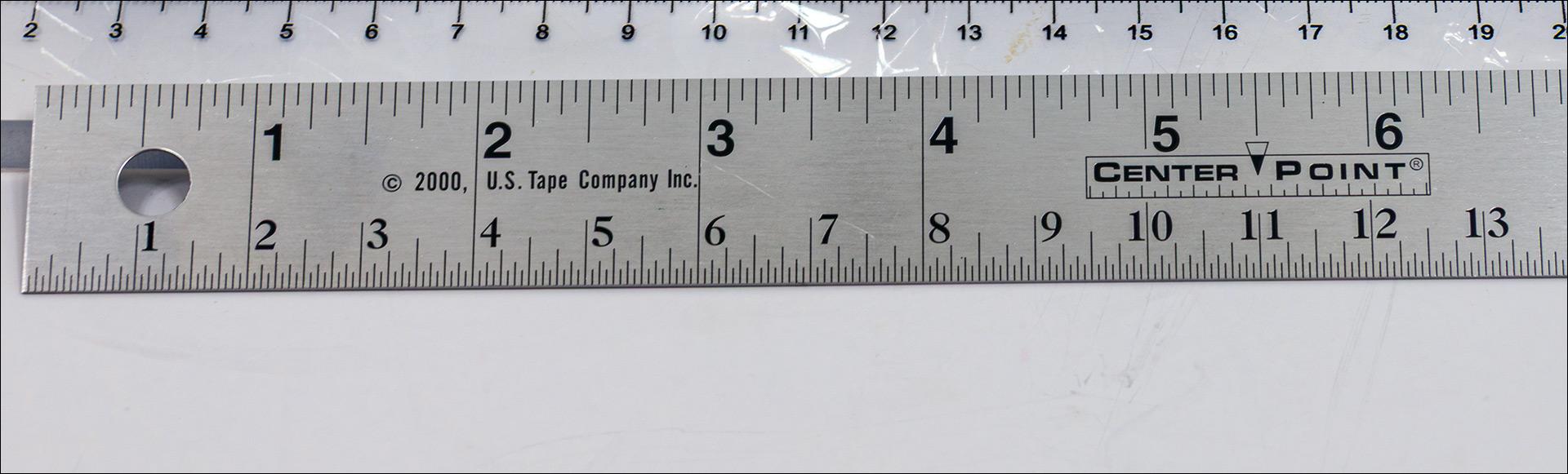

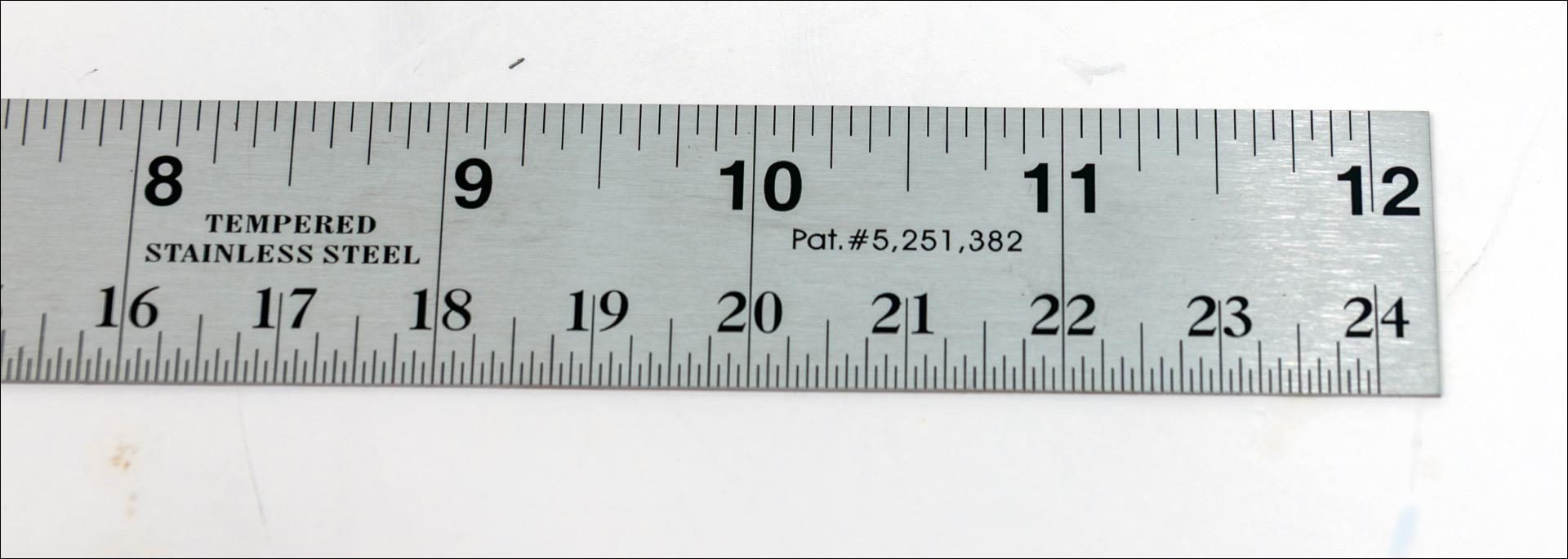

The logo for this ruler is a square with a centre point arrow and the brand name of the ruler is Center Point which is sold by US Tape Company. I figure it was placed at the 5.5" mark just to confuse the hell out of people as it has nothing to do with measurements. kgg Nah, it's a short foot sorta like a short ton (2000lbs). kgg

-

@toxo and @fredk The more options the better. Like when I am doing a dog lead I use a 6' steel ruler. kgg

-

I finally got tired of doing calculations in my head when trying to find the centre of something. Since I was taught, trained and worked in the Imperial and US systems until Canada converted supposedly to the Metric system. Normally the Imperial system is my go to for everyday type measurements. So I finally broke down and bought a 12" centre finding ruler sometimes called a doubling ruler. The ruler: i) Imperial measurements up to 12" or a you can get a larger 24" version ii) Two scales. A measuring scale and a centre point scale iii) Material: Tempered Stainless Steel iv) Sold by US Tape Company (https://www.ustape.com/product/centerpoint-straight-edge-rulers/) v) Made in China vi) patent number: 5,251,382 which is for a tape measure not a ruler???? vii) Status: Expired - Lifetime viii) Cost: I paid $18.90 CAD plus tax for total of $21.35 CAD ( $15.35 ) from Lee Valley This is a very simple design. You just measure the item say 8 1/4" and find 8 1/4" on the bottom scale and that is the centerpoint location. Anyone with a laser or 3d printer could easily make one. To bad they don't have a metric version for better accuracy. kgg

-

Servo motors: You can use either a brushed or brushless servo motor on any industrial sewing machine and it is a straight swap out as the mounting hole pattern is the same. You may have to move the "go" pedal slightly to the left or right. You can buy from a vendor or from Amazon / Temu / Ebay but you are not limited to the dealer should you want / have to change the motor. Brushless servo motors come in typically three puke flavours. Cheap ones have 6 internal coils for the servo motor, mid grade have 9 internal coils and the better ones have 12 internal coils typical wattage ratings of 1/2 hp to 1 hp. The more internal coils the better. Brushed servo motors are simpler to repair with no computer controls, longer lasting with typical wattage ratings of 1/2 hp to 1 hp so less frustration. kgg

-

Carefully and with two people. The strongest one on the heavy end. I would suggest making another table and avoid swapping them back and forth??? kgg

-

I'm glad the you got it freed up. As far as I'm concerned there's nothing better then good old fashion Diesel. It works better then any of the "penetrating oils" just smells a bit. I would now flush/soak the area with synthetic transmission fluid. That will soak in and flush out the old garbage while lubing. Sorry, can't help with the amount of movement you should have. kgg

-

Thank you. Looks uncomfortable but I have never worn one that way, always worn one on the outside. kgg

-

Maybe a vise and a couple of boards. kgg

-

I am going to ask two dumb. Why are the clips on the front of the holster and how does it attach to your belt??? kgg

-

I have had great success with diesel and so so with penetrating oils. Once you give it a go with synthetic transmission oil the smell usually is gone. Another suggestion is to use heat like from a heat gun or propane touch and when it is hot hit it with oil for a fast cool down. That may free it. kgg

-

I would get a wire brush and scrap all round the unit particularly around the feed eccentric seam and then add a few drops of good old fashion diesel around the feed eccentric seam. Wait about 24 hours to let it soak in, a few light tabs with a hammer and without any needle or bobbin run it at different speeds for a few minutes. If it hasn't freed up start over with a few more drops of diesel. Once freed oil the heck out of it with some synthetic transmission oil. If you can't get it freed like @CowboyBob has suggest replace the unit. kgg

-

Have you tried unpluging the servo motor cord from the wall outlet. Some electronic items even through you have the power switch in the "OFF" position they are still drawing power and are basically in a "Sleep Mode". I would unplug and wait a few minutes just to make sure it has fully powered down and cleared it's memory. On my LS-341 clone which has a brushless servo motor and electronic control when I throw the power switch to the "OFF" position the electronic display stays light for about a minute before going blank. So there is a power draw. I would contact both the store and Artisan to clarify your warranty. Having a damaged cable could have or is causing a short which in turn could have caused an error or worst case fried the controller. If you damaged the wiring chances are you are going to be on the hook for a new cable and possibly a controller. If it does turn out to be the controller unit it maybe cheaper just to replace the complete motor setup for about $150 to $200 for 6 coil motor or $300 for a 12 coil motor or a brushed servo motor for about $175. The trouble you are having tracing the source of the problem highlights the difference between a brushed servo motor with no fancy electronics and a brushless servo motor with a electronic controller box. As you can tell I am not a fan of the brushless servo motors. I like my machines to be as simple as possible. Sewing machine, speed reducer (on some), servo motor, drive belt(s) and a go pedal. The two machines with brushless servo motors have the needle positioning disconnected. kgg

-

Rather then you fiddling with a new machine be it a demo unit I would go bring back the machine to the seller and ask them why the 794 needles don't fit and have them correct the problem. kgg

-

According to their manual Page 13 THREAD SPECIFICATIONS: Breaking down what "794s Serv 1 230 ...... SM 53-5 " means i) the 794s Serv 1 denotes the needle has a chisel point tip made for leather sewing ii) the 230 denotes the size of needle. Here is a good reference chart for the thread size vs the needle size needed ( https://www.tolindsewmach.com/thread-chart.html ) iii) the SM 53-5 is the Tippmann Boss part number for the needle. You can order these directly from Tippmann using their part number or from other vendors just by specing the needle system, needle size and shape of the tip of the needle. The needle system (794) denotes the length of the needle. All 794 will be the same length. Are all the needles the same length when you put them side by side?? It maybe as simple as you don't have the screw holding the needle backed off far enough. Otherwise I would call Tippmann. kgg

-

I'm not a moderator just your average joe user and probably a pain in the butt at times. I wholeheartedly appreciate the work and effort that all the moderators do to help keep the rest of us on track and this forum running. You really need to rethink what you said and your tone. It really doesn't do you any favours and may come back to haunt you in the future should you decide to stay when you do need help. Have a nice day. kgg

-

nicely done. kgg

-

Have you thought of using Chicago screws as you can get them in various sizes (diameter and length). Like @fredk I would be more concerned with using AL but then again I have had Copper rivets turn green. kgg

-

My suggestion would be to cut your teeth using a flatbed machine with a standard inline Single fold binder attachment and Double fold binder attachment then experiment doing the edging on various scrap cloth and leather. For this you can buy inexpensive binding attachments off Amazon for about $10 to $15 and you will not need to change the feed dog or presser foot or the needle plate. Size your folder based on the width of the finish tape size you need. Example: 10mm fold over i) you need a 20mm tape and a Single fold binder attachment tape to get you approximately 10 mm fold over on fabric (depending on thickness of fabric)with a raw edge. ii) you need a 40mm tape and Double fold binder attachment tape to get you approximately 10 mm fold over on fabric (depending on thickness of fabric)with a raw edge. The most important thing I can say is make sure that the material you are trying to edge stays snug up against the tape in the folder and the space between the needle / presser foot and the edge of the binder is keep to a minimum. Slow sewing to maintain contact in the binding attachment will help prevent binding tape wonder. I have a set of the 90 degree binder attachments that I never use. I use the inline style (Single & Double fold ) binding attachments (1/4" to 3 1/2") on both my flatbeds and cylinder arm machines. For what I do I never have found the need to change the feed dog or needle plate to do binding on a cylinder arm. As a note: The main advantage a 90 degree binder attachment has over the inline is the ability to do tighter turns. kgg

-

I think you need: i) the right size of folder for the size of binding tape, ii) the folder has to have the correct size opening / pathway for that thickness of binding tape, iii) the correct amount of back tension on the binding tape.

-

Personally I would remove the cotter pin on the catch arm pivot point, the catch arm that catches the side of shaft and see what going on. Maybe the hole in the larger piece at that point has worn the pin or the hole in the larger piece has been enlarged. What do you have to lose? kgg

-

Here is a decent video on how the safety clutch works. ( If your machine will not reengage as @CowboyBob has suggested due to parts being seized I would suggest removing it and soaking it in diesel for a day or so then oiling it. If it still will not work either replace it or as a very last resort tack weld it in place. If you tack weld it in place you will not have a safety and if you jam the machine up you probably or more then likely going to damage / destroy other internal spots. kgg

-

Nice you should get good use of it. kgg