kgg

Contributing Member-

Posts

3,343 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

Willbury in Ontario you are also facing another couple problems, certification and insurance. Nanny state anyone. 1. When you install equipment that is not CSA approved you will need your setup inspected by the Ontario electrical inspection authority and tagged before it is put into service unless you buy a certified setup from a CSA certified manufacturer. Forbid anything happens and it has not been inspected / tagged potentially you maybe left holding the bag. This in the past did created problems prior to the new trade agreement. If I am not mistaken now they have an agreement where CSA or UL certifications are recognized on both sides of the border. An example would have been as simple as buying say a electric stove across the border in the USA and you had a fire. The first thing the fire inspector would check was the nameplate for the CSA certification, no CSA certification your insurance probably would walk. 2. Count on installing a system that can handle at least twice the current of the three phase load rating. Which in turn means your operation cost to operate the clicker will increase. Depending on your location and setup you maybe better just off getting a 3 phase drop to your property. Some addition things to checkout, kgg

-

Juki 1541s Presser Foot Not Moving Not Walking Not Working

kgg replied to threedwag's topic in Leather Sewing Machines

If you could do a video of the rear of the machine it may be more helpful as this would show what the rear drive rod is doing. It could be as simple as one of the bolt has come loose that tightens down to this shaft. kgg -

Understanding Bonded Nylon and Bonded Polyester Thread

kgg replied to Trouthunter's topic in Leather Sewing Machines

Like the old adage, you get what you pay for. My experience is if the thread is going to be exposed to a lot of bleach, as in washing, and drying the bonded polyester thread will hold up much better. kgg -

Understanding Bonded Nylon and Bonded Polyester Thread

kgg replied to Trouthunter's topic in Leather Sewing Machines

It depends on what is designed for. The main manufacturers have different types of thread made for specific sewing purposes. On the bottom of your spool it will have a manufactures name, thread size, colour, weight of spool, type and brand name. Example would be say: Coates, V69, Black, 1 lb, Bonded Polyester, Dabond You then can go to the manufacturers website to figure out all the specs on the brand (Dabond) and what the thread was designed to do best. If it is a generic unlabelled, typically Chinese, thread best of luck. I have see it as stiff as a board and as weak as domestic general purpose V46 and labelled V92. Colour also makes a difference to the stiffness particularly in black as it is a result of the dying process. The best thing to do is by a quality brand like American Elfird (made in Canada and USA) or Coates for the purpose you are sewing. You will spend a little more but the quality will always be there. There is nothing more frustrating then a bad spool of thread. kgg -

Since V69 has a breaking strength of 10.6 lb and V92 has a breaking strength 14.2 lbs you could try tying a piece of thread to 14 lb of weight and see if you can lift it without it breaking. If it breaks it is V69 if not it is V92. Just a thought, Merry Xmas kgg

-

Hi jimi, Merry Xmas, my experience with the 3d printers may help someone down the road. kgg

-

TOTALLY BUMMED OUT!! CANT GET A COBRA Class 26!

kgg replied to KennethLee's topic in Leather Sewing Machines

Well said Uwe. kgg -

TOTALLY BUMMED OUT!! CANT GET A COBRA Class 26!

kgg replied to KennethLee's topic in Leather Sewing Machines

Adding your $500 premium that may put you in the ball park of a Juki LS-1341. Which you may want to consider. kgg -

Advice on buying a post head sewing machine

kgg replied to kjack88's topic in Leather Sewing Machines

Definitely is not that ladies first time doing that work. A master. kgg -

I would seriously look at the Juki LS-1341which is rated for V138, thread top and bobbin. Lots of parts / accessories readily available at reasonable prices for Juki and Juki clones not so much for the Pfaff. If you don't need a cylinder machine since you are not doing bags maybe the Juki DNU 1541S or better a 1508 flatbed machine. kgg

-

Kenmore 148.15600 - Will it sew leather?

kgg replied to bellssn690's topic in Leather Sewing Machines

Simple answer is NO. It is a domestic sewing machine made for fabric probably maxing out at V69 and at $250 it seems to me way overpriced. The Consew even through is more expense I think it would be your better option. Those that use the Consew machine would be better to guide you. Remember "Buy Once, Cry Once" , don't be penny wise and pound foolish. kgg -

Reliable Barracuda and its look a likes

kgg replied to Trouthunter's topic in Leather Sewing Machines

I thought they stopped doing the V138 upgrade but could be mistaken. All these machines were basically intended for was the offshore repair of sail material but can do decent work on other material as well. The pressor foot and feed dog are very aggressive but that can be somewhat tuned out not too leave as many marks in leather. Stitch constantly can be a challenge particularly as material thickness increases. They will do nicely for the occasional heavy use but are not built to withstand it for long. Unless you really need the zig zag feature you would be better off getting a good used machine in the Juki 1541S (compound feed, rated V138 top and bobbin) class or if you don't really need V138 maybe you could go down to a machine in the Juki 1181n (walking foot, rated V92 top and bobbin) class depending on what your needs/wants are. kgg -

My experience is that the 1541S does not like things less then 3mm thick as the feeding is a little too aggressive while on the same amount of material the 1181n happily sews along. The 1541S excels at the mid level of thick stuff while the 1181N excels at the light to mid weight stuff. My 1181n is basically setup for lighter stuff and binding / cording. The pressor foot on the 1181N has a much smaller profile with the feed dog nowhere near as aggressive. The 1181N reminds me more of the feel and sound of a really nice old domestic Singer humming along, just with better capabilities. kgg

-

Ooops me to I forgot to mention I use V69, V92 and V138 in both the Juki 1541S and 1181N. Both machines came sewn off with V138 threaded top / bobbin out of the box even through the 1181N is only rated to V92. I figure I could push the top thread to V207 but keeping V138 in the bobbin without too much problem in the 1541S. kgg

-

In my opinion it is all going to depend on what and how thick as well as the thread size you are planning on using. The main reason I got the 1181N was that for the 1541S to do lighter stuff I was spending 15 to 30 minutes dumbing it down if I didn't it would have a tendency to tear stuff up. Then I would have to spend about the same time resetting the 1541S. If you are going to be doing mostly (90 percent) heavy / thick stuff go with the 1541S or larger otherwise get the 1181N. Eventually you should get a second machine. Whatever you decide, if it is possible, try a sample of what you are planning on sewing on both machines see which one works best. There are couple of good video's showing how the 1541S does on thin stuff you should at. kgg

-

Hi Smithi, welcome to the forum. I have both the Juki DU-1181N as well as the Juki DNU-1541S. The 1181N is a much lighter machine then the 1541S. Personally I would find a 1541S not a 1541 where the "S" destination refers to it having a safety clutch. Better still would be a 1508. To a youtube search for Juki 1541 vs 1181 and Juki 1541 vs 1508. Just my opinion. kgg

-

I like the cheap disposable thread snips as nylon Rigging said when they are dull toss them, for stuff cutting stuff I really don't care about how the cut looks because it is going to be covered I use cheap dollar store scissors and for the good stuff that needs to be cut nice and proper, I use 440 stainless steel or Titanium scissors. I think it really comes down to your budget, intended use and how long you want to get out of them. My good scissors were expensive but they are 20 years old and back then they were really expensive. kgg

-

Sewing machine models for carpet binding/auto upholstery

kgg replied to Rachal's topic in Leather Sewing Machines

Here in Ontario, Canada the Pfaff's aren't very common and can be expensive to repair. If I am not mistaken the Pfaff 145 and 545 are older versions of the 1245. I have a German casted 1245 706/47 walking foot with a clutch motor that I am planning on selling. kgg -

Sewing machine models for carpet binding/auto upholstery

kgg replied to Rachal's topic in Leather Sewing Machines

On the less expensive side depending on how much your carpet pile will compress and the type of backing on the underside of the carpeting. Your portable sewing machines may do the job and fairly inexpensive on the used market. Those that may work could possibly be your Sailrite LZ (USA), Techsew 611(Quebec) , Reliable Barracuda (Ontario) but check with the suppliers and if possible test drive with a piece of carpet using the thread and binding you are planning on using. kgg -

To add to Constabulary links: Mitsubishi DU-105 -- Very Clear https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwicsf2MqNHtAhWoElkFHbVLBe8QFjACegQIBhAC&url=https%3A%2F%2Fwww.supsew.com%2Fdownload%2FMitsubishi%2FMitsubishi%20DU-100%2C%20-120%20Instruction%20Manual.pdf&usg=AOvVaw3uTFUneRig7cFyUxoVSoNu Singer 211g 155 -- Very Clear version better photo's https://www.google.com/url?sa=i&url=https%3A%2F%2Fwww.supsew.com%2Fdownload%2FSinger%2FSinger%20211G155%2C%20211G156%20Service%20Manual.pdf&psig=AOvVaw2fFVFzIkTEfn8WS-q4xSKd&ust=1608166909268000&source=images&cd=vfe&ved=0CAMQjB1qFwoTCKCC392m0e0CFQAAAAAdAAAAABAI For a start stop turning the main pulley wheel away from yourself should only be turned away from yourself in small amounts to reset the safety clutch or help clear a jam of thread at the hook otherwise it could cause timing issues. The Mitsubishi and Singer manuals should help you with a lot. From the Mitsubishi Manual: Stitching length can be adjusted with the stitch regulator push button on the bed and the balance wheel. 1) Pushing the push button down and turn the balance wheel slowly to ward you. 2) So that the push button goes down further and the balance wheel running. (I guess they mean free wheeling.) At this time set the graduation of the dial on the Balance Wheel with the marking on the arm and then release the push button shown in Fig. Caution: NEVER depress the button while the machine is running. Out of curiosity what size of needle are you using as it appears you are using V46 thread.

-

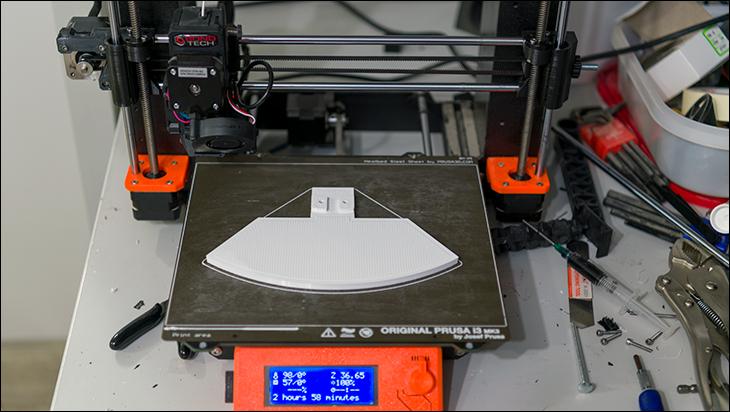

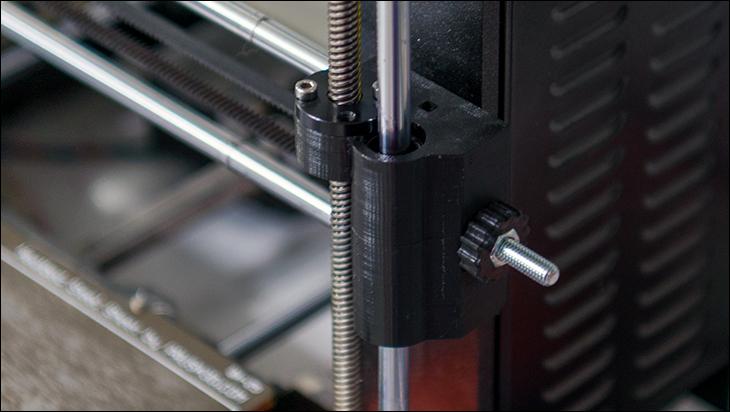

Some of you may know that I like my 3d printers for this hobby and other stuff. I figured I share some of my experiences those planning on getting into it or planning on upgrading equipment. I first purchased a Prusa i3 MK3S it came not assembled to save a few hundred in assembly costs. That in itself was a 12 hour assembly journey. Used it for about 120,000 meters and started to notice some minor print changes and decided to get a second machine so we bought another Prusa i3 MK3S and a Bear upgrade kit along with the Bontech extruder assembly. That assembly made the first look like a walk in the park, definitely not for the faint of heart. It took about 40 hours to assemble. Thankfully we had the Bear Prusa Upgrade completed as we had a catastrophe fan failure at about 160,000 meters on the first machine so we then replace it with a whole new Bontech Mosquito extruder. We got about 20 hours of use and then had a stepper motor support failure. Which we suspect was why we were having previous minor print changes related to belt tension. Upon examination of the failed part it was obvious Prusa cheaped out on proper infill needs for that stress location. We printed on the Bear Prusa Upgrade a much better stepper motor support and for the other side a better tensioner mechanism. We installed a 1mm nozzle in the new Bontech Mosquito on the older Prusa i3 MK3S machine. What a difference in print time. As a comparison we printed a simple 6.5 mm thick part on the Bear with .4 mm nozzle and the same part on the rebuilt Prusa i3 MK3S. The Bear Prusa took 10 hours 58 minutes to complete and the rebuilt Prusa i3 MK3S took 2 hours 58 minutes to complete. Does it ever lay down filament. That is a significant reduction in print time, saving 8 hours. Guess what is getting upgraded next on the Bear Prusa Upgrade. If you are planning on going the Bear Upgrade route, which I would strongly suggest, buy: 1) HiWin, not the chicom rails and linear blocks (H and C). Chicom are no where near as good. C were out of stock and had to mix in match 3 to get one 'good enough'. HiWin "just works". 2) Extruders are Bondtech Prussa Mosqutio Kits. Dont bother with the E3D v6 based Prusa upgrade kit. Not worth it. Go for the mosquito. Much better results. BUT pay for the SLS printed parts. MUCH better quality. For other details or links to parts drop me a note. Photo 1 --- Rebuilt Prusa i3 MK3S with the part showing the time. Photo 2 --- Bear Upgraded Prusa i3 MK3S and UPS in background for both machines. Photo 3 --- Rebuilt Prusa i3 MK3S new stepper motor support. Photo 4 --- Rebuilt Prusa i3 MK3S new belt tensioner support.

-

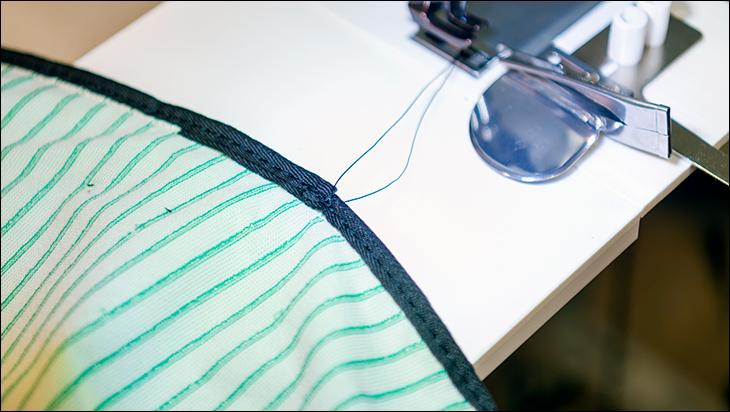

I figured I share how I finish the edge binding using a cylinder bed with regular folders made for flatbed machines. This way I can without any mechanical changes to the machine share binders from my flatbeds with the cylinder bed otherwise I would probably have to buy a new needle plate, presser foot, cover arm and use 90 angled folders at about $200 CA. Equipment: i) Kobe LS-1341 10" cylinder bed ii) V138 top and bottom thread iii) Mini 8" x 8" mini flatbed conversion table iv) 3/4" (19mm) raw edge binder made for flatbed machines which is inexpensive less then $20 CA The photos show 3/4" (19mm) edging on 3mm thick material, not perfect finish but will stop fraying. All comments welcomed. Stay Safe, kgg

-

I used a spray bottle of good auto de-greaser in combination with diesel fuel to get rid of the gunk in a Pfaff with good results. I used a couple of old toothbrushes to scrub those hard to reach dirty spots. Then basically gave it a good flushing / bath with regular sewing machine oil before doing a full oiling. Did most of the cleaning outside because of the diesel fuel. I have found diesel fuel when let to sit for a day to be a good fluid for freeing up seized parts. kgg

-

Backpack with piping

kgg replied to scrapyarddog's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That is excellent work. kgg -

Yes, I had to get another 100 yd spool of 3/4 " Polyester Twill Tape to complete the edging of some 60 - 3' x 3' puppy incontinence pads. I still don't have my edging tape machine fully up and running. Price was reasonable at about $16.00 for the spool. Their complete list of products is at http://amefird.ca/products/ . I do like the A& E stuff they put some engineering into manufacturing a quality thread but you do pay for quality. kgg