Search the Community

Showing results for tags 'chaps'.

-

I have a set of antique woolies that have a musky odor and some mold. What is the best way to kill all of the mold and remove the odor? Specifically in the hair, it is 3-4” long maybe Mongolian or Tibetan. Thanks!

- 3 replies

-

- wooly woolies

- chaps

-

(and 6 more)

Tagged with:

-

Hi all! It's been a little while since I've posted. Here's the latest thing off the bench. This is also my first time free-handing sheridan-style carving. Let me know what you think. Comments/critique always welcome.

-

I recently purchased a Pfaff 138-6/21-BS and I'm looking for information I can get on the specific machine. I've been trying to figure out what it will be capable of and how I can help make it capable of chaps and maybe some lightweight tack. I've heard multiple different answers as to what thread and needles it's able to use, and I'm just wondering if I can get an answer for what it's maximum is. I also had some questions on the feet and the drop down feeds on it. Here are my questions: 1. What are my machines maxes for thread and needles? 2. Will it be able to do sets of chaps like I'm wanting? 3. What kind of feet are available to me that would be suitable for chaps? 4. Will the drop down feeds tear of the grain side of chrome tan leather or vegtan? 5. If it does, is there anyway I can potentially avoid the problem? Thank you so much in advance! I'm super excited to have this machine as well, as it's my very first sewing machine. I'm just starting out as an actual leather business and I'm hoping this machine will help me get started!

-

Finally, I have finished my pair of 19th century shotgun step ins chaps. It took me nearly a year to get them cut out. I went for very simple yokes with no tooling as I'm not very good at it yet and I'm happy with the simple appearance. The leather for the chaps themselves is from The Hide House. Mocha apache bison vegetable tanned medium hand full grain 4-5 oz 51sqft hide. The yokes are 5-6 oz Chestnut Brown Lamport Leather. I was able to get the yokes, back belt, and the end pieces that go at the bottom of the leg out of a 30x60cm piece. Overall, I'm very happy with how they turned out. as I have a lot of leather left over from the hide, so I have enough to make a matching waistcoat.

-

I am going to begin to start making western chaps. Does anyone know what type of tanning process the ranchers used in the 18th century. I am more interested in natural tanning techniques.

-

I have received two small bear skin hides from a customer who wants them made into chinks. I have not made any before or woolies so advice would be appreciated. My plan is to make a base from light chap leather and glue and sew the bear skin to it then apply yokes, side pieces, etc. Ones I have seen appeared to be this way as the bear skin did not wrap completely around the leg but stopped at about the inner pant seam line. Does this sound right and would work well? Is there anything else I might not be thinking of that someone who has done this can advise? I do know I will have to shave down the hair under yokes, etc. to glue like with hair on cowhide but there is always little things that come up in new projects. I also attached the 1st yoke I just finished tooling. Still needs dyeing, antiquing, etc. but comments are welcome on it too.

- 14 replies

-

- tooled leather

- saddle

-

(and 1 more)

Tagged with:

-

Hello does anyone have a pattern of shotgun chaps in a dxf file I have a leather cutting system I would like to cut some chaps Jack@kurisusa.com

-

I'm just about to get my leather for the yokes and back belt on my chaps and I'm not quite sure how thick the leather should be. I was thinking 3.5-4mm as the body of the chaps are 1.6-2.0mm, but let me know what y'all think Also, if you have any suggestions on a color that would complement this. Let me know.

-

Last minute Christmas order for a couple young cowboys. Hopefully they get there in time. Merry Christmas.

-

i'd like to know if they would be any significant different between these two bison leather made by the hide house that would make one better for making working step in shotgun chaps. https://www.hidehouse.com/Leather/Apache-Bison-Bison-Full-Grain-Aniline-Finish-BA02-P.asp https://www.hidehouse.com/Leather/Navajo-Bison-Bison-Full-Grain-Aniline-Finish-BN22-P.asp

-

i hear at 19th century step in shotgun chaps were made bigger so they could fit over your boot's. does anyone know how much bigger.

-

What cut of a cow hide would you use to make chaps?

-

does anyone have a chap lacing diagram for closure

-

-

- 11 replies

-

Does anyone have any good- moderately priced but high quality Concho & Buckle suppliers? Looking for 1/2"; 3/4"; & 1" size buckles and larger conchos: say 2" and larger? I specifically do not want them to look like the cheap Tandy stuff. Thanks

-

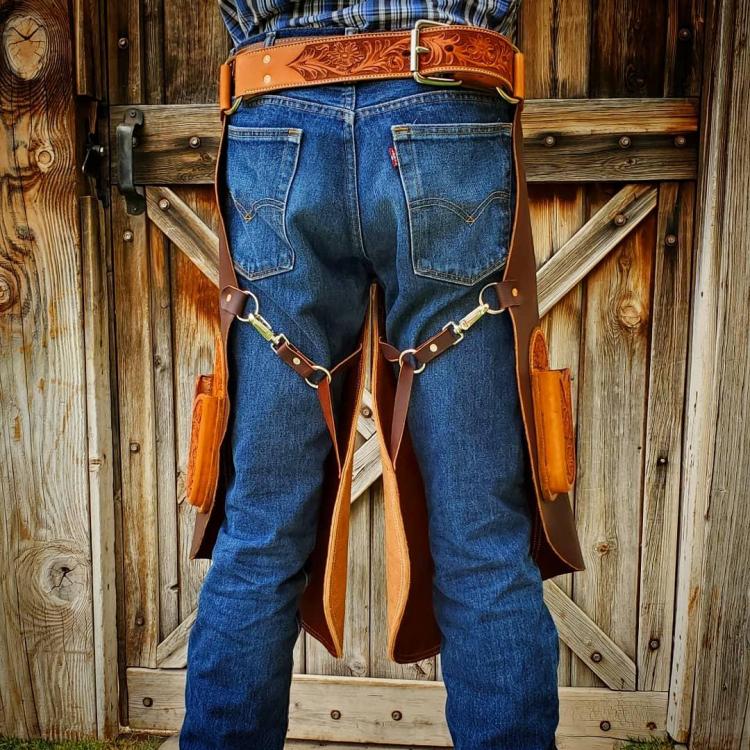

Here's something fresh off the bench. These are bison leather shotgun chaps for a cowboy friend of mine. We were rounding up cattle in heavy thickets and he needed chaps badly. Our shirts keep getting torn but I don't think I can fix that. This leather is great working chap leather because it is very tough but supple enough to be comfortable but it is a little scarred. He was very pleased with them. Let me know what you think. Comments/critique welcome.

- 30 replies

-

- chaps

- bison leather

-

(and 3 more)

Tagged with:

-

Can anybody help? I made a pair of chinks with hand tooled and finished yokes and twisted fringes - the result is gorgeous- very happy customer. But she wore them at a horse show where she got drenched in the rain- fringes started to untwist! What to do now??

-

Here are some chink chaps I made for two of my sisters. I think they turned out pretty well and they are getting a lot of use. Let me know what you think. Critique is always welcome. Thanks for viewing! Ryan

- 22 replies

-

Hello everyone, I've been asked to do a custom pair of step in chaps for a customer. I havent made a pair of chaps yet but would like to add this to my list of items. Can anyone give me some pointers or a step by step process? Thanks!

-

Hello everyone, I've been asked to do a custom pair of step in chaps for a customer. I havent made a pair of chaps yet but would like to add this to my list of items. Can anyone give me some pointers or a step by step process? Thanks!

-

Hi, I would like to hear your ideas on shop layouts... I specialise in chaps, chinks, and armita's, and have feet problems. So that causes issues if I can't walk as much as I'd like. Any of you have the same type of issues? A person always seems to end up running back and forth for this tool and that pattern, some glue, a hammer... The list goes on. Thanks for any input and ideas!

-

Okay, so I’ve worked at Tandy for all of 2 1/2 months. I’ve made 2 belts, and almost 3 hats, a flat cap, and tam’o’shanter ( which is now the lining of the flat cap, and I’m almost done with a pretty good tri-corn. Oh! And a card pocket thingy. Before that my leatherworking experience consisted of a set of coasters in the third grade. Today, a gentleman came in and plopped a plastic bag on my table an asked me how much I would charge him to renovate a pair of 100 year old chaps. I explained my inexperience and gave him the name of 2 companies that I know do chaps all the time. Too far away, too much lag time, he needs them this Saturday. He is doing a reinactment at a county fair. So it doesn’t need to be really sturdy or reinforced. I explain that I think a strip on the outside to widen it and lengthen it will be better weight wise than a full sheet. 3” inside and 4” on the outside and down to 42” at the bottom. So we get a piece of oil tanned utility hide that matches his old chaps color wise. With wiggling and shifting we get an acceptable drawing on the leather. (He helped measure and mark). He left after paying for the leather and signing an IOU for the finished chaps. I cut them out. One of them is 2” shorter than the other. There is plenty of leather left. So here are my questions. Can I bevel or skive the back of the oil tanned so that I can glue a section to the missing part? Trying to put it together in such a way that it looks, at a distance, to be one piece. I am a fairly crafty devil, and think a distance of 2-3’ can be done reliably. How thick should the glued/skived part be? Will that be strong enough if I use Leather Weld or Barge? Or would it just be better to cut them even and call it good? Will machine sewing the strip on the edge and 3” inside the original chaps be secure enough, or should I glue them as well? The chaps are not flat or regular by any means, but they are still flexible and softish. How can he preserve the original leather so that it isn’t stained by the oil tanned hide?

-

Hello all! My dad asked me to make him a pair of chaps. The deal was that he'd buy the materials and I'd do the work. Sorry, but that was a special deal for dad only. This took me about 40 hours to do. All of the pattern/design is my own work. Let me know what you think! I will post some pics of my dad wearing them soon. Thanks for looking! -Ryan

-

I am looking at getting another machine. I have a heavy stitching machine Cobra Class 4. Now I am looking for one that is more versatile I have used a Cobra Class 20 and really liked it but am also looking at a Juki 1508H I can buy local. I have heard the Juki is a little more versatile. Thoughts?