Search the Community

Showing results for tags 'machinery'.

-

Wondering if anyone has information about how large batch manufacturers crease leather that is not just belt strapping but also curved. This can't all be done by hand, can it? Creasing wheel would only work for straight strap and hand creasing is not efficient for large batch.

- 2 replies

-

- leather creaser

- large batch

-

(and 1 more)

Tagged with:

-

- Leather Machine Co. Cobra Class 4 w/stand Asking $2,750 - Master tool self centering belt punch w/ dies Asking 1400 with dies - Master tool little wonder with staple dies Asking $300 with dies $4,000 FOR ALL THREE MACHINES (save $450) Located at Goliger leather in Ventura Ca

-

THIS is s stitching machine! This was used in production for the backseat on tall bootlegs of heavy military and riding boots. Pay attention on the direction of the rolling foot! Not sure if on this photo you can guess the actual size of this machine, but a normal patcher would look tiny next to it...

-

I would really appreciate some expert thoughts on what kind of machine I should invest in for making footwear, please. I’ve spent hours (re)reading many excellent threads on this forum to try to learn about machines, needles and thread (all new to me). But I am having trouble narrowing down my options. I’ve been making footwear since 2015, mostly by hand. I make both lasted and unlasted shoes (see my website at https://tozafoot.com and my Mastodon feed at https://ohai.social/@tozafoot). Since 2020, I have been concentrating on unlasted / stitchdown types, because it’s much easier to end up with a sole that’s very flexible, and to vary the toe shape without paying for an expensive last. I’m not a complete sewing machine novice, but the thought of having to set up and maintain a complicated machine rather daunts me. I’ve used (and own) a domestic machine for making things like curtains, pillow covers, aprons, some clothes. And I have been on a few taught courses where I have used other people’s (already set up!) industrial machines for sewing a very limited number of footwear uppers: I have used flat beds with presser feet, and cylinder and post beds with roller feet. So I am familiar with things like stitch length and tensioning, but I’ve never had to swap out thread sizes, needle sizes, presser feet types or footplates. For my hand sewing I've been using Ritza (Tiger) thread: 0.8mm for uppers and 1mm for attaching uppers to soles. Stitch lengths have been 2-4mm for uppers, and 6-10mm for attaching uppers to soles. I wouldn’t want a machine to do any stitch length larger than 10mm, and probably 2-8mm would be ideal. From my very limited experience and understanding (and apologies if I am getting some of the terminology wrong): I think I prefer a roller foot to a walking foot because when I used a roller foot, I found it easier to stitch close to the edges while still seeing what I was doing, and to make tight curves… but maybe I’m wrong? I don’t think I am too bothered about whether it is a post or cylinder machine, although post machines are often used for footwear uppers, and there must be a reason for that! I believe I need a machine that will sew 2-20oz thickness, but mostly 3-14oz (=1-6mm). For example: a 3oz upper to a 2oz lining; adding decoration and straps could increase upper thickness to ~8oz in places; the uppers then need to be sewn to a 5-8 oz sole. I think this means that ideally I need #46 thread (#14 needles) to #277 thread (#25 needles), but I could probably just about manage with #69 thread to #138 thread (especially if I sew two parallel stitch lines with the latter when I need a very strong seam). In an ideal world I would have a treadle-powered machine, because I’m kind of old-fashioned, and get negative joy from having to set up and deal with electric motors and speed reducers etc. And I loved using an old treadle machine in someone else's workshop. But I recognize that realistically, a servo motor with a speed reducer may be the way to go. I think I may need some support in configuring and learning how to use the machine, so buying from a good dealer (rather than, say, Craigslist) may be useful for troubleshooting. My budget is $2K to $3K (or maybe a bit over for a super machine, especially if it will have good resale value). I can’t currently see how to turn my hobby into a business, so any machine I get would likely be used for 8-20hr a week. Based on this, I have identified the following machines that might work for me: TechSew 830. Post bed, with dual drive roller. A bit on the pricy side at around $3.1K including tax, but I could spring for this if it really is the best option and will have reasonable resale value. My main concern about this is that its max thread size is #138. Also, its max stitch length is 5mm, and in an ideal world I would have slightly longer stitches at times. Consew 710 UX: roller foot, post bed, but again only uses up to #138 thread. Class 26 Cobra or TechSew 2750. These would handle heavier thread (up to #207), and have longer max stitch length (8mm), but will they still be OK for the thinnest uppers I need to stitch (~2oz)? A Cowboy 3200 fitted with the narrow needle plate that RockyAussie developed, so it can sew with much thinner leathers and closer to the edge than the factory defaults allow. This would sew #69 to #346 thread (perfect), and has a 12mm maximum stitch length, but the arm diameter is pretty large, and I am still not sure about the walking foot. Are there any more that should be on this list? Should I knock any off? Is there anything else I should be looking for? Any pros and cons of the various models I should particularly consider? What should I ask a dealer when I enquire about these? Thank you for any advice you can provide!

-

-

-

- belt machinery

- machinery

-

(and 5 more)

Tagged with:

-

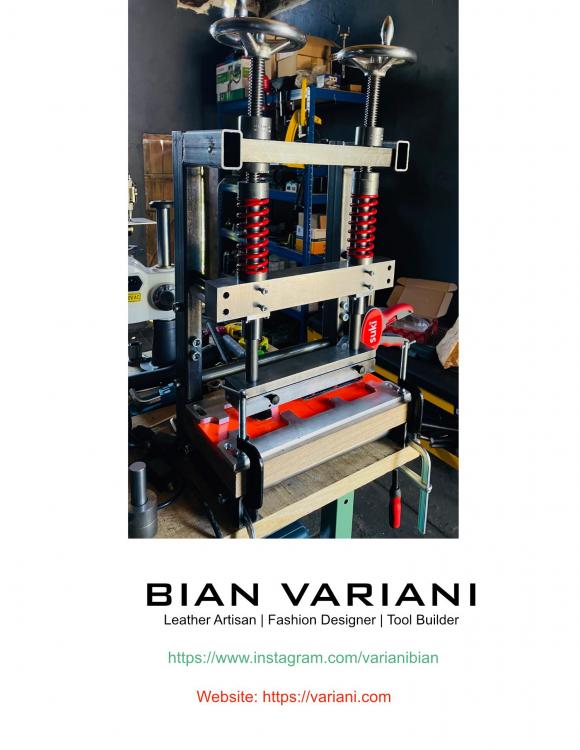

This is one of my 1st belt press/punch that I made for leather belt straps. This is the Hole-Punch for the machine above!

- 8 replies

-

- belt press

- belt punch

-

(and 8 more)

Tagged with:

-

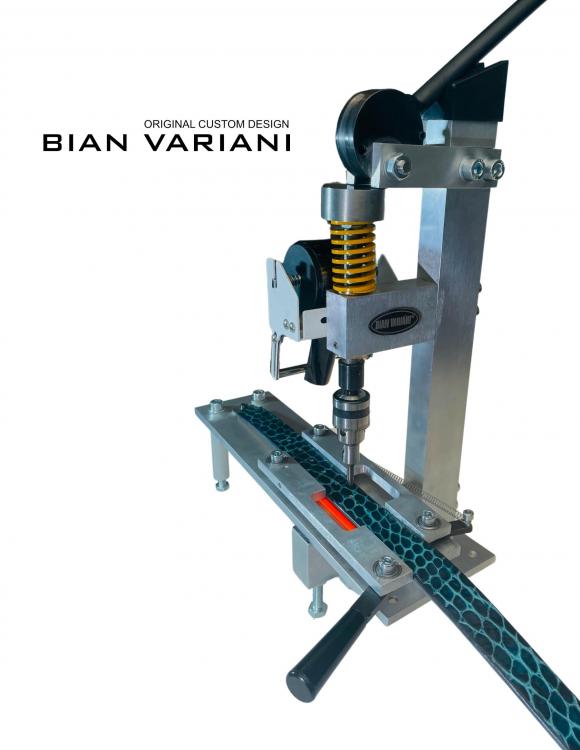

As a Leather Artisan I have struggled with Edge-painting leather belt straps, so I engineered my own edge painting tools which work great and currently solved all my problems. Does anyone else have an alternative suggestions? I always love to hear and to learn from others and new techniques.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

Custom made belt-press, tip cutter and heat press that I made. The biggest problem that I solved in this build is that I created custom alignment guides so I know where to exactly position the belt during the process. More pictures of my work is available at: https://www.instagram.com/varianibian/

-

I am looking to sell this Landis Aristocrat Model L outsole stitcher. It's in northern NJ for anyone who'd like to pick up -- but weighs nearly 800 lbs. (Unable to ship unless you arrange all of it including a pickup.) I'm looking to get around $600 for it. It works perfectly! My dad was a shoemaker but has since retired and doesn't need all his machinery. Hope someone here might be interested.

-

Strong, reliable workhorse 20 ton hydraulic click press for sale. This machine has been in almost daily use in our shop, has been regularly professionally serviced, and is in great shape. The only trouble it's given us has been the occasional relay switch wearing out. Asking $5000 CDN If you're interested, or have questions about the machine, please shoot me a message. Thanks. Specs as follows: 220 v / 3 phase Bed 20" x 40" Head 24" x 18" Overall Depth - 34" Overall Width - 40" Overall Height - 66" Weight 2000 lbs Located in Toronto, Ontario, Canada

-

Interested in selling a United Shoe Machinery Company ICM-C leather clicker, used in late 70s and early 80s by my father who made fire bellows for LL Bean. I last saw it up and running in 2015 but have not tried to run it since. Haven’t located a manual for it. Research shows the machine is from 1958, stamped ICM-901. Located in WI northwoods. I’ll help load anyway I can. Also have 500+ feet of Swiss chocolate Heritage leather, grade TR-X and other bellows-making material. Originally purchased from Cudahy Tanning Company out of Cudahy, WI which merged with Prime Tanning Company out of Maine in 2007.

- 6 replies

-

- clicker

- leather clicker

-

(and 2 more)

Tagged with:

-

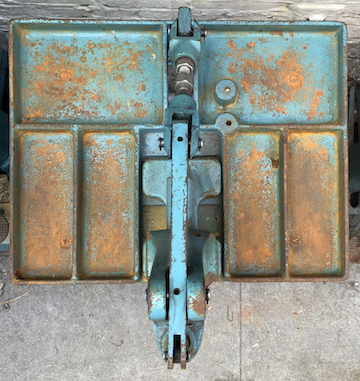

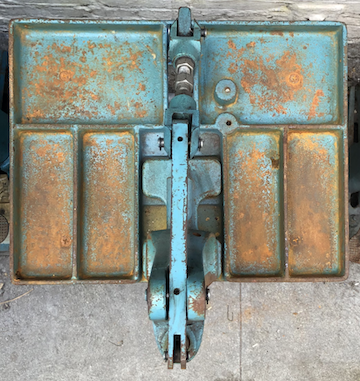

Hey everyone, I am a leather goods designer based in Los Angeles specializing in leather bags, wallets, and other leather accessories. I've been using this grommet machine for a couple years now. It is in fair condition: some rust, but runs well. Although I'd love to keep it, I need to clear up space in my studio. Please feel free to ask me any questions by responding to this thread. Alternatively, you can contact me through eliotylee@gmail.com Asking price (price flexible): $250

-

Hey everyone, I am a leather goods designer based in Los Angeles specializing in leather bags, wallets, and other leather accessories. I've had this Stimpson 479 R1 Foot Power Machine for a couple years now. It has been serving me well and is in good condition. It can run up to a #4 grommet and is hand feed only. Please feel free to ask me any questions by responding to this thread. Alternatively, you can contact me through eliotylee@gmail.com Asking price (price flexible): $150

-

Hey everyone, I am a leather goods designer based in Los Angeles specializing in leather bags, wallets, and other leather accessories. I've had this Stimpson C1 Foot Power Machine for a couple years now. It has been serving me well and is in good condition. Although I'd love to keep it, I need to clear up space in my studio. Please feel free to ask me any questions by responding to this thread. Alternatively, you can contact me through eliotylee@gmail.com Asking price (price flexible): $250

-

Hey everyone, I am a leather goods designer based in Los Angeles specializing in leather bags, wallets, and other leather accessories. I've been using this grommet machine for a couple years now. It is in fair condition: some rust, but runs well. Although I'd love to keep it, I need to clear up space in my studio. Please feel free to ask me any questions by responding to this thread. Alternatively, you can contact me through eliotylee@gmail.com Asking price (price flexible): $250

-

Hey everyone, I am a leather goods designer based in Los Angeles specializing in leather bags, wallets, and other leather accessories. I've had this Stimpson 479 R1 Foot Power Machine for a couple years now. It has been serving me well and is in good condition. It can run up to a #4 grommet and is hand feed only. Please feel free to ask me any questions by responding to this thread. Alternatively, you can contact me through eliotylee@gmail.com Asking price (price flexible): $150

-

Hey everyone, I am a leather goods designer based in Los Angeles specializing in leather bags, wallets, and other leather accessories. I've had this Stimpson C1 Foot Power Machine for a couple years now. It has been serving me well and is in good condition. Although I'd love to keep it, I need to clear up space in my studio. Please feel free to ask me any questions by responding to this thread. Alternatively, you can contact me through eliotylee@gmail.com Asking price (price flexible): $250

-

Hello everyone, I just became a member of this site and am excited to be apart of this community. I am a leather goods designer based in Los Angeles. I specialize in leather bags and other leather accessories. To clear up space in my studio, I am trying to sell old machines. The prices are flexible. I have a Stimpson C1 Foot Power Machine, Stimpson 479 R1 Foot Power Machine, and grommet machine. They are used, but they still function well. Attached are some pictures of the machines. If interested, feel free to message me by responding to this thread!

-

Basically brand new. I used it a total of 3 times. Realized it was too industrial for my needs. Features a D-2 steel blade and can be hand-cranked or motorized for optimal control. Top of the line industrial Leather Splitter. Drive Unit with Reversible Motor. Features D-2 Steel Blade Drive Unit with Reversible Motor Weight: 300 lbs. (136.08 kg)

-

Lightly used Mighty Wonder clicker press and sturdy, adjustable height workbench for sale! Both pieces in great shape. Asking $1,200 for the pair together. The press was originally $1,500, and the workbench was over $300. The workbench has a solid butcher block top, with holes drilled for the clicker to bolt securely through the surface. Very sturdy and heavy duty, it's been a great set-up. Pick up in Memphis, TN.

-

We are selling the machinery from a company that made leather horse halters and dog collars. He had a pretty big operation and ran the business as long as he could. I am attaching a brochure here with pictures and pricing. If you see anything you are interested in, just let me know. We must sell everything. Leather Equipment Brochure - Pictures and Pricing.pdf

-

I am in southern California (Anaheim) selling 2 used clicker press in good condition. looking to get $1,500 for each or $2,500 for the pair. DM for all inquires on the machine. Below is a video of a identical machine running. I can provide pictures and anything else needed

- 2 replies

-

- 18-17 ton

- clicker press

-

(and 2 more)

Tagged with:

-

Hello, I am selling a shoe repair oven with infrared lamps used to revive the glue, as new (used only a few times). Heating temperature at 45°C in ~5 minutes. My price: 140 GBP. Retail price is around 450 GBP, check below: http://www.bicifestival.it/lavorazione-artigianale-pelle-bdd-1_26/forno-a-raggi-infrarossi-per-calzature-jlrhqclq-odd-1903.html The item will be shipped from Romania. For UK the shipping cost is 30 GBP. For other countries I will check best shipping option at request. The item is listed also on ebay: https://www.ebay.co.uk/itm/Infrared-oven-for-shoemaking-repair-FORNO-A-RAGGI-INFRAROSSI-PER-CALZATURE/233017359077 If interested, please let me know. Best regards, George

.jpg.b20ff7c23b292d94e8cbbb963c935609.jpg)

.jpg.82e3232ec8242e67bee32435b289a3d4.jpg)

.jpg.60529efef7c905b8c9d118ddb07abbce.jpg)