All Activity

- Past hour

-

@Wizcrafts I should have been more clear but I only meant the presser foot lift being 15mm, not the actual thickness the machine can sew. When upcycling it's helpful to have more room to move things around under the foot. All the machines I mentioned have a listed clearance of 15-16mm. They also claim to handle #207 (Tex 210) thread. That's a great thread and needle chart, thank you. referencing that and some videos, I believe #138 would be plenty for my applications and the apparent option for #207 eases my doubts there. And the low end at size #69 is perfectly fine too. The 441 class threads and needles would definitely be a commitment though. My being on the border of heavy and super heavy duty is exactly what I was afraid of. Great point about the throat plate as well, I didn't think about that. I do not have the budget for two machines right now, maybe in a couple years, though that seems like the best eventual solution. I suppose a 1341 class machine will at least allow me to handle some heavier stuff now while the super heavy stuff waits for the future.

- Today

-

@keenbean Just to tag in on @Wizcrafts comments: The Juki TL Haruka uses HAx1 needles with a shank diameter of 1.63mm and uses up to max #18 needle which means the max thread size is V69 (metric 40). Typically the largest thread size for a domestic machine. The machine weight is about 25 lb. The Juki LS-1341 is a cylinder arm uses 135x17 and 135 x16 (leather) needles with a shank diameter of 2mm and uses up to max #24 needle which means the max thread size is V138 (metric 20). The head weight alone is about 82 lbs. The Juki LU-1508NH is a flatbed uses MTx190 needles with a shank diameter of 2mm and uses up to max #25 needle which means the max thread size is V207 (metric 15). The head weight alone is about 93 lbs. The Juki TU-1508NH is a cylinder arm that would be the equivalent to the flatbed Juki LU-1508NH. The head weight alone is about 97 lbs. The Class 441 machines like the Juki TSC-441 cylinder arm uses 794 needles with a shank diameter of 2.5mm and uses up to max #28 needle which means the max thread size is V415 (metric 7). Think of a needles with similar shank diameter as a 2.5" finishing nail, big hole. The head weight alone is about 123 lbs. kgg

-

A few questions first. What weight of leather are you using? Are you going to line this? Is this the side leg of the breast collar? Are you attaching a two inch D? Will the breast collar be under heavy use or will it be mostly decorative? Is this for you or someone else? To me it doesn't look like if you centered rivet of the concho will catch the tab. You could add a couple copper rivets and/or stitch it with a W or V sort of like the picture below. Looks like you have about two inches of tab you can catch. The tab is not optimal shape to take advantage of the strength of the entire stitch line. The transition will be a little high and rough it needs skiving and you don't have much lenghth to skive down and maintain strength. Lining the breast collar will help some. The answer to your question is, the choice is up to you.

-

@keenbean First, take a look at this thread and needle chart. It shows the diameters of various sizes of thread and needles and tells you which needle to use with a particular thread size. You really need to define a range of thread sizes, then find machines that can use the range of needles that are best matched to the thread. But, keep in mind that lockstitch machines for overlapping knots that must be pulled up inside the material without seeing them on the top or bottom. The thicker the thread, the harder it may be to conceal those knots. Different classes of sewing machines are able to handle different ranges of needles and thread. Most upholstery grade machines are meant to handle a range of thread from #69 through #138, with a corresponding needle range of #18 through #23. Extra heavy duty machines may extend the thread range to #207, which calls for a #24 needle. From your description of the range of materials and thicknesses involved, you will be on the borderline of heavy duty and super heavy duty. The Juki 1341 and its clones may or may not live up to your expectations. You want a 5/8" clearance under the foot (15mm). The only way you can get that amount of lift on a walking foot machines is if it is built to lift at least that high without the tip of the needle sticking out of the inside foot. The 1341 and its clones are probably not built with that extreme amount if foot and needle lift in mind. Ironically, the Juki LU-1508NH flatbed machine is built to lift that high, including the tip of the needle. It accomplishes this by using a longer needle system with a longer stroke. The 1341 and clones are made to use system 135x16 and 17 needles, with are standard length for upholstery grade machines. At their maximum rated lift, the needle bar just barely clears the lifted feet and the needle's tip is just inside the bottom of the inside foot. You'd have to ask a dealer, or somebody who has tried it to know if these machines can accept the longer system 190 needles that would be needed for a higher than standard foot lift. While the upholstery grade machines run out of lift around 1/2 inch, and are limited to a maximum thread size of #138, the 441 class machines are happy with thicknesses up to at least 3/4", with some able to sew 7/8 inch. However, these machines are built for super heavy duty sewing with large thread sizes and correspondingly large needles. As such, it is difficult to find any leather point needles under a #23, and even harder to find round points under size 22. These needles are perfect for #138 thread, top and bottom, but are way too big for thinner thread. Further, these machines have very large oval holes in the feed dog to clear needles up to a #26 or 27. Thin material can get pushed down inside the hole. To solve that problem, at least two people are producing narrow feed dogs and throat plates for the 441 class machines. So, you'll have to choose between modding a lesser machine to use a longer needle, then figure out how to increase the foot lift, or dumb down a more powerful machines to use thinner needles (if you can find any) with thinner thread.

-

spring flowers and good food

Sheilajeanne replied to chuck123wapati's topic in All About Us and Off Topic

Northmount, YES!! That's exactly the problem I was having! Too much water in the condensation drainage line, and the pressure sensor wasn't working properly! Maybe it's a design flaw that's common to a certain make of furnace. The furnace is only about 2 years old, and replaced the oil furnace which was installed when the house was built in the late 1960's. Anyway, he's order a new pressure switch. Hoping that will fix things... I can only get the temperature up to around 18 C. I can live with that, but I have to bundle up. The night it was really bad, it was extremely cold and windy outside, which made the temperature inside the house drop quite low. -

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

spring flowers and good food

Northmount replied to chuck123wapati's topic in All About Us and Off Topic

My furnace started acting up a couple weeks ago while we were away for a couple days. I can remotely monitor our house and could see that the thermostat was calling for heat, but none being delivered. I have a separate heating system for our basement (glycol boiler and perimeter baseboard heating loop) so I just turned up the basement thermostat. When I get home, I find that the pressure differential switch that detects whether the draft is adequate or not was acting up. It had water accumulating on one side so couldn't provide a correct signal to light up the furnace. After fussing with it several times, I decided it was time to find a supplier for that switch. Finally found one and placed the order. 5 days delivery time. Continued to have to clear the water out of the sensing tubes for a couple days. The guess what? It starts working correctly again. Now I have a spare switch. Decided it is a good idea to keep the spare as insurance. It's been working just fine for several days now. The real problem is poor design. The switch is mounted low, below the the pressure sensing lines. So condensate (water) from the wet exhaust gas builds up over time and offsets the actual pressure differential. Had troubles with it when we first had the high efficiency condensing furnace installed about 20 years ago. Pointed out the problem to the installer/supplier and the "Maytag Man" wouldn't do anything about it. So over time, condensate builds up, and the problem re-occurs every so often. But not for the past 5 or 10 years. So I should move the switch to a location higher than the pressure taps so any condensate drains back to the source. May I'll get around to it some day! But I have a spare switch that should keep it at bay for ... -

arlen.myles joined the community

- Yesterday

-

Hello all, I'm an upcycling artist based in Minnesota. I make various bags and clothing. I love working with heavy fabrics and I'm finally running up against the limits of my trusty Juki TL Haruka. Case in point, I tried making a canvas bag with some #8 (18 oz) canvas this past weekend and, while it did great up to around 8 layers, it really struggled past that which is understandable since the design I used involved some areas with upwards of 12 layers (20 on the side seams!). And that's without things like flat felled side seams. As my main focus is bags, I am looking for a cylinder head, triple feed machine. I am looking to sew heavyweight canvas (up to 30 oz preferably!), 4-8 oz leather, heavier vinyl, as well as upcycling some odd materials such as carpet samples, bath rugs, jellyroll rugs, vinyl banners, etc. I began looking at the Juki 1341 and it's associated clones and after LOTS of research, I narrowed my preliminary selection to the Thor GC1341, the Cobra Class 26 and the Cowboy 6900. After making the previous tote I realized that a bag with heavyweight canvas and leather will have some very thick and dense sections so punching power is obviously a concern. Beyond that, I'd prefer a decent presser foot clearance (15mm+), relatively low maintenance (the reason why I'm a bit hesitant on the cobra, as it appears to require significantly more involved manual oiling), a servo motor with EPS and speed reduction (I'd be willing to buy and swap in a kinedyne 750 motor if need be), easily sourced accessories including a double fold binder and a "space saver" table although I'm confident in mounting the machine to a third party or home-built table if need be. Some nice-to-haves would be easily adjustable presser foot height, dual thread tensioners and a foot operated presser foot lift (I'm tall with long legs so knee lifts can be a big awkward for me). It would also be a plus to have the ability to use ~18 size needles so I can use the cylinder to get to hard to reach areas on less heavy articles without shredding them but I understand that that isn't what this machine is for. I'm not super familiar with industrial thread yet but it seems like all the options I looked at can use thread which would be fine for my uses. So given all that, my main questions are: Are the class of machines I'm looking at capable of sewing what I need? Are there other better options I'm overlooking? Do I need to look at 441-level machines or similar to sew with the mentioned weights of canvas and leather reliably? I should also mention that I am pursuing a mechanical engineering degree and am mechanically inclined, so I would be comfortable servicing and modifying parts/machines. I also have access to a fairly well-equipped machining shop at my university. Let me know if any more information is needed and thank you for your time! This forum is a wonderful resource.

-

Rafer1 joined the community

-

LOL, Chuck and HS! Lent is coming this week, so I stole this off of FB: A protestant moved into a community that was almost entirely Catholic. When Lent rolled around, the Catholics were upset when nearly every Friday their new resident would barbecue himself a lovely steak, instead of eating fish as the Catholics do during Lent. A number of the men got together to discuss the problem. "Listen," one of them said, "I've talked to him, and he definitely is a Christian. Why don't we see if we can get him to convert to Catholicism?" The all agreed that sounded like an excellent idea, so they nominated one of their group to approach him. Much to their delight, he agreed! So, the following Sunday, they arranged with their priest to do a short conversion ceremony. The priest sprinkled him with Holy Water and said, "I baptise you in the name of the Father, Son and Holy Spirit! Behold, you are no longer a Protestant - You are now a Catholic." But the following Friday, when dinner time rolled around, once again they smelled the tantalizing odour of barbecued beef coming from the man's backyard. They went over to his house, and were just in time to see him put a steak on the BBQ grill. He sprinkled it with water, and said, "In the name of the Father, Son and Holy Spirit, you are no longer a steak - you are now a fillet of fish!"

-

spring flowers and good food

Sheilajeanne replied to chuck123wapati's topic in All About Us and Off Topic

Wow, that really IS ridiculous! I've been dealing with hearing aid batteries since I was in Grade 8, and the only thing I find annoying is some hearing aids make it ridiculously hard to get the battery in and out of the battery slot. My cochlear implant has made battery removal a snap, though. I just use the magnet on the receiver's headpiece, place it over the battery - mission accomplished. Canada still uses the dial packs for batteries, which make it almost TOO easy to remove a battery from the pack. Have had a few wind up on the floor while changing batteries while driving. (Yeah, probably shouldn't do that...) I would reallyreallyreally be P.O'd if Canada switches to the system you describe, Chuck. It sounds like the blister packs they use here for larger button style batteries, like the ones that go in garage or auto remote controls or the SNARK guitar tuners. I've said a few nasty words getting THOSE critters out of the packages, believe me! Darren, those are beautiful! Well done for a first attempt! We are having unbelievably cold weather here, and I do worry about putting the dog out and forgetting about her. I have done that now and then, and with these cold temps, she could easily suffer frostbite. Last night, it got down to -25 C/-14 F! Maybe I need to start setting a timer, too. My memory isn't quite what it used to be... Oh, and did I mention my furnace STILL isn't working right?? The furnace guy was out again the day after I called him, and diagnosed the problem, but he had to order a part to fix it. Meanwhile with these very cold temperatures, I've got so many blankets on my bed that it's hard to turn over! -

Thanks tomorrow I'm going there to figure out what the problem really is, I'll try to remember to take some pictures

-

Making the pendant for Gini was my purpose in tooling a tiny flower, this is a completed one and she was happy so job accomplished.

-

I may have an original one - will check in the days to come.

-

Hi there, I’m making this breast collar from a template that wasn’t in hind sight super detailed. I’m trying to figure out the best way to attach it to the D ring, now realizing I should have given myself more length for overlap. I’m putting a concho on the circle portion. I’m wondering if the rivet from the concho and a couple of stitches will be strong enough or should I start over?

-

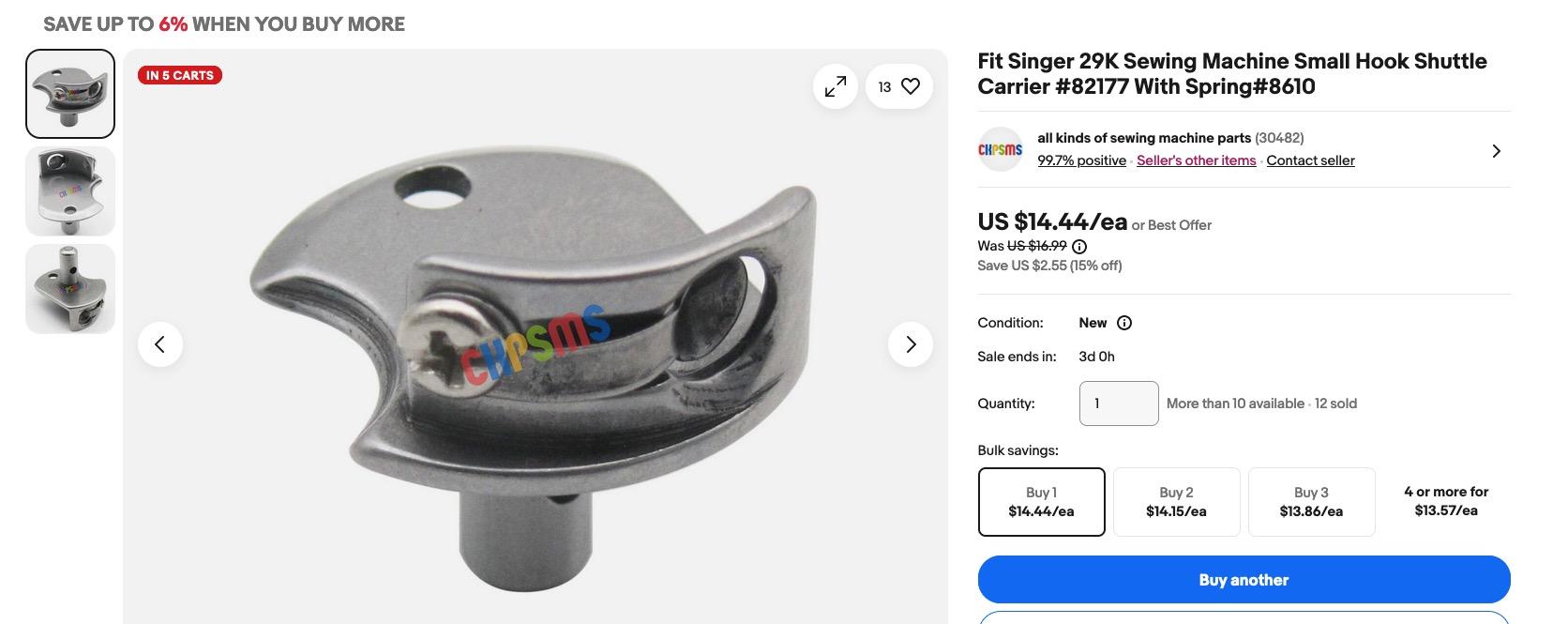

I might have actually found one... It says fits 29k3 and small shuttle carrier..the worn gears I may be able to get around with some shimming...time will tell.

-

I'll post a new thread too, but seeing as thsi is one of two threads here that mention this part...thought I'd post up here as you guys on this conversation will get notifications... I have a 29k3..that i suspect will become a boat anchor...but no harm in asking. any one have a scrap machine and will to sell me this carrier? The shuttle carrier plate is broken, this is probably my fault, but the machine was 'broken' anyway, the drive being so worn and the housing was letting the shuttle carrier move and bump in to the needle. Had to drill out the grub screw. A couple of weeks of heating, soaking / small impact driver and it was not going to move. Think I put weight on the edge of the carrier as I drove it out of the gear So here is my carrier, I do not think silver soldering will save this I see plenty of parts from China..but only the bigger ones for the newer machines, or 11 mm diameter gears where this takes the 3 tooth 16 mm gear. Did any one ever gets parts made for theseolder ones?

-

When u design a new holster pattern

Dwight replied to rccolt45's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I have gotten a reputation as the "odd ball" holster maker. Made an appendix carry holster for a double barreled derringer . . . made a double shoulder holster rig that doubles also as a pair of suspenders . . . made a double carry vest for notebooks / pencils / other oddball stuff / could carry a small auto pistol in it . . . made one to carry a long barreled .22 auto with a large scope mounted on top. And that just scratches the surface of my shenanigans. I simply make a decision that "this" holster will carry this weight / in this location / so it needs to be ______thick. I cut a piece that I know will be 1/2 inch to 1 inch too wide and too long along sides . . . get that dude sloppy wet . . . thumb mold to start with . . . then stick it on the vacuum former. Depending on how hard I do or do not want this . . . I may stick it in the hot box for hardening thru heat. Either way it then gets dried. Come back within 48 hours after the above . . . cut out what I need . . . put a back on it . . . glue / trim / sew / sand / and finish. I have more back patterns than I have for the fronts. May God bless, Dwight -

I have some letter templates that look just like that, amongst others. I have done an assortment of lettering, so with practice, that can be achieved. HS

-

I like that 👌, 😆

-

.thumb.jpg.7b83907b17613afe0cdc856f1257806a.jpg)

New to the forum and wanted to introduce myself

tsunkasapa replied to Second_Chance_Leather's topic in Member Gallery

I don't do podcasts, but I have a 3 disc CD player and a few hours of the Chieftains or Clapton, Janis and I'm good for the afternoon. Oh, and Jimi!! -

MOST of the 1/4" sets I've seen are on a par with your Tandy set.