All Activity

- Past hour

-

Left handed Shoemakers insole/channel knife made by Tina of Germany. Sells new for $219.00 I am selling new out of box for $175.00 plus shipping New TEKTON TOOLS Nipper/Tack puller Made in USA $20.00 plus shipping NEW - LASTING PLIERS $40.00 plus shipping NEW - BRASS SMOOTHING TOOL. Used for smoothing leather toe area of shoes and heel area. I paid good money for this tool. $25.00 plus shipping More later

-

The doctor told me last week I'd have to cut down on my drinking. Only one glass of whiskey per week So far I'm up to the third week of August 2217

-

Juki LS1341 - presser foot adjustment

nylonRigging replied to MackProvisions's topic in Leather Sewing Machines

I would imagine that it same as 1541 . there an access plate on backside that you have to get to a screw . It little hidden and you have to look Upward to see it. You have to lift UP the manual press-foot lever to even see and have access to the screw . You also have to make the foot height adjustments with presser-foot lever locked Up position with loosening and then re-tightening the screw . - - - - Today

-

I was bitten by a wolf today I had to go to the hospital for treatment The nurse asked me 'Where' I said 'No, just the usual ordinary type'

-

Pretty slick

-

Used Juki LS 1341. Recently serviced and in good working condition. Originally purchased used but I haven't put it to much use. I believe it is equipped with a speed reducer/smaller pulley (forgive me I don't know too much about these). It can sew very slow, controlled stitches. Selling because it's too heavy duty for my needs. I'm hoping to replace it with a post bed machine instead. Asking $2000 obo for head/table/motor. Pick up in Long Beach CA, or can possibly meet somewhere in LA.

-

As I wandering the lanes of Scotland I heard a farmer shouting I think he was a Rolling Stones fan but he got some of the words wrong He was shouting ' Hey M'Cloud get offa ma you'

-

I'd skive and roll the edge (at least on the 'outside' of the panels), but using contact adhesive. Basting tape will be a pain to stitch through (and also to stick down in curves) and can damage your thread. Notching would depend on the radius and thickness of the (skived) leather; do a test on a bit of scrap first. You can also go for slightly rougher look by skiving the edges of the leather tape really thin and leaving them as-as. And finally you could go for a 'coupé net' where you don't add any leather tape on the edges of the bag panels and seal them with edge paint.

-

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

I also needed to repair the Belly Band, (or whatever it's actually called.) The owner didn't keep the leather clean, it was covered in sweat, dirt, and oils. I cleaned it with saddle soap and a toothbrush. My repair was to replace the broken loop that held a D-ring. Miss T was going to cut back the stitching so I could remove the rivet and the old loop, then replace them. Then I would saddle stitch the removed stitching. She took the band into her shop, pulled about 1-1/2" of stitches and discovered they had glued the two panels together. So I cut a square into the back of the band, and drilled out the rivet. The loop was glued into place as well. I cut out as much of the old loop as possible and made a new loop, and put it on with a chicago screw. Worked well. A closeup of the new loop. Unlike the pics of the fenders, this piece hasn't been treated with Mink Oil yet. I also made new laces so she could wrap the fenders near the blevins like she prefers. I wasn't going to try and recreate that. The project is pretty much done at this point. I'll be back to sheaths and holsters, a belt now and then. -

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Wow, been away from the topic for a while. Weather. We had ten days of snow and ice and because of my physical challenges the wife won't let me out to go to the shop when the footing is challenging. Thirty surgeries so far and don't need thirty one. LOL. The weather finally turned decent and I was able to get back out and finish the work. I was also waiting for hardware. I had ordered rivets and burrs, but the first set that came in were too short at 1/2", I reordered 1" rivets, and Springfield is a great company, but slow. It took a week. I also ordered more Mink Oil, it was a lot faster coming from Amazon, two days. No matter, stuck in the house ten days. The view of the Fender Assembly from the rear: I didn't remake the stirrup straps, the owner didn't ask for them. I reused the blevins for the same reason. But, everything went together well. The shape of the back pieces is by design, she will curl them and lace them to keep them curled. The view from the front.... For a first attempt, I was happy with the result. My daughter sent her friend pictures and got back a one word reply. "Wow!" I guess she was happy, that's all that matters. -

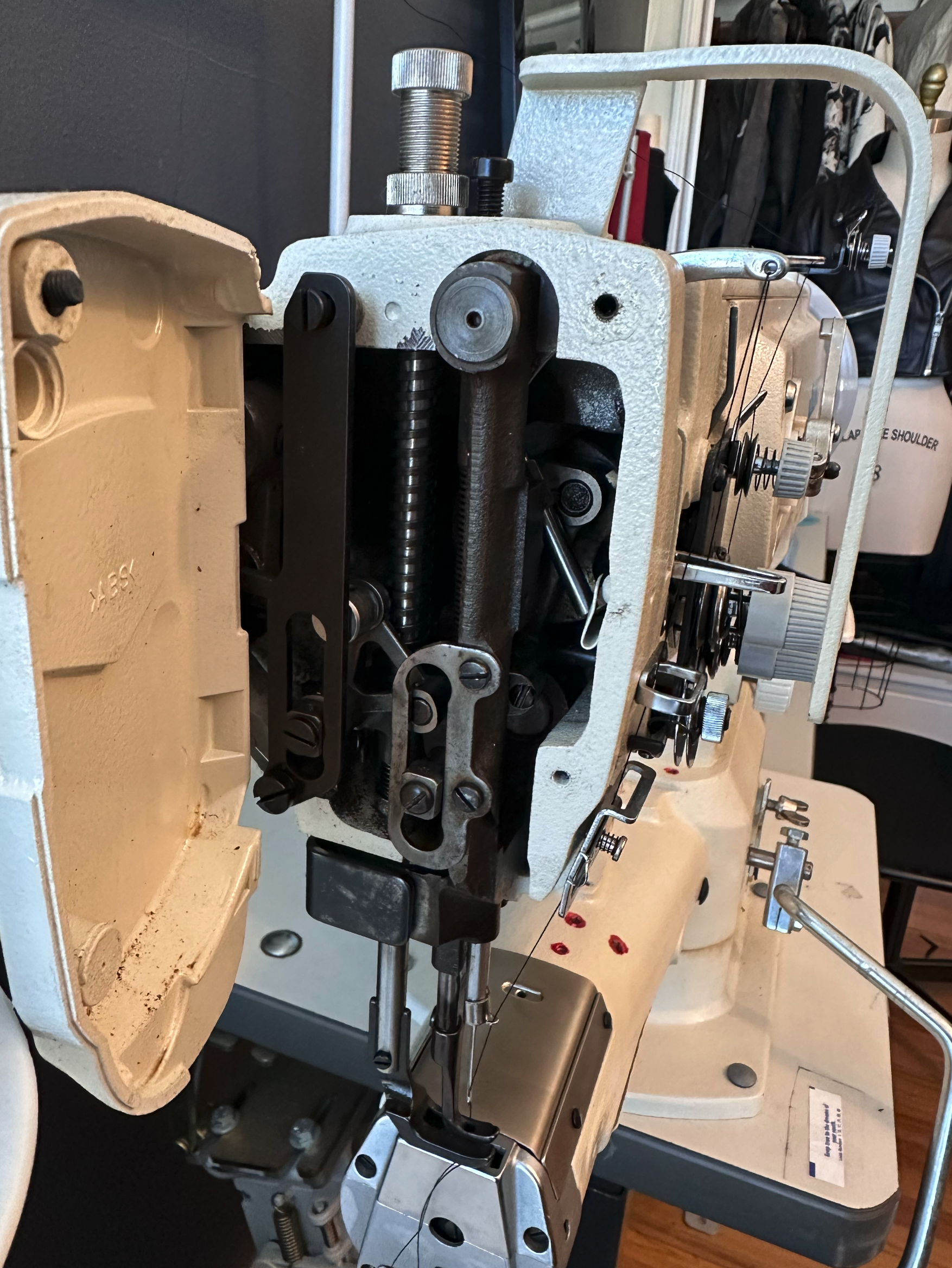

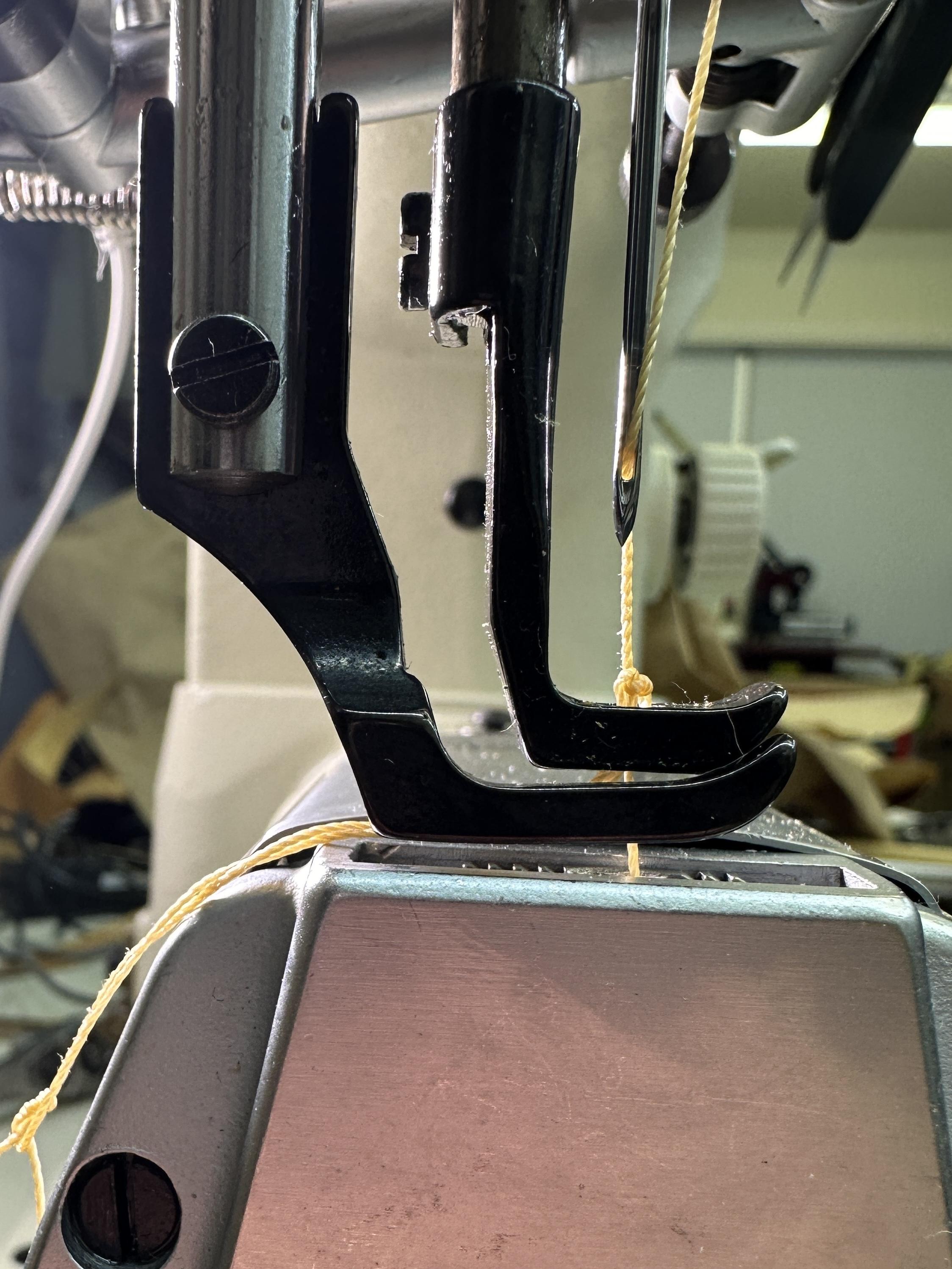

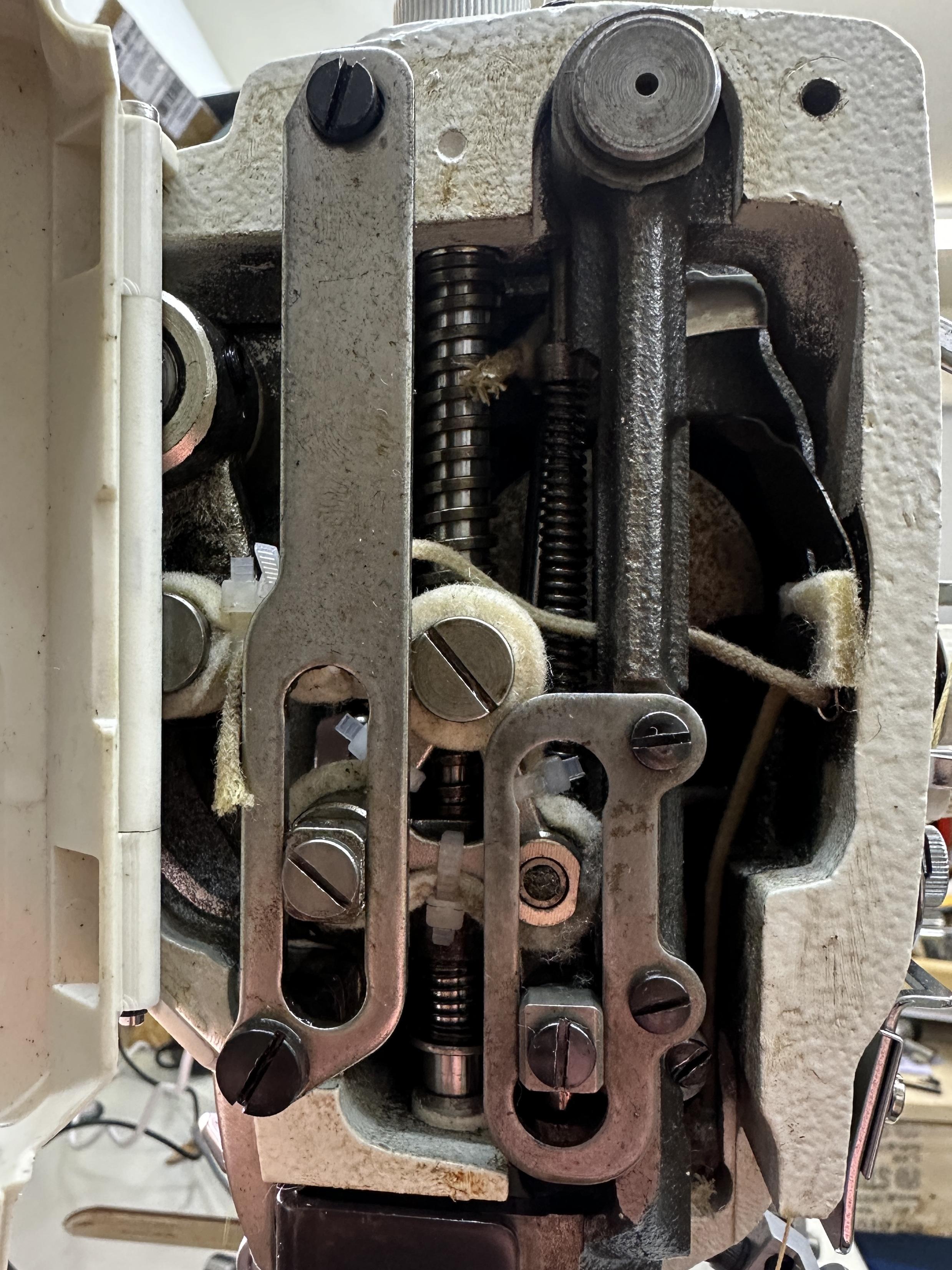

Juki LS1341 - presser foot adjustment

kgg replied to MackProvisions's topic in Leather Sewing Machines

As a note the difference between a 1341 and 341 is minimal. You probably don't have the manuals for your machine so here a some that will be helpful as well as a needle size to thread size chart link ( https://www.tolindsewmach.com/thread-chart.html ) : kgg Juki LS-1340&42 Servcie Manual.pdf Juki_LS-341N_Engineers_Manual.pdf Juki_LS-341N_Instruction_Manual.pdf -

using glue with leather

stampingdelight replied to stampingdelight's topic in Leatherwork Conversation

@Hags @Handstitched @fredk thanks so much -

does anyone use outside spring calipers/inside spring calipers in leather working or even other tools like those besides wing dividers? if so what is best way to use them?

-

A. short finger nails are a must or latev/rubber gloves to cover them b. run a groover between all the stitching holes before you stitch edit to add; c. dilute any dye you may use and use multiple coats to get the desired colour or finish d. wet the leather before putting on the dye. not soaking dripping wet, just sponge some clean water on .this helps the dye spread thru the leather

-

I just picked up a used 1341 and noticed some of material slightly slips while sewing. When the needle reaches the top most, shouldn't the presser foot go all the way down to the throat plate? If so, can anyone help me and explain how to adjust the presser bar to go down?

-

A few thoughts from my first time applying tools or finish to leather... Workspace is important! Everything must be clean! And I understand why I've seen people wearing gloves working with leather. My pieces look thoroughly manhandled, which of course they. I felt like a fingernail scratched some surface every time I moved. I already know what I'd do different. I beveled the edge. Smooth, even passes are critical. I presume I'll get a feel for the right angles and pressure. I sanded with 240. I tried to go "one way" but again, I'll figure out the grain. More like wood? Or steak? 😉 I did one pass with tokonole. Clearly I used to much. But I see what one application did and how to make it better. Even for a first time, I think it looks better than it was. This weekend I teach myself saddlestitch!

-

Recommended Source for Hermann Oak Tooling.

PastorBob replied to Latigo Smith's topic in All About Leather

KC is a great guy and have done business with him multiple times at Traditions. The Live Oak leather they have tools nicely. It just doesn't seem as "sturdy" or have as much density as HO. Almost kind of floppy. But after tooling and dyeing, it firms up pretty nice. I have been pleased with it. It seems to be cheaper too. -

' How do men in Australia find sheep in long grass?' Very enjoyable indeed HS

-

i think it came out pretty darn good!

-

Yes, you can notch the life out of the first fold because no one will see it. More careful with the second. Skiving might help as well.