All Activity

- Past hour

-

On Facebook Marketplace . . . you can pick up a decent 12 inch wide planer for 100 bucks . . . or at least I did. Then cut your HDPE about 11 1/2 inches wide . . . run it thru the planer. If you do it right . . . all the pieces will be THE EXACT same thickness . . . and can be either screwed down or double sticky back tape . . . put to the table. Take a thin file . . . just BARELY take the length wise edge off the sides . . . your leather will never notice it if you just cut enough off so it is not sharp. The two pieces should slide together really super flat. One thing about it though . . . after about 15 years . . . it has a tendency to become brittle on the edges . . . I have a 3 by 5 piece to prove it. I could probably cut out a piece that would be 2 1/2 by 4 1/2 . . . but I can snap off pieces of the edges in about 3 inches or so. But I gave up on it . . . went to Joann Fabric . . . bought their 3 ft by 5 ft sewing table piece . . . it is the second one now in a little over 10 years . . . cost 75 apiece. To me . . . that is worth twice the price. Hold it down I bought a 4 x 8 sheet of it last spring for a little less than 300 bucks for a different project . . . shop around . . . you may find it . . . I had to go to Columbus Ohio . . . population one million . . . to get it. May God bless Dwight

-

Are you saying the main shaft moves horizontally (and takes the handwheel with it)? Send a video maybe. You might try preventing the horizontal movement to see if the machine can still turn without binding up. If it binds up without the horizontal movement, then maybe the horizontal movement is by design. Also check to see if there are any screws loose near the main shaft whose job it might be to keep the shaft in place. On domestic machines I've seen C-clips used to prevent horizontal movement of the hook shaft. If a C-clip were missing, there would be a groove cut in the shaft but nothing in it.

-

The small mundane safety equipment was called "hearing protection" . . . on two destroyers with 5 inch / 38 twin gun mounts. (that's a bullet that's 5 inches in diameter . . . weighs 39 pounds . . . and can land 12 miles away . . . guaranteed within 500 feet of your landmark . . . the 38 means the barrel is 38 times the diameter of the bullet) We almost pulled up along side ammo ships . . . off loaded the ammo straight to the gun mounts and let er fly. Actually would get done with the bombardment . . . cut the rudder . . . full speed ahead . . . out to the ammo ship in the South China Sea . . . hated like nobody's business to get involved in any of that exercise. There were times when one would have thought everyone except the guys down in the engine spaces were deaf. After a couple hundred rounds . . . if you were close enough . . . your body would shake with every loud noise . . . and you said "huh" for several hours. My first ship did not get "official" recognition for it . . . but we just may have been THE first ship to drop ammo on the Ho Chi Minh trail. We were with the group of ships that spent a bunch of $$$ on 5 inch and 8 inch boo-letts . . . messing with Charlie in the early spring of 1965 . . . pock marking the trail for miles in either direction. Yeah . . . little orange rubber ear plugs would have been darn near wonderful . . . just had not been invented yet. May God bless, Dwight

-

Vinegaroon can be tricky, even on a piece of leather that you haven't done anything on. When you start adding things to the leather it becomes even worse. The vinegaroon works with the tannins in the leather so one piece of leather may not react the same way another one does. Sometimes even if the leather comes from the same cow. At this point the leather that's on that scabbard is the best you're going to get with vinegaroon. You'll have to use a commercial dye on it, like Fiebing's Pro, if you want to save it. You tried conditioner on the test piece of leather, try some neatsfoot oil if you have any or virgin olive oil see if that helps at all. This will usually deepen what you have. When I want something black I tend to use vinegaroon as a base then add Pro dye to the leather. This way I use much less black dye and it prevents rub off.

- Today

-

My dad was a bricklayer and one summer when i was 12 we were putting up a pretty tall chimney at a neighbor's lodge. I fell 3 stories off the scaffolding when I slipped on a bit of grit. After laying in the dirt and eating a little somehow I pulled myself together and got up. We took the rest of the day off work.

-

I haven't had relativly safe job since i was 14. I broke out in the oil patch at 18 and spent seven years working on rigs, back when heavy drug and alcohol use was almost a requisite for employment, then spent 30 years working in a prison maintenance shop, teaching dried out inmates how to hold a job. The last 15 years as the manager of an all-trades physical plant. I've seen my share of really stupid accidents in my life, some deadly, done a few myself, and luckily survived like Dwight by the grace of god. Really smart people are the worst at safety IMO because they are smart enough to know better but "it'll never happen to them", idiots come in a close second because they just won't do it, followed by the guys that have "done it all their lives that way". I've taught, reprimanded and worked with all of them lol. I could gross ya'all out with the gore, but i won't. Take the small, mundane safety equipment as seriously as the rest of your gear and equipment lest you be half blind and deaf at 66 like I am, its no fun saying huh all the time, makes you feel stupid. And yes, I said idiots lol

-

singer 45k Singer 45K25 Roller Foot

Cumberland Highpower replied to nategines's topic in Leather Sewing Machines

That was my post you quoted I think. I recently sold my 205-64 so that's not a problem for me any longer! LOL "Big" money is subject to interpretation I guess...With German goods it's always to be expected. The irony is that any roller feet Adler would have in stock were either made back in the days of "West" Germany with a production cost of 10% of today or made in the Adler parts plant in Romania where they pay $800 a month tops in wages. I'm still a little sour about the $126 I was charged for an Adler thread guide pin for one of my 205-370s....And the $26 charged for a plastic lift lever ball.... But if you need it, you need it, Right? -

Development of best servo motor for leather sewing machine

GerryR replied to CowBoyOUTLAW's topic in Leather Sewing Machines

So, you have a high torque, slow start-up speed motor, which means you have a special controller for it (?). What are the power requirements for it? How big is the motor? What are the output shaft dimensions? What are the mounting requirements for the motor and controller? Is the speed controlled by a foot pedal or a dial on the control box? Do you have provisions for a position stop (needle up-dwn)? These are just some questions I have for any new system I would consider. It sounds like your system already exists, so should be easy to answer. -

Some exotic inlay for 1911

PastorBob replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice work!! -

@mbnaegle totally off topic, but i was working on a vintage radio and got zapped, it was unplugged. Capacitors didn't bleed off before I worked on it. But I hear ya . USM motors are so good . Finger is not quite healed , yet. What I read in your post made me feel the pain as I was reading it , ouch ! I wonder how many leather workers on here are now paying (more) attention to what they are doing after reading this thread ? It's so easy to get get distracted 🙄

-

Some exotic inlay for 1911

Stetson912 replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I had used multiple layers. Both of these were made from laminated 4-5 oz leather to make the front and back panels. The front panel requires additional work obviously. I cut the window out, trimmed and skived the plug, skived the areas of the panel from the stitch lines to the edges, glued the plug in place, glued the caiman over the plug, then glued the window over everything and stitched it together. -

Lessington Leather joined the community

-

My cousin's husband used to have an antique business. He would often restore antique furniture and sell it. One day, he was pushing a piece of wood through the band saw, and was using his hand to push it instead of the safer (proper)way of using a scrap piece of wood. The saw blade hit a hidden nail, his hand was pulled into the blade and he lost two fingers. The hospital managed to re-attach one of them, but the other was too badly mangled. I don't have any major work-related accidents to report, though working with horses has left me with a few sore joints and scars. Stupidest accident was when I put a pitchfork through my rubber boot while forking manure. Fortunately, I was wearing two pairs of socks and the skin wasn't broken! I think I'd had a very late night the day before, so wasn't all that wide awake! Worst horse related accident - was riding a young mare recently retired from the track. The stable had recently bought her as a school horse. They only teach the racehorses to run in the one direction, so when the instructor told us to canter, she picked up the wrong lead. She was also feeling really fresh, so she took off like she was going out of the starting gate at the track. When she hit the corner of the arena, I think she must have tried to change leads, got her legs all tied up in a knot, and crashed into the wall. Next thing I know, I'm lying in the dirt, my watch is ripped off my wrist, the knee of my britches is ripped open, and I've got a huge bruise above the knee and another one below the knee and everything is spinning (mild concussion). The instructor comes over and asks if I'm okay. I shake my head, which is still spinning. Now this was the funny part. Next thing I know, I look up and HE is up on my horse, checking to see if SHE is okay! Eventually I managed to get back up on my feet, and took the horse back to her stall. I'd ridden that horse several times, and had mucked out her stall that morning, but couldn't remember where it was - had to ask someone! Yeah, definitely a bit concussed!

-

FidelityLeather joined the community

-

That's a good idea. I use to just put a small piece of leather under the clamps. Those hobby lobby clamps work great tho. There's like 30 or so clamps in a pack for I think $10. Not a bad deal.

-

I use regular hdpe cutting boards. I sand them with straight or orbital palm sanders with 220ish grit paper. It doesn't melt and clog but makes a super fine dust that sticks to everything if not using dust collection. Definitely wear a mask. Running plastic through a wood planer machine would be terrible on the blades of machine. I have a couple different boards I use. Some for just cutting and some for just punching. Then after sanding them several times and they are just wore out. I grab a couple more cheap ones from the store when I go to town.

-

You may be able to learn what is out of adjustment by slipping the belt off, and hand wheeling slowly. If there's enough force generated to break the thread, you'll likely feel that at the handwheel and you can see what is binding or yanking. It may be easier to feel if you are stitching somewhat thinner material. I'd also be interested to see what the hook to needle timing is. Beautiful old machine 😍

-

I have been very fortunate thru the years . . . lots of times and places . . . stuff coulda done me in . . . Safety gear has been part of it . . . staying alert is a part of it . . . not taking crazy chances . . . all have helped out. My guardian angel did his thing a couple weeks ago though . . . I have a table saw I bought without a blade guard . . . got it ordered . . . was using it before the guard got here. I sawed down a 24 inch or so piece of 1 x 4 down to 1 x 3 or so . . . had both pieces from the other end of the saw . . . was bringing them back to me . . . over top of the saw . . . and somehow the big piece slipped or something in my hand . . . fell down to the blade that was slowing down . . . hit it just so it would become a 1 x 3 pine rocket. Thing caught me perfectly on my upper gum line . . . above my teeth . . . below my nose. I looked like the guy who just lost to Mike Tyson or something for a couple of days. Honestly . . . my worst industrial accident ever. I got a hole burned in my thumb by 450 Volts aboard ship . . . didn't really even hurt . . . even though I jumped like a white tail bunny . . . that was the second worst . . . Worked maintenance electrician and mechanic for 30 some years . . . 4 of em in the Navy . . . climbed more ladders than I'd like to talk about . . . used more power tools than I could probably name off in the next hour . . . Got a sneaking hunch my guardian angel will wipe his brow and say . . . "Finally . . . he's here . . . " when I walk thru the pearly gate . . . as he has done a great job for me down thru the years. May God bless, Dwight

-

Not really a shop accident, but for the last 17 years my "shop" has been horse barns with broodmares and youngsters. We had purchased a mare that hadn't been handled much. I getting to know her and trimming a hind foot when she decided to jump through/over me. She didn't make it and broke 3 long bones in my foot, although I didn't know it at the time. A veterinarian friend stopped by the next day and offered to take some x-rays. He determined the foot was broken. I made an appointment with a foot/ankle surgeon and took the x-rays along. During the appointment a thunderstorm knocked out the power and they said I'd need to come back for x-rays. I told them I happened to have my own x-rays in my backpack. The surgeon was impressed and said he gets x-rays from podiatrists that don't even look like a foot. I told him that equine vets have experience radiographing patients that are less cooperative than me. So he put me in a walking cast and sent me on my way. Twelve years later the mare and I are like two flies on a donkey's ass. She produced a pretty black filly this year and is pregnant for next year's foal. She's in her late teens and this might be her last foal. She will retire here as a babysitter of weanling foals.

-

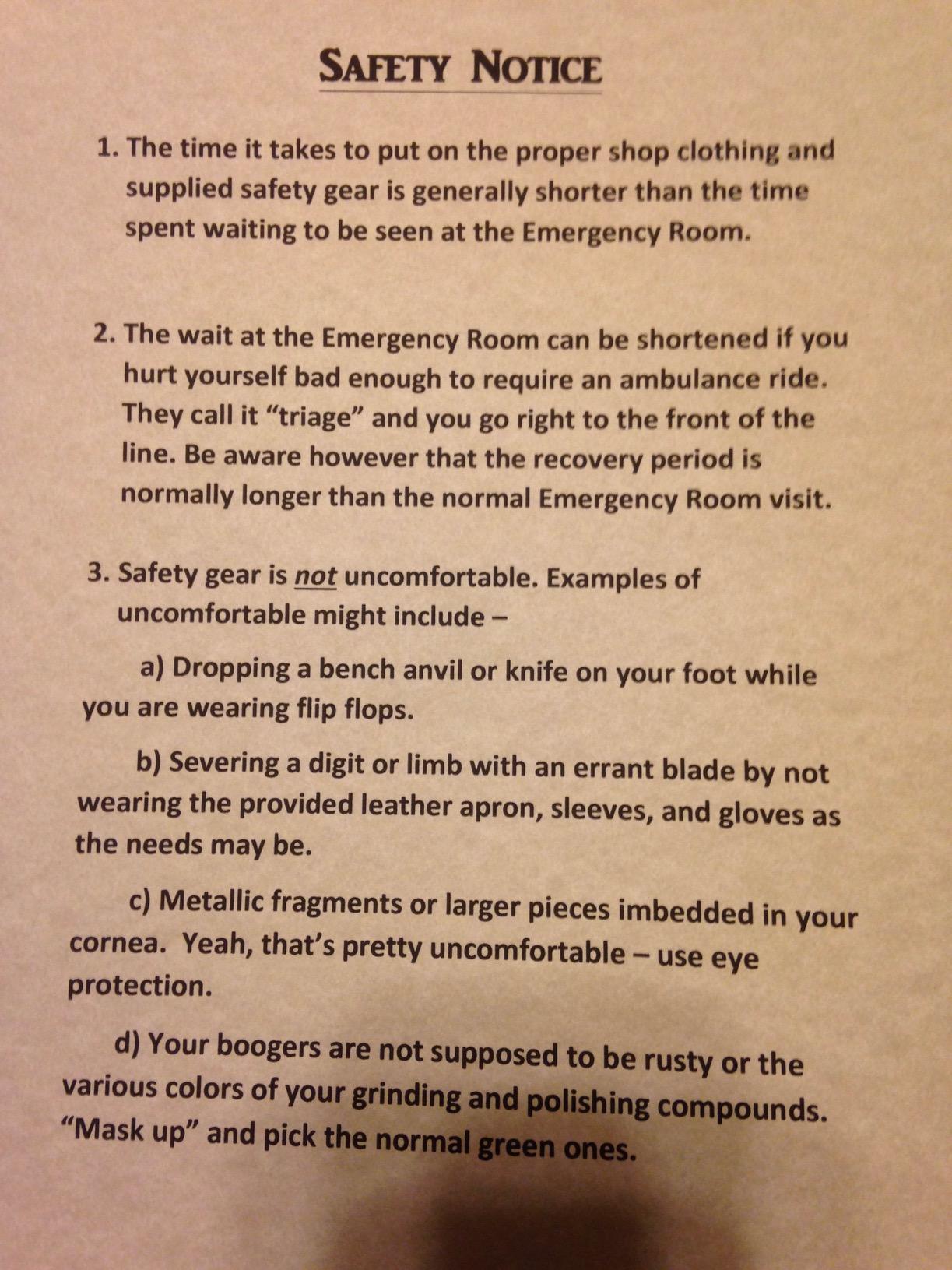

When I first got my business license I had a county inspection - some work place guy and a fire dept inspector. Not pain in the a** guys, they just wanted to know what they’d up against in a fire or industrial accident. I’m a one man shop so mostly formality probably. Really pretty cool guys. The work-place guy noticed I didn’t have a workplace safety poster in place. He said to just send him a picture when I got it and he’d sign me off. I came up with this. He said it was official enough for him and one of the best he’d seen.

-

Success! I was able to remove the cover underneath the shuttle assembly (not sure if that's the correct terminology) and move it around until it started picking up the bobbin thread. I did some test sewing and it appears to be working well! Any thoughts on the horizontal play in the main shaft that is connected to the motor pulley? At the top of the cycle it moves about 1/4 inch and then "clunks" back into place as it continues the cycle. I can't think of any reason why it would do this and want to make sure using it like this isn't going to cause undue wear. Once I'm confident that it's operating correctly I can start work on the motor, trundle and speed reducer. I do believe you're correct on the age. The serial number ends in 86, which I believe is the manufacturing year. I did see that old post about you having an english translation for the mechanics manual. I didn't realize you did the translation yourself. I'm sure they were very appreciative! If you can locate it I would be very grateful if you would send me a copy. The old owner removed the motor and trundle connections so any pictures of that setup would also be greatly appreciated.

- Yesterday

-

cowhawk joined the community

-

I presume the needle is hitting the needle plate? That will happen if you put sideways pressure on the workpiece, been there done that! You have to guide the piece not force it.

-

Had some mishaps over the years, always due to being an idiot with a tool or using it without the proper guards. Personally, I don't like trying to make machine's "idiot proof" as it seems that they keep coming up with better idiots, but if something had a guard when it was new, it's better to keep it in place and adjust your job rather than take it off and forget about it. Ultimately, no guard will compensate for someone not keeping their mind on their work or trying to do it faster than is safe. It's better to treat the machine like it would kill you if it could, like a tiger on a chain, not a kitten to play with. I was cutting up some 3x3x3 hardwood blocks a few years back and didn't plan ahead and cut them to length before I sized the height/width on the jointer or planer. Being in a hurry, I made the idiot decision to run the short blocks through the table saw. One bound up and kicked back into my face, making a comical *ploink* noise and I later found it had a dent in the side where it hit the floor AFTER hitting me. It momentarily dislocated my jaw, knocked my safety glasses off my face, vision went blurry for a bit, and I was bleeding pretty good. Got a ride to the hospital and was EXTREAMLY LUCKY that it just skipped off my face doing no bone damage, no bruising, and I only needed 14 stitches and some superglue to get put back together. Also fortunate that the ER guy on duty that day specialized in facial sutures, and he dug some wood shrapnel out of my face. Got a neat scar out of the deal, but better than that I gained more respect for using a table saw correctly and I replaced the missing blade guard. I finished the blocks later (belt sander), which were being cut into some support rests for a tool, and the one with the buzz mark across the side where the blade caught It I kept visible for a personal reminder. Speaking of table saws, long before my time my dad worked with a leather shop that did silver work as well. He was doing some silver work on a mechanical die press and it took the last 1/4" off of one thumb. He went to the hospital but didn't bring the severed bit, so they had to pull the bottom edge of the wound up under the nail (which he said hurt the most). For the longest time, he had one thumb shorter than the other, which made for some fun stories, until one day he cut 1/4" off of the OTHER thumb while using a table saw. This time the doctors didn't want the bit and stitched it up like they had the other thumb, so for many years he kept the severed bit in his desk in a little jar of formaldehyde. He used to say when he was buried he wanted us to burry ALL of him, but when he passed we couldn't find it (I miss him anyway and don't mind if he wants to haunt me). Speaking of thumb's, another time I was making adjustments to a band knife splitter, which required the machine to be opened up but running so I can see how it was moving and make adjustments. While I was sitting and giving it a moment to run, I noticed one of the blade wipers was vibrating. I thought that it was covering the blade and I stuck my thumb on it to see if the vibration would stop, and when I did it slid back letting the blade slice into my thumb about 1/2". The guy I was with wanted to call 911 but after I had a chance sit and to breath through the wooziness, it didn't seem so bad once I taped it up, so I finished my work for the day and went home. When I got there my visiting father-in-law helped me re-dress it and told me 'Nope. You're going to the hospital.' Once there, the nurse messed around with it cleaning it out and by-golly that was x10 worse than when it happened. They recommended stitches but too much time had passed (6 hours), so they would have to cut it back open If I wanted it to leave less of a scar. I was more concerned with infection than cosmetics and they confirmed that I didn't NEED stitches, so they taped it up and gave me some antibiotics. As it healed, I realized I had cut through a nerve as the end of my thumb had lost feeling, but it closed up fine and didn't hurt. After 3 or so years I've got about 90% feeling in the end again. I've gotten nicked by non-moving band knives plenty of times over the years, but I still cringe when I think of getting my fingers that close to a moving blade again.

-

Try 20 feet with an extension ladder sliding out from under me. Landed on my feet, crushed right ankle that the MD couldn't even bother to look at the x-ray or radiologists report. Came down between 2 rising stem gate valves on 6" lines. Right side of my shirt was ripped open, slight scratch on my chest. Could have ripped my shoulder off if I had been a few inches further forward. Very thankful that didn't happen. The ankle was bad enough, limped for 15 years. Still can't bear to lace up an ice skate to go skating 54 years later. For years, too much or too little exercise on that ankle resulted in severe pain. Had to keep moving, but not too much, We have lots of safety standards. They are there for a reason. If I had waited for my fellow worker to come back and brace the ladder before I stepped down onto the rung, this wouldn't have happened. He was called away because a couple 1000 scfm air compressors had tripped and had to be restarted immediately else the whole utility plant that supplied steam, compressed air, 54MW of electricity, utility water, boiler feed water, cooling water would have been lost and the whole process including a refinery would have shut down. We were in a isolated location 100 miles from the electrical grid. I should have just sat there and waited!

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)