-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

Stealing Pictures of Others Work

JLSleather replied to immiketoo's topic in Leatherwork Conversation

This is - in a nutshell - the essence of copyright law. If you purchase a pattern, or instructions, etc -- you have the right to make goods from that, INCLUDING items for future sale. What is actually protected is the WRITING ITSELF. Keep in mind always... a copyright is only good to the extent that it is enforced. You can send letters all day long to "tell" someone not to use your images (patterns, articles, whatever) but to actually stop them you would need a judgment, which is neither instantaneous or free. -

A Holster and belt

JLSleather replied to OLDNSLOW's topic in Gun Holsters, Rifle Slings and Knife Sheathes

"purdy" is spelt witha Dee ! -

Nothing to add -- just this is worth repeating

-

I've never ordered that exact stuff, but as a rule "craftsman" is a nicer word for.. well.. something less nice "Craftsman" isn't a word Hermann Oak uses in their grading -- this is someone else's story. http://www.hermannoakleather.com/about/grading/grading-20140524202323 I use H.O. leather in A and B grades, always been good leather -- consistent thickness, clean surfaces, tight grain, well split, tools and forms great.

-

Looks like some good practice ta me -- and the shield looks good!

-

M&P Shield 9 Holster

JLSleather replied to IngleGunLeather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I ordinarily aint big on ostrich, but I gotta admit ya made it work -

I've had my third and final issue with Fiebings saddle tan dye. I'm not sure what they're doing different than before, but that saddle tan just doesn't work any more. I used quite a bit of it in the past. One batch, I tried mixing with that alchohol everybody was on about. Got splotchy, ugly results. Pitched the holster it was on, and tried again on a different piece of leather. Got same results second time, so I threw out the dye and got a fresh bottle (it DOES get old, you know). But I got the same results - in different leather -- I tried that next bottle 3 ways - thinned with alcohol, thinned with reducer (fiebings), and straight out the bottle. Tested after glue/sew and tested flat on teh table, and tested hanging on a hook. All tested on A-grade HO, from the same "batch" (order) but not from the same hide. All same results. All of this going on, EVERY other color I used came out just fine - -it was ONLY the saddle tan. So, I'll just use another color,or combination of colors.

-

How to test retention

JLSleather replied to hwhleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That's a good point. I think some people don't realize this, and some people don't want to talk about it. I've seen like .020" difference in two guns which are supposedly "the same". -

IWB Holster Hardware

JLSleather replied to Venator1's topic in Gun Holsters, Rifle Slings and Knife Sheathes

A simple article about turning your favorite '50/50' pancake into an IWB available now. It's free, but you get 20% off 'til Friday http://www.jlsleather.com/diy/pattern-making/gun-holster-patterns/ -

IWB Holster Hardware

JLSleather replied to Venator1's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Well, yeah-- there's a little more labor involved. Just making the point that the PATTERN is one step away from any 'pancake' pattern you have that you like. No need to purchase another one just for that -

IWB Holster Hardware

JLSleather replied to Venator1's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Note this is nothing more - or less - than a simple "pancake" holster with loops added over the slots (or sometimes INSTEAD OF slots). Refresh the page (or hit F5) to play the animation -

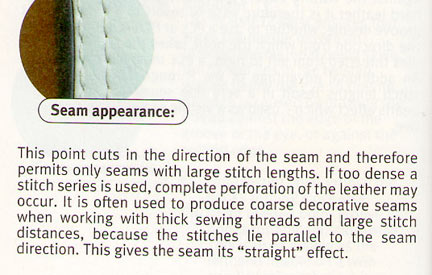

I never use "S" needles, or recommend them, and this is why. Good to see "them" actually state it. While the stitch is "straight", so is teh cut in the leather, and the tighter the stitch, and the closer the spacing, the more likely to fail. Much better to go with the "LL" point needles.

-

Pin punches are great for replacing shear pins, but not so good on leather You'll want a set of hollow HOLE punches.. much better for leather. I'm not recommending any particular brand, but this one will show you the idea. Something in about a size 6 or 7 should be fine. https://www.tandyleather.com/en/product/craftool-round-drive-punches

-

Ruminations about presses

JLSleather replied to carguy4471's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Good to consider these things, but there are some relatively inexpensive ways to keep from going too far with a press -- guage, limit switch, or even a simple bolt in the right place (much line a cinder block under the car when using a jack ) Finally getting my stuff out of boxes around here.. looks like I'm only missing ONE blue gun ... so see what else isn't here.. -

Ruminations about presses

JLSleather replied to carguy4471's topic in Gun Holsters, Rifle Slings and Knife Sheathes

YIKES.. I didn't realize the bag was that much money. Seems like the vacuum would be better for forming turns/twists/corners (since it pulls IN as well as down), and with the hyd version, a guy would want to put something between the foam and the leather so you don't "texture" the leather with the foam. In the ONLY video I ever recommend, Sam A. uses a hyd press to form a G19. One IMPORTANT difference here between that and what you often see... Sam's corners are ALREADY in the holster due to the unequal front and back patterns... WHereas with those 50/50 things, a guy would 'smoosh' down (only).. nothing in the hyd to pull in the front / back (top of slide and under guard). OH .. perhaps worth stating here: LOTS of boys 'n' girls are making holsters without EITHER method. -

If you're going to purchase patterns, I would recommend: For shape / design: How To Make Holsters Art of Making Leather Cases (there are 3 volumes - each with its own subject matter For learning to tool leather: Tech Tips Pictorial Carving and pick up some downloadable carving designs while you're there. This will let you concentrate on learning the carving. There are thousands of books and patterns available these days (not to mention an ocean of why-tube videos), but I have yet to see any which give a more complete understanding of the PRINCIPLES laid out in these (including some which apparently think that if they charge more money, some people will think they are "worth more"). The point of these materials is not to carve and / or make THAT project, as much as it is to show you WHY it's done that way so you can create your own.

-

Tandy Euro Bend

JLSleather replied to carguy4471's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Been a few years, but I've been to both of those. Both pretty small stores - always wondered why they were so close together but sold / stocked the same items. Must be quite a few hobby folks in that area. -

Ruminations about presses

JLSleather replied to carguy4471's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Oh, yeah -- here ya go. Some pics of what one set up looks like and some holsters made with it And the link to the parts kit (the link in that thread doesn't quite work any more). http://www.veneersupplies.com/products/Project-CRS-Continuous-Run-Pump-Vacuum-Press-Kit.html And then a guy would need a bag (available in the same place) and a pump (seems most guys get the HF pump). Course, if you're leaning to the hyd version, then you'll likely want some foam pads to insert between the press and your leather. http://www.knifekits.com/vcom/index.php?cPath=41_524 -

Ruminations about presses

JLSleather replied to carguy4471's topic in Gun Holsters, Rifle Slings and Knife Sheathes

A cheap hyd press from HF will do your molding - the 12 ton is enough, but the 20-ton is virtually same cost This has one advantage over tthe vacuum in that it can also be used as a clicker press. The 'plus' of the vacuum is that the pressure is applied in more than one direction, simultaneously. There are threads from a few years back about which parts were included in a "kit', which was then paired with a cheap HF pump. -

If you're using contrasting thread, it's easier to dye the part under the belt loop before sewing on the panel. And you'll likely find it faster and easier to pick up some type of punch for the slot rather than drilling. Some use an oblong punch, some use a round punch for each end and a knife of some sort between.

-

depends how big the slot. Usually, a modeling spoon works.

-

Well.. uhh.. while i appreciate the vote o' confidence, fella aint gotta go farta find somebody knows more about sewin' than me

-

Why you don't buy the cheap stamping set on Amazon...

JLSleather replied to jphillipw's topic in Stamping

List it in the for sale section -- it's KUSTOM