-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

Bernina 217n-08

Gregg From Keystone Sewing replied to LadyDragonfly's topic in Leather Sewing Machines

I know quite a bit about this one. This was sold by both Bernina and Durkopp, both as a model 217. A lot of sailmakers like this for light seaming work. Very high quality, all parts are available now from IMCA Global who is now bringing this back strong. I've been able to get parts from them from time to time. CLICK HERE for Imca Global's product web page, with lots of links and downloads for this machine. Bernina 217 Owners book.pdf -

We'll, they are all good machines, all designed for the same work. Two I would eliminate from this list anyway is the 205RB, this is a new model machine, BUT is only a top bottom feed; not a true walking foot with top, bottom and needle feed with alternating pressers like each and every model that you listed. Also, the Pfaff 545 is from the 60's, not a bad option,but does not belong on this list.

-

Need help timing a double needle machine

Gregg From Keystone Sewing replied to Kd0afk's topic in Leather Sewing Machines

Uwe, This is excellent, great tips that we all can learn from. -

111w155 Tension Unit Repair or Replacement

Gregg From Keystone Sewing replied to Willie0's topic in Leather Sewing Machines

This should be an easy fix. The threaded tension stud has collapsed, and needs to be opened up. Just remove the tension thumb nut, tension spring, and insert a screwdriver to open up the stud, then put everything back on the way it came off. This will allow the threads to grab on the thumb nut and provide you with consistent tension. -

Cast iron bed crack - options

Gregg From Keystone Sewing replied to DonInReno's topic in Leather Sewing Machines

This is old school, and how we do it, too! Lot's of them. Many of them in this location in the bed as well. Clear sign of a drop. The machine will never break on it's own unless it's a stretch and the weld gives out. Maybe some did break the frame under normal use, but I don't know. No two machines are the same. -

Which VBelt size for a Speed reducer

Gregg From Keystone Sewing replied to MacB's topic in Leather Sewing Machines

3L fractional size, 3/8 in. top width, 7/32" thick. By the way, that looks like one heck of an on/off motor switch you've got there. -

Singer 2281B362

Gregg From Keystone Sewing replied to JensenHandcrafted's topic in Leather Sewing Machines

I realize this appears to be similar to a Singer 281...I've never heard of or seen any model numbers even remotely close to this, nor can I find any information for this class, let alone subclass. -

Glad you were taken care of and found the information that you needed.

- 39 replies

-

- able290

- chinese shoe patcher

-

(and 1 more)

Tagged with:

-

Consew 199 Timing/Tension Reliabilty

Gregg From Keystone Sewing replied to spotty's topic in Leather Sewing Machines

-

Consew 199 Timing/Tension Reliabilty

Gregg From Keystone Sewing replied to spotty's topic in Leather Sewing Machines

Two things that may help; Consew 146 and 199 series need a lot of upper tension. Like any zig zag where the hook timing is being split needle bar height is a critical and sensitive adjustment. Do what is in the book first, then follow the text instructions. Normally, needle scarf comes in high on one side and low on the other. Very common for the needle to be pushed out of the way on one side if this is not done correctly. Often, it's a see touch feel type of adjustment. -

Consew 339 RB-1?

Gregg From Keystone Sewing replied to warhorse1700's topic in Leather Sewing Machines

Consew 339RB-1, made by Seiko in Japan, is an excellent machine, double needle, walking foot, large bobbin with reverse and safety clutch. This best suited for V69 thread, but can sew lighter. Most common uses are for canvas, upholstery. You can sew with one needle, but you will be limited to what you can sew with the double needle presser feet, and cannot install a cording or zipper foot. Even regular free sewing can be an issue with the regular double needle feet. -

Servo motor speed limiter

Gregg From Keystone Sewing replied to JeffHami's topic in Leather Sewing Machines

Yes, the motor will have to shift off to the side to accommodate the speed reducer. This is why a new setup with this is often a cleaner setup, if you can't deal with three extra holes where the motor was. -

Servo motor speed limiter

Gregg From Keystone Sewing replied to JeffHami's topic in Leather Sewing Machines

I think I understand what you are are asking; you are looking to "add" a speed control knob or dial to an existing motor to be able to adjust the upper limit of the maximum speed. Either the motor has the ability to input this through the use of a potentiometer, such as some of the Efka motors, or you are going to have to be an electronic genius and be capable of making up something on your own for your specific model motor. I do not know of any digital brushless motors that have an input like this, and as said you can adjust in the motor parameters as per the instructions for your specific model. Other motors like the with brushes Consew CSM550-1 have a dial like this. -

Seiko does use the 1st two numbers of the serial number for the model year, so this is a 2001 model.

-

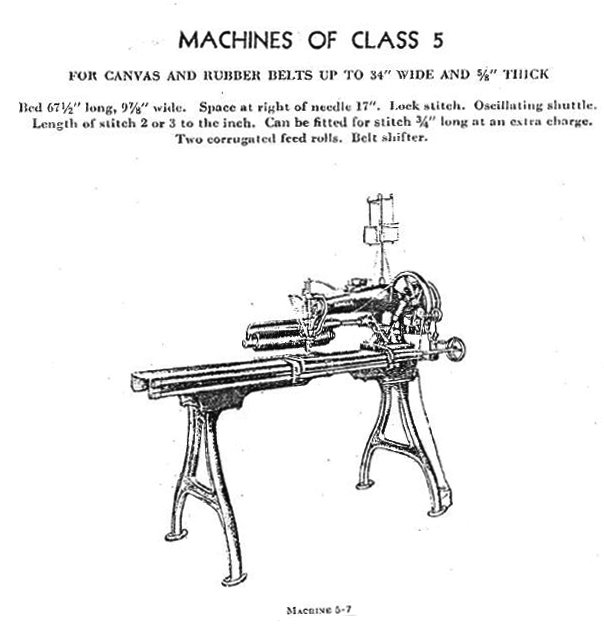

industrial singer class 5-9

Gregg From Keystone Sewing replied to meswaine's topic in Leather Sewing Machines

Other than look, I guess can talk about it. Or at least type on a message board about sewing machines about it. Hope that helps! -

industrial singer class 5-9

Gregg From Keystone Sewing replied to meswaine's topic in Leather Sewing Machines

-

That's what I and the mechanic here were thinking as well. Also, make sure all of the parts are in there, we were looking for the needle guard index #45, but the image you provided didn't show enough information to confirm this. I would really think that if you have two different types of throat plates, and neither work correctly, to look elsewhere for the issue.

-

Uwe, No, you're the man! Seriously, I appreciate you and your knowledge. Again, I learned a lot of new tricks with your 441 timing video. Some things were the same, some were new, and some were different. If you have not seen it yet, it's a good one, CLICK HERE for YouTube video. Anyway, back to the issue at hand. Uwe is correct, ShelathaLore. -Get a better grip on the knob, love the leather and vice grip option, and put some force into it. Make sure that we are turning the correct direction, long or short stitch length. Don't be afraid to do this, we've got your back!

-

Good lord our shop's a mess. Nice pictures everyone.

-

See attached for owners book for Consew 28 28.pdf