-

Posts

1,025 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by TomG

-

Before you use a syringe, make sure the end cap makes it waterproof. If you overfill the chamber, it may leak out. Not sure though.

-

I use mine for cutting the slits for doing mystery braid and stuff. It's a PITA to change setups for different sizes, and that black holddown bar is a bit flimsy, but it does a good job of doing what it's designed for after it's set up. Be sure to use sharp blades. Stropping them once in a while helps.

-

If you try to pour dye in, you're probably going to have a mess. Pull the cap off the top and slide the sponge tube out. Drop one end into a small bottle of dye for a few minutes and let it saturate. Then put it back into the pen and cap it back up. Dip the tip into the bottle to pre-wet it and you're good to go. When it runs out, just resoak the sponge tube. I really like mine.

-

White Dye

TomG replied to Hooper26's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

So, where do you get the stuff to do it and are there any issues with doing it by hand? -

Generally, when you fold a thicker piece like that, you wet the back side down a bit, let it soak in a few minutes and then do the fold. Tom

-

This had me puzzled. I have used Tandy's double cap rivets for years now and never experienced that problem. I believe they use the same caps as the rapid rivets. I set a few in a strap and rubbed the hell out of them on my desktop, a formica embroidery table top, a cutting board and my granite slab. I rub hard, like I was doing a rough cut when sharpening a knife. The only one that showed the base metal was the slab. I'm not sure what's going on with yours. Any way for you to post photos? I am getting ready to switch to the solid brass rivets and may switch to OTB for them if Tandy is having quality issues now. I can see them cutting down on the plating thickness to save money. Tom

-

Hi Wiz, Thanks,,, Yep. Already did the decision on a bottom price. I always do that anyway . Don't think I put FIRM on it though.... I just got in from vacation, so will check that tomorrow . I haven't had to battle the Nigerians lately, but I've had a few "official" Microsoft support folks form Manila call to tell me my PC was in serious trouble and the could fix it. I couple of them even held on while I "had the FBI start a phone trace on the call". Talk about being faithful to a script. Hmm ... I wonder how long they held on after I hung up? Thanks Tom

-

Thanks for the input, Floyd. I've had a few inquiries locally but they were from people who wanted it for next to nothing. I don't really mind shipping, but was not up to speed on ways and costs. I have a much better handle on it now. Thanks to all Tom

-

Thanks to all. Guess I'll just keep my listing as local Too much expense for this old singer 155 Tom

-

What is the best way and approx cost to ship, say, a Consew 206 and table? I know it depends on distance and weight, but just looking for a ballpark Thanks

-

If you get a pair of flush cutting nippers, and if you can reach the riet post between the layers, you can cut them out with almost no sign of it. Depending on the leather and such. I have on occasion, been able to use them to gently get under the cap and cut or pry it loose. Tandy does carry a nickle plated brass that may hold up better, but I've never used them, so can't attest to that. Tom

-

Hi BigMatt. I am finally getting around to mounting the binding foot I bought. I meant to ask you.... Did you have to replace the feed dogs and needle plate or did the ones that came with the machine work OK? If you replaced them what did you use? Thanks

-

Coloring or Painting leather lighter than its original color

TomG replied to RussInVegas's topic in How Do I Do That?

Found it. Thanks. Yeah.. He's proud of his stuff.. But in all fairness, a lot of those items take a LOT of work... And the hardware is probably a bit steep. Let me know how the hat goes. I won't spend that much on a pattern unless I KNOW I'm going to make one <g>.... -

Coloring or Painting leather lighter than its original color

TomG replied to RussInVegas's topic in How Do I Do That?

Where did you find the pattern? I did an internet search and tried the URL on the photo and can't find it. -

-

-

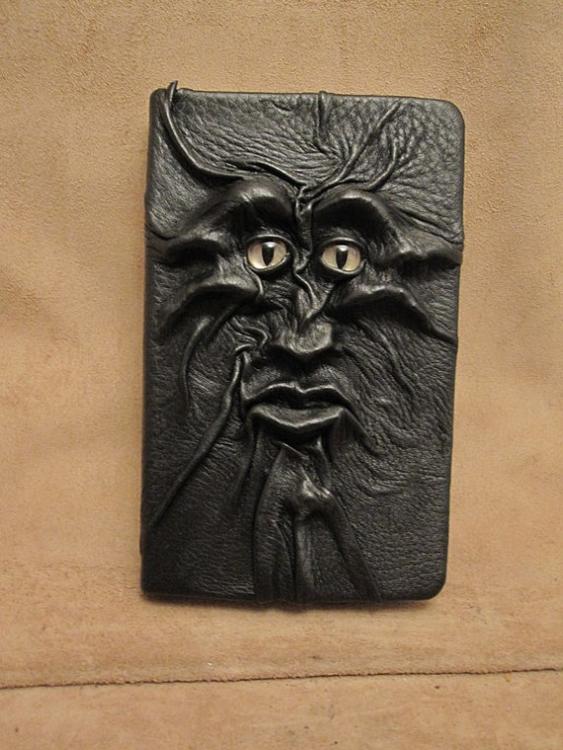

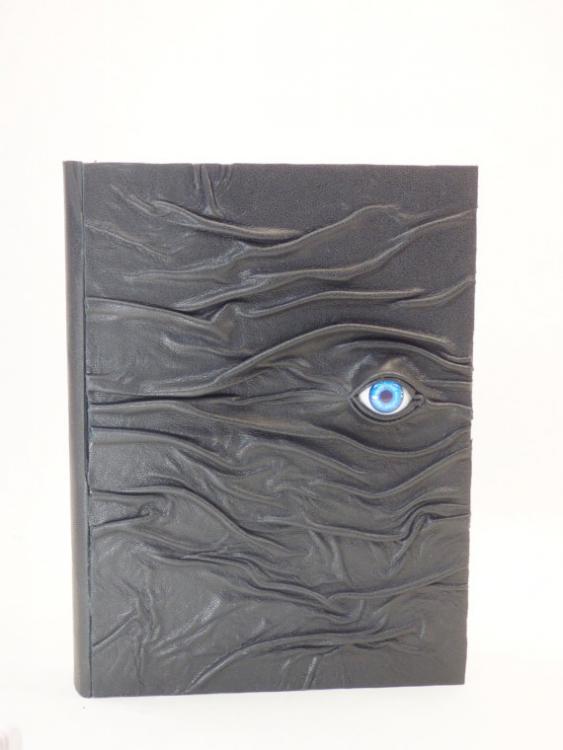

I saw some of these at a Ren-Faire a while back and found them intriguing. How is the leather secured/stiffened and how is the eye secured? I assume some form of glue. I'm thinking of making one for my grandson since he's gotten into Harry Potter lately Thanks

-

What did you use for the end caps?

-

They hire unexperienced people and expect them to sell products they do not understand. This is all wel and good IF they allow the manager and other staff to train the people. And this would require crafting leather. It's a cost of doing business if you want to hire people who have no experience. It's up to the manager to control when they do this - during downtime I can understand them not wanting them to do "side job" stuff at work, but a blanket ban is ridiculous.

-

I'm in Tandy frequently and they've shown me their work. Maybe they did it at home and brought it in. I thought they did it there. I'll have e to ask next trip. But I agree. They should be allowed to tool leather. As long as the store and customer is not neglected. Ad that should be a manager call Tom

-

How many dog collars can we make with a skin ?

TomG replied to Doglover's topic in Leatherwork Conversation

First, I believe you are talking about a side, not skin. Second, 18 sq ft is not a usable number. There will be unusable leather on that side. Too much fat, too many flaws, too much stretch, short pieces, etc. Third, if you're going to line them, you might want to use thick leather for the strap and thin or splits for the lining. Sounds like you are just doubling up. About the best you can hope for is to measure the side as if cut into a rectangle and hope you get to use 75% - 80% of it. It will vary by the actual piece- 5 replies

-

- dog collars

- skin

-

(and 2 more)

Tagged with:

-

Yeah.. I'm not a prude by any means, but i don't think that's appropriate for this type of forum. And especially not on the main page. If it was a "biker" site, it might be expected, but I think most of the ladies.. and all of the kids.. don't need that.

-

I haven't seen the page(s) you are referring to. But, IMHO, skulls in the mix of leathercraft are fine with me. I've done them, but don't "focus" on them at all. But I agree with biker. We have an Adult section that questionable "art" and discussion belongs in. And honestly, I feel that you can be "adult" without all the profanity. What's that saying? Profanity is the sign of a small mind? Or something like that.. See. I just wrote 10+ sentences and not a single swear word !!!! Yea Me.. Bwhahahahahaha.

-

Has anyone used this to support soft leather when sewing bags? I saw it on a Leather Bag Tutorial I bought. It is supposed to stop stretching as you sew. I only found one place that carries it and shipping is more than the roll of tape. Any idea of if it's worth it or if there is a more readily available substitute? Thanks