I have done some fairly extensive experimentation with the edge paint. Thought some of you might be interested in what I have found.

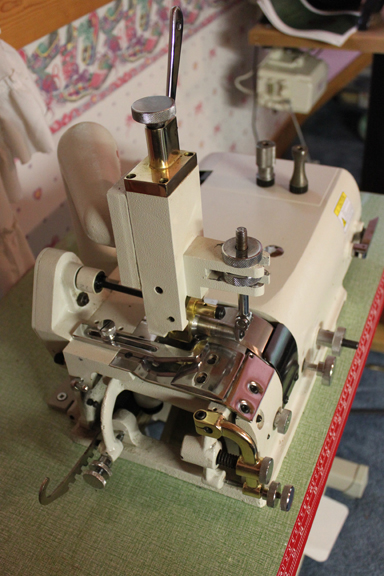

Several folks sell this little tool. Best applicator for edge painting I have found among several. I am currently using Giardini mostly because I think it is one of the best out there. Has great consistency out of the bottle. Don't dip this tool into the large, 250ml/1000ml, bottle. The grooves on it have a tendency to pick up some little bits of loose leather you may have left behind so they get transferred into the large bottles and contaminate them. I have two or three different sized bottles I use, most are available at craft stores. Shake the large containers briskly then tap on the sides gently to dispense with the bubbles that occur and mess up your edge job. Pour a small amount of the paint into the small container with a tight closure. Don't dip the tool more that just about to the large diameter edge of the brass. I tap the tool on the edge of container so there isn't so much paint on it. I roll paint onto edge so that finish side is facing me making the large end of tool the same. I have yet to get paint onto either the backside or front of the leather I have used it on. Have edge painted 1 mm thickness out to a quarter inch plus.

You must prime the edge with any one of the manufacturers clear edge agent. I bought a 1000 ml bottle of Fenice when I first started using the edge paint, it works great with those I have tried for finishes. I sand the edges very lightly before sealing, allow the sealer to dry for several hours or over night, then sand very lightly again with 600 grit sand paper/cloth. Two coats of finish are all that is needed with the Giardini with most leathers. I am sure some leather could possibly need more applications. Veg Tanned or Chrome tanned both do very well. I haven't tried any oiled leather, I doubt the products would stick very well. The finish paints dry in 15 or 20 minutes but I don't put the leather pieces to work for at least 24 hours.

Have made coasters of finished leather and unfinished, horse hide and cowhide, Kangaroo, it doesn't seem to matter from my experience. If I am going to put a row of stitching at the coaster edge, I do that before painting. Using a roller or stationary sewing guide drags a little against the edge paint. Obviously if you don't need to use a guide that doesn't matter.

I bought a set of brass edge irons for a modified solder iron which I find practically worthless for what I have done so far. Simply do not need it. I have no problem with edges falling off, cracking, buckling, or anything else. I have the paint on an iPhone case that is over a year old and I give the cases a bad way to go in my daily work, no deterioration.

In my research I found the Fenice paint to be too "Runny" in consistency. Found a product that is used in all latex paints known as HYDROXYETHYL CELLULOSE, HEC FOR SHORT, guess what it does!!!! used as a thickening agent. Comes as a very fine powder, Amazon has it, I bought a 6oz. bottle. You can get it in larger quantities of course. If you have Fenice product, pour a little into a small container adding a very small amount of the HEC so you can see what it does or when you reach the consistency you desire.

If I can answer any questions you may have let me know.

Ferg