-

Posts

1,183 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Josh Ashman

-

Distressed Plainsman Holster.

Josh Ashman replied to Forester's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice Forester! great job! I've heard that a great way to "distress" leather is to throw it in a clothes dryer for a while. I tried it once, put a brand new, slightly damp holster in the dryer with a load of towels my better half had just finished drying. Left it in for about 30 minutes and it did seem to "age" the leather a fair amount. That was some time ago and haven't had the urge to try it again, so that that for what it's worth. you might experiment around a little and see if it works for you. Anyway, again, great job! That's a nice looking holster! Best, Josh -

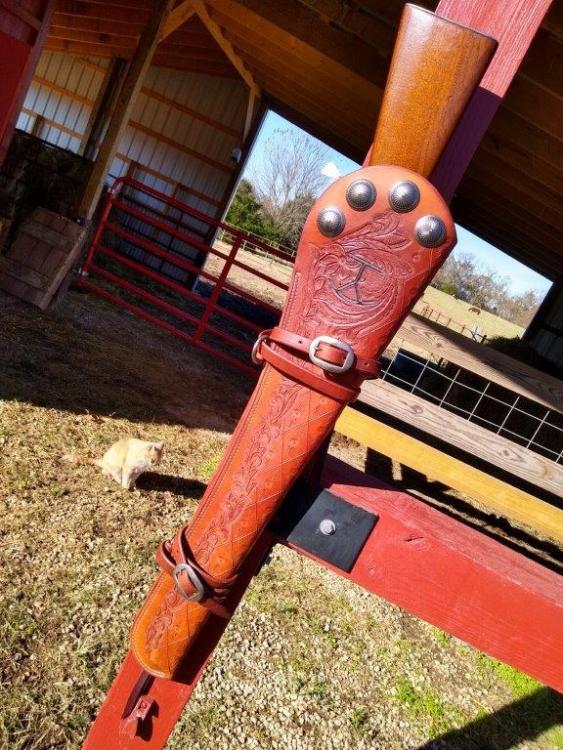

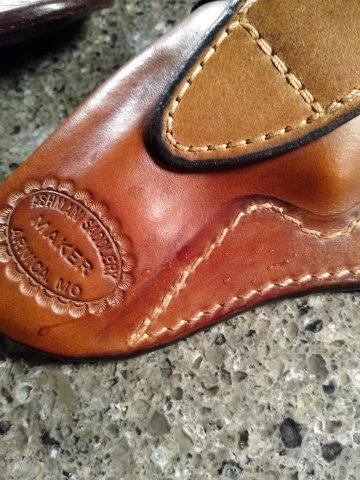

Fancy Scabbard

Josh Ashman replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You're certainly welcome! Good luck with it! -

Fancy Scabbard

Josh Ashman replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

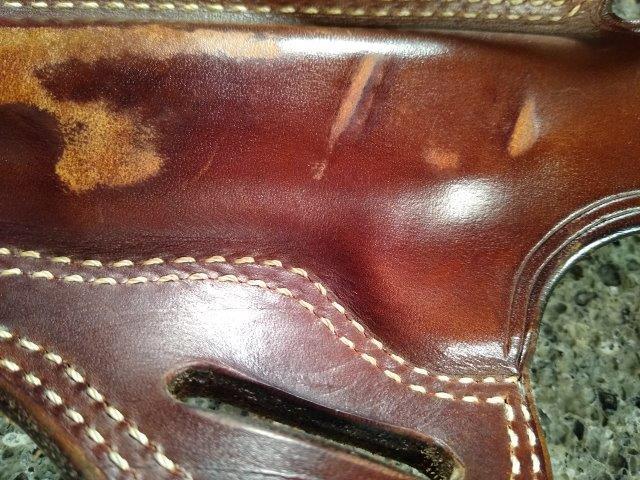

Thanks for the kind words folks! Much appreciated :). As for the finish questions, no dye of any kind was used. Just NF oil (I get the 100% pure by the gallon from Weaver, but in my opinion it doesn't matter what brand or whether it's pure or the compound) and Aussie Wax. I do give it some saddle soap once I get the color I like. I apply 2 or 3 coats of oil to the grain side with a scrap of shearling, so a healthy dose then put it in the sun for anywhere from a few hours to all day. If I want it darker I'll oil more and put it back in the sun. Each hide darkens different amounts so there isn't anything real consistent, I just keep at it until I get it looking how I want. The Aussie Wax is the same, liberal coat and put it in the sun. It will darken the leather quite a bit so if you're using it you'll want to stop with the oil before you get it as dark as you want. As for whether it's the sun or heat, my best guess is that it's the sun for the darkening but you want the heat as well, especially to get the Aussie Wax to "melt" into the leather. I will also add that having the sun filtered through a vehicle windshield doesn't seem to lessen the darkening, although If I'm not worried about rain or a dog running off with it I usually put the item in direct sunlight. In my opinion this finish only works if you're ok with supple leather. I don't use it for any sort of "carry" holsters as I like them to be rigid and with this much oil and "greese" (aka Aussie Wax) the leather won't be rigid. As a word of caution, you can certainly overdo the oil, you don't want to saturate anything and applying it to the flesh side can do that in a hurry. I don't think this scabbard will get much use. I made it as a Christmas gift for my dad. He loved it :). It might carry a rifle on his truck seat from time to time but it might just get hung on a wall. Hope you all have a great Friday and weekend! All the best, Josh -

Fancy Scabbard

Josh Ashman replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That's kind of you to say Dikman! Thanks! -

Fancy Scabbard

Josh Ashman replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Jeff! The "finish" for this was a few coats of NF oil with several hours of sun tanning in between, then a liberal rub down with Aussie wax and back under the sun for several hours. The color variations might be played up by the lighting but most of it is in how the hide soaked in the oil & wax and how much the sun darkened some areas vs others. This time of year I often put my "sun tan" finished leather on the dash of my pickup and little things like a shadow from the rear view or the inspection sticker will impact the amount of sun and therefore darkening an area gets. As for work habits, our opinions aren't much different. I've got little use for people who goof off when they're on the clock. I'm not on the clock and nobody is paying for doing something I'm not doing. Although If I don't get back at it soon I'll also be feeding in the rain. Take care Jeff! Josh -

Hey Bransen, Seems like the "waxiness" of the leather has been well covered, I have nothing much to add to the conversation there. I don't know that anyone has mentioned thickness yet. Even if the W&C traditional is dry enough to take water in order to be able to mold it, I wonder if it wouldn't be so thick as to be an issue with holster work. Of course it all depends on what you're making, but FWIW all the harness I've seen comes in 12 oz or thicker which is a bit thick for most holster work in my opinion. I've heard that W&C will split hides, so maybe you're thinking of doing that? Or maybe you have a good splitter and the weight the leather is sold in isn't an issue to you? And maybe again, you're wanting to make some thick holsters for your own reasons. I'm not trying to say "right or wrong" just that if you hadn't already considered thickness it might be something to think about before buying a whole side. If you end up getting a side I'm curious to hear how it works out for you. All the best, Josh

-

I thought I might share some pics of a scabbard I finished up recently. I thought it turned out nice, but then again I only play at leather part time so I'm not really sure. I'm hoping that somebody who actually works with leather will let me know if it's OK. I'd stick around and wait for a response but I have to get back to my day job that pays me for doing something else. hahahaha! Couldn't stop myself Jeff. As for the scabbard, it's 10/11 HO Craftsman and the hardware is JWP (aka Horse Shoe) from Weaver. Have a great day folks! Josh

-

IWB Holster

Josh Ashman replied to Hildebrand's topic in Gun Holsters, Rifle Slings and Knife Sheathes

This thread makes me laugh . I think Jeff came closest to guessing Todd's intent with Jason in a close 2nd. I'm not sure I have it quite figured out myself. I have seen "flat front" holsters with the molding on the back. The guy making them claimed they were quite comfortable and that the flat front concealed better. I don't buy that for a minute, but everybody has their opinions. My opinion Todd, worth exactly what it cost you, is that for me purpose built works best. Any time I've tried to make something that did several things well it didn't really do any one thing great. Good luck figuring out your design! All the best guys, Josh -

Thanks Bobby! Semper Fi!

-

Thanks Chuck! Have a great day everybody!

-

Thanks folks!

-

"Fancy" saddle scabbard I finished up the other day. Pretty happy with how it turned out. Built out of lightweight Chahin skirting that I've had sitting around for years. Seemed like a fine use for it! Have a great folks!

-

Looks great Ryan! Very nice job!! All the best, Josh

-

Holster Finishes Test

Josh Ashman replied to wizard of tragacanth's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I found this to be pretty interesting, thanks for sharing Nick! I was a little surprised by what you found and had some time this morning so I tested the finish on a few items I had handy. My test was done on my very well worn OWB 5" 1911 holster that is in semi retirement, a "worn once" OWB I made for a GP100 that I just never really use, should be the equivalent of a new holster and my phone case. Both holsters have my standard carry holster finish of Fiebings pro-oil dye cut with alcohol a wipe down of NF oil and then a top coat of 50/50 Mop & Glo/water. My phone case has my standard tack finish of several coats of NF oil and a coat of Fiebings Aussie Wax left to soak in the sun until it's absorbed. I used items I had on hand as I didn't want to take the time to properly finish samples. Test samples; I placed a drop of water on the back of all three; 5 minutes later this is what they looked like; I "flipped" the holster/case to shake the water off and this is what they looked like; Then I wiped off any remaining water with a cloth and had this; They sat for another 10 minutes and looked like this; It seems the pictures tell it all but just in case What I saw was that the "new" holster finish shed the water and didn't really allow it to soak in at all. The worn holster finish did allow some penetration, but not much and after 10 minutes of drying time it wasn't visible. The tack finish allowed some water to soak in and left a very visible water spot, although there is more to that story. I expect items treated with the tack finish to move and be flexible. It's a different finish than a carry holster and I give my tack items occasional maintenance. Here's the tack finish after a quick wipe down with NF oil; And after a quick wipe down with a scrap of sheepskin that had some saddle soap on it; Still visible if you know where to look, but basically good as new. And just for fun, what happens when you get caught by more than just a drop of water. Left to dry out then wiped down with a little NF oil followed by glycerin saddle soap. No damage at all, just gives a person a reason to clean things up. Anyway, not totally different than Nick's test and hopefully some additional interesting info. Have a great day folks! Josh -

Latest Holster

Josh Ashman replied to Hildebrand's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Good looking holster Todd! Sorry to hear the snaps are being a problem, I'd have thought 3 line 24's would have worked fine. I wonder if you can make it OK by casing the fold and hammering it down a little then letting it dry. Doing so would remove the constant pressure the fold is placing on the snaps and may be enough to make it work. Drilling out the female part of the snap and replacing with PTD's may also help. Another option would be to punch 2 - 1/4" holes clear through the holster (use a wood block and scrap piece of leather to punch into) about 5/8" apart then run a piece of lace through them and put half a bleed knot in it. The lace would back up the snaps but could still be undone if wanted. Anyway, we all run into unintended problems. I'm sure you'll find a fix. Again, it's a great looking holster! Nice job. All the best, Josh -

I've heard of people using kydex stiffeners sandwiched between 2 layers of leather. However, as Lobo noted I don't personally see any reason for it. I build my gun belts out of 2 layers of 7/8 HO cemented and stitched no additional stiffener is needed. If a person were to use inferior leather or cut their belt blanks from too low on the hide down near the belly maybe they would be helpful. But, if using good leather cut along the back I just don't' see a reason for them. My $0.02 for what it's worth. All the best, Josh

-

Sorry to hear about your busted up leg! Great looking bags though! All the best, Josh

- 11 replies

-

- saddle bags

- crutches

-

(and 1 more)

Tagged with:

-

S&W Bodyguard .380 AIWB

Josh Ashman replied to chiefjason's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice! -

Rough out IWB step by step

Josh Ashman replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Small world Doug! We're 7 miles north of Stockton Lake! I'm a transplant from west central Utah, met a Missouri girl, you know the rest ! After growing up in the great basin area I sure do love the big MO woods too! Hope TX is treating you well sir! All the best, Josh -

Rough out IWB step by step

Josh Ashman replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You're certainly welcome sir! Thank you, and good luck on your Commander holster! All the best, Josh -

Flat versus Curved for Pancake holster

Josh Ashman replied to bcraig's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Cheers Jeff! Hopefully it's cooled off enough a guy can get out and go fishing up north. Still too hot down here! -

Rough out IWB step by step

Josh Ashman replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks BHP! It is always nice to see how others do it! I have to wrestle with it a little the way I do it too, maybe I'll have to give you way a try as well! Just FYI, I guess I'm up to about 5 weeks of daily wear with this guy and it's one of my favorite holsters! No desire to switch it out of daily wear. All the best, Josh -

Flat versus Curved for Pancake holster

Josh Ashman replied to bcraig's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Sticking to the discussion on holster styles and skipping the rest, I completely agree with Jeff's comments above. Clearly the OP has carried for some time and is familiar with what he wants. Build both and see which you like best. I took a few pictures of some of my older pancake style holsters that have been used a bunch. All for 1911 type pistols in Officers Model, Commander Model and Government Model lengths. You can see in the pics they are all used. The OM is about 80/20 flat, the CM probably about 60/40 flat and the GM is 50/50. I can't tell the difference in comfort or retention, but clearly other people can. It's not much more difficult to build one style over the other, mostly some modest adjustments in process and you can build either. Just for grins I included pics of the OM and GM with a belt through them wrapped around an empty bucket. The flatter one does sit closer to the bucket, which in turn would mean it sits closer to your body while wearing it. But to me it's such a minute amount that it simply doesn't matter. Again, everybody is different and something that doesn't make a difference to me might make a huge difference to somebody else. FYI, I wear at 3:00 maybe if I wore a holster further back it'd make more difference? Thank goodness we're not discussing politics or religion, huh? Have a great day folks, Josh -

Flat versus Curved for Pancake holster

Josh Ashman replied to bcraig's topic in Gun Holsters, Rifle Slings and Knife Sheathes

It'd be quite a trick to form wet leather and not stretch it. Cut you a 8" square of leather then form it over a holster front. Now lay it flat again and it's no longer a 8" square. You stretched it boss, even if you didn't mean to.