-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Depends a bit on the belt diameter a bit 8mm / 5/16" belts works best for patcher machines I´d say and maybe you can shorten it a bit if it appears to be to loose. I tried no slip spray and it became messy over the time but maybe no slip spray is different over here or depends on the brand. Be careful with oil on leather drive belts. If you take too much oil... well - it´s oil, what else can I say. Colophony is a good thing and I heard bee wax works well too but have not tried it by my self.

-

How To find a Canary in a 206RB-3

Constabulary replied to banjo48's topic in Leather Sewing Machines

is it probably coming from the motor? I´d take of the V-belt and hand crank the machine.... -

2 ways - either disassemble everything and send the bits in several packages (I did that once - lots of packing and wrapping) - or - ship it assembled tied onto a palett. Maybe you can take off the head and pack it separately in a sturdy cardboard box padded with 1.5" styrofoam plates on all sides top and bottom and tie it onto the palett too. Then you probably can put the table flat onto the palette. That will safe you some hight - maybe hight matters in terms of shipping costs. I´m on the other side oft he pond so I cannot tell you how much shipping would be - maybe check with U-ship.

-

Then you have to buy a sole stitcher - modifying an (probably) undersized machine does not make sense.

-

The last picture shows a post bed machine with an oscillating shuttle hook if I´m right? F.i. like the old Singer 34K or Adler Class 7. So if I get you right you want to modify a machine like the one in the last picture with a rotating / movable horn from from sole stitcher in the 1st picture? I don´t understand the purpose and I don´t think it is possible.

-

What is this old German cyclinder machine a clone of?

Constabulary replied to alexitbe's topic in Leather Sewing Machines

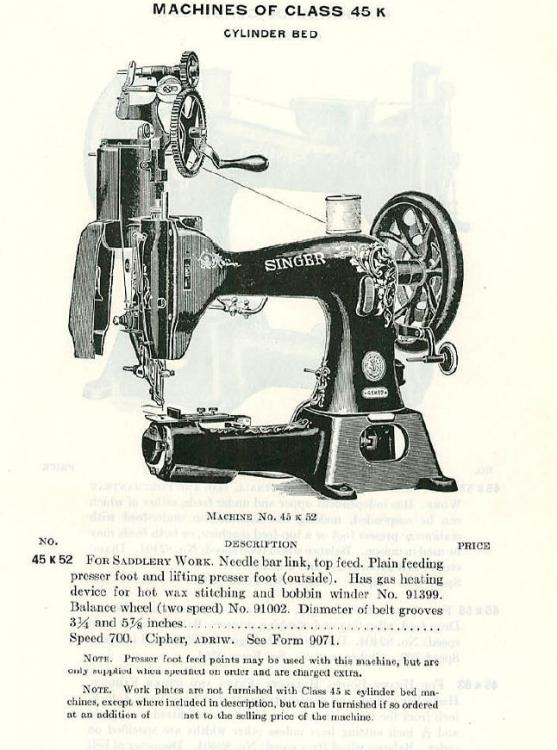

It´s the class of an Singer 17, Pfaff 25 / 28, Adler 48 and the like but with additional top feed and a slightly larger feed dog. It will not sew 1/2 leather. it is by far not the Class of an 45K, Adler 5 / 105 or the like. I have an old sales leaflet form Adler - the Adler 48-3 seems to be more or less "the father" (or grandfather when you consider Singer 17 as the original machine) of the Koehler machine and that was used f.i. as a binding machine. See pictures + text. -

Anyone heard of this brand of sewing machines?

Constabulary replied to kubacik's topic in Leather Sewing Machines

TEXI is sold by some dealers in Germany - another Chinese clone but what I have heard quality is very good approx like GLOBAL sewing machines or the like.... But I never have touched one. -

How To find a Canary in a 206RB-3

Constabulary replied to banjo48's topic in Leather Sewing Machines

I there a binding when the machine chirps? Maybe a slightly bent slide bar on the thread take up lever? Try some oil on that spot. if there is a binding you have to replace it. May sound stupid but try a shorter stitch length and adjust the foot lift hight. I once had something similar at a friends Duerkopp 239 - just an idea nothing proven. -

I also have removed the NPS from my servo - useless at slow speed (for me). Safe the money and buy a flip down edge guide instead - or thread or needles

-

Nice to see all the details on theses machines - was about time for some documentation pictures. Lots of knowledge (and manuals?) got lost over the time. AWESOME !!!

- 21 replies

-

- singer 45k52

- singer

-

(and 2 more)

Tagged with:

-

Darren - you should probably link your Ebay shop in your signature here: http://leatherworker.net/forum/settings/?area=signature

- 21 replies

-

- singer 45k52

- singer

-

(and 2 more)

Tagged with:

-

Singer 29K58 - Bobbin winder arm

Constabulary replied to ThomasMD72's topic in Leatherwork Conversation

I think the 29K bobbin winder College Sewing in the UK is selling will work for your 29K58 https://www.college-sewing.co.uk/store/82087-BOBBIN-WINDER-COMPLETE-SINGER-29K -

pfaff 545 hinge Will Pfaff 1245 hinge blocks fit a 545

Constabulary replied to clintooo's topic in Leather Sewing Machines

I have an english manual for the 545 - send me your email address by PM as the file it too big to attach here. -

Vintage Singers are work horses. I have a 133K3 from 1932 - and it still works very well! Here are pictures of the main tension unit but w/o the two felt / leather washers. The washers go between the disc and pulley, they are approx 1mm thick. Jimi is "Mr. 45K" so your are in good hands with your machine

- 21 replies

-

- singer 45k52

- singer

-

(and 2 more)

Tagged with:

-

This 45K model originally had a wax heating unit but I guess you don´t have it, right? You will not find other parts than needles, shuttle, and maybe some smaller standard parts for this machine. You will have a hard time finding presser feet at all. This is not the "standard" 45 this one is quite special so parts are no longer available as the machines is tooooo old. To nowadays standards I´d say the machine is outdated but that means nothing as long as it serves you for the purpose you need it for. May I ask how much have you paid for this machine? Don´t know if you made the right choice. As long as the machine works for your purpose then why not. Seems to be a "top feed only" machine. It has no feed dog and needle feed would not work with this needle plate. I guess you can adjust the stitch length somewhere on the feeding mechanism, but I´m not sure. Otherwise it looks like a fixed stitch length machine as I don´t see a stitch length adjuster. Machine was made in 1916 but that means nothing when properly refurbished. Most 45K do not have reverse just as yours. I have to admit that I have not worked with this particular 45K (52 subclass) but with some other 45K and similar machines. So this 45K may have some "specialties". Machine looks correctly threaded. You can adjust the tension on the thumb screws of the pre tension unit (back of machine top of head) and on the main tension unit of the face place. Not sure if my eyes are cheating me but the tension spring on the main tension unit on the face plate looks a bit light and probably incomplete. Usually the 45K main tension unit has 2 discs, 2 felt washers, a pulley, a (quite) heavy tension spring and the nut on the stud. Are all these parts present on your tension unit? I can post a picture of the tension unit later. You also have to adjust the tension on the shuttle hook but that's mentioned in the manual Thread breaking can be caused by too much tension, wrong needle / thread combination, poor / too old thread, burr in the needle eye or on other parts the thread runs over. Here is a pictures how the original 45K52 setup looks like Sorry - I have to run....

- 21 replies

-

- singer 45k52

- singer

-

(and 2 more)

Tagged with:

-

Singer 31K18 & 31K48 - help!!!

Constabulary replied to Trevor Baret's topic in Leather Sewing Machines

you can also carefully tap the wheel on different spots with a hammer and a piece of wood while turning the wheel. But a gear puller is for sure the better idea. When the wheel is off check the shaft for rust and burrs where the shaft has the notch and grind down them with some sand paper or a file. -

Adler 67-63l. How big a needle can I get away with?

Constabulary replied to Matt S's topic in Leather Sewing Machines

Usually up to 138 thread (20 ticket) max with 140 needle. 180 and 200 needles will not work not only because of the too thick thread but the 180 / 200 needles will most likely not fit through the hole of the feed dog. The whole machine is not designed for it. -

Outside Presser Foot Bar broken, Pfaff 335

Constabulary replied to Stuggi's topic in Leather Sewing Machines

Ha - that's even better - never thought Pfaff parts could be "cheap" -

Looks pretty much as the guide I´m using on my 111G156. Where is the development in this guide? Maybe I´m missing something but this is the same as the Kwokhing with just another mounting bracket. Could not be too difficult to make a proper mounting bracket for the "standard" Kwokhing guide.

-

Outside Presser Foot Bar broken, Pfaff 335

Constabulary replied to Stuggi's topic in Leather Sewing Machines

I measured 8.75mm on both the Pfaff 345 and Singer 111 presser foot bar so I´m pretty sure you can use a Singer 111 presser foot bar on you Pfaff 335. However - I cannot make promises but this would be the least expensive solution. I'd say check with this seller regarding the length of the bars. Diameter wise it should work, I think. http://www.ebay.com/itm/SINGER-111W-FOOT-BAR-PART-208566-/301985798960?hash=item464fc19b30:m:m4-bjys6Vfts06MAhMqimsg -

I don´t know if you have many options when you need a roller foot for this machine. I don´t know the 51w51 in particular and if there is just one special roller foots for this machine. If you are unsure what to do you have to contact your local dealer or one of the well known dealer who have banners on top of this page and ask if they have a proper roller foot for your machine. Usually changing a presser foot bar is rather easy compared with needle hook timing or other adjustments. But if you don´t know how ask your dealer of post some pictures of your machine with removed faceplate so maybe some members here can help you. But first look for a roller foot - I have no suggestions for you - I'm sorry!

-

Outside Presser Foot Bar broken, Pfaff 335

Constabulary replied to Stuggi's topic in Leather Sewing Machines

I also have a parts list of the old version - send me a PM with your email and I´ll send you the two files by email -

I don´t think constant pressure will help you with the pin. I rave restored a few patchers already and never had bigger issued with this pin. Usually 3-4 hammer strikes will loosen it. The pin clamps in the driving rack arm and not in the casting and the pin is tapered so when you give it some hearty hammer strikes and I´m sure this will work. Have you tried a heat gun or blow torch for either problem? When you drill it out the roller pin and damage the driving rack you will most likely have problems installing a new roller properly.

-

Outside Presser Foot Bar broken, Pfaff 335

Constabulary replied to Stuggi's topic in Leather Sewing Machines

Original Pfaff parts are quite expensive most of the time. But sometimes you can interchange parts from different brand machines. F.I. - Duerkopp machines are using a lot of Singer parts (or the other way around). So what I would suggest it a Singer 111 presser foot bar. I can give you some measures later because I can compare a Pfaff 345 and Singer 111. It´s just a guess - I have to pull out my digital caliper and will post the measures later today You can replace it. In best case you can pull it out to the top when you have removed the thumb nut and parts below and loosen the set screws the presser foot is clamped with. Since you have a parts diagram it should not bee too difficult. I have an instruction book (User manual) for the old Pfaff 335 I can send it you by Email if you are interested send me a PM. -

Machine beginner Renaissance Faire

Constabulary replied to Goblinworx's topic in Leather Sewing Machines

I NEVER EVER would buy one of these sailrite LSZ thingies for heavy leather work. You probably have to climb over different thickness materials and the sailrite is a top and bottom feed not really a compound foot machine and it has no needle feed. Look at this BULLSHIT - I hope this will cure you from the idea of using this LSZ thingie for heavy leather work. Oh - and don´t forget to watch the 2nd Video - it show "how well" this thingie works for heavy leather