-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

There seems to be a roller foot for this machine but it seems to be a special roller foot or you have to replace the presser foot bar. Look at these pictures: http://www.usedvictoria.com/classified-ad/Singer-Post-Sewing-Machine_23628221

-

Click the F5 button and refresh the page and then try again uploading the resized images

-

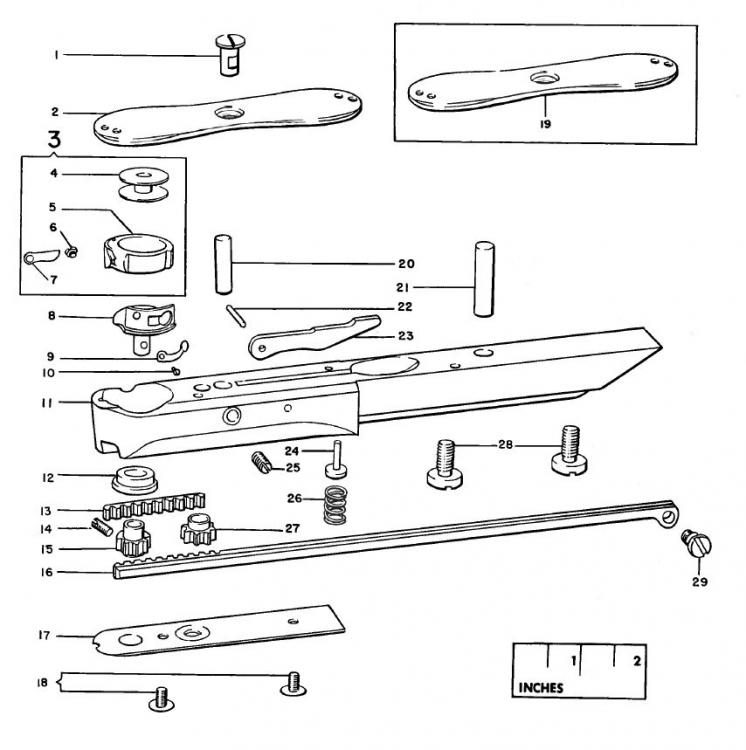

I think you will have a hard time drilling a hole through the center of the small shaft of the shuttle carrier. And BTW there is a small screw going through the shaft of the shuttle carrier which attaches the driving gear to it. Check out a 29K parts list with exploded drawing (this is from a later model 29K but basically the same around the shuttle). #14 is the one of the tiniest parts in this machine but it kills your idea.

-

Not exactly for the 29K15 but this manual should give you the basic instructions. 29-4.pdf

-

College Sewing ships worldwide AFAIK. Not sure how much they charge for shipping to the US but shipping for small orders is around 8 GBP to Europe. But most parts you need are available on Ebay.com too. Or check with dealers who have add banners on top of this site. I grind down the rounded sides the way that the BCL moves freely up and down just like the old part when mounted to the revolving handle. Maybe you have to grind down some spots on the revolving handle too. This is a bit of trial an error. I think I have mounted it 5 or 6 time until it worked. A Dremel tool is very helpful for this.

-

I´d buy the parts new and modify them, thats for sure the better deal on the long view. I once restored a 29K1 maybe the thread is helpful for you:

-

Seems to depend on the machine and hook a little bit. On my 133K3 the best needle position for a turn seems to be when the needle is on the way up and almost leaving the material / the tip is still inside the material. My 111G156 and 307G2 do not have these problems at all. Basically I think the best needle position is all the way down (BDC) before the loop has been formed or when the stitch has been almost completed and the needle tip is still inside the material. But thats just a rough guess. But my 133K indeed acts a bit different...

-

The Singer in your picture is at least from the late 1950´s but most likely newer. You can tell that for the attached plaques. If the blurry picture is not cheating my eyes its still in the original condition. You for sure will find most of the wear parts for this machine w/o problems f.i. at College Sewing in the UK. The other one is probably 1 century old and as Shoepatcher said there are no longer parts available. The availability of parts is priceless if you want to use the machine for a longer period of time. How much is the Singer machine?

-

I have an Adler 48-7 which actually is the ADLER version (or call it a clone ) of the Class 17-30 Singer as far as I can see. Its a nice machines for light to medium work f.i. for the shoe industries or sewing finer leather goods. Personally I´d consider it more as a light duty machine as it has a quite tiny feed dog and also a quite small bobbin. But depends on from which end you are looking. If you did fabric work with f.i. a size 90 needle and 40 thread most of the time its more a heavy duty machine but when you have sewn saddles and holsters with a 200 needle and 11 thread it is a light duty machine. A size 120 needle and 30 thread is what it works well with. BTW - all metric sizes since you are from Sweden.

-

I have not worked on a 29-4 but a 29K-3 (the K probably makes a difference). I have installed new bell crank levers to older 29K´s and I´m sure the the feed motion ring slide works too but both may need some smaller modifications. You at least have to grind down the ring on the outside of the BCL a little bit. But as I said I´m not 100% positive the the 29K is using the exact same parts as the 29 (w/o K). You probably have to compare parts lists. But I would guess the parts are the same. I actually have a 29K3 parts machine because I had two 29K3 with broken parts (same as yours) so I made one machine out of them - let me know what you need and I will check if I have the parts. Where are you located?

-

Hand Wheel Desperately Needed adler 467

Constabulary replied to venator's topic in Leather Sewing Machines

Haven´t noticed Erics post - I´m sure he is the man for that! -

Hand Wheel Desperately Needed adler 467

Constabulary replied to venator's topic in Leather Sewing Machines

or Juki: http://www.ebay.com/itm/Hand-Wheel-Flywheel-110-71362-For-Juki-DDL-8300-DDL-8500-DDL-8700-Machine-/162018745696?hash=item25b911dd60:g:JpQAAOSw~bFWLqwu or Mitsubishi http://www.ebay.co.uk/itm/MITSUBISHI-DB-120-S-N-HANDWHEEL-MF10A0682-/290723355341 -

Hand Wheel Desperately Needed adler 467

Constabulary replied to venator's topic in Leather Sewing Machines

Don´t know how it looks and what the shaft diameter is but maybe you can try a different brand hand wheel with either similar shaft bore diameter of if the bore is smaller you probably know someone with a lathe. Maybe a SEIKO hand wheel. http://www.aliexpress.com/store/product/Industrial-sewing-machine-handwheel-synchronous-DY-car-car-initiative-turbine-head-pulley-hand-wheel-turbine-head/1901342_32459554146.html -

Singer Class 31 I guess

-

Check with College Sewing: https://www.college-sewing.co.uk/?s=135x16 Sometimes its worth checking their needle offerers

-

Thread gets caught under hook occasionally

Constabulary replied to Uwe's topic in Leather Sewing Machines

Drop in replacement more or less. The 111G156 came with an OEM Made in Germany Singer hook with fixed shaft (the one in the picture) but I once restored a Duerk. 239 a while ago and that machine came with a bunch of extra parts incl. some hooks. The mechanic of the two machines looked very similar and my Singer hook seemed to be a bit worn though it still worked fine. I just gave it a try and it worked well. Only technical difference beside the replaceable shaft is that the Singer hook has a slit in the shaft for the set screw whereas the Duerkopp hook hasn´t (hook saddle and gears are the same with the same set screws). Recently I have replaced a needle bar on a Durkopp machine with a 111 needle bar from College Sewing - worked well. So I know for sure that many Singer 111 and Duerkopp 239 / 241 / 245 (245 is needle feed) parts are interchangeable. They are also using the same feet. -

Thread gets caught under hook occasionally

Constabulary replied to Uwe's topic in Leather Sewing Machines

This seems to be the one but no shaft http://www.miketony.com.tw/en/2-1958-34698/product/HOOK-130-13-115-id182703.html however - the HDU249 is cheap on Ebay: http://www.ebay.de/itm/HDU-249-249-592-Hirose-Sewing-Machine-Hook-For-Durkopp-249-541-Machine-NEW-/371441580712 -

Thread gets caught under hook occasionally

Constabulary replied to Uwe's topic in Leather Sewing Machines

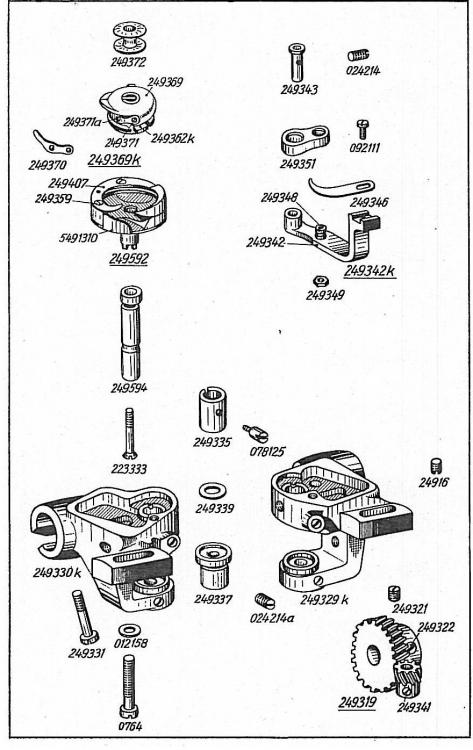

I know there are alt least 3 different hooks for the 239. One is for small bobbins and has a bar across the bobbin case like the 111w hooks have, one has a bobbin case cap like Pfaff or Adler and the 3rd is a large size hook with cap. I think the one you linked is the cap type hook but w/o the deflector tin and shaft. But I think it needs a different hook saddle. Here is a picture from an older 239 parts list. Maybe this one could be an option but it´s just a guess (because of the extra deflector) https://www.college-sewing.co.uk/store/HSH1215MM5-HOOK-and-BASE-HIROSE -

Thread gets caught under hook occasionally

Constabulary replied to Uwe's topic in Leather Sewing Machines

Now that I see the pictures... I´m using an original OEM DUERKOPP hook with replaceable shaft in my 111G156 which also has a "deflector tin" under the hook. Maybe some Companies have discovered this problem earlier. Thats probably why I never ran into this problem. The DUERKOPP 239 and 241 and the like are using a lot of Singer 111 compatible parts. Pic 1 Singer hook on the right in Pic 2 on the left. All other parts are DUERKOPP -

Thread gets caught under hook occasionally

Constabulary replied to Uwe's topic in Leather Sewing Machines

My 2 cents from just watching the Video: I think you cannot fix this even with more travel on the regulator spring. You just have to make the turn when the needle is in deeper position. The thread is "caught" in the needle hole (in the material) so I don`t think there is much you can do. -

Yes, remove the pin on the needle bar and the larger one in the middle of the arm (both from back to front) turn around the arm and you will notice the hole from where you can hammer out the roller in.

-

usually the arm has a hole on the bottom from where you can hammer out the roller with a pin punch or the like. Because of the shaft - if you dare hammer it back as good as you can I did that with my Singer 34KSV5 and the wobble is almost gone. I have used a dial gauge to find where the wobble is and hammered from the other side - it just took 2 or 3 hearty hammer strokes.

-

Advice for a nooby please guys

Constabulary replied to sparky20006's topic in Leather Sewing Machines

So what is your budget? My 2 cents: If I had to choose from then I´d take - non of them. But the closest I think could be the Singer 110K124 but I still would not buy it. All other are more ore less garment sewing machines. Before I start telling you why better read this thread: And / or watch Arthur Porters Video: -

Check this thread - seem LW member TREVOR has what you need