-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Cobra 26 presser/walking foot marking up leather

Constabulary replied to AtomicLeathers's topic in Leather Sewing Machines

have you tried to reduced the foot pressure? -

Help - Need a part # for my Pfaff 545-H4

Constabulary replied to suzelle's topic in Leather Sewing Machines

18344 appears to be the hook needle guard for the 145 This is the needle guard for the 545 / large hook machine series: old # 18481 or new # 91-018-481-05 (large hook machines) https://armastore.eu/91-018-481-05-pfaff-1290-needle-guard-b Pretty sure you can get the part (at least) from authorized Pfaff dealers. -

Pfaff 335 H2 complete rebuild thread

Constabulary replied to Woehlk's topic in Leather Sewing Machines

How about British Racing Green? It´s close to RAL 6005 afaik. Very classic color and never out of date Always wanted to paint a machine with 6005 but I always end up with silver or crackle coating (very predictable ) -

Help in identifying this skiver please

Constabulary replied to BrissyTrimmer's topic in Leather Machinery

could be an old German FORTUNA Model. I have one on a shelf which I have started to restore some years ago but never finished it. Let me check I think it looks similar. -

do you spin the hand wheel towards you or away from you?

-

Consew 206 RB-5 Oil Wick Placement

Constabulary replied to OneShort's topic in Leather Sewing Machines

usually the wick end is hanging into a small "pit" in the casting where access oil is collected which is behind the 3 bars. Not sure if it is the same on the 206 but maybe worth checking. -

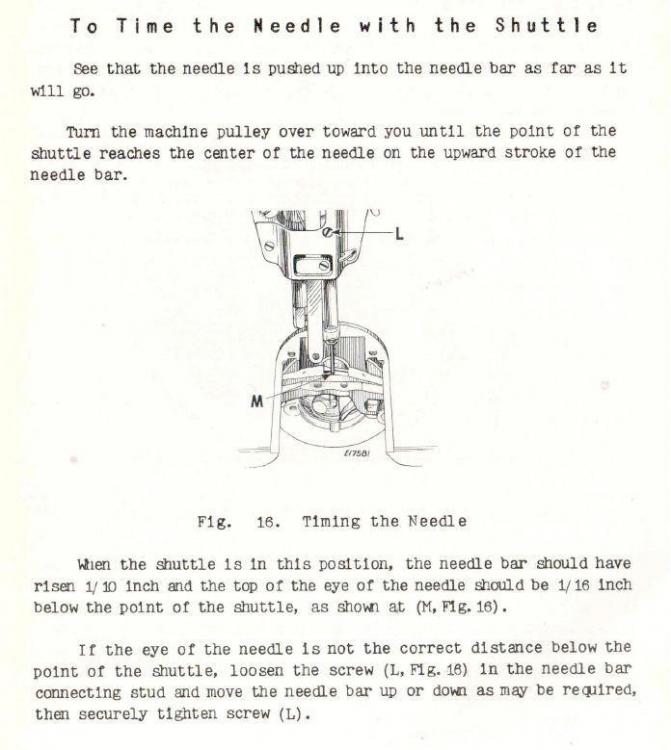

this is from a slightly different machine but the procedure and values are the same for most CB hook machines. Hope this helps.

-

Screws and Bolts for 111 Walking Foot / Feet

Constabulary replied to suzelle's topic in Leather Sewing Machines

well, you could switch the machines heads so no need for full set up tables - of course depends on the machines. In my 111G156 table I also use my 307G2 (same bed size) and also the 212G141 with an adapter "box" (cause of longer bed). I have to admit the 212 in this case it is not not very conformable to use but I don´t use it very often so it is kinda okay for what I do. In my Singer 51w table I can also use the 143w and 107w (also same bed size here). -

some folks here did upgrade the hook @DonInReno was one of them IIRC

-

Screws and Bolts for 111 Walking Foot / Feet

Constabulary replied to suzelle's topic in Leather Sewing Machines

there is no quick change device for 111 feet - not possible IMO cause they are clamped inside the presser foot bar. Option: Buy more machines - one for every step in the manufacturing process. -

Have not compared the ones you linked (Singer type) with Pfaff but as long as you can find check springs advertised for Pfaff I´d rather buy those: https://www.college-sewing.co.uk/9101093705-check-spring-pfaff-145-1245-genuine.html Foot is a left toe foot https://www.college-sewing.co.uk/91-040475-04x5mm-outside-foot-pfaff-generic.html You may find equivalents on Ebay as well.

-

Check this:

-

Modern. Computerized postbed machine trouble

Constabulary replied to Manakawari's topic in Leather Sewing Machines

Have you checked with JACK North America? If you check with them better do not tell you have imported it from China better say you bought it from a closed business and you need support. -

Have to admit - I did not expect this result!

-

Pfaff 145, 545, 335, 345, 245, 1245, 195, 595, 1295 and the like all share the same feet. AFAIK the Singer 111 type feet (they look similar sometimes) are not interchangeable with the Pfaff type feet. AFAIK no other brand (other than Pfaff) is using their type of feet. The Singer 111 type feet is the most common type and is used by most of the common sewing machine brands (including most modern clones) other than Pfaff and Adler and nowadays Dürkopp-Adler. If you have a "foot fetish" machines using the 111 Singer feet would be the best choice I´d say. This is a good read if you have a foot fetish https://www.college-sewing.co.uk/parts-by-type/single-needle-walking-foot-feet.html

-

should be mentioned in the manual - (see picture) loosen the thumb screw and repositioning. This will alter the foot lift - highest foot lift in upper position lowest foot lift in lower position. I don´t know how significant the difference in the stitch length is but to be honest I don´t think this is practical.

-

Don´t know but maybe your feet are not lifting high enough but that can be adjusted on the rear side on the curve / cam. If the major problem is the shorter stitch length when sewing over thicknesses (don´t know what sicknesses you sew over and how significant this is on your projects) I would say you will have that with any other triple feed / needle feed machine as well cause the needle bar rock frame has a high pivoting point and therefore you have a pendulum effect and the needle is entering an leaving the material always in a certain angle but never in 90°. The thicker the material the smaller the stitch length. The only needle feed machine with a constant stitch length in all material thicknesses that I know of is the BUSMC #6HM (and similar machines) cause the needle enters the material always in a 90° angle. But that machine is probably an overkill for you - for me it was so I (sadly) sold it. Another option may be older drop feed + jump foot machines like Adler 5 / Singer 45K / 132K / 133K. But they have aggressive feed dogs and may mark the leather and many do not have reverse. EDIT: BTW - the Singer 108w is a triple feed too but with a different rock frame (little bit like the BUSMC #6) and the needle is entering and leaving the material in a 90° angle but it cannot sew 1/2" and has no reverse. If I was a sewing machine engineer I would scale up this thingy and add reverse EDIT II: if you want to upgrade from a class 69 I´d say an "affordable" machine could be a 341 Juki clone. You may look for "341 cylinder arm" machines in the UK. But I´m not sure if it would solve the "sewing over thicknesses / stitch length issue" - most likely not. But they use the standard Singer 111 type feet. Interestingly I just figured they seem to sell (sold atm) for approx 1/2 price of the "known" clones on my side of the pond. https://www.sewtex.de/SIRUBA-Naehtechnik-243/FREIARM-STEPPSTICHMASCHINEN--CYLINDER-BED-LOCKSTITCH-MACHINES-246/Cowboy-CB341--Cylinder-Bed-341-Sewing-Machine-1853.html

-

good lord - to be honest - I´m not sure if it really is worth the time and money (in parts). Maybe leaving it as is is the better option for "just" an exhibition item.

-

Yes holes are too wide for the chosen thread, I would go at least 1 needle size down - maybe even 2 but depends on the thread and if you use bottom thread 1 size smaller or not. The thread charts you find are rather a rule of thumb, they work under certain conditions but since mentioned thread size is calculated by weight per 1000 meters and not by its actual thickness so you have some variables. So use these charts as hint but not as a fix rule. Cotton thread, Polyester thread and Nylon thread may have a different actual thickness at the same thread size. Regarding needle - believe it or not some years ago I ordered 3 or4 different size of System 328 needle from a brand I do not remember but it was not Schmetz or Groz Beckert. Two where the exact same size but with different needle size stamped on the needle. Not kidding! Maybe it was a production error - maybe not. You know what I mean? That said - you always have certain variables when you choose the right thread and the right needle for a certain project. And of course the type of leather you want to sew matters too. This may be useful for choosing the right needle tip. https://www.schmetz.com/en/industrial-needles/needle-compass/cutting-points/ My favorite leather tip is S-point cause I like straight seem stitches better than slanted. My 2 cents

-

How to change the belt on Singer 153W 104

Constabulary replied to youdesiremenow's topic in Leather Sewing Machines

-

Pfaff 335 H2 complete rebuild thread

Constabulary replied to Woehlk's topic in Leather Sewing Machines

when you are bitten by the bug there is no cure - cast iron sewing thingies can become addictive. Guess how I know. But meanwhile I found a way to let some of them go again (but only when other cast iron is knocking on the door) The color reminds me of some "Pink Panther" British SAS desert Landrovers. https://www.pinterest.de/pin/759419555889957308/ -

Ouuuh - thats an ambitioned project ! Keysew in PA it out of business as I have learned recently. Maybe worth checking with Toledo Sewing Machines in Ohio.

-

FWIW - when you have skipped stitches it most of the time is the needle bar set too high / needle bar has risen by the time.

-

singer 29 sewing foot part #8666

Constabulary replied to shoepatcher's topic in Leather Sewing Machines

He wouldn´t cause he only has one of them ====== Have you checked the foot lift adjuster on your machine and have set the stitch length adjuster to a longer stitch length? Have you read the manual? To start with something - please post some good clear pictures of your machine from front and back.