-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

$100 for both? So $50 each? Go back and buy the 2nd one too - asap!

-

The Adler 220 and SEIKO JW8BL are similar machines and they share parts with the Singer 144 / 145 - you can check for parts f.i. on the College Sewing website. https://www.college-sewing.co.uk But I´m sure you will find dealers for these parts in the US as well but the CS website gives you a good idea how much conversion parts would cost.

- 11 replies

-

- 145 w 204

- adler 220-50-273

-

(and 1 more)

Tagged with:

-

check this thread - only difference is that the K10 has a roller foot (if in original setup) so the manual should work for you.

-

What is the right bobbin thread tension?

Constabulary replied to Gymnast's topic in Leather Sewing Machines

Ha - way cool! So having too much top tension now is a kind of art work. Very impressive - things like that would never come to my mind. THAT GUY IS A GENIUS!- 28 replies

-

- thread tension

- lower thread tension

-

(and 1 more)

Tagged with:

-

looks good

-

I don´t think new motor replacements are available anymore. Maybe check with some old school sewing machine dealers they may have some 236´s on their shelves for parts.

-

Chinese Imported Sewing Machines

Constabulary replied to willford's topic in Leather Sewing Machines

I don´t think you can when your knot is properly balanced in the material and you are using the same thread and needle in either machine. A 301 stitch is a 301 stitch. A singer 111 stitch line will look the same as a Pfaff 145 or Adler 67 stitch line for the same reasons. So when someone says this or that machine makes a beautiful stitch... - hell yeah - why should it make an ugly stitch? Proper machine adjustment and the choice of thread and needle and the material you are sewing are the key factors for a good looking stitch line. Machine poorly adjusted or the wrong needle or thread combination for the chosen material can make a stitch look ugly but not the machine you are using - as long as it is properly adjusted / set up for what you want to sew. -

What is too low? Regarding markings on leather - since the 239 has 2 foot pressure springs I´t try to remove either the long leaf spring on the rear or the one with the screw cap. Trial and error.

-

long arm machines had longer drawers than the short arm machines IIRC.

-

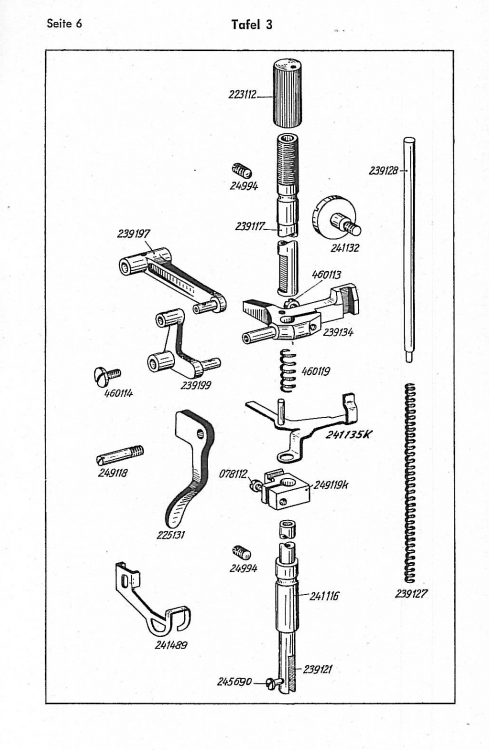

I have no idea what you did but just from the pictures, Id first remove the screw cap for foot pressure adjuster (# 223112) or the outer foot, then loosen the 2 clamps screw on the outer foot bar (#078112, #460113). Remove leaf spring on the rear if necessary. Then put back on the outer foot. Then tighten the 2 clamp screws and put back on the screw cap. That at least should bring your feet back in a "quite normal position" - I guess cause do not know what exactly you did (what screws you gave turned).

-

singer 45k clearence between 98607 and needle

Constabulary replied to Deeio's topic in Leather Sewing Machines

Huh - to be honest I haven´t seen this before - looks different to what I have seen so far. I do not think it is a 45K58. Maybe JIMI knows more - he is the 45k whisperer -

singer 45k clearence between 98607 and needle

Constabulary replied to Deeio's topic in Leather Sewing Machines

To be honest I do not think the shuttle is the problem. Your shuttle really looks good. The machine seems to be down graded for what ever reason. I think the machine is (or was) a 45K58. Please post a picture from the left side. I think parts are missing. -

singer 45k clearence between 98607 and needle

Constabulary replied to Deeio's topic in Leather Sewing Machines

Your shuttle is a NÄHMATAG shuttle made in Germany. NÄHMATAG made quality after market parts but to OEM Specs for all kind of sewing machines. And I believe they back then made the OEM shuttles for the Singer factory in Wittenberge too. I have used a lot of different shuttles from various makers (but no Chinese) in my 45D and several different machines of the same class (CLAES, Adler....). To be honest I never had issues with any shuttle. ATM I run an Adler closed frame shuttle in my 45D. I´m not sure but is it possible that you insert the needle with the scarf to the left? The needle scarf has to face right / to the side where the hook catches the thread loop. Also check the needle hook timing / height of needle bar. You machine is missing the blade spring on the rear side and some other parts for controlling the jump foot as it seems. EDIT: just noticed the plain long shaft foot on the foot bar so seems the jump foot mechanism has been removed. EDIT II: Can you post a picture from the left side of your machine - I´m not sure but looks like the complete lower tension unit is missing. That could be part of your issues. -

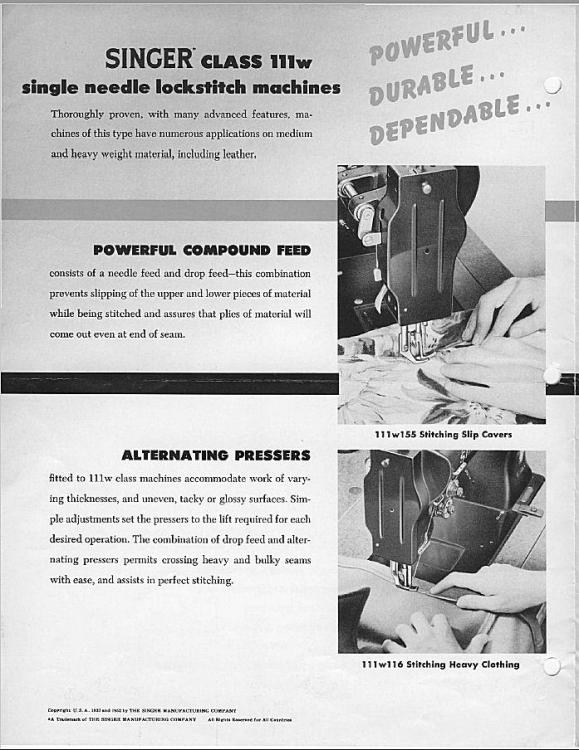

AFAIK "the original Singer" compound feed is drop feed + needle feed only (commonly called needle feed). And the addition of the alternating presser feet makes it the so called triple feed. But Singer had no term for this combination - in manuals and parts lists usually you read "compound feed with alternating presser" or similar. Let me check my files.... I think certain terms sometimes got mixed up. A walking foot can mean everything where a foot is feeding the material. Some say 29K are walking toot, some say a jump foot machine (like 132K6) is walking foot.... and so forth. I think triple feed is the more accurate term for top, bottom and needle feed machines. EDIT: This is what I meant Singer 111w Class Machine Brochure_compressed.pdf

-

Singer 17-23 hook to needle clearance

Constabulary replied to Wyowally's topic in Leather Sewing Machines

Well - a #24, #25 needle is IMO out of the comfort zone of a light duty leather machine like the class 17. IMO #22 is the max needle size for a machine of this type. Yes, I know the manual says up to #25 but still. The very small spools do not hold much of the thick thread anyway, not talking about higher foot pressure you may need for a #25 needle. my 2 cents EDIT: Seiko still makes clones of the Singer class 17 (their model is TE-6) and they recommend needles up to #19. Beside of that - IIRC the class 17 shuttle runs in a race like the CB kooks and I do not think you can move the race further the to the right to allow a larger needle. -

https://www.rickert-werkzeug.de/de/Allgemein/Ledermesser-Schneiden/Ziehmesser/Riemenschneider.html?gclid=EAIaIQobChMIobvE-_ue9AIVGNN3Ch03TQmYEAQYASABEgIYt_D_BwE https://schuhbedarf.de/werkzeug/scheren-und-messer/riemenschneider-eco-fuer-guertelriemen-bis-10cm-schnittbreite.html or ~ 1/2 the price on ebay (seller ships from Germany) https://www.ebay.de/itm/334167673969

-

-

I have a reworked manual in German language if that helps but I do not translate it and cannot attach it here because of the file size. Send me you email address my PM.

-

Help identifying this Pfaff 335

Constabulary replied to evilblackdog's topic in Leather Sewing Machines

Just from the two pictures... This is not a binder machine, it has fix position arm cover and no posts for the binder. It´s a plain sewer. Throat plate missing, inner foot missing, stitch length adjuster assy + scale plate missing (because of different adjuster "thingy"). Expect that you may need a different motor (probably). If you need a motor expect approx. $300 to invest. -

The 367 came in several different sub classes. Looks like this once was a binder machine. You probably have to replace some parts for doing plain sewing (sewing area is covered). Don´t know what subclass this machine is (or was) but seems it has some bells and whistles that plain sewing machines do not have. I never have seen the lever on the upper arm. Maybe it is for controlling the upper feed so it could also have been a ruffler machine too. Maybe this machine is an overkill but cannot tell from the pictures. Not sure is this machine really suits for needs - we just have too few information. Maybe you can post some picture front and back view w/o cloth covering things.

-

the 2 shown parts (the ones with arrow) do not belong to an Adler class 30 machine.

-

I don't know the difference either. Beside what dikman said the SV model sometimes is a standard model with just different accessories. The 110 is a machine with very short stitch length. Usually they have 3 preset stitch length that change by shifting gears on the left side of the machines. So a different (maybe longer than standard) stitch length could be but who knows. Keep us updated with your projects.

-

Looks like they are the same machines so question is how well is the machine setup with motor and how well it is adjusted by the dealer (sewn off and so forth) To be honest no matter what machine with what motor you buy I would always add a speed reducer. That is so much more comfortable. Some motor may start super slow but often do not have much low speed torque. The speed reducer compensates this and the advantage of a speed reducer should not be underestimate IMO (adding torque & reducing sewing speed). I have one on ALL my machine tables. ALL - no matter the motor and no matter the machine - it´s just a lot more comfortable. My 2 cents.

-

Some like it some don´t like it because it often looks just ugly (IMO) but thats a personal opinion. I would always go the speed redcuer way as long as I do not find a proper looking fly wheel with a grip on the rim (not just a pulley). It´s not the technical aspect, it´s the optical aspect. But thats just me. I built my cheap DIY speed reducers for less than 25€ I think.

.jpg.cb44915078e44301970ac8ab8bd61b45.jpg)

.jpg.1f4dfc9cc495ec2f2a70a0b4b0c740c5.jpg)