-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

The Consew 310 looks to be a bottom+needle feed design, based on the Consew 310 parts diagram. Not a bad starting point for leather work. Finding parts and service information for this oddball machine may be hard. The fact that the parts book doesn't even tell you what needle system to use is not encouraging. Hopefully the machine came with a pack of needles or a sticker that indicates the needle system. Since you already have the machine, the best way to find out if it will sew 8-10 oz leather is to just try it out. Get some leather point needles of whatever mystery needle system this machine uses and experiment.

-

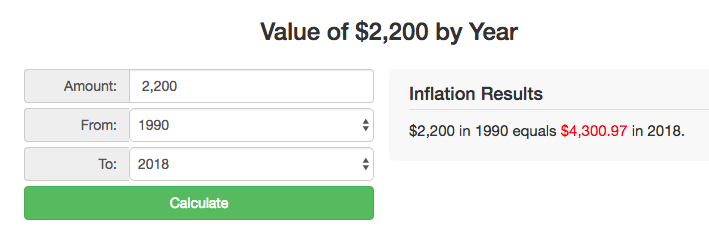

And taking inflation into account, that $2,200 in 1990 is roughly twice that today. So the USD $450-ish price for that LU-563 is roughly 10% of what it cost when new. Sounds like a bargain to me.

-

Here's a nice heavy-duty table-top sewing machine you can operate by hand - the Consew 733R. It even has reverse. It's also quite portable - if you're quite strong

- 5 replies

-

- budget

- lightweight

-

(and 2 more)

Tagged with:

-

A Juki LU-563 in good working condition is a steal at CAD $600 (USD $456). That machine may well be gone by the end of the weekend. If I were you, I'd go pick it up NOW.

-

That $6,700 price tag is likely referring to the new Juki LS-2342, but a typo crept into the model number. It happens . . . a lot.

-

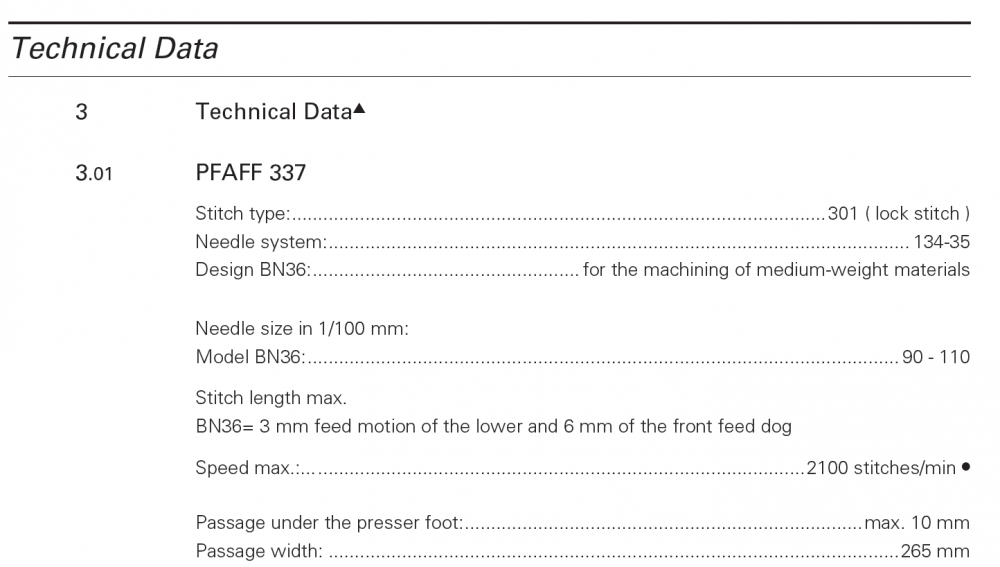

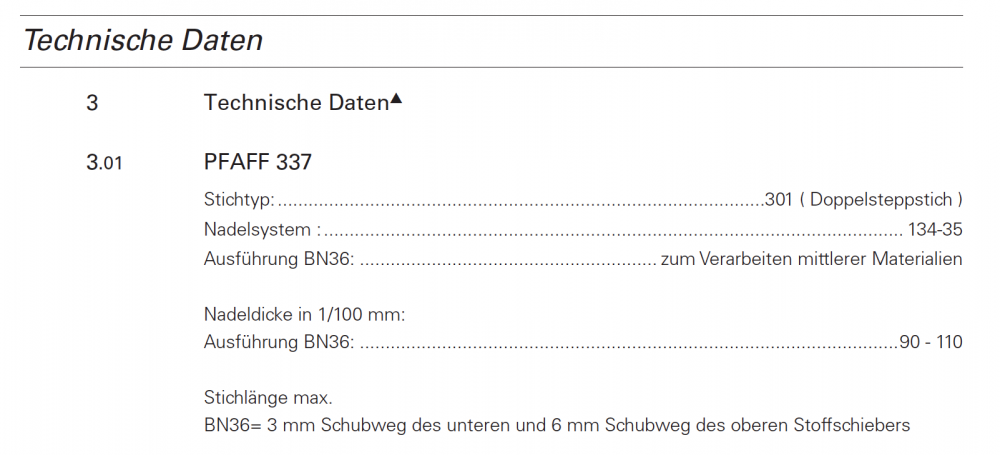

The modern version of the Pfaff 337 lists a max stitch length of 3mm of the lower feed dog and 6mm of the upper feeding foot. The english version of the manual is plain wrong - the German version talks about 3mm lower and 6mm upper fabric transport. There is only one feed dog. The upper feed can be adjusted smaller to match the feed dog at 3mm max., but you can't adjust the feed dog feed movement up to match the upper maximum feed of 6mm. You could, theoretically, remove the feed dog and only use upper feed, but that's unlike to give satisfactory results. Your type plate also shows "BS N 36". The "S" simply indicates fabric (Stoff). I doubt they ever made a leather version of this sleeve setter. Here's the english (wrong) spec page: Here's the original German spec page: Don't be afraid to start a new topic. This Pfaff 337 info doesn't really belong in a topic about the Pfaff 335.

-

Thanks for the tip @Pintodeluxe , I'll have to give it a try. There are several machines on my shelves that probably will benefit from this paint.

-

Timing got off with reducer pulley!

Uwe replied to rockthecasbah121's topic in Leather Sewing Machines

On some machines, if you change needle size drastically you may need to adjust hook-to-needle distance. I'm guessing that you put in a much thicker needle after your wife broke the thin one - although you haven't really told us yet what size needle you're using now. A thicker needle will simply come closer to the hook because it's ,well, thicker. Some machine designs are more sensitive to this than others. Many industrial machines are not the one-adjustment-fits-all needles kind of machines. It's often more of a one adjustment fits exactly one particular combination of needle/thread/material etc. Some needle manufacturers make specialty needles where the hook-to-needle-scarf distance does not change as you change needle size to avoid the need for hook distance adjustments. As for adjusting needle and take-up lever to reach the high point at the same time, I'm afraid you're out of luck. Both are driven by the main arm shaft and the relative movement/timing is fixed in the design on most machines - and for a good reason. I am curious as to why you'd want to change that. -

Timing got off with reducer pulley!

Uwe replied to rockthecasbah121's topic in Leather Sewing Machines

And you're sure that you have the correct needle in the machine, right? Maybe the needle is simply too short. Installing a needle from an unmarked container or a loose needle you found in the drawer is asking for trouble. -

Timing got off with reducer pulley!

Uwe replied to rockthecasbah121's topic in Leather Sewing Machines

It's possible that the needle bar is simply set too high. If the needle is too high the thick part of the needle just below the eye doesn't ride against the needle guard and this may allow the needle to come too close to the hook. Ideally, the needle guard prevents the hook from touching the needle even if you push the needle towards the hook. Check the safety clutch first, though (assuming the machine has one.) The increased torque from a speed reducer is indeed more likely to trip the safety clutch. Some safety clutches are so tight they keep spinning the hook even after they trip. You have to make sure the safety clutch is properly engaged before you evaluate or adjust hook timing. If there is no safety clutch the hook may have slipped on the hook driving shaft and now arrives at the needle too late. -

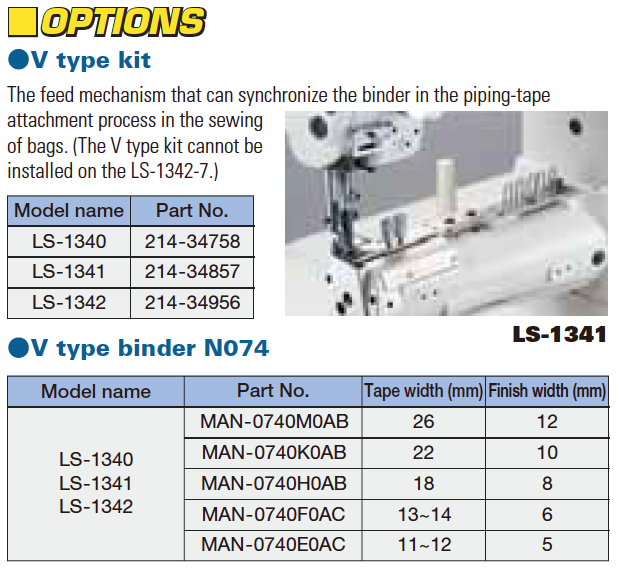

The Cobra Class 26 is really just a copy of the Juki LS-341, the predecessor of the Juki LS-1341. There's probably nothing wrong with the Cobra Class 26, but there's also no point in pretending it's anything other than a brown copy of the Juki original. Since the Juki LS-1341 is a current production machine, parts and accessories should be plentiful and readily available from any Juki dealer. Hopefully this includes both serrated and smooth feed dogs - your Juki dealer will know. Presser feet of any shape and form are readily available at various quality and price points from many vendors. The Juki LS-341 and LS-1341 use standard Singer 111W style feet which is great if you want to have a large assortment of specialty feet for piping etc. without breaking the bank. I don't have a Juki LS-1341, but my Juki LS-341 is among my favorite designs, and I'd hope the Juki LS-1341 improves that design even more. Binding on a Juki LS-1341 is possible, but the Juki binding parts kit (part# 214-34857) to do it properly runs upwards of $400 and that's before you buy an actual tape folder. Here's a screen shot of the binder options section from the Juki LS-1341 brochure (ls1340.pdf) Here's a picture of the binder kit for the LS-1342 just for reference and to give an idea of how many parts the binding kits contains: The Juki TSC-441 class (and Cowboy CB-4500 and other clones) are BIG machines and they can be downright intimidating when you sit down in front them. Not everybody gets a warm and fuzzy feeling from these monsters and it may limit willingness to actually use one. Best to try it out in person first. Hopefully your local Juki dealer has a well stocked show room. Juki also makes a medium-heavy duty cylinder arm machine that is bigger than the Juki LS-1341, but not as big as a Juki TSC-441. This relatively new machine is the Juki LS-2342 (Juki-LS-2342 flyer.pdf) The Juki LS-2342H version goes up to thread size 266. I saw this machine at a trade show and it is very impressive. This might be a good option if it's in your budget (not everybody is looking for the cheapest option, some folks want the best they can afford.) Here's a picture of the Juki LS-2342 that gives a sense of scale:

-

If you can get a new Seiko STH-8BLD-3 in a table with servo motor for $1,300 then go for it! They're great machines and certainly capable of doing what you want to do, the rest is up to the operator. The $800 end of the range may still be a good price for a local 206RB-2 setup. Anything is worth precisely what somebody is willing and able to pay at the moment it's for sale. Attempting to answer "what's it worth" questions in a vacuum is almost always pointless and I regret falling for it. I'll be more vigilant in the future.

-

I have no specific knowledge of the Pfaff 1245 706/08 model, sorry. Maybe it was the eighth time some factory asked Pfaff to make yet another special version of the 1245-706 subclass because the factory couldn't possibly live with any of the seven versions Pfaff already had. Industrial sewing machines in general have a long history of super rare special versions that came without any customized documentation. The buyer knew what changes they asked for, that's all that mattered at the time. They were willing to pay for the machines, but they weren't willing to pay for special documentation. You may be the owner of the only Pfaff 1245 706/08 in existence, for all we know. Some undocumented vintage machine servicing comes down to trial and error, which is hard to do unless you have a warehouse full of donor machines and parts to experiment with. On some machines, if a parts fits and works, it's not important whether it's the correct part or simply a compatible part. Best of luck with your sewing machine project and if you do eventually come across any documentation, please post it here.

-

I'd peg it between $800 and $1,200 but much depends on the details - and your definition of "good." Just like with cars, some are worth every penny, others turn out to be regrettable money pits.

-

You can create an Ebay or local CL search with notifications and wait for one of the usual suspects to pop up: Singer 111W155 or 211W155, Consew 225 or 226 or 206RB, Juki 562 or 563, Adler 67 or 167 or 267, Pfaff 145 or 545 or 1245, just to name a few popular ones. All in the list except Singer 111 and Consew 225 have reverse. All in the list can sew upholstery. You can also look at a close-up of the presser feet and throat plate to roughly determine what type of machine it is. Things to look for: three vertical bars (two presser feet bars, one needle bar) and a feed dog are a good sign.

-

Not correct, sorry. There are many subclasses in the Singer 111W and 211W category that cover just about all combinations and permutations of bottom, upper, and needle feed. Only some models have a unison (bottom+upper+needle) feed walking foot design that is preferred by most upholstery folks. The Singer 111W155 is one of these unison walking foot designs.

-

Obviously, the only proper thing to do is to get a high-end made-in-Germany sewing machine of roughly the same vintage as the BMW you're restoring For example, I have a Pfaff 545 H4 N10 that I bought in, of all places, St. Louis when I attended a car club event about two years ago. The H4 means it has very high foot lift, the N10 means it can make 10mm long stitches. It wasn't working when I got it, but it's a big hunk of buttery smoothness now. The only fly in the ointment, so to speak, is that in exchange for the 10mm stitch length you give up reverse. But lack of reverse is not a show stopper for a determined seamster. YouTuber and automotive upholstery guru Cechaflo uses machine that have reverse, but he usually locks his stitches manually. I could be talked into selling the machine. The nice thing about high-end vintage sewing machine originals is that they hold their value very well. You can buy a nice vintage Pfaff or Durkopp Adler now and sell it again for about the same in a year or two, if you take good care of it. It really makes no material difference whether the machine is 30 or 32 years old.

-

The Pfaff 145/545 parts manual (PFAFF-145-545.pdf) may contain some clues regarding the specific parts differences between the S and L versions of the Pfaff 145. Personally, I wouldn't necessarily rule out a Pfaff 145 for leather work just because of the "S" in the model descriptor.

-

That Juki is gorgeous - definitely a keeper in my mind. Ferdco lived off the reputation of that modified Juki long after they stopped using Juki's. I'd be tempted to carefully peel those Ferdco stickers off - the value is really in the Juki brand and all it implies. I'm voting to keep the Juki and the Pfaff and sell the clones.

-

The Juki LS-341N is well supported in terms of available information, manuals and parts. The Juki is a good choice for sewing bags and wallets and should handle 6mm veg tan leather without trouble. I know nothing about the Mitsubishi and there's almost no information available online. They may be fine machines, but you won't get much help because very few people know or own them. So unless you have local support and resources for the Mitsubishi, I'd recommend the Juki.

-

Out of the machines you're considering, I'm voting for the Adler 269 - they are seriously nice sewing machines and are comfortable sewing the things you want to sew. The thick arm on the Adler 269 has room for full motion feed dog mechanism and a vertical axis hook, which I prefer. It's not overkill for what you want to sew, but rather "just right," in my opinion. Adler 69 and Pfaff 335 have thinner arms, which is great if you absolutely need it, but they usually have feed dogs that only go back and forth but not up and down.

-

I made a video some time ago that illustrates the desired needle guard (aka hook washer) setting, as recommended by our resident expert Eric ( @gottaknow) I check and adjust this detail every time I work on a machine and I consider it an important step in hook adjustment.

- 14 replies

-

- skipped stich

- needle size

-

(and 2 more)

Tagged with:

-

Definitely not an Adler 205 or Juki TSC-441 design. Other current machines that appear nearly identical use a "GB6-180-2" model designation, sold under Thor and Kingmax brands. Top + Bottom feed machines. I've not found an "original" manufacturer that produced this design. I'm starting to think that Ferdco just bought semi-random lots of machines, changed out a few parts, if any, and put their seemingly home-made Ferdco stickers on it. Many Ferdco models appear to be more of a marketing/branding exercise than an engineering effort. Not much different than the current crop of clone manufacturers or badge engineering resellers like Consew. Ferdco built their reputation with the early models that were modified genuine Juki TSC-441 machines. They soon moved to cheaper, anonymous clone manufacturers. Here's a picture of the Thor GB6-180-2 just for comparison:

-

Problem of Juki TSC-441leather sewing machine

Uwe replied to sakuraleather's topic in Leather Sewing Machines

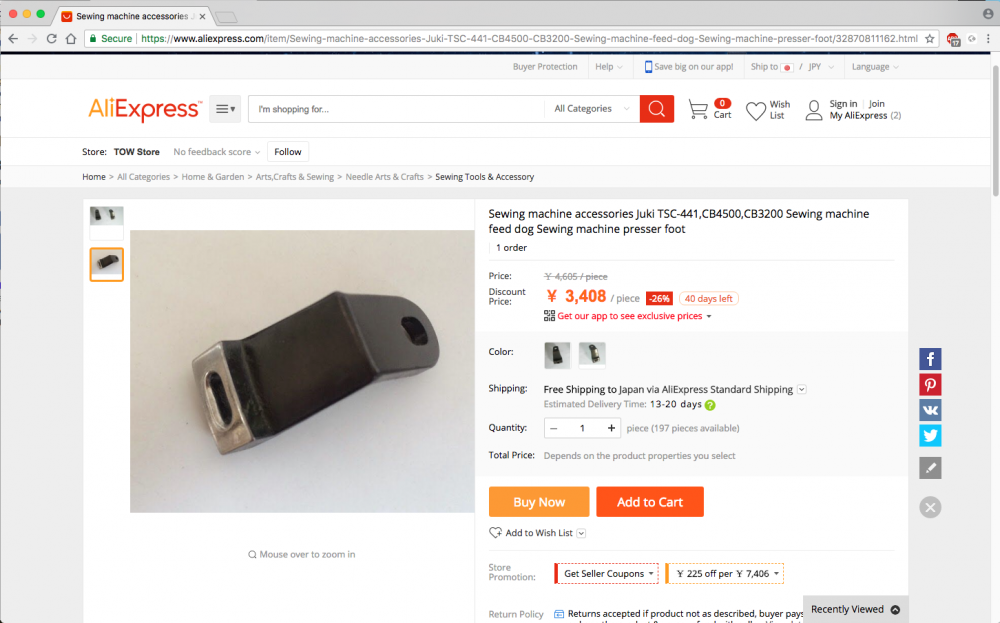

Those smooth feed dogs are also available online from places like AliExpress.com. Juki probably makes them, too, and I would hope there's a Juki dealer in Japan. You can also try a needle feed throat plate and remove the feed dog entirely. Which option is best really depends on the project. I made a lower needle guide for a 441 needle feed throat plate some time ago. This video shows how this setup can work. Here's the screen shot of the AliExpress page:- 9 replies

-

- juki tsc-441

- leather sewing machine

- (and 2 more)

-

Lots of things can be re-assembled incorrectly. Since you have twin machines and one of them works as it should, your best bet may be to put them side-by-side and very carefully compare every last bit of hardware involved in the stitch length and reverse mechanisms. How far does a part move? In what position does it start and stop to move? Things that appear the same at first glance often turn out to be not quite the same upon careful inspection. Finding or noticing that one thing that's off is a key skill in sewing machine repair and adjustment. Many mechanisms that translate partial rotary motion to linear motion need to be "centered" to work as designed and provide the correct range of motion, both linear or rotary. The stitch length and reverse mechanism does this rotary-to-linear movement translation in four or five different places in sequence (the reverse lever rotates a shaft which moves an arm that in turn rotates another shaft, and so on.) Some of these linkages are adjustable and if they're not properly "centered" they may not provide the correct linear or rotary motion. Whatever movement the reverse lever makes when you push it down needs to produce a precise 180˚ rotary movement somewhere else in the reverse mechanism. I'd also check the feed mechanism, especially since you changed the timing belt. If the feed timing is off, it may not transport the material as far as it should, or the needle may penetrate the material after it already started moving towards the back (or before it reaches the front.) Make some stitches in stiff paper to get a good needle hole distance measurement. I made a stitch length gauge some time ago for a video (https://www.youtube.com/watch?v=iiaaT1npYrQ). You can download the PDF file and print it out yourself: http://docs.uwe.net/SLG.pdf