-

Posts

3,794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by YinTx

-

Outside of NM or Tx, I think most don't know Hatch Chile. And in Tx, they want to spell it chili. And somehow chile grown in the Rio Grande Valley gets sold as Hatch green Chile. I can say it doesn't taste the same. all very confusing to the outsider. Who wants to know if they need a passport to visit. YinTx

-

LMAO. Showing their level of intelligence. Also, here in the good ol US of A, we have a lil state called... New Mexico. I've lived there. Folks wouldn't ship 46 miles across the state line or do any business with us because "its' a foreign country." or "We don't take Pesos." erhm.... it's a state. In the UNITED STATES!!!.. you can drive here without crossing a border ya know? We used the dollar too. But you couldn't convince em to to look at a map cuz they knew better. Now I'm in Texas, so not so bad. Course, sometimes when folks from out of state learn where I've been, they want to know if I speak Spanish. YinTx

-

Finally able to show these off!

YinTx replied to YinTx's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Appreciate it! YinTx -

Since I am from across the pond, I haven't a clue. Why is this? YinTx

-

Finally able to show these off!

YinTx replied to YinTx's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You have no idea. !! "Hi, my name is YinTx. Thank you for welcoming me to TT Anonymous. I have . . . lots of tools. erhm... I think I may have Tool Troubles." and, thanks! YinTx -

Really nice work! YinTx

-

Handstitch vs Machine for artisan pieces

YinTx replied to Warhauk's topic in Leatherwork Conversation

I hand stitch. Very little machine stitched. I hand tool leather, nothing press/embossed. Can't say that I've ever had enough folks pay enough $$ to make those two endeavors profitable. I think it was maybe Maker's Leather that did a survey and overwhelmingly customers were not willing to pay extra for hand stitching. So he bought machines and never looked back. If you are good enough with the machine, you can get a very high quality stitch, that some will have difficulty differentiating from hand. Most customers don't know any different, and luxury house brands machine stitch with horrible quality and get away with it. Things to ponder. YinTx -

They moved _from_ Newark to Harrison, so your catalogue would be correct. Now, they did apparently stamp some of their tools "Newark" after the move, but not for too long. YinTx

-

Thank you. It was a bit of an ordeal, but I've enjoyed it. And it has rapidly acquired a golden tan hue from the South Texas sun. It really doesn't match the interior of the car, but I'm not in the least bit concerned, lol. YinTx

-

Big changes for Swarovski = bad news for you (!)

YinTx replied to ButtonLady's topic in Hardware and Accessories

Yep, I see some lawsuits around the issue of "I paid high dollar for Swarovski so I could sell my products advertised as having Swarovski. Now I can no longer charge the premium that I paid for your products. Give me back my $$." YinTx -

Finally able to show these off!

YinTx replied to YinTx's topic in Gun Holsters, Rifle Slings and Knife Sheathes

@Rossr, subtle but I finally picked out some of the differences. Notice the tail is below the body on the new logo, and above it on the old. Also, _PARIS_ is below the logo, new one has BLANCHARD. Old one has that above the logo, instead of VERGEZ. The old one has the ears perked up, and the collar is wider. Gait appears more of a trot in the old version vs. fully outstretched run in the new one. I think I still didn't do the old version justice, but then I'm the only one using the thing, so none of any of this really even matters. Just me being persnickety. YinTx -

Finally able to show these off!

YinTx replied to YinTx's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you, and indeed, I do! YinTx -

Finally able to show these off!

YinTx replied to YinTx's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Didn't think to look for that. I just had noticed that some of the different tools I had seen had slightly different versions of the logo and mascot. So I did what I could to match the one on the actual knife the sheath was for! I had a link to some older website they had, which was in French. It seems they have updated recently. I get em where I can! The smallest one is an HF Osborne, also, and have never seen one that tiny. Not sure it started that way, but who knows!? The others in the background are C.S. Osborne (Newark), 3 W. Rose, and 2 Gomph. Tis but a fraction of the collection I seem to have amassed over the years. Have sold a few, and need to sell a few more. The Blanchard you put a handle on came from an individual in England, who said he got it from a fellow in France, who claimed it was really old when he purchased it in the early '70's. YinTx -

Finally able to show these off!

YinTx replied to YinTx's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you. And really nice work by @Rossr making the handles and ferrules for those two blades! Really happy with them. YinTx -

Finally finished up the sheaths for these three, so I can put them all in the same photo! 3 knifes, 2 have handles made by none other than @Rossr (burled handle, and the handle on the Blanchard). The Blanchard I have been using, and really like the functionality offered by this blade design. The burled handle fits very nicely in the hand, especially if you have larger hands. The third knife is an HF Osborne that I recently acquired. I took a photo of the Blanchard Emblem and used it for the basis of the sheath design, since the emblem is slightly worn, I have no idea if I represented it correctly! YinTx

-

Post a photo of said board. Maybe someone with the correct factor will appear. YinTx

-

Did they tell you what was wrong with the main board? Perhaps someone can repair it...?

-

I've also taken smaller bites to go round the corner, as in multiple passes. Kinda like cutting a rounded corner in leather with a straight edge: small cuts result in a curve. YinTx

-

It is nice work. I do have a question for you tho: on the molding around the back, it looks like the scope and mounts would result in too much retention: ie locked in place. Do you find this to be the case at all? Also, the deeply recessed moulding around the trigger guard: does it interfere with the trigger at all? YinTx

-

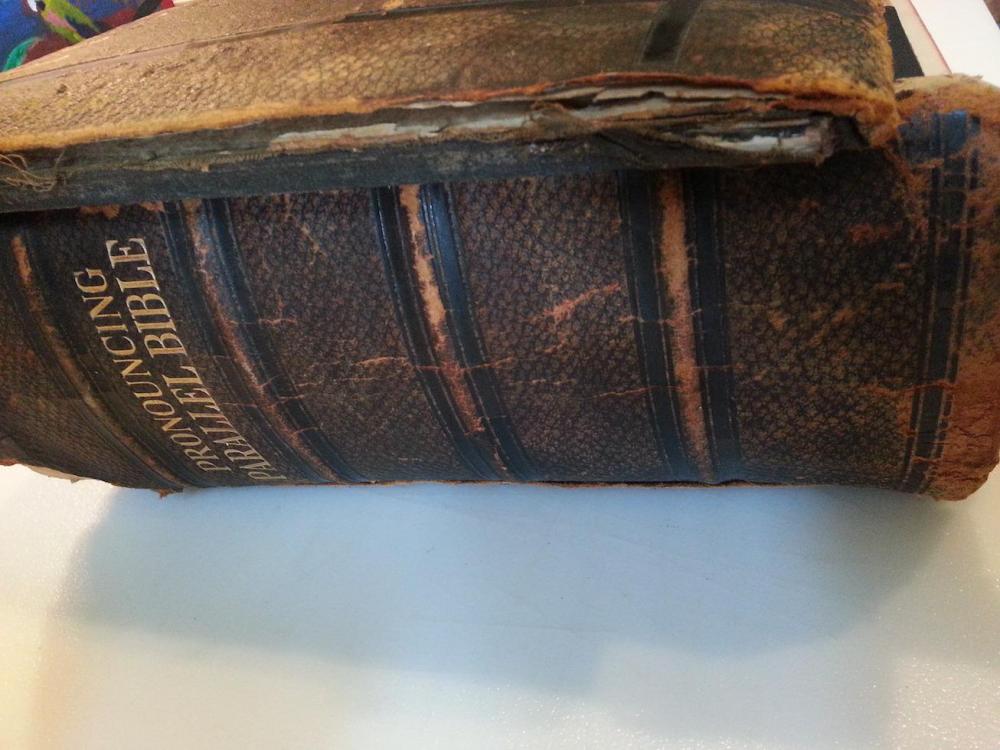

Well, at least I know to keep it under $3-400, otherwise I could have someone else do it! Of course, that is only the cover, not any repairs that are needed... They have an interesting take on binding, for sure! Thanks for the link. YinTx

-

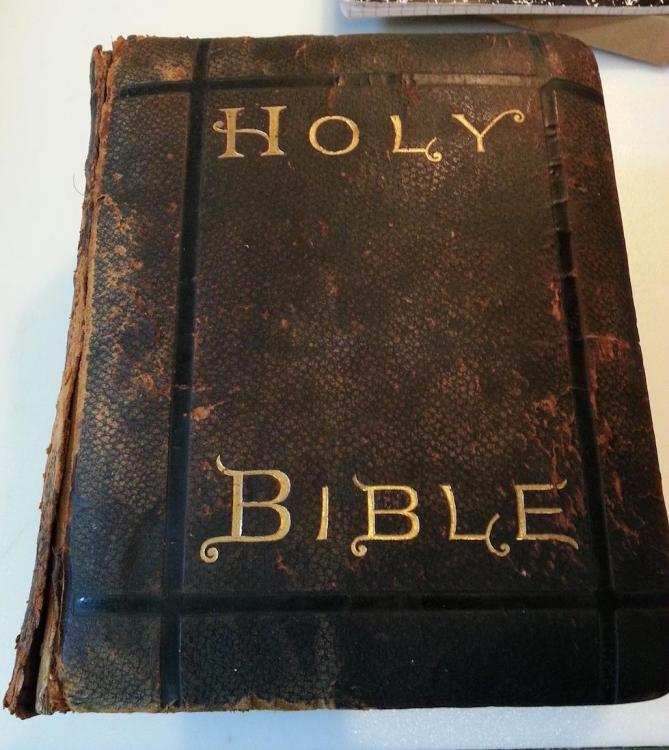

An old Bible circa 1890 has me going down the winding bookbinding path... YinTx Edit: It weighs about 15 lbs ... with a pillowed cover... wouldn't want to start small or simple or anything...

-

Wow, thats a stout looking little beast! YinTx

-

yes, rabbit holes. I do leather work. I need a strap cutter. Check out this cool vintage strap cutter! Ah man, it needs a gib. Gee, I could make that $5 gib. I need to do a little research on metals. Oh, I see. I think I need an anvil. And a forge. And a hammer. I could make a forge. I need to research that. I need a good spot outside. I need a small building outside for my vintage metal working tools. I could build that. Probably need to run 220V to the building. No problem, I can learn how to do that. I probably need some electricians gear. Some of those gloves would be nice. To go with the gloves I got for working in the forge. That I need to build. So I can make that gib, for that strap cutter I need to fix. So I can cut leather straps, because I do leather work. This is my daily life, lol. YinTx

-

I've usually seen them as you have it. On occasion I'll get one in with two gibs on the bar, not sure why. Also, I've had better luck with some of the older ones with rosewood and brass handles than the iron ones, not sure why. Depends on what I am strapping as to which one works best. Also, whichever one is set up already sometimes works best. YinTx

-

Yep, thats the one. Sometimes they are different. Osborne sells new ones if your spares don't fit and you need replacements. YinTx