-

Posts

3,798 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by YinTx

-

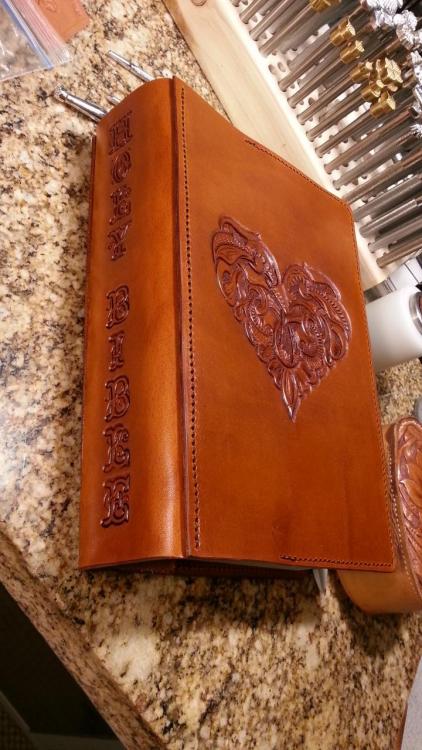

Thanks for that feedback. You are right, I normally would run the stitch all the way, but I was worried it would look bad on one side or the other if I had the tension wrong when it got to the single layer of leather. Have to build up some sewing machine confidence there, I suppose! I was happy I could run the two words on the spine, instead of just choosing "Bible," and I agree, the font is spot on for it. YinTx

-

Thank you both! I had to shrink the tooling pattern, which made it even more difficult to tool, as if Jim's stuff wasn't complicated enough already! And the machine stitching made me really nervous. Glad to see others think it came out alright! YinTx

-

Wally World Purse

YinTx replied to Dwight's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I would be interested, might enlighten me on what folks don't like about my version! YinTx -

Wally World Purse

YinTx replied to Dwight's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I made a few items like this. I think I have 3 or 4, they haven't sold, even for really cheap. Let me know how it goes for you! YinTx -

Skull & Roses Clutch Wallet

YinTx replied to AndyL1's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice. I like the touch of inverted carving on there too. YinTx -

Trying to make a more affordable item, so first time machine stitching, and unlined. Please let me know what you think! It is a Jim Linnell tooling pattern that I used, not sure I did it justice. YinTx

-

After 3 years: gone full-time and moved to Siberia. Here's my progress!

YinTx replied to karlova's topic in Member Gallery

Absolutely love your design aesthetics and color choices. You are definitely and artist! So glad you share your stuff with us, very inspirational. YinTx -

You should not need a new blade. a new one will probably still need sharpening. What kind of leather are you tooling? Have you cased it? Have you stropped the blade? What did you use to sharpen it? Do you have a photo of the blade end? YinTx

-

A Belt Thank You

YinTx replied to Dwight's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Ain't nuttin wrong wit dat! Came out alright, if I do say so. YinTx -

I think I've visited there, nice area if I recall. YinTx

-

That is a steal. If I didn't already have 4 or 5 of these things, I'd be all over it. YinTx

-

The impatient side of me took over, and I did the other adjustments first. The spring looks like it could be squared off, so I'll have to get a grinder out and get after it. I've been out of commission here for a couple of days, I'm semi-back. A lot of adjusting on this machine, including having to center the needle over the feed dog - it was hitting the back of the hole! Had to figure out where that adjustment was on my own, I didn't see anything in literature or in YouTube that had it. Doesn't mean it doesn't exist, just that I couldn't find it. Suffice to say, I found the screw to turn. Adjusted the presser foot to needle foot timing some more, needle bar height, hook timing again, took the hook out and removed the burr and scratches, then polished it up with 2000 grit, cleaned the race, put everything back together, and seems to be stitching pretty good. At least the best it has ever stitched, considering the foot coordination is finally right probably for the first time in it's existence. I was able to stitch up the stockings I was making, but unfortunately am unable to get it to backstitch - the hook will not catch the thread off the needle in reverse. Suspect it needs more hook timing adjustments? On the plus side, it is not shredding thread anymore. I'm feeling confident enough in the progress of the machine to go looking for some 794 needles in different sizes! I'll post up a video of it running as soon as I can, perhaps someone can see something it isn't doing correctly that I am unaware of. Thank you all for the continued help. Still troubleshooting the inability to backstitch, the odd alignment of the linkages to get the presser foot to lift, and the clunky clunk noise it makes as it lifts the presser foot. YinTx

-

Must say that looks like it was truly a labor of love! Nice work! YinTx

-

That was the video I was referencing on my first post. I spent many hours back and forth with it. For some reason, the numbers on this machine don't match his, could be because this is a Techsew and not a Juki? After I finish stitching the jobs I have, I may play with it some more to see if I can get them closer to his. I am beyond ecstatic that I have finally gotten the feet to sequence correctly, after finding the camshaft out alignment 180 degrees. Supposedly per the individual I purchased it from, this went back to the supplier to fix when it was purchased new, and they sent it back this way, and it has never sewn correctly. Right now, I am getting it to stitch, feet march correctly, both feet lift, backstitching works, tension is good, only complaint I have is the rear presser foot seems to be a bit jerky moving up and down, not too smooth at all. It is very well oiled, so not that. YinTx

-

It may be a simple adjustment. I have had some success today, since there is no professional around that I know of, I'm the defacto mechanic, so I do appreciate the tips and help. This troubleshooting may help others too. If you have time and desire, kindly refer to the other thread I started and provide any input you like. Thanks again, and back to the regular programming! YinTx

-

I have this part adjusted to where the point sticks out about 1mm. I am studying the following video to see if the eccentric cam has slipped on the shaft... at the 1:40 mark, my machine is doing the opposite of what @Uwe indicates it should be at, which may explain why the feet move opposite of what they should. I'm trying to figure out how to adjust this cam...

-

@Wizcrafts, thank you for that pointer. I did watch this video, as mentioned in my post last Wednesday. To avoid hijacking this thread, tho they are related, here is the thread that I started that discusses some of the issues I am having. I am beginning to believe that something slipped on the shaft causing the linkages to move in opposite directions than they are supposed to. Hoping someone has seen this before, or can point me to the right direction to understand how to get it back into timing. Since the post, I have been able to get the shuttle hook timing a lot closer as highlighted by RockieAussie. I have the presser foot lifting a bit more, but still the needle foot raises when the needle drops, and drops when the needle raises. YinTx

-

"Reverse Dye" Tooling - Impressions Remain Natural Color

YinTx replied to BenjaminKortz's topic in How Do I Do That?

@fredk's method is one way, another is block dying. The example you show appears to be done with block dye method. Do a search on this site for a better description of the process than I will be able to provide! YinTx -

Really cool tho. How did you get that texture on the fish?!? YinTx

-

Can you clarify this instruction? A bit confusing.. If the outside/back foot is already resting on the needle plate, how can you drop it down another 3/16"? I think I am having similar issues with my machine, foot timing is way wrong (inside foot is raising when needle is dropping, binding when trying to get it any different). Thank you in advance, YinTx

-

I'm going to agree with you there, oval grommet setter missing the bottom anvil. But I've been wrong before. The hole in the side is reminiscent of a rivet setter, which doesn't match the oval, so yeah, good mystery! YinTx

-

Maybe someone can help me out with this frustration. After 6 years of the machine collecting dust because it won't sew, I've been tinkering with it because I have some projects that just need a sewing machine to be finished. So here is where I am at: tried @Uwe's video showing how to set timing, not working for me. Looks simple, but not happening. When I loosen the hex head bolt to adjust the shuttle hook, adjust it, then you have to rotate the handwheel back so you can tighten the bolt, which means the shuttle hook is defacto put back out of timing because it stays still while the shaft moves. WTH? The best I can get is the hook not retracting (sticks out 1/8") at it's furthest back otherwise it will not interact with the needle correctly (ie, completely misses the needle, which will already be up before the hook comes to try to catch a loop). At just short of 20 degrees is when the hook and the needle cross, not the 30 degree mark. Also, trying to set the presser foot and needle bar foot coordination, but it isn't happening either. Tried a hundred different guesses also, none working. Always, the needle bar foot is going up when the needle is going down. And the presser foot hardly moves (5mm lift). Anyone have a simple way of setting this? Once again, tried to follow @Uwe's video, set the linkages vertical. Now its a disaster. Clearly I am doing something wrong, or something is set up backwards or I don't know. What should I be looking at? The video I made in 2015 clearly shows my issue, which I didn't know I had at the time. You can see at the 2:47 minute mark when I spin the hand wheel how bad the foot coordination is. Other than that, the rest of the video is just discussing the binding issues, which seem to have been reduced significantly. If you mess around with the linkages too much, it'll bind up solid again. I would really like to get this piece of iron functional, so if anyone has tips, suggestions, clues, etc, please let me know! YinTx