-

Posts

2,656 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Tugadude

-

reading your post, it seems that you might be using one needle. Definitely look up a tutorial on saddle stitching. I believe Nigel Armitage's video is on the "How do I do that" part of the forum as a sticky. Or maybe it is in the beginner section. You can also find it on Youtube. BTW, there are options on starting and ending the saddle stitch. Explore different methods and then decide what is "right" for you. I don't bother back stitching to begin a row, but I don't make stuff that is subjected to extreme usage conditions. I typically end my row of stitching with two back stitches and then cut and melt or if it is something that I want to look extra nice, I'll pass the thread ends through one hole only and then cut. That way there is no melted end showing and the thread ends are tucked in-between the layers of leather. Gives a nice, finished look. Good luck!

-

First project

Tugadude replied to Issy's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Yes, the cat is cute! When hand stitching pliable leather like that a couple things can happen. One is that it is tricky to pull the threads with even tension without buckling the edges excessively. The second is (and that might have happened here) is that you can get a wobble in the backside. You said you paid attention to it, but it is a skill like anything else and you will get better over time. Your cutting looks great and overall the stitching is decent, especially for a first project. You might have slipped a couple times with your needle priority? Look at the stitches towards the middle. Hard to tell. What chisel were you using? If it is not sharp, that could do it too. Also, what surface were you working on when you made the holes? That could also make a difference. Too much give isn't helpful. -

Outstanding work, literally the Humvee of briefcases. Love the stitching, especially the double rows, very nice!

- 24 replies

-

- project

- lso angeles

-

(and 6 more)

Tagged with:

-

Should I save leather from old chair?

Tugadude replied to metroplexchl's topic in Leatherwork Conversation

Sure, repurpose it! Make a purse, Dopp kit, whatever. I took an old leather jacket and made two purses, no problem. Gave one to my youngest daughter and one to my wife. They love them. -

Sorry, should have checked the other thread. The Craftool chisel from Tandy is excellent, I use one all of the time. You can polish it to make it easier to remove or stick the tines in beeswax before hammering. You are definitely doing something different with the needle priority. I will try to add a pic of one of my bags with the Craftool chisel.

-

Well you've got the basics going! Now time and experience will sharpen your technique. I'm no carving/stamping expert but it looks good to me. The overall cutting and design is good too. Biggest room for improvement is the stitching. I saw that in another post of yours, I think. You are somehow stitching without priority, both left hand/right hand and possibly over/under. Study Nigel Armitage or Ian Atkinson on Youtube for technique and tips. I think you said you are using a chisel. Which specific one?

-

What kind of stitching to use for a leather bag?

Tugadude replied to CraftyNick's topic in Sewing Leather

Thread could be bigger for sure. What specific chisel are you using? You mentioned 3mm, but what brand? -

Smart the way you angled it. I've seen lots of flat ones where you basically have to be looking down on them to find anything. nice setup!

-

Having my doubts about Springfield Leather

Tugadude replied to CaptQuirk's topic in Leatherwork Conversation

I assume you've called them? Did they get things worked out? I buy from them frequently but tend to go into their store when I'm in Springfield on business. I find them to be super friendly and knowledgeable. Several of their employees that work the floor know me and always greet me. I'm in business and I can tell you my company makes mistakes. But we're still a leader of the industry because we take care of our customers. If you aren't satisfied, talk with the owner. He is there most days I've visited. I'm certain they want to get it right and for you to be happy. As for the flat rate shipping, they posted the very legitimate reason why that had to cease. Good luck. -

Wallet with big stud button

Tugadude replied to AKworkshop's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Stud button or not, that is some fine work! -

First Bi-fold wallet

Tugadude replied to flux41's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

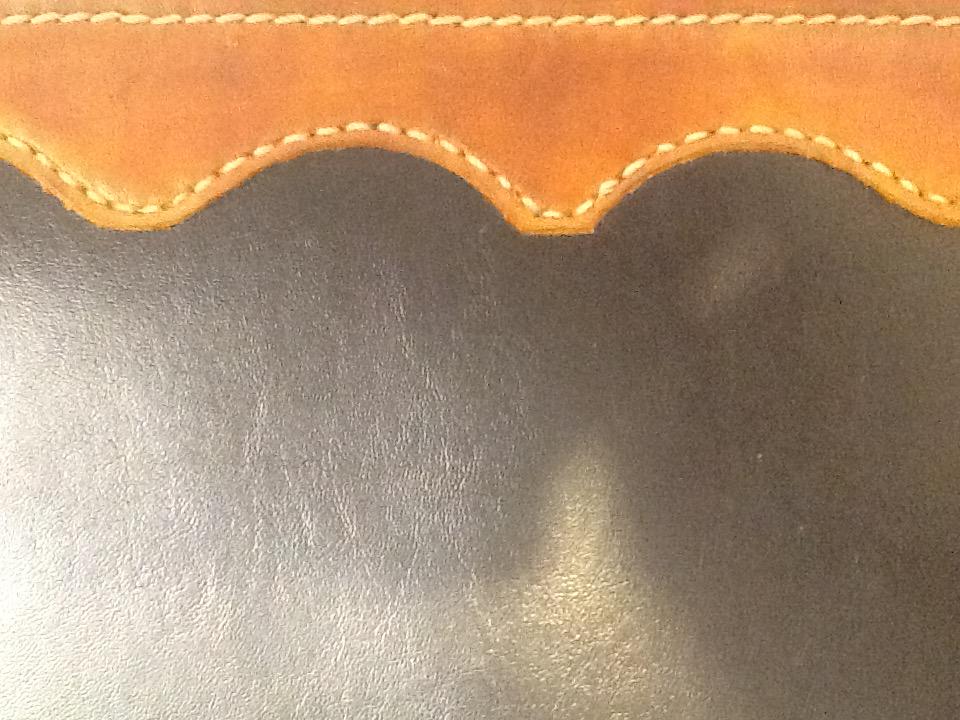

Beautiful work and I love the look, texture and supple appearance of the leather. Love the shape of the pockets but agree that the stitches should go higher. Lining might be desirable, but it adds thickness and that might be objectionable to you. Keep up the good work! -

Natural color but probably has Supersheen or carnuba creme on it.

-

I like gum tragacanth, but could live without it. Even water can cause spotting on certain leathers if you're not careful.

-

Watch Strap

Tugadude replied to Dunluce's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Agree with hole spacing. I have a centering ruler I use that has holes in two different spacing intervals on it. They are actual holes and I can make a dent with my scratch awl resulting in perfect spacing. there is no reason why you couldn't burnish the outer strap and then attach the lining. The color doesn't bother me, but might bother some. I know of nothing you can do to prevent the lining leather from absorbing sweat and/or oil. It just happens and I think most understand it. Maybe you can delay it, prevent no. -

First wallet, would love feedback

Tugadude replied to Gstone's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I think it is great! As far as suggestions, not criticism, maybe move the stitching line out closer to the edge. At least on the sides. The bottom is about perfect. Also, look at the bottom corners. The stitching curves yet the leather is square. Nothing wrong with that, but I prefer my stitching to match the profile of the leather. You already realize you can eliminate the bulge by making the outer piece 1/2" longer than the inner and not stitching all the way across. BTW, I think more pics should feature toes! Just kidding, but I couldn't help but notice. -

Thanks, that is my plan too. Now to find the time..... nice work!

-

Love everything about it. I'll bet it has a very pleased new owner. Curious how you did the innards.

-

Might be a separation or a "Y" division at the top. Not sure. I'll bet a whip-maker could help you on the way to braid this. Good luck!

-

Not much help, but seems pretty simple. Just appears to be a braided "tube" that slides up and down.

-

Alternatives to poundo board/matt for punching

Tugadude replied to plinkercases's topic in Leatherwork Conversation

-

Very cool find. I'm sure you know you can have a fabricator cut it square all around if you feel the need, or chamfer the front edge and such. Not necessary, but might be worth doing.

-

Not sure where to post. (Sitting position)

Tugadude replied to Rlbuckers15's topic in Leatherwork Conversation

Not silly at all. Ergonomics is a way to make your environment conducive to comfort and productivity. Like people on phones all day wearing a headset instead of cradling the phone between their shoulder and ear. Experimentation with varying chair and table heights will help. Also don't discount a strong work light. When I can't see well enough I used to bend over more to get closer to the action. Hurts after a while. Adequate light helps. About 30 years ago I had an inside sales job and headsets were rarely seen. Used to be I couldn't turn my neck without pain, the muscles having shortened up. Made driving unsafe. Good luck