-

Posts

5,251 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

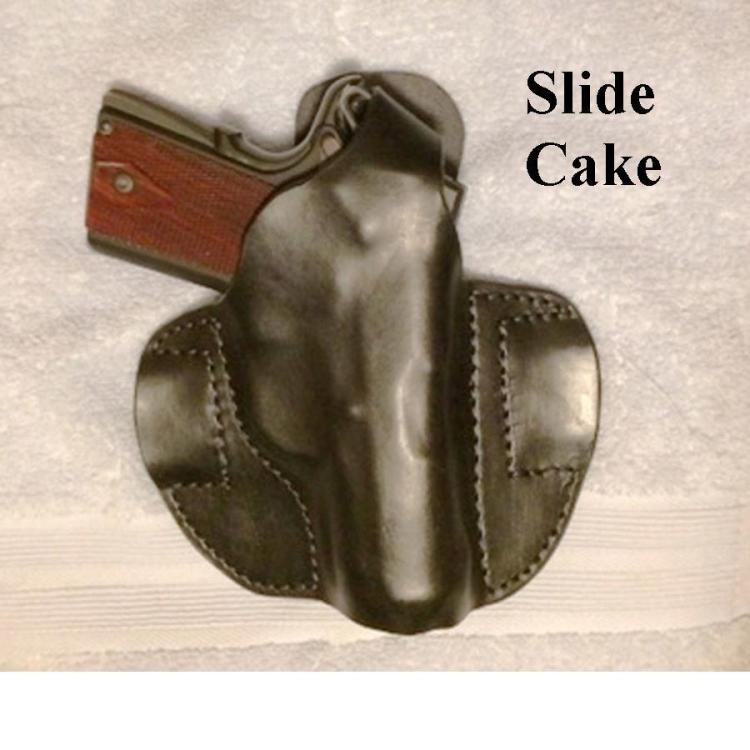

Badhatter . . . this is one of the single most comfortable OWB I have ever made. Your belt slips thru a slide before the holster . . . behind it . . . and then thru another one. If you are interested . . . I can fix you up . . . just let me know. The one you see there . . . is an officer's model SA 1911 . . . with thumb break May God bless, Dwight

-

At 79 yrs . . . I have always despised trying to make two things exactly alike by using templates and / or patterns. I like them similar . . . but still unique and "one of a kind". My leather work is the same. I use manila file folders to make "sort of" patterns . . . they get me to be where I can cut a piece of leather . . . and know it will fit a 1911 . . . a Ruger Vaquero . . . or a double barreled derringer. I then wet mold the weapon . . . let it dry . . . and complete the project from there. Each holster will fit the intended weapon or any just like it . . . but laid side by side . . . one may be a tad longer . . . one may be a tad wider . . . one may have double stitching on the outside . . . one may have a thick welt VS thin welt. Just how I do it . . . but again . . . common ol' manila folders and a razor knife have always done well by me . . . get that "sort of" pattern out . . . outline it with a ball point pen . . . go to cutting and I'm good. May God bless, Dwight

-

Call Bob . . . tell him what you want . . . 3 bucks each . . . I got my dozen May God bless, Dwight

-

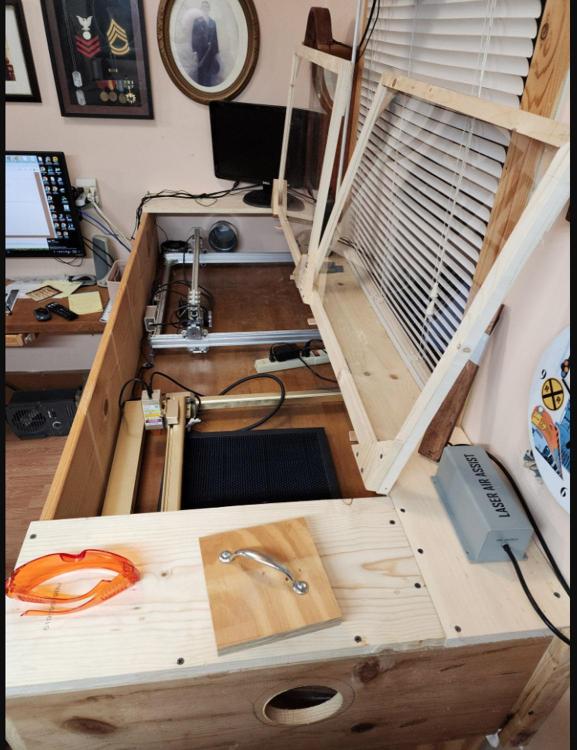

Suffering a stroke leads to finding new methods and means

Dwight replied to BillB's topic in 3D Printers and Lasers

I've got two of em . . . a 3000mw and a 10 watt . . . they sit side by side in a box I built on a door . . . (10$ slab door from a used fixit shop) . . . have a 7 inch fan blowing thru a round hole in the side of my shop . . . works great. I have used Lightburn . . . found LaserGRBL (free software) . . . works real well . . . only have to remember when printing anything . . . it prints in a mirror image . . . have to change it before printing . . . otherwise works real good. May God bless, Dwight -

Used Gun belt holster lining shrunk?

Dwight replied to DabblerMcPancakes's topic in How Do I Do That?

I would toss the liner (unless you want to make a knife sheath out of it). Buy a piece of leather from Tandy store . . . put it together. My guess would be it did not shrink . . . somebody just put together something to sell . . . two oddball pieces that "almost" matched. May God bless, Dwight -

If I used one . . . it would be my marine vinyl apron I made to use when I'm dying leather. Vinyl cleans up real easy . . . is waterproof . . . can be easily made into "what you want" . . . and it is not overbearing and hot. Perfect for my BBQ May God bless, Dwight

-

I cut off the fingers from latex gloves . . . put the bobbin in there . . . write with a felt tip marker what size it is or whatever Been doing that for 20+ years . . . But may look into this. Looks neat May God bless, Dwight

-

Different leathers, different ounces, so confusing!

Dwight replied to Pqstraub's topic in Leatherwork Conversation

Just for my own knowledge . . . why do you need them to be 8 ft long? May God bless, Dwight -

This may not work for you . . . but I have a Singer model 6800C . . . that I got for doing lighter leather work. On Ebay . . . https://www.ebay.com/itm/374896756955?epid=10041454101&itmmeta=01HZ3H9NT837YTP72W8VG1Q29P&hash=item57499688db:g:k1oAAOSwaqRk5glf&itmprp=enc%3AAQAJAAAA8Dh9V5%2FtBAi6HE5PCbE5Wrfsqmi0LzGNxb6OvQQIsJ5%2F4xH4uEUV%2BQWaKf4f8NCJTKb%2FoX0lF2OaNrMRHiexn%2F8BixUOr37IVOthsZGNlapgd576HfEMLwSLV2vg9M6EffBj7Q%2B90l%2B30RM47tLUd106F17XPOmFdZIGaqJ2QBV%2Fshq%2BuofR3c6DhcYUYj%2FsRGhe8Mvs4MX8nx%2BqccwullNgA%2FyHvlidkeVsdyN8tnsopUl24Ky4axUIs9wM29Lp8QILk47jjmWLNHdS%2FxuD9taeFkrDKLTHik0q%2FfAbPE3C9iXzmSmuYRDrKB%2Bz28QiFg%3D%3D|tkp%3ABk9SR6jdpvH4Yw I've sewn some thinner vegetable tanned and other leathers with it . . . and I use carpet thread exclusively. The leather will rip apart before it breaks the carpet thread. Go to a Singer sewing center . . . take some leather samples with you . . . and stop at Joanns and get a spool of carpet thread . . . tell the sales person you want to see a demo of that product. It just may do exactly what you want . . . and even though it has a lot of other options on it . . . I do straight and zig zag stitching only . . . and I love it. I have a couple of vests I need to make . . . similar to what the folks wore on the old Ponderosa show and others . . . I will definitely make them on my Singer. May God bless, Dwight

-

Shiela What is the size of the cover . . . and what weight of leather did you intend to use?? Also . . . on the cover itself . . . what size image were you wanting?? If I'm successful . . . it'll be in about 2 weeks as I have to do some traveling Just let me know here . . . I'll see it while I'm out and about. May God bless, Dwight

-

Thanks Sheilajeanne . . . I'd never seen that image before . . . it's gorgeous. I just might try to see what I can do with my laser machine . . . I know I can cut the outlines and the major lines in the images . . . but I don't how it will do on the subtleties . . . May God bless, Dwight

-

That's sad . . . but thanks kgg May God bless, Dwight

-

Prayers upward bound . . . May God bless, Dwight

-

Pictures of your items work wonders for understanding. May God bless, Dwight

-

Two new carry holsters

Dwight replied to Yellowhousejake's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Have you ever tried dip dying your products?? That is all I do . . . and it will alleviate the vast majority of the raw leather look. Takes more dye . . . but it also lasts longer . . . because it goes much deeper into the fibers. May God bless, Dwight -

Two new carry holsters

Dwight replied to Yellowhousejake's topic in Gun Holsters, Rifle Slings and Knife Sheathes

The undyed leather on the basket weave is a product of trying to get too much detail in the molding of the revolver. That molding is great for the light brown one . . . but when you stamp something with a basket weave or similar design . . . just go light on the molding . . . I simply insert the weapon . . .and whatever molding is produced by the weapon being in there . . . is what I go with. Have never had a disappointed customer yet. My first commercial holster was a pancake . . . for a 1911 . . . and it just printed a tad too much for me . . . went with an IWB . . . but I did like that paddle . . . was really comfortable. My son still wears his Glock 19 that way . . . May God bless, Dwight -

I don't remember who it was . . . supposed to be a well known western figure of the latter 1800's . . . Was one tough hombre . . . and a hard nosed cowboy himself . . . When asked how he died . . . the answer was, he laughed himself to death when he saw a "store bought cowboy . . . in a 10 gallon hat . . . wearing wooly chaps" Sixty years ago I could have told ya who he was . . . have long since forgotten . . . just always remembered that mental image . . . May God bless, Dwight

- 3 replies

-

- wooly woolies

- chaps

-

(and 6 more)

Tagged with:

-

The machine will depend largely on what it is you want to sew . . . Give us some ideas as to the major group you want to sew . . . May God bless, Dwight

-

Different Holsters

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That's a good looking alternative to my all black version . . . And I also like the longer barrel . . . Definitely better than throwing rocks . . . although historically a guy named David was pretty good. I did black because my customer wanted it for concealed carry . . . and it was IWB . . . hidden amongst the shadows. Have fun with it . . . may God bless, Dwight -

Different Holsters

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

My preferred carry gun is my SA officer model with walnut grips . . . feels SOOOOOOOOooooo good in the hand . . . and it shoots great as well. But in many circumstances . . . especially as a pastor . . . discretion is necessary . . . so I have a little olive drab (??) S&W shield. Handling it . . . I hate it . . . but for concealment . . . it goes in my back pocket . . . and I'm Roy Rogers all over again. May God bless, Dwight -

Different Holsters

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you . . . Yup . . . suicide straps . . . both the Ruger and the Glock . . . belong to a fellow in his mid / late 80's . . . all sorts of rhumatizz . . . and I had to put something on there to make sure he didn't lose one to some teenage "grabber" if he was out. He couldn't handle a thumb break. Thumb break went on the derringer though. May God bless, Dwight Yeah . . . ugly it is . . . but .45 it also is . . . which kinda gives it a bit of a pass. They're super ugly in 9mm May God bless, Dwight -

Different Holsters

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks . . . .45 Long Colt / 410 shotgun . . . kind of a "big boy" derringer. May God bless, Dwight -

Recently asked for a pattern for a derringer holster . . . wound up making my own. Also got a request for a big boy . . . Glock 10mm full size with laser And a request for a Ruger .45 . . . with laser. Derringer was a pain in the neck . . . my vacuum pump ran overtime getting that thing shaped up . . . The Glock and Ruger needed special treatment so the holster didn't turn on the laser . . . wound up making a kydex interior holster . . . covered with 7/8 veg tan . . . saddle tan to finish it with couple coats of 50/50 resolene. Holstering and unholstering . . . sounds like the kydex holster . . . makes one do a double take looking at the holster. Anyway . . . sure don't plan on making these for a living . . . three of the hardest holsters I've ever made. May God bless, Dwight