-

Posts

5,250 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

Good way to go is find something you need to do . . . and do it . . . post pictures . . . ask for comments. Generally speaking most folks here are gentle . . . but honest in their admiration and / or criticism . . . The old saying goes something like . . . "most of our good decisions come from experience . . . and experience comes from bad decisions" My first holster I made . . . no one on here has or will see . . . it was that ugly . . . but looking at others . . . I was able to see what I did wrong. It's at the bottom of my holster box . . . rarely eve sees daylight. Jump in . . . join the fray . . . and "glad to have you" May God bless, Dwight

-

A few years back I was having trouble with my light tan dyes . . . not being even . . . especially saddle tan. I don't recall the impetus that moved me to try oiling first . . . I did . . . have NEVER had another problem like that since. I use a cheap pig hair brush from Harbor freight . . . put on a very light coat . . . just enough to make it look wet . . . Let it "dry" for 24 hours . . . the dye goes on perfect . . . every time. I don't always oil for black . . . it depends on the leather . . . But if it is anything other than black . . . it ALWAYS gets oiled first. That is for all my holsters . . . belts . . . sheaths . . . and gun cases . . . which is mainly what I do. May God bless, Dwight

-

Yessir . . . been too busy with holsters to really jump into the belt thing . . . but I most certainly will be doing that. I tried one application of the oak leaves . . . did the cardboard thing first . . . liked it . . . tossed a piece of junk leather in there for kicks and giggles . . . turned out too dark . . . have to try again some future date. My plan is to bring the two pieces of the belt just close enough together that the laser does not "overlay" the etching . . . and I'll go in there with my cutting and stamping tools and join them together. Got two large semi-autos that hit the shop the other day . . . both have attached lasers . . . making holsters for them . . . and it is a "chore" for sure. Gotta get them done . . . plus a half dozen belts . . . then "Lord willing" I may get to go back to playing and experimenting. May God bless, Dwight

-

There's two of us for sure. Sometimes I use mostly my Tippmann Boss for that . . . as I can EXACTLY place the stitch where I want it. Had to do that for a holster last week. Turned out looking really good . . . at least that was my opinion. It was for a little FIE .22 revolver . . . and so help me . . . I could easily have made a holster for a S&W 29 . . . 6 inch barrel . . . easier and quicker than that little rascal. May God bless, Dwight

-

Diluting Resolene

Dwight replied to Mungo's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Get a Skippy peanut butter jar . . . or the like . . . nowdays they're plastic . . . Mine has a mark about 1 1/2 inches above the bottom . . . and another about 3 inches up. Fill up to the bottom line with water . . . add resolene to the top line . . . I've got my mix. Then I grab my brush . . . dip it in the solution . . . and start painting. I paint it very wet to start with . . . to the point that moving my brush back and forth will produce a lather looking pile of bubbles . . . once I get that . . . I quit adding and start stroking . . . up and down . . . left and right . . . diagonal both ways . . . and brush until there are not bubbles or streaks. It leaves a very nice "semi shiny" finish . . . I have not liked the results I got from adding more water . . . if I wanted a duller finish . . . I'd pick another product . . . or just oil it . . . rub it till all the dye quit rubbing off . . . and call it a day. May God bless, Dwight PS: the brush in the picture is the 2 inch size . . . I actually use the 1 inch size on everything . . . belts included -

Actually, Sarina . . . I would only do that for a circle that I knew would be say 14 to 18 inches in diameter . . . or less . . . and only if I knew that the wrinkles on the inside would be a problem for the user or wearer. For example . . . if my customer wanted a "stuffed" nose piece on a bridle or halter . . . a showy piece . . . I would get the measurement from the horse . . . make a round piece that width and that diameter . . . because I know the nose of a horse is tender . . . and if I made the piece and there were several large wrinkles inside it . . . they could rub and irritate the animal . . . which I would never allow if at all possible. I'm a horse lover guy. It would probably be less of a problem for a collar for a small dog . . . but in that case . . . it would be an ugly and "not professional" looking product . . . so again I'd make the model . . . so my finished product looked really nice if at all possible. I have access to power tools and lumber . . . so for me to make a circle that is 13 inches in diameter is a piece of cake . . . taking me all of 25 to 30 minutes . . . I would staple or otherwise fasten the inslde piece of leather to the wood model . . . form the rest of the pieces . . . and then using an awl . . . punch thru the leather . . . into the wood . . . for the stitching. Once the pieces are made . . . I then glue them together with Weldwood contact cement . . . and they are easily stitched using my Cowboy 4500 or in some cases . . . sewing it by hand . . . with a stitching pony. For rivets . . . I just do the same thing . . . punch thru the leather into the wood . . . and not worry about it . . . I've done it many times. Not being able to do it any other way . . . I find that "necessity is the mother of invention" . . . and needing it done makes me invent a way to do it. May God bless, Dwight

- 21 replies

-

- foam padding for leather

- layer

-

(and 2 more)

Tagged with:

-

-

I've had .45ACP loops on a belt before . . . they were just made tight . . . never ever lost a bullet . . . Don't have any of mine move either that are 45 LC or .44 mag . . . or .357 mag. Where I put em they stay. It's all in doing it correctly the first time . . . May God bless, Dwight

-

I'm glad you got the job . . . you did well May God bless, Dwight

-

Yep . . . still here . . . glad to have ya back . . . May God bless, Dwight

- 21 replies

-

- foam padding for leather

- layer

-

(and 2 more)

Tagged with:

-

No . . . the leather goods I do . . . get line 24 snaps or a buckle . . . Never used line 20 snaps . . . even though I got a bunch of em one time in a trade . . . they gather dust in a little plastic holder. Hanging on to em just in case May God bless, Dwight

-

Nate . . . I'm 79 yrs old . . . have neuropathy in my hands and feet . . . along with a tad of arthritis. Snaps were an absolute pain for me the last couple of years . . . UNTIL . . . I was in an Amish fabric shop up near Mansfield, Ohio . . . saw these snap pliers . . . bought em . . . HAVE NEVER LOOKED BACK . . . I actually only bought one set the first time up there . . . but I got sick and tired of swapping out the male setting set for the female setting set . . . so I bought another set of the pliers . . . now I just grab one . . . then the other . . . then hang them back up. They have never done a bad job on my snaps since I got them almost 2 yrs ago. I think I saw them also in Hobby Lobby . . . Anyway . . . they work great . . . and while I didn't do it . . . they are fixed up so you can drill a hole in your work bench . . . run a wire down to a pedal . . . and you can hold the piece with both hands while you step on the pedal . . . setting the snap. Each set of pliers was about 40 bucks . . . and the set of line 24 snaps setters . . . was 20 bucks. You have to buy the setters separate. May God bless, Dwight

-

Now if it were saddle tan . . . full basket weave . . . with maple leaves . . . antiqued . . . Just kidding . . . it's great the way it is . . . and I'm much more into practical leather anyway . . . and that certainly will meet that requirement. May God bless, Dwight

-

I would love to have a true pattern for those you see on the westerns on TV . . . These are beautiful that you made . . . but I'm looking for the style that a typical cowpoke would have had . . . May God bless, Dwight

-

Yessir . . . good looking . . . May God bless, Dwight

-

Does anyone have a good saddle soap receipe

Dwight replied to ToddW's topic in Leatherwork Conversation

Last saddle soap I used . . . Bought it at Tandy's . . . Works pretty good . . . best I remember . . . have not used it in a while. May God bless, Dwight -

I messed with light burn a while . . . finally gave up . . . went back to LaserGRBL and it does everything I need. Maybe I'm just not fasisteecaited enough to use lightburn . . . May God bless, Dwight

-

I'm not sure what you mean by creasing . . . of you are making nose pieces . . . collars . . . etc . . . they are made to be round or rounded . . . they are not made to be straightened. The whole function of the technique I told you about it to make sure the pieces fit . . . it stays rounded . . . and it does not wrinkle on the inside most piece. May God bless, Dwight

- 21 replies

-

- foam padding for leather

- layer

-

(and 2 more)

Tagged with:

-

You can play the math game . . . or you can do it the easy way . . . Determine what would be the smallest you would probably make . . . cut out yellow pine circles that size. Measure and cut the bottom layer . . . then use a dress makers cloth tape measure to measure the outside of that piece. Cut the filler . . . lay it around the piece . . . measure it . . . cut the top piece . . . glue em together around your circle. You don't have to make one of every possible size . . . you could make say a 7 in dia . . . 8 in dia . . . 10 inch dia . . . 12 inch dia . . . and the 12 could be used for anythng between 10 and 12. Easy peasy. May God bless, Dwight

- 21 replies

-

- foam padding for leather

- layer

-

(and 2 more)

Tagged with:

-

Click the envelope in the top right hand corner . . . then click "compose new" Just like addressing an email. May God bless, Dwight

-

Move the telephone . . . you can put it on your nightstand . . . lol You'll have fun with that roller unit . . . my son and DIL love the glasses I did for them for Christmas Put their names and an image of their house on them . . . May God bless, Dwight

-

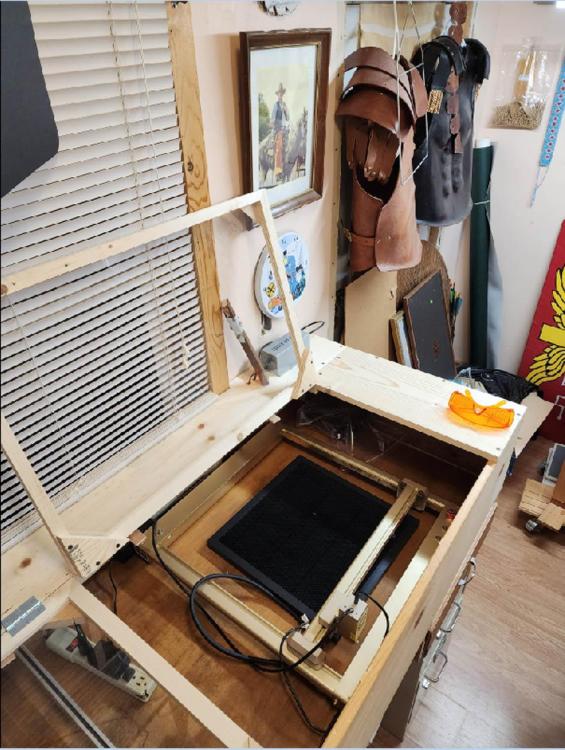

Well . . . here is the setup . . . Laser 3 is my low powered unit . . . laser 2 is the 10 watt unit . . . and laser 1 shows both in the box I built for them. In the bottom of laser 1 you can see a hole in the box . . . there is a corresponding hole and fan at the other end. I tested it tonight . . . wondering if the fan was powerful enough . . . it runs off a USB port . . . and works great . . . is quiet. I was burning leather . . . and none of the "aroma" slipped out where I was. Anyway . . . that's the setup. May God bless, Dwight

-

I dip dye exclusively . . . unless there is some mitigating factor that makes me do it otherwise. All projects . . . especially if it is any tan or brown lighter than "dark" brown . . . get a first dressing with neatsfoot oil on the hair side only. And if I remember to do that . . . it is after all the forming and stitching is done (unless it is a "white stitching" project). Depending on the piece . . . sometimes I do the darker brown or black . . . sometimes not . . . if the leather is more flimsy I avoid it . . . if it is more than average firm . . . it gets a dose. Let it set for 24 hours . . . and as much as possible . . . one "kinda slow" . . . but uniform . . . pass thru the dye pan . . . similar to the above picture . . . wipe off any excess with paper towel . . . and then lay it horizontal for about 20 minutes . . . then either hang up to dry . . . or go to the "hot box" . . . as needed. Did a bunch of belts for a show one time . . . dyed em and hung em up to dry . . . and re-dyed em all the next day. The dye had migrated down to the bottom of the hanging piece . . . they were all noticeable darker at the bottom than the top. NEVER did THAT again. I DO NOT have splotchy problems . . . unless I get too near the edge of a veg tan piece . . . where the leather is "harder" there. I can touch that up with a dauber though . . . BUT . . . I use only Feibings pro oil dye . . . and Feibings reducer . . . 4 oz bottle of each . . . mixed together . . . makes my dye. I only do 4 colors . . . normally . . . none of this "can you make it match my aunt's 70 yr old book bag?" stuff . . . learned that is a losing program. May God bless, Dwight

-

I just finished the doors for my "fully enclosed" work area for both of mine. The low powered one is something less than 1 watt I think . . . actually does beautiful work on shading or outlining . . . will definitely use it. The 10 watt will cut thru plywood (3/16 thick) like it really knows what it is doing . . . and I'm very happy it does. It'll be doing most of my pattern cutting once I get one simple last touch finished . . . gotta put an exhaust fan on it . . . I'll pop up some pics when I'm done . . . maybe even later today. I did some drinking glasses for my son /DIL for Christmas . . . we were all happy with that outcome . . . Will be doing key fobs like they are going out of style later on . . . more than anything else . . . just to use up the scrap . . . maybe make a buck fifty (lol) on the stack of em. One has a 16 x 16 work area . . . the other is 14 x 14 . . . both with adjustable height . . . Glad you are doing well with yours too. May God bless, Dwight

-

Not meaning to pick on you Thom . . . but compared to my laser cutter . . . yours looks like it was cut with a chain saw. I use a little air compressor with my 5 watt laser . . . and one thing for sure I make is key fobs . . . I wipe the edges of em down with a terry cloth . . . and they are good to go. May God bless, Dwight