-

Posts

5,258 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

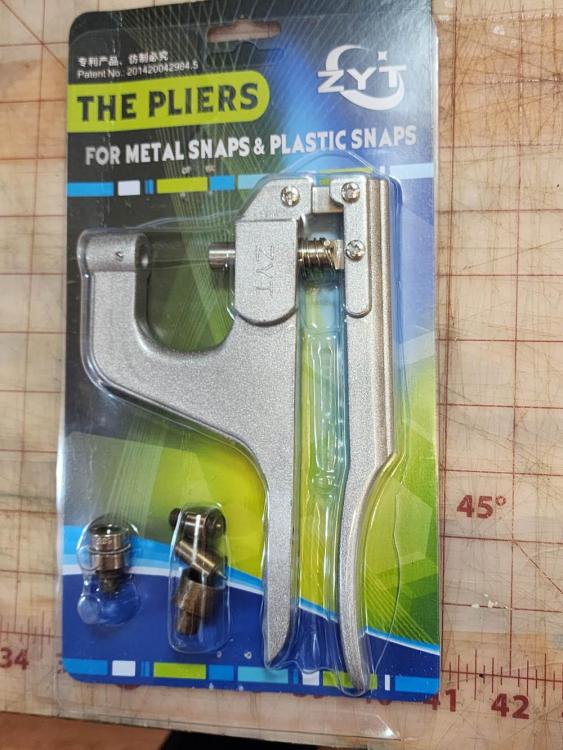

Etsy, Ebay, Amazon, Temu . . . they all have them. Be careful with Temu . . . theirs may be a knockoff . . . buy somewhere else. May God bless, Dwight

-

Hammering requires holding one piece of leather . . . sometimes two . . . a top snap part . . . a bottom snap part . . . a snap tool . . . a mallet . . . the snap anvil . . . over a small anvil or other very hard surface 5 or 6 items . . . having to be held with two hands. Sometimes it works . . . sometimes it doesn't. This tool works first time . . . every time. Simple as that. I don't have time to take a pair of side cutters . . . wiggle it between the snap part and the flesh side of the leather . . . cut off the bad snap . . . and then dig out the parts again . . . re install the snap . . . and hope the second time that it works . . . when using the exact same leather . . . it didn't the first time. May God bless, Dwight

-

Been using snaps for 20 + years . . . from Tandy . . . basically have never had any serious problems with them. I find when I do have a problem . . . it is not the snap . . . but the installation. If they are done right . . . they work. Best snaps in the world are not worth a dime if they are improperly installed. Take the time to learn to do it right . . . and you will be good. The picture enclosed is THE snap tool . . . almost impossible to not do it right . . . 35 bucks for the handle . . . 20 for the set of tools to go with it. You have to change tools from the male piece to the female piece . . . so I bought a second handle . . . don't have to waste time changing the tools. One of my better investments. May God bless, Dwight

-

Sandal mid and strap opinions

Dwight replied to okiwen's topic in Shoes, Boots, Sandals and Moccassins

First . . . I am not a sandal person . . . but I can be talked into something similar so to speak. PERSONAL OPINION: I will NOT buy a product like that with a stiff sole. The idea of them (for me) is comfortable . . . My favorite pair of footgear in the whole house is a pair of wool lined . . . suede . . . moccasins . . . and they have the very same leather on top as on the sole. OTOH . . . as I am sometimes an actor portraying a Roman Centurion from the days of Jesus . . . I wear a similar piece of footwear called a Caligae . . . which is a sandal made of three pieces of leather. The first is a piece of serious cowhide or horse hide or buffalo hide . . . it is the sole . . . maybe 14 or 16 oz if you can get it. The middle part (for the ones I make) are sewn to the sole . . . with the sole being heavily gouged for the stitches around the edge. This middle piece forms the pieces which go up around the foot . . . holding it on to the foot. The third piece is simply an inner sole . . . cut to fit inside the middle piece . . . it is the piece of leather on which the foot rests. There are no heels on this footwear . . . flat soles . . . no arch support . . . nothing but leather and the stitching. And yes . . . they are very comfortable. Spend an hour or so on youtube . . . use Caligae as your search word. They often show the sole part as being several layers of leather . . . this accomodates the hob nails they used. You don't want the hob nails . . . just one or at the most two layers for the soles. May God bless, Dwight -

First off . . . you are not Ford or General Motors . . . so the wide social presence is seriously not needed at the moment. But you can put up a very simple website for about 150 bucks the first year . . . show really good photographs of your product line . . . and invite questions. Don't attempt to do a JC Penny web site . . . remember the old axiom about keeping it simple. Second . . . by your own admission . . . you have little experience . . . and what you do have is not popular. You need to develop a style and product line first . . . something that YOU can do . . . that you are comfortable with . . . and truly like to do. For me . . . I will never develop a line of men's wallets . . . but belts and gun holsters are my forte. You also have a community . . . where you live . . . there are VFW . . . ladies aide's . . . other "gathering" places. There are also weekend community yard sales . . . etc. You are looking for a place where people congregate and have bulletin boards . . . or have walk thru customers. Post pictures on their bulletin boards with your name and phone number. MAKE SURE TO GET THEIR PERMISSION TO DO SO FIRST. I have some friends who run a gun shop . . . anyone asking about a gun holster . . . gets my phone number . . . and the usually become another customer. What you are needing is LOCAL traffic that will give you instant opinions on your product . . . good / bad / OK / bad stitching / wrong color / etc. . . . The necessary word is INSTANT . . . something a "social presence" will not give you. Selling on Etsy may generate sales . . . but feeback is long coming . . . and you cannot have a personal conversation about the product . . . like you would have at a community yard sale. You also can make a couple dozen items of what you want to make . . . and see WHAT sells . . . toss the stuff you have carried in your inventory to 6 months worth of sales . . . and it is still there. Get new stuff. It took me a half dozen weekend sales . . . I drove 75 miles one way to each . . . but it made all the difference in the world for my product line. Also . . . try to find something you have a natural affinity for. There are all too many "leather workers" on the interrnet . . . who have to have someone else make a pattern for them for every belt . . . every purse . . . every holster . . . every sheath . . . In short . . . they have no ability to imagine and define . . . do this first . . . then that . . . then that . . . etc . . . and come up with a completed product that you are proud of . . . and your customer is happy with. They could produce good looking leather Walmart bags . . . and not much more. Last of all . . . most important of all . . . don't be afraid of Ebay . . . it is a real good place to "try out" your idea of a product. If it does not sell in 90 days . . . kill the listing and try something else. And while you are on Ebay . . . figure out the average price to ship your product to your next door neighbor . . . and the person living in the most distant state. Add that to your asking price . . . and advertise "Free Shipping". Don't advertise 100% satisfaction guaranteed . . . but when you get even a half reasonable complaint . . . have them ship it back to you at your expense . . . and when it gets there . . . replace it with the complaint addressed. You will build customer satisfaction that you cannot build any other way. Make that Ebay listing for 1 single product . . . don't aggravate the problem with check boxes for size . . . shape . . . length . . . color . . . etc. If it is a 36 inch man's belt with rosebud stamping . . . put a really good picture of it on there . . . and advertise it as such. You can then use the same picture for one you advertise as 38 inch long . . . another at 40 . . . one at 42 . . . etc. That also prevents mistakes on size . . . color . . . etc. But last of all . . . have fun as you start out. Don't start in a product line that causes you grief making it. If you are not having fun doing it . . . find something else to do . May God bless, Dwight

-

I have one that is 20 years old . . . have no idea how many things I made on it . . . paid the 1K for it when I got it. I would consider it a stingy insult from you if you offered me 500 for it. I would probably take 800 . . . but there would be extenuating circumstances for otherwise. May God bless, Dwight

-

Maybe not . . . safety and mag disconnect are always on left side . . . can be on the other side but are not always. May God bless, Dwight

-

I gave up on that idea years ago . . . I use a glass jelly jar . . . unscrew the lid . . . use it . . . screw the lid back on . . . just make sure you don't get any glue around the mouth of the bottle. I use throw away "acid brushes" . . . little metal handled things from Harbor Freight . . . about a nickel apiece or so . . . start out the day with one . . . usually pitch it before starting out the next day . . . but sometimes it is still useable . . . especially if I did something late that last evening. Anyway . . . that's my system . . . and I have to toss a little thinner in it every now and then. May God bless, Dwight

-

You simply take the one side of the last piece of the puzzle . . . sand it with some 80 grit sand paper . . . and Weldwood contact cement it where it belongs. OR . . . put a concho on top of the cup . . . threaded into the last piece of the puzzle . . . hidden in it's lodging place. May God bless, Dwight

-

If you go to Google . . . type in spur strap acrylic templates Hit your enter button . . . you'll probably find more than you bargained for there. I personally created my own with a couple of pairs of spurs . . . took one afternoon of messing around . . . and maybe 4 sq ft of junk leather. I don't have a market for them here . . . but I have a few samples in case someone comes by. May God bless, Dwight

-

In many cases . . . yes . . . it is easier to cut that way. It is also easier to stick your pattern with a thumbnail . . . scratch it with the knife . . . or smudge the devil out of a complicated cut. The above are the reasons I cut mine dry. May God bless, Dwight

-

Pinto . . . just a suggestion . . . 24 years ago . . . I bought a Tippmann Boss . . . used it for holsters, knife sheaths, belts, wallets . . . and whatever until 4 years ago . . . replaced it with a cowboy 4500. The Boss is a good place to start . . . find out what you really want to do . . . and will get you going. Good used ones can be had for 800 or so . . . May God bless, Dwight

-

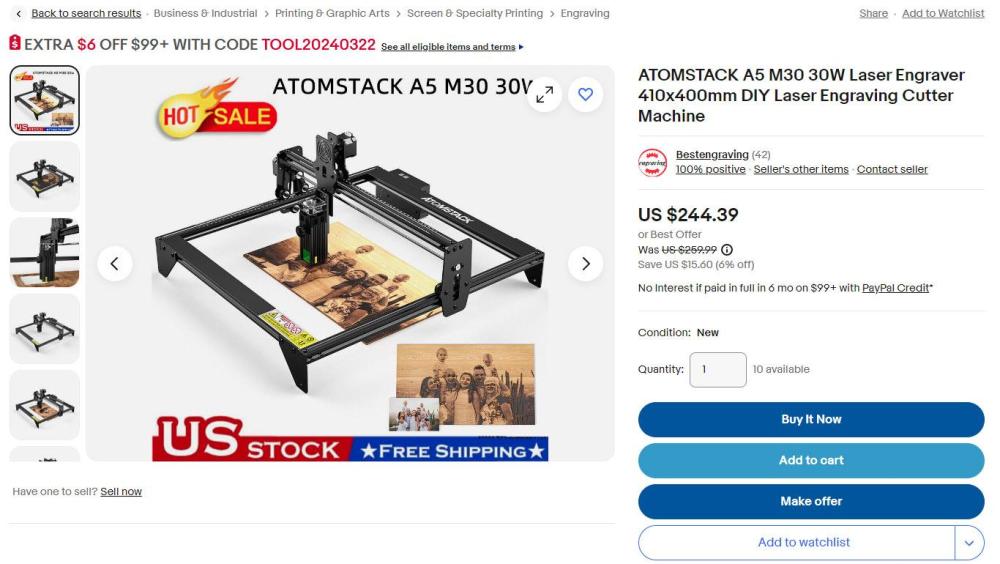

Let me suggest to you that you spend just a medium amount of money . . . buy yourself a small laser engraver. I cannot vouch for the machine I'm picturing as mine are both different brands . . . but this 30 machine should cut your leather very easily . . . set it up so it does it in 2 passes . . . you will want a air blast kit with it . . . you can put the designs on it first . . . then let it cut it out . . . Cutting leather stinks . . . need to do it in a well ventilated area . . . or fix up one like I did . . . but the end results are fabulous . . . May God bless, Dwight

-

Look for the spools that kind of stand upright . . . maybe 5 or 6 inches tall . . . on a black (all I ever used were black) plastic spools designed only to sit on one end. Tip them over and look for a size number . . . sometimes it will say "Size XXX" and sometimes it will be just XXX. The ones you are looking for are "138, 207, 277, 346, 415" For most holster, belt, knife sheath work. . . 138 is too small . . . 415 is a bit large. Most use 207, 277, and 346. I almost use 346 exclusively. Hope this helps May God bless, Dwight

-

How do I fix this inconsistency in leather stain?

Dwight replied to Springrose's topic in How Do I Do That?

"Fixing" that dye job unfortunately would be best done re dying it in a darker color or black. What you need to do to prevent such occurances in the future . . . is first apply a light coat of neatsfoot oil . . . and then give it about 24 hours to disperse itself eavenly thoughout the leather piece, Only apply it to the hair side (slick outside side of the leather) Lighter tans are especially vulnerable to that splotchy look without the oiling. May God bless, Dwight -

Welcome from Marion Ohio May God bless. Dwight

-

Line up Lining and Outer leather in Zip-Around Case

Dwight replied to matcanada's topic in How Do I Do That?

-

Any idea on how to make one of these?

Dwight replied to MasonLikesLeather's topic in How Do I Do That?

What he ^^^^ said -

Two thicknesses . . . identical thickness of each . . . will do a lot better than one piece of the same total overall thickness. THAT is why most good CCW belts are double layer . . . stitched and glued . . . and for NO change . . . add a stainless steel liner. May God bless, Dwight

-

Dyed leather is returning to original color??!!

Dwight replied to AmericanSon's topic in How Do I Do That?

In 20+ years . . . I have had one similar problem. I could not find the exact shade of grey I wanted for "MY" holster . . . so I invented it. I kept playing with black, saddle tan, and british tan until it did what I wanted . . . and I was some kind of seriously glad. I wanted almost a battleship grey for it . . . Dyed the holster and belt . . . all was good . . . about a year later I noticed the black seemed to be leaving . . . giving me a brownish red holster . . . with a mostly grey belt. Holster keeps losing the black . . . belt I think has stabilized . . . Not big deal . . . i'ts my personal holster . . . and I can live with it. Just glad it was not a customer . . . May God bless, Dwight -

I can name a half dozen I've known of my my lifetime . . . once were great . . . good food . . . good service . . . good price . . . friendly people A piece at a time . . . it all went to hell in a broken bucket . . . and it was usually the quality of the food that went south first. May God bless, Dwight

-

Concealed carry holster for Rock Island armory 1911 3.5 bull barrel

Dwight replied to badhatter1005's topic in Show Off!!

What he ^^^^^^ said . . . looks good. My only comment is I kind of envy you . . . my very first CCW holster was a paddle . . . and my son carries a Glock 19 . . . most of the time in a paddle. Much as I tried . . . I just could not get comfy with it . . . It was in my way driving . . . no matter where I put the thing . . . the weight of it hanging on my belt wanted to pull my britches down . . . and I finally just gave up . . . went to an IWB . . . pretty much stayed there ever since. I do a shoulder holster occasionally . . . and a slide cake OWB . . . also occasionally. But I'm glad you found your system. May God bless, Dwight -

Actually,Sheilajeanne . . . you and I are in similar canoes . . . my closest Tandy is basically an hour's drive away . . . and like you . . . I want to see what I'm getting on the leather. I'll call Scott and have them send me conchos . . . tools . . . dye . . . etc . . . but for the skins, I want to see that dude. I also long ago developed the habit of taking a micrometer with me and buying the thickness of leather I want. The range of thickness for any skin is pretty broad . . . and I have certain thicknesses I want for the work I do. Makes life a whole lot easier when I don't have to stuff it thru that little machine that works on the thickness . . . May God bless, Dwight

-

Bean counters are the absolute worst possible candidates for anything but bean counting . . . most of em I've met were just above sub-human . . . May God bless, Dwight