-

Posts

5,248 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

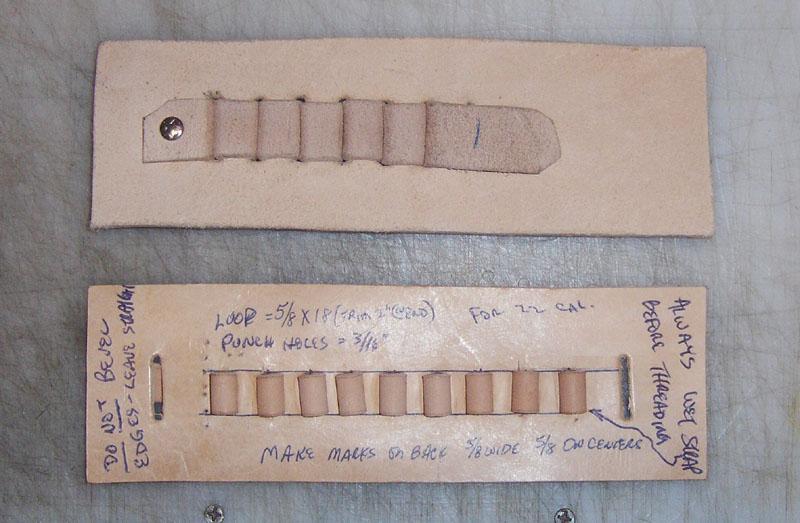

Many cops from decades back carried ammo in a belt carrier for their revolvers . . . very similar to the Ebay picture here. https://www.ebay.com/itm/Wild-Alligator-leather-Cartridge-Ammo-case-Belt-Carrier-Gator-30-cal-357-FB7/202642612871?hash=item2f2e70e287:g:c5MAAOSwH2RcUMdr If you want to make one of these . . . take a suggestion . . . make the carrier portion out of 7 oz vegetable tanned leather . . . make the loops out of 4 oz vegetable tanned leather. Cut the slots for the loops 1/16 of an inch shorter than the width of the loop material . . . get the loop material very wet (not dripping . . . just wet) . . . and form them around the actual type of ammo the person will be carrying. Don't use snap caps . . . unless you plan on hammering the ends of the cartridges while forming them. Snap caps many times are not the size of real ammo . . . Don't worry about the leather "stretching" . . . if you form it right . . . that belt carrier will be serviceable for 20 years providing it is not seriously abused. Closing up the bottom under the cartridge makes you have to drag it out of the holder by it's rim . . . a precarious thing to have to try to do if you seriously need to reload that two shooter. Leaving the bottom so you can lift the bullet up by the index finger . . . is much quicker and easier. If you make it quick and easy with the bottom covered . . . the bullets will probably fall out given the chance. And yes . . . I have made a bunch of cartridge belts. Use the pictures below to show you how to lace the loops. Put a stitch or rivet at each end of the loops. As you can see . . . the loop goes into and out of the same hole as it makes the loop. May God bless, Dwight

-

knife sheath for a finnish blade.

Dwight replied to WyattEarp's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Beautiful May God bless, Dwight -

Double Buscadero Belt Sizing

Dwight replied to Forester's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I'll bring the customer in if I can . . . take some scrap leather . . . make a "belt" that is 4 inches larger than the most used hole in his standard belt . . . stick a buckle on the thing and have him put it on . . . below his regular belt. Line up that hole with the snap on the front of his jeans. Place marks on the left and right side of the person . . . on this "belt" where the seams of his jeans are. That mark will be placed at the back side of the barrel of the weapon in the holster. Make the holsters first then do the outline of the belt . . . place the weapon in the holster . . . bring it around on the outline of the belt (this is done on a series of manila folders taped together) . . . and mark the backside of the barrel . . . that is the center of the holster placement. At least that is how I would do it. But I do my best to not do buscadero belts . . . single holsters like Clint Eastwood wore usually are fairly easy to do as they can be shifted as needed . . . better yet is the rig that John Wayne favored . . . they are even easier to make. Buscadero's were truly never a part of the "real" old west . . . it was a Gene Autry / Lone Ranger / Roy Rogers invention to give it some pizazz on the big screen. Even Marshall Dillon's rig . . . or the Have Gun will Travel . . . they were only sound stage stuff . . . not real. May God bless, Dwight -

Double Buscadero Belt Sizing

Dwight replied to Forester's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Neither . . . measure the "most used hole" in the belt the person wears today . . . Add 4 inches . . . that is the measurement from the outside of the buckle on the buscadero belt to the center of 7 holes on the tongue of the buscadero belt. Doing it that way . . . it has never failed me. But . . . yes . . . you do do the measuring the bottom way. May God bless, Dwight -

Chest rig for a Glock 26

Dwight replied to Hags's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Why do I get the feeling some of y'all watched the movie Tombstone?? Doc Holliday is alive and well . . . at least in spirit . . . May God bless, Dwight -

Here is an example of the weaving . . . Very little bulk . . . and even when the leather of the belt stretches (as all leather does over time) . . . the loops don't have anything to pull them wider as is possible with the sewn on loops. Plus . . . I only have a Tippmann Boss sewing machine . . . I can weave one of these belts in about half the time it takes to sew it . . . May God bless, Dwight

-

Well . . . james . . . first off . . . don't do what you are talking about. THE way to do cartridge belts is to weave them . . . not sew or stitch them. Others on here will disagree . . . but a sewn loop will one day become a loop that the bullet either falls thru completely . . . or falls out of while you are walking down the road . . . in my opinion. The pictures tell the way to do these . . . basically you punch a hole in the belt . . . weave the leather loop thru the hole . . . then back thru that same hole . . .leaving a loop of leather on the outside to hold the cartridge. All you do is rivet both ends . . . no sewing at all. May God bless, Dwight

-

Doc Holiday Shoulder Holster Pattern Needed

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

My email is good . . . check the PM up above . . . May God bless, Dwight -

Doc Holiday Shoulder Holster Pattern Needed

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That would be quicker and easier . . . Measure his belt . . . from the outside of the edge of the buckle . . . to the hole he uses most . . . and get his jean's size. Lemme know. Also need to know what gun he plans to use. AND . . . is he left handed or right handed?? May God bless, Dwight -

Doc Holiday Shoulder Holster Pattern Needed

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Good morning James3 . . . yes, I guess you could talk me into making another one. But you are back a ways in the line of "stuff" I'm doing. Among a pile of "other stuff" . . . Got a Fury holster to do (from Brad Pitt . . . tank commander in the movie "Fury") . . . which is a kind of a complicated piece of work. As well . . . a full size 45ACP in a shoulder holster . . . with 2 mag ammo carrier under the other arm . . . all incorporated into a pair of leather suspenders . . . for a fellow who steps down the road at about 6'3" and 300+ lbs. While having to put up with more snow this winter than in the last 3 or so . . . But we'll get to you . . . but gotta find the patterns first . . . somewhere in my menagerie of a leather shop. I'll need your height / weight / right or left hand / gun you plan to use / color you prefer etc . . . May God bless, Dwight -

Nylon or polyester thread

Dwight replied to ps0303's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I use waxed 346 nylon . . . hand stitching . . . Tippmann Boss . . . or any other leather sewing. I seldom . . . emphasize seldom . . . use anything else. May God bless, Dwight -

New Holster For Special Pistol

Dwight replied to AzShooter's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Your holster reminds me of one I did a number of years ago. Long barreled .22 . . . think it was a Browning . . . had a scope on top of it . . . should have gotten a picture of it . . . but forgot to. Yours looks really good . . . May God bless, Dwight -

Something Different

Dwight replied to MarlinDave's topic in Gun Holsters, Rifle Slings and Knife Sheathes

In order for something like that to work and work right . . . you need to make a form similar to that part of your leg . . . pad it so that it correctly mimics it . . . put on an old boot that simulates what you have . . . then put the base piece of leather around it . . . make a form fitted outside holster piece . . . out of wetted and dried veggie tan . . . (drying it in a 140 deg oven will make it more sturdy . . . THEN . . . using your "leg model" put the little hand cannon in the outside piece . . . lay it up against your model . . . mark where the edges should be . . . glue it and sew it there. That's how you make those things . . . not meaning to pick on your effort . . . but you used sloppy floppy leather . . . and did not allow for it to be pulled up tight when it is put on. That application needs a form fitted holster outside part at least. I would have made two . . . one for the pattern . . . and the second one the whole thing would have been wetted . . . put on the form . . . and tossed into my hot box to dry and seal the form of it. May God bless, Dwight -

What you need to do is get the back wet . . . not enough to come up and mess with the tooling . . . but wet none the less. Then take it in your hands and re-form it the other way . . . so when you lay it down so the tooling is up . . . then the belly or center will look bowed up. It will take a bit of time to do this being careful not to mess up the tooling . . . but if you keep bending with your fingers . . . holding down the sides . . . pushing up in the middle . . . you'll get it. Then if you have a hot box . . . put it in there to dry . . . if not, an oven at 140 deg F or less . . . lay it down in there . . .tooling side down . . . let it dry. You can then put it on the wall . . . the screw will pull it flat . . . but only pull it tight enough to put the dimmer handles back on. A couple coats of Resolene on the front and the back will help it maintain that new shape. May God bless, Dwight

-

Very nice.......... May God bless, Dwight

-

Zipper Experts? How to Sew This Zipper Connection

Dwight replied to dzsteez's topic in How Do I Do That?

On the middle picture . . . if you take a needle and some black carpet thread . . . go up about 10 brass pieces . . . sew it together there . . . you shouldn't have any trouble. The middle piece on the zipper puller will catch on the threads and stop. At least that is the way I've done it in the past and it worked like a champ. May God bless, Dwight -

Some Decorated Functionality

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Cattledude . . . It will drop 5 of them under a Sacagawea dollar coin at 100 yds . . . hoping for some coyote action if I can ever get my rifle ready . . . my quad ready . . . and the weather to cooperate here. Seems like one of them wants to argue all the time. May God bless, Dwight -

Some Decorated Functionality

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Don't know for sure, Chuck . . . Bassett makes it from Dripping Spring, Tx . . . But I'm not sure about the Garand . . . I think the empty rounds go pretty much straight up . . . the M14 tosses em out the side. My empties all land in a nice little 4 ft circle about 6 ft in front of my shooting stand . . . and 2 ft to the right. My Garand shooting always saw em go up high past my face . . . usually to the right and behind me slightly. My AR's all shoot that way too. But give em a call . . . worst they can say is no. May God bless, Dwight -

Got a new 50mm scope . . . had to change the mount . . . new cheek riser. Added the logo from Destroyer Squadron 7 out of San Diego . . . both my Navy ships were part of it . . . May God bless, Dwight

-

I dye my own leather goods for the same reason cars come off the assembly line in different colors. They are done to order . . . one red, two black, one grey, three blue, etc . . . I can basically dye my leather any color I want (within reason) . . . except white. THAT I do buy . . . white. May God bless, Dwight

-

I was asked if I could do one . . . fortunately it was a small semi auto . . . with a laser that really looks and acts like it is a piece of the original equipment. All the sides were smooth transitioning from gun to laser . . . no humps . . . no bumps . . . etc. That made just adding an inch or so here . . . another over there . . . round it all off in front . . . etc . . . The trick was making it tight enough to be secure . . . loose enough that it did not cause problems . . . As it turned out . . . I shipped it to the fellow . . . he responded that he was not ready to place the order . . . did not have funds to pay for it as they were going thru a serious couple of problems in their lives . . . and the reason he thought about getting one was for his wife to have with her as her transit to work or back . . . was at zero dark thirty . . . and he was laid up and could not work at the moment. Wound up being a charity job . . . May God bless, Dwight

-

Now that is a good thing to know . . . thank you. May God bless, Dwight

-

Take a needle and poke it . . . it's a straight thru hole . . . all you need to do is clean it out. May God bless, Dwight

-

I've never seen one "in person" . . . but like you . . . have in the movies and television programs. It's a "safety" type . . . supposedly only if you know the secret . . . I wouldn't make one or have one . . . too complicated in my book . . . because like Murphey says . . . "If it can go wrong . . . it will . . . and at the worst possible moment". I couldn't have my holster (or a customer's) failing to open at that critical time. May God bless, Dwight

-

There is a guy who hits our county fair . . . all his belts are about 50 inches long. He measures you . . . cuts the end off the belt you chose . . . punches 5 holes in it and he's done. They're generic belts . . . all pressed, none stamped . . . but the would-be wranglers lap em up like candy. May God bless, Dwight