-

Posts

5,257 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

Suspenders

Dwight replied to Dwight's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Here you are my friend . . . the grid on that table top is all 1 inch squares . . . The white piece with the kinda circle at the top is the back piece . . . add 2 1/2 inches to what you see there on the grid . . . that is to fold under and rivet. The shorter white piece is the adjustment piece up front with the buckle . . . add 5 inches to what you see . . . to fold under and rivet. I make the actual suspender straps 1 1/4 inches wide or 1 1/2 inches wide . . . depending on what they are doing . . . etc. The brown strap is part of a test pair I use to measure the person with. I had to take them apart for another reason . . . and don't have them back together or I would show you them. But anyway . . . that's the pattern that will get you the suspenders I made shown earlier in this thread. Have fun. May God bless, Dwight -

Suspenders

Dwight replied to Dwight's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

What I do is simply measure from the belt loop in the center of the back . . . up over the shoulder . . . to the front loop on the britches. Then it is a matter of deciding "Y" shape or "H" shape . . . making a pattern for the pieces . . . and going from there. I don't have time right now . . . but later today if I can . . . I'll show you my patterns laid out on the work bench for that last pair. May God bless, Dwight -

Suspenders

Dwight replied to Dwight's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

No . . . if they are adjusted to the right size . . . and have smooth leather on the inside so they slide easy . . . they're no problem. That's the 4th pair I've done in the recent past . . . none had elastic . . . no complaints at all. May God bless, Dwight -

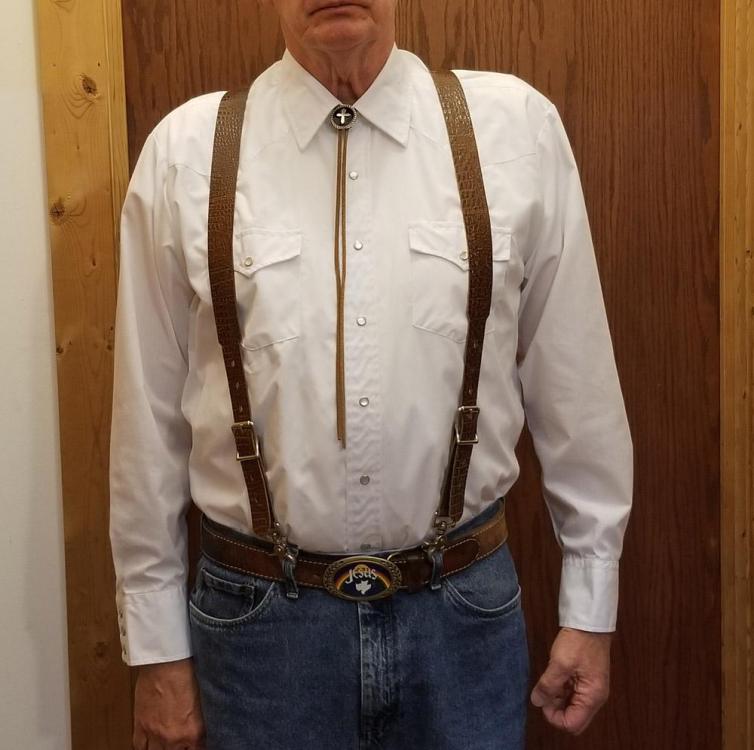

Three of the last 5 projects have involved suspenders . . . of one sort or another. Finally . . . I got to do just a pair of suspenders for a preacher friend of mine. It's imitation gator hide . . . two layers bonded back to back with Weldwood . . . horse tack to hold em on the belt loops . . . buckles up front to adjust with. Just might up and make me a pair. May God bless, Dwight

-

It probably is industry standard for those promoting gunbelts with stiffeners . . . but that is very much like saying that Chevrolet is the industry standard for trucks. Just one opinion . . . that may or may not be shared with the rest of the world. May God bless, Dwight

-

What kind of stamping are you planning on doing . . . That will be the first determining factor. May God bless, Dwight

-

Total New Rig Design For Me

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Ummm . . . that belt he's wearing I made 10 or so years ago for him. It's over 50 inches to the most used hole. May God bless, Dwight -

Total New Rig Design For Me

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks everyone for the good words . . . It was a case in itself . . . after we first got started . . . he had to go out west for a few weeks . . . got covid . . . Came home . . . took a long time to get well . . . Original plan of front to back double suspenders wound up getting scrapped in favor of the three legged design . . . Had to add legs to the holster and mag pouch that way . . . I got a bunch of interim orders I would work on when he wasn't available . . . all in all it took a bit over a year to get it on his shoulders and out the door. But it was fun. May God bless, Dwight -

If you use 4 layers of veg tan . . . say 10 oz . . . 2 of them put together with Weldwood contact cement for the front and 2 for the back . . . you can put neatsfoot oil on the two interior layers to keep your sword from rusting. The contact cement will keep it inside the leather. Make sure to put a welt all around the outside of the sheath . . . and cut it so it fits within 1 1/16th of an inch of your blade. The welt should be 8 oz or so. Contact cement that welt to the back slde of the sheath. Next . . . mold the leather to your sword . . . by wrapping your sword in 8 or 10 mill plastic sheeting (two wraps is plenty) . . . and wet mold the two halves to your sword. Lay down a very smooth 1 x 4 board . . . cover it with parchment paper (your wife has it in the kitchen if she bakes). Lay down the back side . . . insert the sword . . . put on the front, carefully aligning the edges all the way around . . . more parchment paper . . . and another very smooth 1 x 4. Add several wood clamps the length of your sword and tighten them uniformly up and down the sword . . . not super tight . . . just enough to get the mold of the sword impressed into the center two pieces of leather. Leave it for an hour or so. Put the sword and leather parts in a cardboard box with a couple of 100 watt lightbulbs at the bottom . . . put a thermometer in there and keep an eye on it . . . don't let the box get above 145 farenheight . . . but you do want it to get up to 130 degrees. In at least 3 places . . . wrap plastic . . . then masking tape . . . to keep the pieces lined up while they dry When it is fully dry . . . it will be really hard . . . you can probably knock someone out with the scabbard alone. Oil the inside two halves of the scabbard . . . SPARINGLY . . . and if you want to do any stamping on the outside . . . put the sword back in . . . lay the bottom (keep it dry) on a couple of towels . . . and gently dampen the top outside layer with a sponge . . . and stamp your leather. Put it back in the box to dry. Contact cement the top to the bottom . . . sand the edges smooth . . . bevel . . . sew it and finish the edges . . . and you will have probably the best scabbard in your knights group or whoever you are "swording" with. You can from time to time oil your blade . . . just be careful about getting the inside of the sheath super wet with oil. That was the process I had devised for my own sword (see pictures below) as one of my alter egos is Centurion Salvatorus Antonio, the Centurion of Capernaum. I got behind in my schedule . . . and just ordered my scabbard . . . and it turns out it is leather made in a similar fashion as I explained. I would never hesitate to use that scabbard as a weapon itself if it was all I had. I think I could knock out a prize fighter with that thing. May God bless, Dwight

-

From what little vinyl experience I've had . . . just one note of caution. You will have to have that foam trimmed REALLY close to the shape you want it. Even marine vinyl . . . thick and tough as it it . . . it also is unforgiving if there is a valley or hill in the foam. That valley or hill will show up worse than coal soot on newly fallen snow. AND . . . actually cutting the foam just a tad bigger allows the vinyl to cover up some of those problem areas. Leather is much more forgiving (and problem hiding) than vinyl. May God bless, Dwight

-

A long time friend of mine (50 yrs + ) asked me a year ago if I could make him a set of suspenders that would incorporate a shoulder holster . . . mag carrier . . . and of course, hold up his britches. Between sicknesses . . . travel . . . and a few other things . . . took over a year to get it done. He drove off with it on yesterday . . . pleased as punch. I felt good making it for him. May God bless, Dwight

-

Have fun . . . just around the corner from you up Marion way. May God bless, Dwight

-

It's a bit tricky . . . but you can also take the large piece of leather (biggest ya got) . . . and cut a running piece around the outside edge in a circle . Keep cutting . . . coming in on that circle . . . and you can get 15, 20, 30 ft of length . . . all one piece. May God bless, Dwight

-

Wanting to build shoulder holsters

Dwight replied to Hags's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Joann Fabric . . . they've got it or can order it. I've never used elastic on any of the many I've built . . . mine are all leather . . . Buy one . . . from a good maker . . . get a used one cheap on Ebay . . . see how they did it. May God bless, Dwight -

Just a giggle for y'all . . .

Dwight posted a topic in Gun Holsters, Rifle Slings and Knife Sheathes

A friend asked me a week ago if I had a Taurus G3 . . . I answered yes. He then asked how hard it would be to make a box holster for one . . . looks like you got a meter or a book or something like that on your side. Told him it was a piece of cake. Made it . . . took it to him for final fit check . . . but not worried because we both got G3's. Welllllllllllll.................. his G3 turned out to be a G3 . . . mine is a G3C . . . 5/8 of an inch shorter barrel. Now I'll be making it over . . . and I'll have a G3C box holster in the plastic tub with the others I've collected over the years. God ahead and giggle . . . I have been . . . or I'd have to go bust something up. May God bless, Dwight -

30.30 leather buttstock bullet loop cuff

Dwight replied to GardeninginCalifornia's topic in How Do I Do That?

Uhh . . . no . . . the loops always come out the exact same size . . . because the "form" that makes them . . . is the bullet that will be held in them. And yes . . . wet molding would probably describe the process accurately. OK . . . why would you want to integrate a rubber butt pad with a leather butt cover and shell holder . . . with a possible cheek riser on it?? The cheek riser and butt cover . . . they go together well . . . A butt cover . . . and cartridge loops . . . they go together well . . . cover, riser, and loops all go togetherwell . . . But a rubber butt pad??? I actually make cheek risers for scope shooters and they work well for some iron sights . . . I just lace em on like the pics enclosed. This one in the pic used brass grommets . . . it was a test run . . . didn't work out. We just punch holes in em now . . . and lace thru the holes. May God bless, Dwight -

30.30 leather buttstock bullet loop cuff

Dwight replied to GardeninginCalifornia's topic in How Do I Do That?

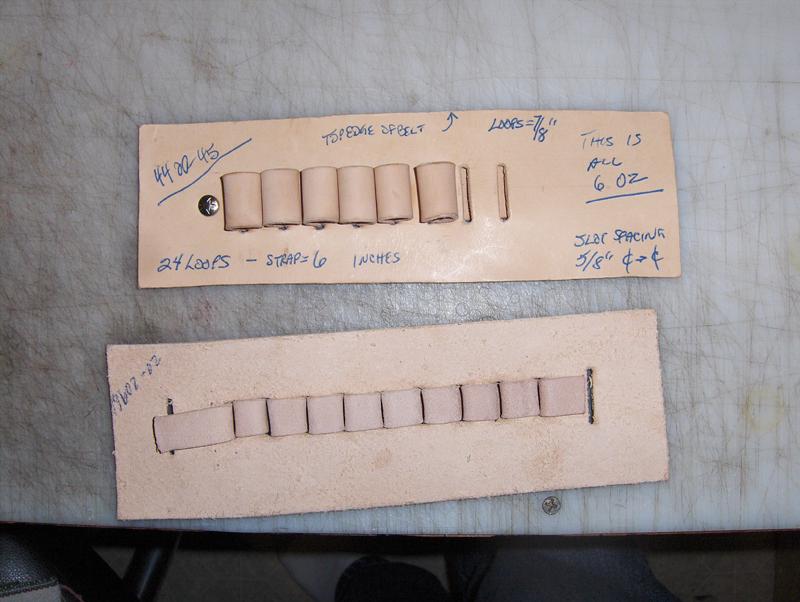

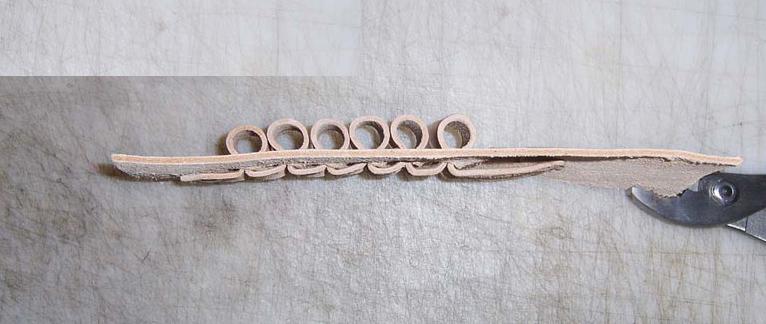

Actually . . . I made em so when the belt was laid down on a table . . . the loops touched each other. Didn't have to worry when it was being worn . . . rounded backsides always separated them a tad. I tried following the sewing idea one time . . . doubt if I ever will do it again. This takes about the same amount of time . . . but I like it much better. besides that . . . sewn loops have to be sewn back somewhat behind the cartridge . . . or over time . . . they get loose and when the belt is taken off . . . clink clink clink . . . bullets on the floor. May God bless, Dwight Check the above post May God bless, Dwight -

30.30 leather buttstock bullet loop cuff

Dwight replied to GardeninginCalifornia's topic in How Do I Do That?

I just looked at it real quick . . . noticed one thing I forgot . . . when you cut the leather for the belt loops . . . cut it about 1/16 of an inch wider than the slots you are using. That way when it dries . . . it dries with a nock in the leather at both ends of the slot . . . and does not allow the loops to move. The fellow who gave me the idea also said he used calf leather. I've never been able to get any calf leather here . . . so I've just used veg tan cowhide . . . have never had any real problems. May God bless, Dwight -

30.30 leather buttstock bullet loop cuff

Dwight replied to GardeninginCalifornia's topic in How Do I Do That?

For the last 20 years + I have made cartridge loops mainly for gun belts similar to Marshall Dillon and others like him. I used a design I copied from some place . . . I've long since forgotten the originator . . . although he is certainly an intelligent fellow. The design uses a loop system . . . where you punch a hole . . . pull the cartridge leather up through the hole . . . around the cartridge . . . then back down thru the same hole. You use the actual cartridge . . . NOT AN EMPTY ONE because they have been shot and have expanded somewhat . . . and you end it with rivets at each end. You would not use rivets . . . just make the two ends go out an inch and a half or two . . . allow the leather to dry . . . then contact cement them to the backing leather . . . and it'll never move. You do the work with dampened leather . . . slightly wetter than you would if you were stamping it with a design. Pull the loops tight around the bullet . . . and what I do is take the bullet out once I have gotten about 8 or 10 of them done. The loop will be set by then . . . and pulling out the bullet allows them to shrink just a very slight bit . . . making the loop tight to hold the bullet after it dries and you put on the final finish. I use resolene . . . it works great. Just do not put it inside the loops. Look at the photos enclosed and holler if you have any questions. You will like the finish product I am sure. May God bless, Dwight -

Looking at the tool . . . . and the price . . . . I'd run from it. My 20 yr old Dremel is still working . . . does not work as good as it did back then . . . but I doubt if the Detroit will last that long. And my Dremel tool alone was almost twice that price. Best wishes . . . may God bless, Dwight

-

OK, Folks . . . the project you all helped me get done is there in the Gallery. Thanks again for the advice and encouragement . . . May God bless, Dwight

-

Making bulk stock for Belts What sizes to make?

Dwight replied to mason1800's topic in How Do I Do That?

I had a guy want me to make him a 53 inch cowboy belt . . . took a while to make it . . . He needed a 56 when he came to pick it up. Fortunately I was able to salvage the job by making a new tongue and installing it for him free of charge. May God bless, Dwight -

Sometimes something is staring you in the face . . . and you cannot see it. I never gave a thought to how it could be arranged to work out right like that. Just thought ya stamped it and bordered it . . . and ya was done. That's part of why I never messed with it before . . . when I did try the results were much less than stellar . . . Thanks again . . . may God bless, Dwight