-

Posts

5,265 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

Using a Vacuum Bag . . .

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I only paid like 7 or 8 bucks for mine . . . I could not find the exact one I bought years ago . . . but this is the nearest I found . . . https://www.ebay.com/itm/391876111610?hash=item5b3da2ecfa:g:gKcAAOSwkklZpdPd I didn't read all the description, etc. . . . but I think this would work. May God bless, Dwight -

Don't look like it would be too hard to make if you got a board . . . pair of pliers . . . some super glue . . . and some # 9 horse fence wire. Go for it . . . May God bless, Dwight

-

Using a Vacuum Bag . . .

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

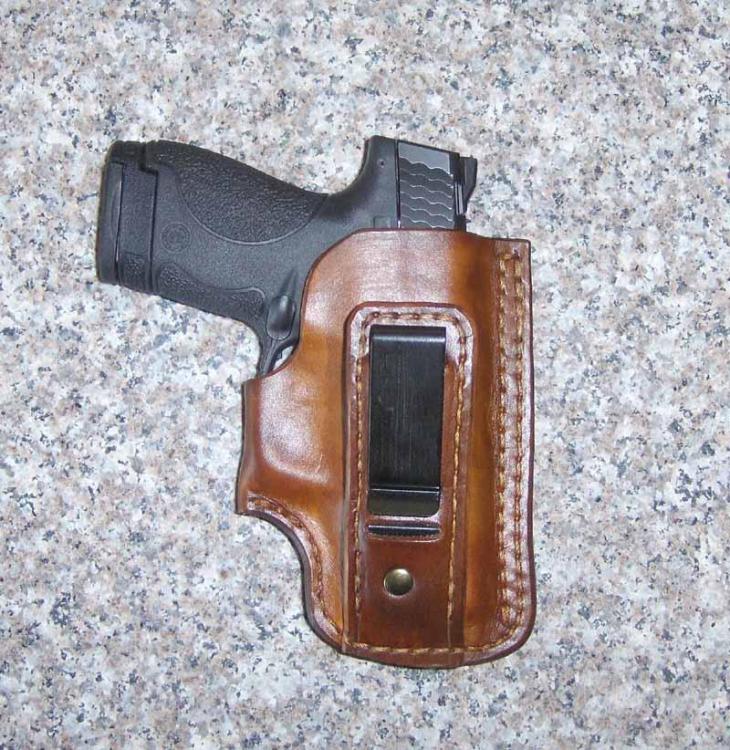

It's a good idea . . . but actually I was surprised the first time I used it . . . the vacuum sucks a bunch of water out of it . . . but it kinda gets to a certain plateau and it doesn't seem to get much more out. The pieces dry really quick though. I started out not having any one to ask . . . had to play "try and see" . . . my basic process is what you saw . . . as most all of the holsters I make are flat backed . . . even the pancakes. I found the regular pancake holster to be far, far less comfortable than a flat backed one . . . and the flat backed ones still have good retention. May God bless, Dwight -

Using a Vacuum Bag . . .

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Truthfully . . . I don't think so . . . but I've never taken a micrometer to it to find out. I pretty much know what size I'm planning on using for what gun and what holster . . . and I just form it . . . sew it . . . finish it . . . and send it. The bag is easy . . . getting that piece off ebay to suck the air out of the bag was the hardest thing of all . . . May God bless, Dwight -

Mike . . . check the video I posted on the vacuum bag. May God bless, Dwight

-

In another thread . . . we discussed using a vacuum pump and a vacuum bag to form holsters. One of the folks asked for some pictures of my "system". Here is a short video of what I do . . . and how I do it. https://youtu.be/3KS1hAQ5c3U May God bless, Dwight

-

I know without a doubt that I will never do that . . . won't be able to find the necessary equipment to do it with . . . but it sure was fun going thru the article and seeing how you did it. Would love to come to your shop some day . . . we'd share a box of doughnuts . . . and together we could make a half dozen items. I'm fascinated by new processes . . . have more process tools than most 4 or 5 guys combined . . . but this is a new one for me to see. Thanks for the info . . . may God bless, Dwight

-

As stated earlier I use a vacuum pump designed to evacuate an air conditioning system prior to re-charging it. It will pull close to a 30 inch vacuum . . . which will suck wet leather down against the model blue gun or real gun . . . and not think twice about doing it. I use a special plastic bag I made myself from clear vinyl bought at Joann Fabric store . . . edges sealed with Weldwood contact cement. A vacuum pump and vacuum seal bags that is nothing more than a food protection device cannot pull that kind of vacuum . . . and if it could . . . I would think it would suck a hole in the bag . . . but I do not know that for certain . . . it may not. But I've seen meat protected that way . . . and it is a great system for that. I just don't think it has the muscle needed for forming holsters. And . . . it depends on what is going on . . . sometimes I use a blue gun model . . . if I have it . . . sometimes the actual gun . . . sometimes a wooden model I have made in my wood shop. They all work about as well . . . one or the other . . .whichever I use. May God bless, Dwight

-

Honestly . . . I don't know the chemistry and so forth of it all. I just know it works. I make holsters . . . belts . . . knife sheaths . . . and I do not wax all of them. Those that I do . . . I rub the compound onto the product . . . go over it lightly with my heat gun . . . it melts everthing and it is absorbed into the leather product. A few light coats of that later . . . and I can take a wash cloth and shine it up right real nice. May God bless, Dwight

-

When using a vacuum bag to form a holster how many HP do you use?

Dwight replied to AzShooter's topic in How Do I Do That?

As Chuck said . . . nothing to worry about . . . I have about a 6 or 8 ft nylon tubing on mine . . . it sits on a shelf . . . never saw any oil residue of any sort on it or around it. May God bless, Dwight -

In order to do the wax melt thing . . . go to the salvation army . . . buy a 10 dollar small crock pot . . . bum your mother out of a pint glass jar. Fill the crock pot half way up with water . . . turn it on high . . . measure the wax ratios on a scale . . . drop em in the pint jar and the pint jar in the crock pot. Go watch a football game. At half time . . . take the jar out . . . pour the wax mixture in muffin papers in a muffin tin you bought for 50 cents when you got the crock pot. By the time the game is over . . . the wax will have cooled and hardened . . . put it up on the shelf and put away the pot and the jar until next time. EDIT: Yeah . . . I forgot . . . I use a 50/50 mix of natural beeswax from my beehive . . . and neatsfoot oil. For my belts, sheaths, holsters, and the other few things I make . . . it is THE perfect product. I did one time put a tad more wax in by mistake . . . it is a bit harder mixture . . . and I use it for burnishing edges. Again . . . works great. Have never seen anything that does a better job . . . both are easy to come by . . . and only need two products on the shelf. May God bless, Dwight

-

That is exactly what veg tanned leather is designed to do. It is perfectly normal. I have one here I made maybe 15 years ago . . . still stout enough to knock a person out if you hit em up side of the head with it. Do not use warm NF oil . . . take a brush . . . put the oil ONLY on the smooth hair side of the leather . . . and just enough to barely . . . barely coat the entire surface. The holster then is laid aside . . . allowed to dry for 24 hours . . . then dyed . . . dry another 24 hours . . . and final finish put on it. You did good. May God bless, Dwight

-

When using a vacuum bag to form a holster how many HP do you use?

Dwight replied to AzShooter's topic in How Do I Do That?

Me too . . . Harbor Freight sold me my vacuum pump . . . and it will collapse . . . and I mean COLLAPSE the leather on the mold . . . big time. I think I tried the giant vac I have once . . . and it just did not do the job . . . so off to Harbor Freight I went. I got this guy: https://www.harborfreight.com/25-cfm-vacuum-pump-61245.html May God bless, Dwight -

Actually . . . I simply went up to the top of my punch . . . took a triangle file . . . and scribed a line that shows the direction the long part is. Then I put the back of it on the dot I made for the back of the hole . . . line up the line on the top of my punch with the direction the belt is laying . . . tap it enough for an impression . . . lift and look . . . if all looks well . . . put it back down . . . slam bam thank you maam . . . there's a hole there . . . and it looks right. That's just the way I do it . . . but that little line up on the top of my punch is truly THE secret of it for me. May God bless, Dwight

-

Made a belt for my boy

Dwight replied to DustinSmith's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Let me also say great job . . . far above my skill level. May God bless, Dwight -

Second Christmas Order

Dwight replied to Treed's topic in Gun Holsters, Rifle Slings and Knife Sheathes

A fellow from down Africa way made famous that style of holster . . . it is called a Rhodesian. I've sold a number of them similar . . . and everyone I've sold found a happy customer. May God bless, Dwight -

Yeah . . . I had to blow the picture up right real big . . . but if you look right real close . . . it is stitched. AND . . . if it was me that put it in there . . . it would be first held in place with contact cement. I even contact cement in beads when I do them for a customer. May God bless, Dwight

-

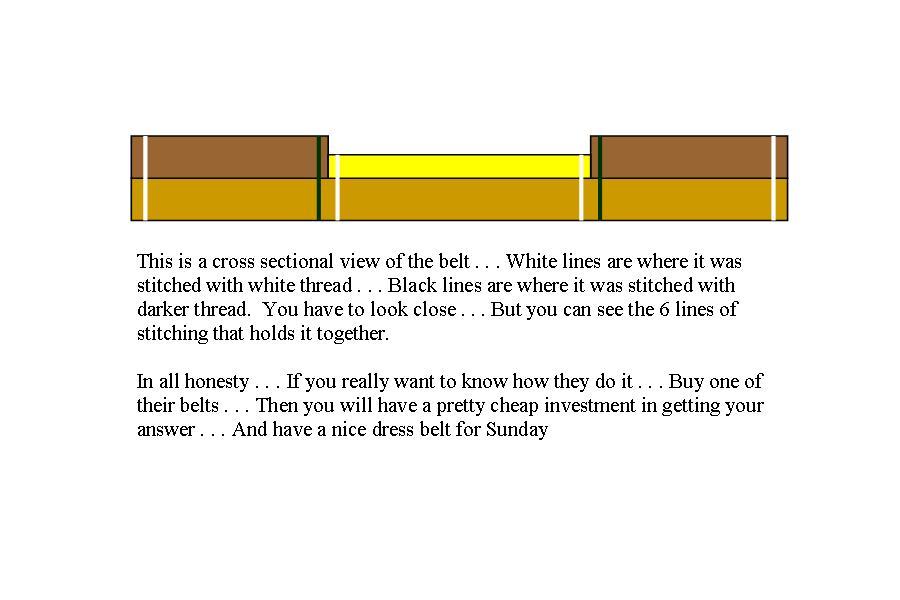

Take a look at this: it tells you in a picture what would take me two solid pages to write. This is how the belt is made. May God bless, Dwight

-

As PastorBob said . . . Mop n Glo or Resolene . . . either one cut 50/50 with water . . . works great. I use a small . . . cheap . . . bristle brush that I buy in box quantities from Harbor Freight . . . they're about an inch wide . . . I brush on the Resolene/water mixture . . . swirling it on the leather object . . . making a foamy looking mess to start with . . . then I brush out those foam bubbles . . . left to right . . . right to left . . . top to bottom . . . bottom to top . . . until it is smooth and "shiny" . . . I then let it dry . . . no heated forced drying . . . just hung up to dry . . . about 2 or 3 hours later I'll come in if it is a belt or billfold . . . or some holsters . . . I'll grab the item . . . and flex it a bit . . . as would be done in using . . . Have never had one customer complain about cracking. May God bless, Dwight PS: I'm thinking the Lord likes you . . . that's two pastors in a row sent to give you information.

-

The first thing I noticed about it is the corrugated presser foot is up on top . . . denting and scratching the top surface of the item you are sewing. So unless you want to sew everything upside down (bottom stitches never look as good as top stitches) . . . you are just buying a a project scratcher. Wouldn't buy one if it was $10. May God bless, Dwight

-

From what we can see . . . looks good from here. Can you post a picture of the finished product? May God bless, Dwight

-

There is another option . . . called a jointer . . . a carpenter's tool. You can rubber cement the hair side of the leather to a very flat board . . . typically a 1 inch thick . . . the same width as the jointer . . . Set the jointer so it is not taking off more than 1/64 of an inch at a time . . . and in successive passes . . . you can get it down to what you want. Then "generally speaking" you can pull the leather off the board . . . and thumb off the rubber cement . . . and go make boots. If the leather is too wide for a jointer . . . the same can probably be done with a planer which is a bunch wider . . . but I've never tried that one. May God bless, Dwight

-

In order to make it work you have to then make all your handles 8 to 12 inches long or you'll be hitting your thumb and forefinger every time you use the dumb thing. I'll keep my mallet . . . thanks. May God bless, Dwight

-

One thing you are doing wrong to start with . . . don't cut off the strip to use for the knives. Just fold over the length you need. Then you can make two stitches . . . one about half way up . . . one at the top . . . that'll hold them. The fold at the bottom won't have to be stitched either. May God bless, Dwight

-

Suspenders

Dwight replied to Stewart's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

So then you can make a pair of caligae . . . the Roman sandals worn by the Roman soldiers around the time of Jesus. They are not hard to make . . . I have the pattern if you want . . . it is three pieces of leather . . . the bottom sole . . . an inner sole that your feet rest on . . . and a one piece cutting that makes the sides of the sandals. They actually are pretty comfortable . . . I have a pair I made to go with my Centurion uniform I wear at church when I am impersonating a Centurion or soldier in a play or something. The picture is not the ones I made . . . but they are very similar. May God bless, Dwight