LatigoAmigo

Contributing Member-

Posts

1,012 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by LatigoAmigo

-

Leatherwork (verb) is the process through which one creates leathercraft (noun).

-

@printmaker Chuck sure knows his materials. Here is what Google AI has to say about sheepskin parchment: Printing on sheepskin parchment is a unique process that produces a distinctive, high-quality result, often used for prestigious documents, diplomas, and certificates. It's a more challenging process than printing on paper, requiring skilled printers and specialized techniques like letterpress, lithography, or screen printing. Elaboration: Traditional Use: Sheepskin parchment has been used for centuries for important documents like religious texts, legal deeds, and academic diplomas due to its durability, strength, and unique appearance. Printing Techniques: Letterpress, lithography, and screen printing are all used on parchment. Letterpress relies on raised images to transfer ink onto the paper, while lithography uses flat stones to print images. Screen printing uses a stencil and a mesh to transfer ink. Advantages of Parchment: Parchment offers a visually bright and clear surface that can enhance the impact of printed text or graphics. Its texture and sheen add a sense of importance and formality, making it suitable for prestigious documents. Challenges of Printing on Parchment: Printing on parchment is more difficult than on paper and requires a skilled printer. Parchment can be delicate and prone to tearing or buckling, so careful handling and printing techniques are crucial. Modern Usage: While parchment printing is less common than paper printing, it is still used for special occasions and documents that require a higher level of quality and prestige. Sheepskin vs. Vellum: Sheepskin parchment is often used for printing, while vellum (typically made from calfskin) is favored for its superior smoothness and durability, according to a blog post on blog.talasonline.com.

-

The closest thing I know of is Bonded Leather which comes in rolls of various "weights" or thicknesses, and lays flat as a pancake. As I understand, it is actual leather that has been recycled. You can find it on Etsy, and from some of the leather suppliers that advertise on this site. Good luck with your project.

-

Can you reliably compensate for crummy lighting with Photoshop?

LatigoAmigo replied to AEBL's topic in Leather Photography

-

You might find this helpful. Encyclopedia of Rawhide and Leather Braiding.pdf

-

-

-

@Frodo You can't handle the TRUTH!

-

I understand why @Squilchuck posted what he did. Several internet trolls, like Frodo and Chuck, polluted what used to be a wonderful leatherworking site that had been filled with positive energy and good leatherworking information, and turned it into a site peppered with disruptive and negative energy.. For the most part I have quit this site, because it has really gone downhill. For example, look at what Frodo posted, showcasing his very sophisticated leather working skills... NOT. Absolute garbage. He has no idea what he is doing, or why. I think that it's important to let the moderators and the advertisers know how we feel about the state of affairs here, so I'm glad to see someone speaking up about it.

-

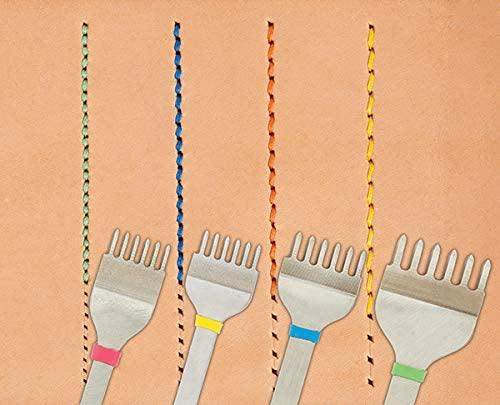

@Davm Braiding and stitching are completely different as you probably already know. Braiding uses lace, which calls for punching a hole, leaving an opening that the lace can "go through the hole a couple of times." Stitching uses thread and that is what your Tandy chisels are for. The diamond stitching chisels don't make a hole, but cut a slot, and are also for thread. Correct me if I'm wrong, but nothing that I know of will give you a diamond shaped "hole" big enough that you can lace through more than once. There is also buck stitching, which uses lace and chisels. Here is a book on braiding that you might enjoy, it's one of my favorites. Encyclopedia_of_Rawhide_and_Leather_Braiding.pdf

-

I hear what you're sayin', but dumb ol' me, I never asked permission, I just clicked on through without a hitch. Maybe I have special privileges because I'm a Contributing Member. Donno.

-

Just to be clear, this thread did not originate in the Adults Only section of this forum, so the early commentators could not have seen that warning. And it may not be a surprise to everyone, but neither permission nor adulthood are required to enter the adult section... it is open to anyone who has signed in.

-

In today's environment it seems inevitable, as you can see who chimed in on this thread and how they twisted the conversation. I've discovered that there's a name for these folks... Internet Troll An Internet troll, or simply troll in Internet slang, is someone who posts controversial, inflammatory, irrelevant or off-topic messages in an online community, such as an online discussion forum or chat room, with the primary intent of provoking other users into an emotional response or to generally disrupt normal on-topic discussion.

-

@Squilchuck has a good point. The people he is referring to, and we all know who they are, have decimated what was once a wonderful site for leatherworkers to share their work and their knowledge, and in my view have ruined this site. It now seems to attract the angry and ignorant. Many very talented members have not posted here in years because of the responses from said members. It is worthy of note that the most members online date is January 7, 2021.

-

A fid is for working lace, not cutting diamond shaped holes. Could you be thinking of something like this? Weaver Leather Supply Diamond Stitching Chisel Set, 4mm, stainless steel for Leather Craft DIY

-

-

That is all I use this for. I've never used a fid to make a hole... that is what a punch is for.

-

My leather seems to be a paint stripper

LatigoAmigo replied to nbutterfield186's topic in Leatherwork Conversation

Won't get much of a response without some pics. Your photos have to be fairly small and in .jpg format. Easiest way is to take the photos with your phone and email them to yourself. You will be prompted to select a size, select "small." This will provide you with images you should be able to post here without a problem. Sorry if that is not your problem. but is a common issue for new people on this site. -

I would say that the best fid is one designed specifically as a fid such as this one available on Amazon. for less than $9. You will find a fid like this is invaluable if you ever get into the various knots that are in the Bruce Grant Encyclopedia.

-

From this book, the "Encyclopedia of Rawhide and Leather Braiding." A classic, this is considered to be "the" book by "the" master of leather braiding. Encyclopedia_of_Rawhide_and_Leather_Braiding.pdf

-

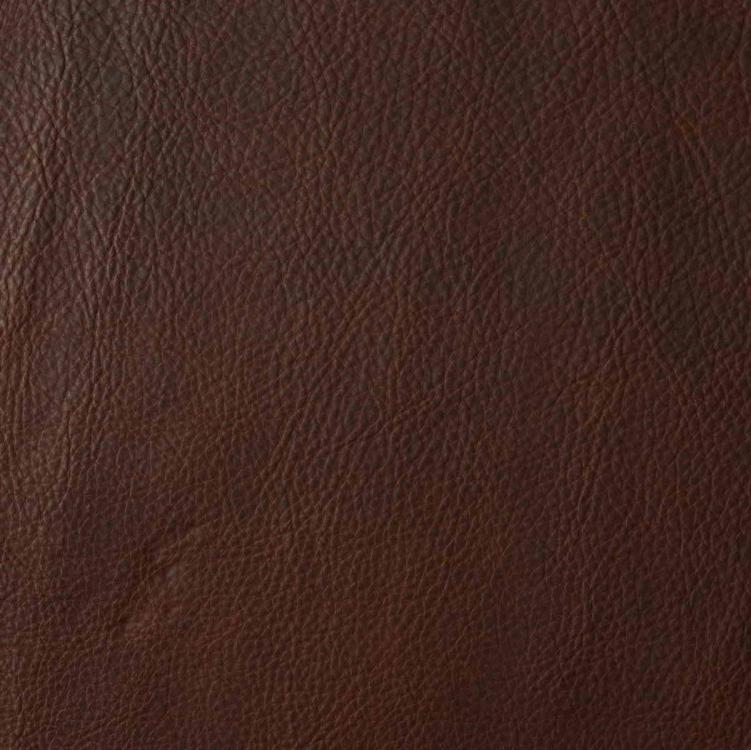

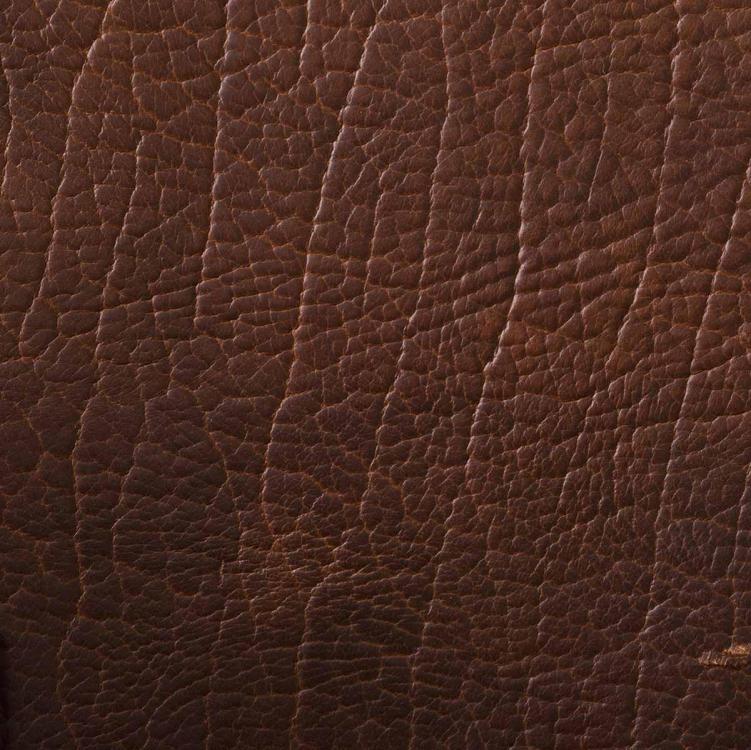

It strikes me as bison (American buffalo). I buy it at the Hide House in Napa, California. They ship world-wide. Here are some examples from their website. https://www.hidehouse.com/

-

@Davm Give this a gander... Bruce_Grant_Round_Edge_Braids.pdf

-

Laser engraving / cutting of leather

LatigoAmigo replied to Dwight's topic in 3D Printers and Lasers

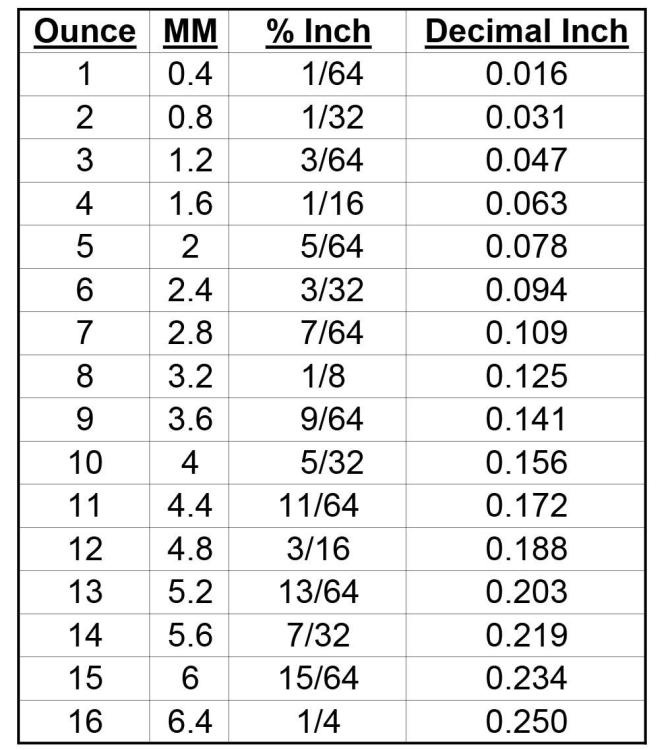

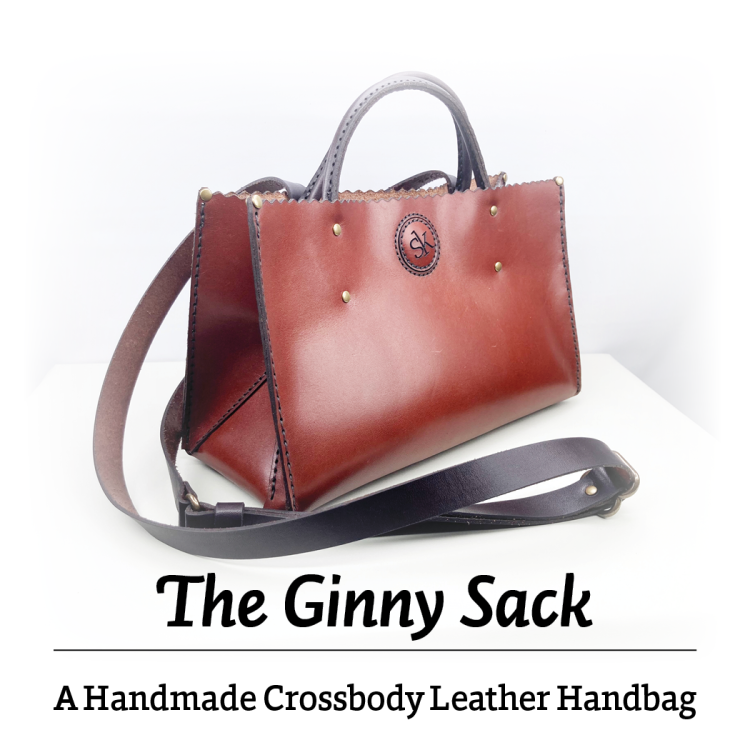

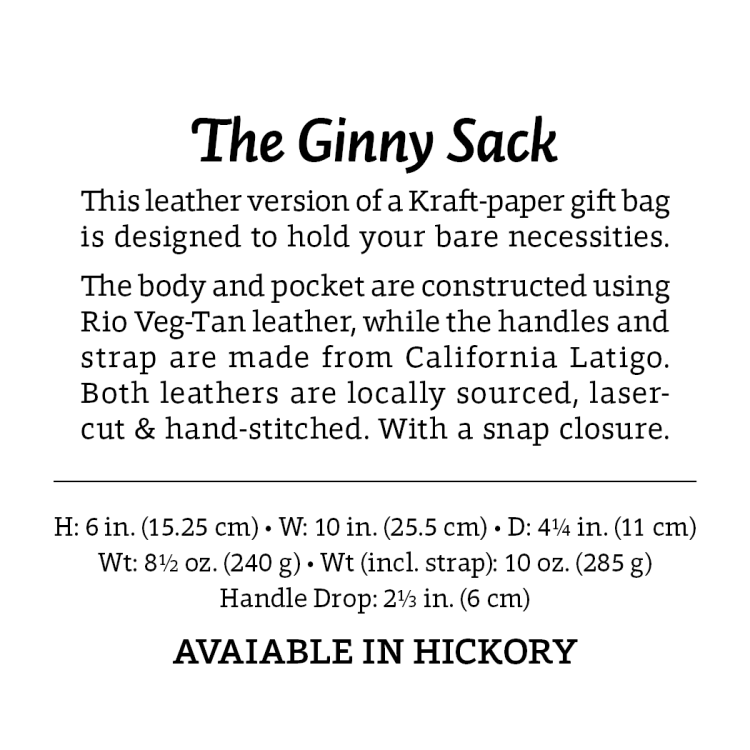

I have software experience, so I saw the laser as an opportunity to produce perfect edges and hole alignment. At first I rented a laser at a maker-space. The 100 watt Epilog did a very fine job of engraving, but with a purchase price of $35,000, it was somewhat out of my range. I picked up a 100 watt CO2 laser for $4,500, but the trade-off is that the engraving on my machine is not very refined, so I do very little of it. As far as cutting, it does a great job, but on some heavier leathers I might have to "go over it" a few times to get it to cut all the way through. The trick that I learned is that because the focal point of the laser is what does the cutting and because the leather does not always want to lay flat, using a light adhesive, I glue what I'm cutting to a sheet of stiff "oil board" or "stencil board" that's available from a local art supply store. Then I use weights and /or tape to hold the oil board flat. I must add that I am cutting mostly somewhat stiff heavier leather in the 4-5-6 oz. range. Also, I not only cut out the pieces, I also cut in the lacing holes, as I only hand-sew my bags. The biggest headache I've had is aligning the laser beam. I replaced the laser tube, all the mirrors and the lens, and it took quite a few tries to get the beam back into play. If the laser is not aligned correctly it will not cut as expected. If you do get a laser and end up needing align the beam, here is a site that you might found helpful. https://smokeandmirrors.store/pages/laser-beam-alignment-guide With the laser, I can cut patterns that are almost impossible with a knife, and the edges are cut perfectly (albeit soot covered). The trade-off with laser-cutting the lacing holes is that they are soot-filled, so I can only use dark thread. Although there are a few trade-offs, I sure hope that is the good news you were looking for, I wouldn't be doing leather if not for my laser. Here is one of my recent bags.