CowboyBob

Contributing Member-

Posts

3,312 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by CowboyBob

-

The best time & to be sure you don't get a skipped stitch is to stop & turn after the thread is caught on the hook ,so this is on the upstroke (approx. 1/4")

-

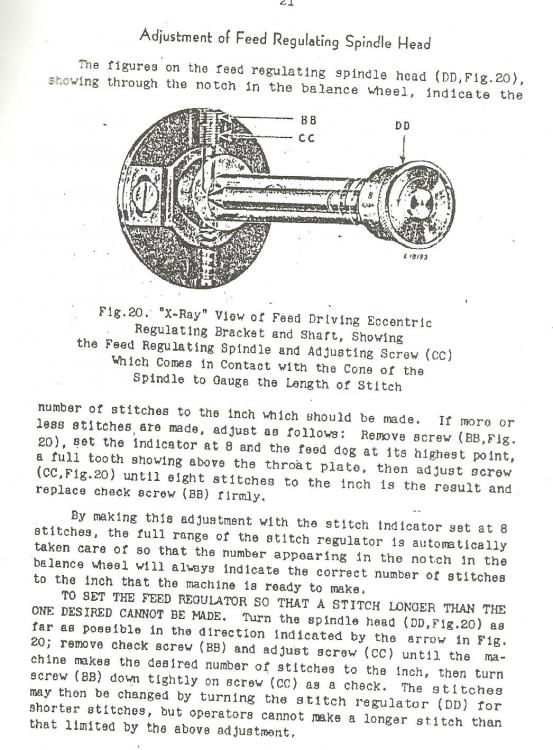

not feeding material adjusted feed regulating spindle head

CowboyBob replied to helena's topic in Leather Sewing Machines

You can always take shaft DD out & get a little longer shaft & then just use the screws CC & BB to adjust the stitch length. -

not feeding material adjusted feed regulating spindle head

CowboyBob replied to helena's topic in Leather Sewing Machines

Try to turn screw CC out then push DD in all the way,then turn CC back down & see what happens.It won't work unless DD is pushed all the way in. -

not feeding material adjusted feed regulating spindle head

CowboyBob replied to helena's topic in Leather Sewing Machines

-

It could be a wornout needlebar hole.loosen the needle set screw & see how much it moves left to right.You will probably need to replace the needlebar.

-

I've heard people say that before.All I have to say is we sell approx. 3-5 a mon & they hold up really good just like most machines will if they're oiled & taken care of.We sold 2 to NASA last year & they called a month ago & ordered 2 more! The dealer might only had this machine in stock

-

The GB needle prices do vary some,the small 16x231,257 are something like Eric says, with the larger 135x17 costing more with the leather points costing more than round points.The GB's used to be made in Czech Republic,but now have moved to India,we sell a lot of them & the quality still seems to be the same. All needles come in boxes of 100 which you can buy @ a better price usually then buying a pk of 10 @ a time.Since then we are stuck with an open pick,but we've been doining it for years

-

Push the feed dog front to back to check for play,even check both shafts underneath push left & right ,adjust as need alittle is needed so they don't bind up,oil every pivot point while your under there too.Making the slot longer in the front will help too.

-

The plate does look like a good idea BUT I was talking about the motor sticking out past the edge of the table since it has to be moved back.

-

I can understand everyone wants to save $$ & I don't blame you for that.But the box style reducer sells for $185.00+ shpg & then all you do is bolt it on, measure for belts & you are done,no making & lining up of plates(or redrilling holes in the table top) & trying to make it work & with that plate that moves the motor back the motor will stick out of the back of the table & you won't be able to push the table against a wall because the motor will hit the wall.

-

We have a box-style reducer that we sell that mounts in between the table & motor & allows you to tilt the head back.

-

Thread jamming underneath is usually a upper thread tension issue,you might look in between the tension discs for lint build-up & then try to tighten the top tension more than where it is now.It should use 138 w/o much problem other than you need to hold on the needle thread when you start as Suzelle mentioned.

- 26 replies

-

- thread size

- sewing machine

-

(and 1 more)

Tagged with:

-

The adjustment is to bend #17,you can put a screwdriver on the upper part on the back side & use another screwdriver on the lower tab on the left on the front side & bend it alittle towards the back.

-

Juki DNU 1541 Needle Won't Stay Threaded

CowboyBob replied to sarahjb's topic in Leather Sewing Machines

I just had a woman call last week I sent a 1541S to & I had her send me a threading pic & it was left to right. -

Zero-Max e1 Adjustable Drive (Speed Reducer) Any Info?

CowboyBob replied to Fallinggator's topic in Leather Sewing Machines

The zero-max is made for lighter torque applications like pullers & will slip when using them for a speed reducer.For $135.00 + shipping you can buy a 3 pulley speed reducer that will work a lot better.You also need to get rid of the clutchmotor & get a servo motor. -

Yes,tighten or turn to the right,just alittle @ a time & push on the pedal to check the change.

- 3 replies

-

- adjustment

- motor

-

(and 2 more)

Tagged with:

-

There is a large bolt on the end of the motor that has a locknut on it you need to loosen,when you go to the rightside of the table & look @ the motor,it will be @ approx. 9:oo position & take a 5/8" wrench to loosen it ,turn it in maybe 1/2 turn & check the amount of play.

- 3 replies

-

- adjustment

- motor

-

(and 2 more)

Tagged with:

-

There is a large bolt on the end of the motor that has a locknut on it you need to loosen,when you go to the rightside of the table & look @ the motor,it will be @ approx. 9:oo position & take a 5/8" wrench to loosen it ,turn it in maybe 1/2 turn & check the amount of play.

-

Most people that have ran both will like the 111w better esp for leather because it has a larger & heavier handwheel & parts are more plentiful for the 111w too.

-

These are the worst ones to repair,where someone else has turned & adjusted things that didn't need adjusting.

-

Well,the OP is a woman so I suppose she might be more inclined to use a man's name.

- 14 replies

-

- cylinder arm

- cowboy 3200

-

(and 1 more)

Tagged with:

-

No,once you start cussing they will start sewing worse & worse!!

- 14 replies

-

- cylinder arm

- cowboy 3200

-

(and 1 more)

Tagged with:

-

I'm glad "Hoss" made the trip to you & is sewing like he's supposed to.Treat him nice,oil him often & don't ever swear @ him & he'll keep sewing like a good Cowboy !!

- 14 replies

-

- cylinder arm

- cowboy 3200

-

(and 1 more)

Tagged with:

-

puckers in waxed canvas stitching

CowboyBob replied to georgeandgracie's topic in Leather Sewing Machines

A 206RB-3 isn't a real old machine but there could be some wear in the upper feed that can cause a problem you want the needle in the material before the inside foot comes down..But the material being shorter on top would lead me to think there is some wear front to back on the inside foot causing the plies to shift.Also what type of thread are you using?Nylon can cause puckers in canvas since it stretches like a rubber band & after it's sewn will relax & pucker.Polyester is supposed t have less stretch & so does cotton.