CowboyBob

Contributing Member-

Posts

3,312 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by CowboyBob

-

The feed is off probably didn't have the take up lever all the way up when he put the belt on ,or the feed cam underneath isn't in the slot on the bottom shaft,the screw that goes in the slot is marked w/a S on the cam.

-

The hook can get jammed up& tie up the lower shaft,so put some oil around the bobbincase & rock the lower shaft back & forth.

-

Would Appreciate Your Advise On Restoring This Singer 45K25

CowboyBob replied to Evo160K's topic in Leather Sewing Machines

Gloss -

Size#200 will work with 277.

-

Information needed on a Singer 150W161

CowboyBob replied to JenniferW's topic in Leather Sewing Machines

The short-arm version of this machine is a Singer 61W2,do a search for that model# & there's a lot more info.This machine is great for quilters w/the long arm.But don't expect to sew much leather with it. HTH Bob -

Singer 29K S.V. 3 Cobbler Leather Sewing Maschine

CowboyBob replied to Constabulary's topic in Leather Sewing Machines

The flat bar & wing nut is how they get the pressure foot pressure on these older models,your 28K51 has the different newer style coil spring. Constabulary,I do see a adjusting screw on the take up lever that none of the 29-3&4 usually have maybe this is why it's a SV?Of course it could of been added through the years as a replacement part too.- 18 replies

-

- singer 29k

- 29k3

-

(and 1 more)

Tagged with:

-

Nice !!!

-

Jomar, I leaning like Eric towards foot pressure..I think your pressure was just loose enough that the leather lifted as the needle pulled up.These types of machines with walking feet always will mark some & some leathers mark easier than others.If needed the marks can be rubbed out by a spoon.

-

Cobra class 4 sewing direction problem

CowboyBob replied to dgkfit's topic in Leather Sewing Machines

Trox,Wiz is right we only use the FL550 & I don't care for the Hightex Cowboy either with the panel on the right like that it looks like any little bump in shipping could break it,also it has a computer chip in it & needs to be programmed.We had some reverse on us & I got tired of trying to explain how to program it.The servo motor we use now has proven to be easy to use & trouble-free so that's what we will stay with!! -

Cobra class 4 sewing direction problem

CowboyBob replied to dgkfit's topic in Leather Sewing Machines

We had the same problem with this motor,it switches direction (or goes to default) in shipping,one of the two reasons we quit using them. -

It might be used to compress the leather after you glue it.

-

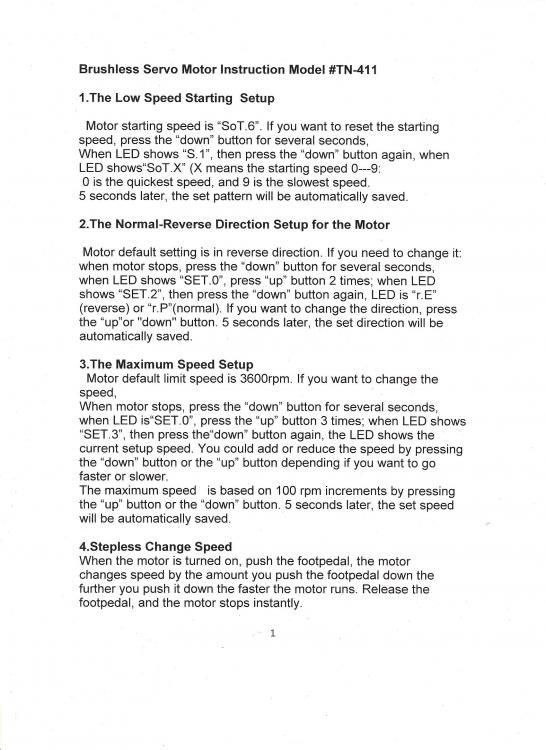

I had consew send this to me. BRUSHLESS MOTOR PANEL OPERATING INSTRUCTIONS.pdf BRUSHLESS MOTOR PANEL OPERATING INSTRUCTIONS.pdf

-

Cobra class 4 sewing direction problem

CowboyBob replied to dgkfit's topic in Leather Sewing Machines

-

All you should need to do is loosen the tension on the spring.You turn the screw in the pic to the left BUT you need to loosen the little locking screw(in the hole @ the top of your pic) first before you turn the larger one.

-

Manual For Consew 206 Rb Manual And Parts Manual

CowboyBob replied to SHYNEJACOB's topic in Sewing Leather

Go to Consew.com & click on resources & look for your model # -

Looking For Info On This Consew

CowboyBob replied to J W Craftsman's topic in Leather Sewing Machines

This machine is just like a Singer 31-15 only it has reverse.It is a great tailor ,dressmaker or for even sewing jeans.For leather you can make chaps & thin stuff but the max thickness would be around 20 oz or 5/16 of in. & that would have to be w/a different motor,that home machine motor would barely sew 1/4",take 1/2" of leather over & try it & see what happens & let them explain their false advertising to you.The value would be $150.00 for the head @ the most as you'll need a power stand w/a servo motor & should even get a reducer so there's a good $400.00 unless you can cobble up something. -

Hello Jomar, I just got home from picking up some more machines & wanted to thank you & your Wife for buying a Cowboy.I wished we could ship it sooner but there is a few ahead of you & we ship them by the order they were sold.But we will let you now when it ships & give you the tracking #.

- 17 replies

-

The Pfaff isn't designed for thread larger than #92,it doesn't have a latch opener so it gets hung up in the position finger.

-

A Couple Questions On My New To Me Singer 29-4

CowboyBob replied to nickortizzle1035's topic in Leather Sewing Machines

Size 92 is the largest that will work,if the machine isn't too worn out #138 MIGHT work ,when it loops underneath try more tension. -

I've sold them to inmates in Texas & they have a lot of problems with them.I'm almost certain they try sewing too thick & have broken the feed bar(the part the feed dog fastens to) along with a lot of other parts.Yes,#92 is as big a thread as they will take & sewing 1/4" max.If you are just sewing upholstery or canvas these are great machines or even 1/4" leather.But for knife sheaths & etc it will leave nasty teeth marks in the leather.

-

111W-153 Stitch Length... Wear Or Adjustment?

CowboyBob replied to Ole South's topic in Leather Sewing Machines

Many times the stitch indicator will be off,the way to set it is loosen the screw in the stitch indicator wheel & tighten it so it's snug ( so you can turn it if needed) then put the stitch length on the longest stitch probably #5 on the machine,then turn the indicator so the #5 shows through the hole,then tighten the screw. -

It a Consew model 3115R & is very similar to a Singer 331K4 do a search for Singer 31-15 there is a lot of info on this site & internet about it.Not the best machine for canvas because it doesn't have a walking foot.It won't sew near 1/2" leather or anything else! I'll bet this person used to be a used car salesman.LOL Probably why the horseman got rid of it.

-

Steve, The shuttle should catch the thread on the first rise of the needle.