keithski122

Members-

Posts

127 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by keithski122

-

Try changing the feed roller for a rubber one if you have the stone one fitted, I did and it stopped this problem.

-

I do have the same motor and controller on my machine however I set it up several years ago so can't remember how I did it. I have extended the pedal arm and the speed controller arm to give more movement. Minimum speed would be set to as low as it will go while still be able to move, maximum speed I set really low but it would take ages to wind bobbins so I increased it so as it was still slow but fast enough to wind in reasonable time. On mine the controller is at the front of the machine by my right knee with the additional controller on the top of the machine.

- 3 replies

-

- ho hsing i90m

- servo motor

-

(and 1 more)

Tagged with:

-

Seiko and Juki compound feed machines

keithski122 replied to Wilder's topic in Leather Sewing Machines

That seiko looks very similar to my typical tw1 899 machine which is also similar to a brother machine. The typical machine I have is fantastic and I couldn't recommend it more, I also have a juki 1508(?) at work and the typical is nicer.It seems to be smoother, less fussy and just easier to use. I guess it would be like driving a lexus compared to a ford. I use it for auto upholsery so sometimes up to eight thicknesses of leather which it copes with fine. -

Check out nippy_kikai on instagram, they make skiving machines and have some helpful videos on using and setting up.

-

Check out nippy_kikai on instagram, they make skiving machines and have some helpful videos on using and setting up.

-

I found that changing the stone feed roller for a silicon/rubber feed rubber eliminated the waste from sticking to the roller and coming back out of the top.

-

Hitting the corner with the needle

keithski122 replied to PlanoMike's topic in Leather Sewing Machines

I just use my reverse lever to position the needle before it makes the corner hole, obviously the stitch will be shorter than previous stitches. -

Presser foot climbing adjustment, is it worth it

keithski122 replied to Waldog's topic in Leather Sewing Machines

I don't have a juki but do have a Typical machine with this feature except I also have a switch which puts it on max foot lift.I love this feature, I do car upholstery and its fantastic when you come to intersecting seams with lots of bulk, hit the switch and it just climbs over the seam without banging into it and shortening the stitch length.I've now moved the switches to the top of the machine for extra clearance and so I don't accidently hit them while sewing. -

I have a Typical sewing machine with all the electronic bells and whistles, also needs an air feed for certain operations, however if the air feed isn't connected it will work with basic functions, ie no auto footlift, no auto high foot lift, no second stitch length on switch.I imagine as long as the motor works it will also function in basic mode, if not a swap to a basic servo motor with needle postioner will get it working fine. However we also have a durkop adler machine at work with similar functions but due to an electronic fault will not work, no manual foot lift so cannot be used even if the motor was swapped out.

-

Skiving machines skive skin as well as they skive leather, first use of mine and I removed the tip skin of my thumb.

-

I do auto upholstery and use the rubber feed wheel as it stopped the problem of waste leather being pulled back over the top of the feed wheel and spoiling the leather.

-

On my machine I've extended the levers on both the pedal and the speed controller to give better control. I've also st the maximum speed to a lower speed (poss 2200) so for the full movement of the pedal its over a smaller speed range which I think gives better control than over bigger range.

-

I have a global machine I use occasionally for auto upholstery(no vacuum). I don't think I need the vacuum, although I do use a rubber feed roller and have fitted an led light next to the bell so I can see if waste is caught up.

-

How do Seiko's stack up?

keithski122 replied to Cumberland Highpower's topic in Leather Sewing Machines

-

I have a Typical machine which is made in China and it is far better than the knackered old Juki I was previously using.Mine was bought secondhand so I have no knowledge of how it was used before but is now used in a work setting and has proved faultless.

-

If the consew uses the singer style foot then the feet are cheaper, more available and more choice of style.

-

Thanks for replying to this. As I wasn't able to see the machine in person and the seller (a sewing machine dealer) would send it by pallet if bought I sent some material for testing but it never got sent back to me.After several phone calls requiring the test panels and details I gave up as I wasn't getting anywhere. I must be lucky because I've since found a Typical industrial machine the same as a brother LS2-B891-705 which is great and at 2/3rds of the price the juki was.

-

No we didn't.Its still at the side of the workshop waiting for ideas or to be sold on. If you could work a way to post a pic that would be really helpful. I found I have to resize pics to post sometimes.

-

Holding thread for first few stitches.

keithski122 replied to TomG's topic in Leather Sewing Machines

I use a sew off tag.Just a two inch square of material, sew item, lock off, sew onto tag, sew onto new material, lock off, sew item and so on.If its not sewing off the end of the item then the tag is easier to hold than two loose threads. -

Fortuna Splitting machine jam and consequent problems

keithski122 replied to Hannamaija's topic in Leather Machinery

A tip for sharpening is to run a sharpie pen over the cutting edge before using the grinding wheel, you can then see where its sharpening the blade. -

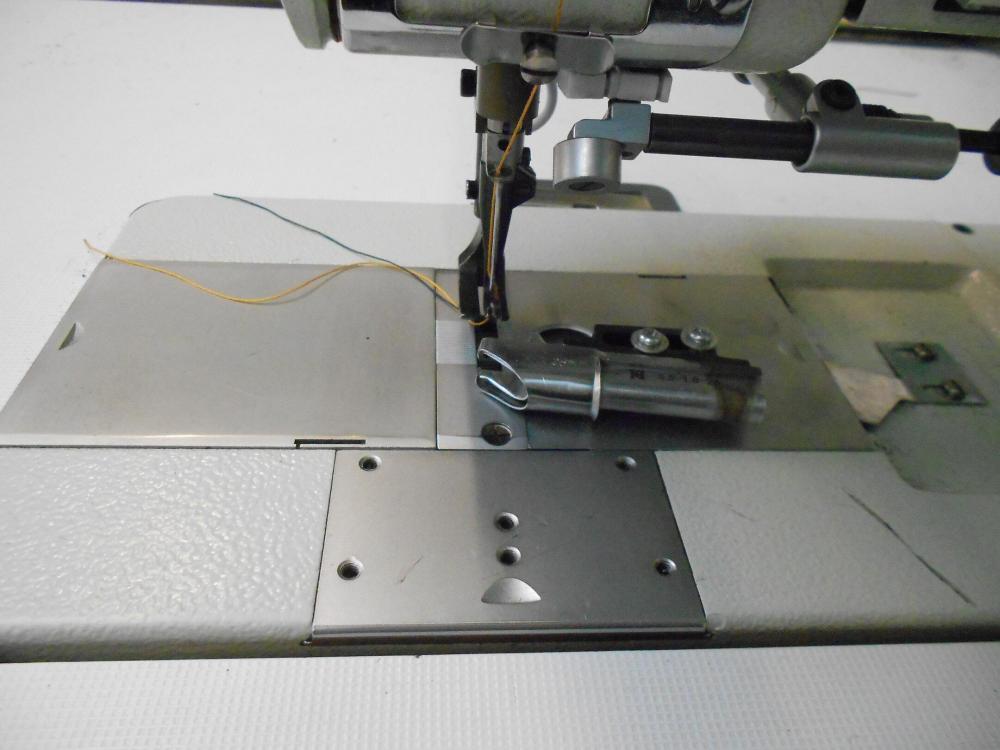

At the moment all binding I do is by hand so just playing about to see if I can get a neater/quicker finish, if it doesn't work no great loss I'll continue to do it by hand. The set up above worked in a straight line apart from stretching the binding causing the carpet to wrinkle.I don't think I tried it on a curve.I've set it on a spare plate so if I get it to work it will be a straight forwards job just to change the plate and the feet and off I go.Binder is fixed as close as posssible to the feet on max stitch length with a couple of mm clearance, once set should not need moving, height is a low down as possible.With the new attachment I've mounted it using an adapter plate so if I need to adjust it back or forth its a simple job to make a new plate.Machine is a typical tw1-899 used for all aspects of auto upholstery so can't be set up purely for binding.

-

On a flatbed machine.I've previously fitted a different binder but never got it working quite right due to the binder not being suitable for a thicker material.It worked but seemed to stretch the binding.Heres some pics of how it was with the older binder and binding results.

-

Binder attachment:- https://www.khsew.com/index.php?route=product/product&path=369&product_id=1900

-

Thank you. Its for carpet binding with the binding being strips of leather or vinyl, maximum I guess of three metres long so no spool.I'll leave the wire off and see how it goes, at the moment its more important to get everything else lined up right. Just for information binder has throat of 9mm material thickness, with binding material size of 26mm (1 inch) 1.8mm thickness.

-

I'm just in the process of sorting out a binder attachment and was wondering what the bent wire is for. I know the binding feeds through it but is it for extra tension or just to guide it into the binder better? On my set up it will need rebending as the flatbed of my machine is in the way, however this means the tape will be higher than the binder shell.