-

Posts

1,422 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Rockoboy

-

I use RD Works. There's a few people on y--toob with videos on using it. (Not that I have watched any, I just bumble educated-guess my way through).

-

Your carving looks so real ... I think I saw him panting!

-

Croc clutch!

Rockoboy replied to motocouture's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

-

Croc clutch!

Rockoboy replied to motocouture's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

@RockyAussie Good to see that guy on the motorbike is protected from grinding sparks while riding his motorbike, but what about his passenger? No protection for him! As for the other 2 pics, a little love-bite never hurt anybody! Nom nom nom!! -

Croc clutch!

Rockoboy replied to motocouture's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

A croc clutch is a nice idea, and your finished product is exceptional, but ... how do you get the croc to carry it? -

I use heat shrink tube on my tools. I have a few different sizes in the same colour that delineates my tools from some other person. The chance of me selecting the same colour and length and applying it in the same place as another person is very small.

-

I have never made a wallet, so no help here, but when you get up and running, I might be a buyer.

-

Braec Moedoic Budget Bag

Rockoboy replied to WastelandOuterwear's topic in Satchels, Luggage and Briefcases

Stunning job on a work of art. I like it all. Do you have any pics of the inside? -

I have never used any Delrin stamps, so I cannot comment on the comparison with brass, steel or diecast, but my 1st option would be Sergey, also known as arbelet12 on this site. I have several of his tools, including a maker's mark and I am almost ready to place another order. His gear is exceptionally good IMHO.

-

Working on the basketweave

Rockoboy replied to doublehbar's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Try stamps from arbelet12 on this site, he has an etsy store as well. very nice stamps at reasonable prices. -

A few projects the last couple of months

Rockoboy replied to A Finch's topic in Archery Quivers and Bow Cases

I shot for more than 10years, 7 days a week for a couple of those years, and I always wore an arm guard, even though I knew the mechanics of tilting my arm and drawing the bow correctly to not need a guard. -

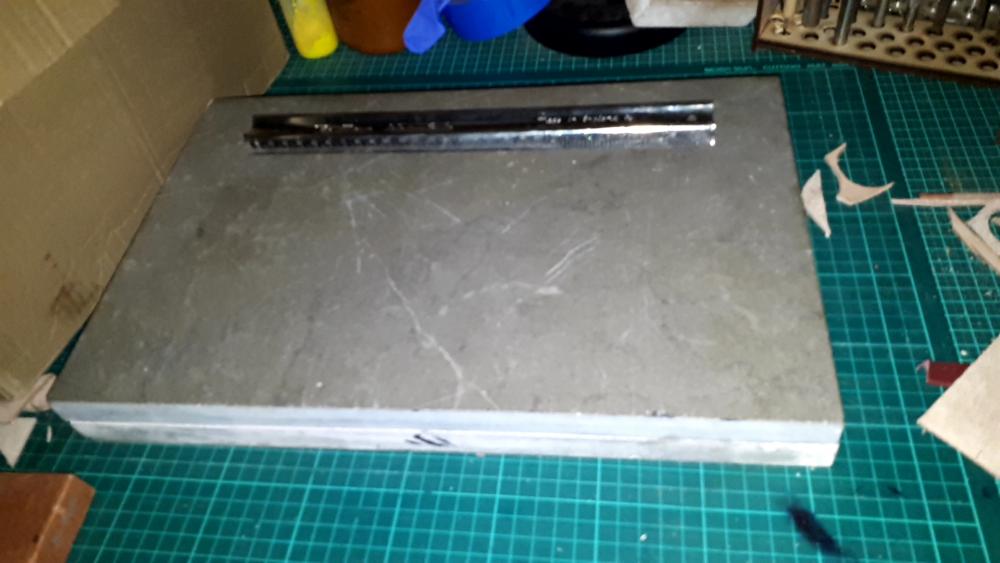

The tiles were given to me, by somebody who wanted them gone without any effort (by him), and stuck together with tile adhesive recommended by the tile store (half a bag from their rubbish pile for free). This stamping surface is approx. 350mm X 250mm by 40mm thick. I have a couple more that are closer to 600mm X 450mm X 40mm thick, but this one is fine for everything I have done so far. I have used some large 3D stamps with a 32oz copper head mallet, where I have struck the stamp several times as hard as I can (ex-boilermaker), and the slabs are still unmarked. The bloke in the tile store said this set-up will be stronger than a single slab because the defects and grain do not go right through, they will be more like plywood.

-

It does not matter what I am doing, I will always use a jig if I can. Marking out, cutting, glue up, clamping etc etc. What a jig will be made out of depends on the task, the amount of benefit of the jig, the chance of reusing it for another run, how much fun I am having making the jig etc etc. For glue up and clamping, I mostly use the spring clamps that come in many sizes from stationary fold-back clips to matchbox to A5. If there's a need, sometimes I use a small piece of leather or MDF to stop the clamp from marking the leather. (Sometimes it even works out).

-

Is this bevelling possibly done from both side of the leather? As in, bevelled the top side and also bevelled the back, then the back filled with ... something ... wax? Epoxy? Wadding?

-

Depends on whether your knife needs grinding or just a decent strop to rejuvenate the edge. Grinding is fairly specialised (or needs somebody who has the gear and knows what they are doing), whereas stropping is fairly easy to accomplish. (I can manage it, so it can't be too difficult). I glued a piece of leather about 300mm X 60mm X 5mm thick to a scrap of flat and smooth timber, applied some green paste (incorrectly called jeweller's rouge, but I cannot remember the correct terminology), and watched somebody with more experience for a minute or so. The end.

-

Singer machines with serial numbers with prefix between FA and FY were made from 1935 according to the google-search I just did. Obviously by the time they got to FE, it might have been years later, or maybe the lettering system was not in alphabetical order.

-

Lets talk about WOW factor in leatherwork.

Rockoboy replied to immiketoo's topic in Leatherwork Conversation

Excellent topic, and some very beautiful sentiments from lots of people. Some of my things I have made, fishing rods, leather goods, wood or metalwork items, acrylic items etc, I am happy to show people. On the flipside, there are some items that I am less than impressed with my own efforts. There are some very talented people on this blog, and whilst I agree with the idea of not ripping-off some other person's design, I have tried some ideas. Some have worked and some have not, but the pleasure is in the making, not the praise and (possibly) fake opinion of people who may not know the worth of that article. -

How did you get into leather work?

Rockoboy replied to Rolandranch's topic in Leatherwork Conversation

I bet she would have, you are killing it, by the sound of things! Well done. -

Not with me, but I will take a couple and post them up. They're a basic setup, that I did not think warranted posting. I've not heard of a store called Woodcraft. About all we have within 3000kms is Timbecon (Australian company I think) and Carbatech, which might also be just in Australia.

-

Hmmm ... far more techy and top quality precision than the big-box hardware stores I have worked in, and the timber speciality stores also know nothing. I am thinking an engineering supplies company would be a better bet, but I don't think there will be any change from $100AUS maybe $200AUS. I will stick with my two layers of 20mm granite floor tiles that I glued back to back with tile adhesive.

-

I worked in hardware stores for more than 10 years, plus I frequent woodwork speciality stores quite often, but I do not recognise the term "surface plate". Can you tell me, what is the intended use of this item please?

-

That's a work of art and functional as well. I love it!

-

I think people are looking at this post from two different sides. Some people are considering how to dye a section, but leave an adjoining section undyed. That's where the suggestion comes from, to use a small paint brush, depleted of some dye etc from billybop, which sounds like a good idea IMHO. On the other hand, I believe the OP is looking for suggestions on how to maintain the lighter and/or pinkish colour of undyed vegtan. Whether or not an adjoining section is dyed or undyed is immaterial.