-

Posts

196 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by TonySFLDLTHR

-

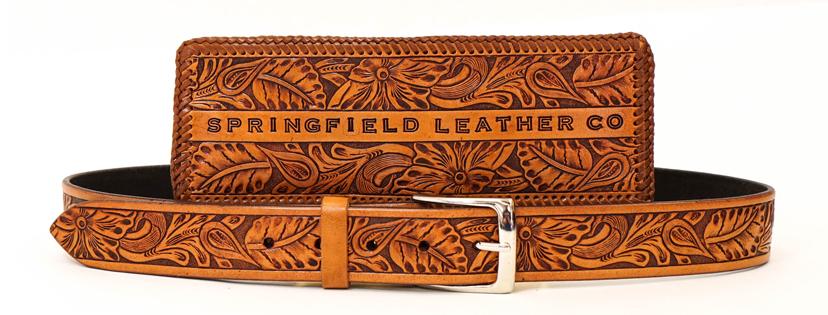

So you know I have not been around in a while. That is because I was tasked with our catalog. It took a bit longer than we thought, but it is here and we have started sending them out. We went out on a limb and totally changed our look of the cover, hopefully you find this insides just as good. With a couple new treats inside! https://www.springfieldleather.com/SLC-Suppy-Guide-2019

-

Just wetting the leather before trying to tool it. If you are just spraying it, it will not soak up as well as say Natural Veg will.

-

Looking for help with a nicked V gouge

TonySFLDLTHR replied to SilverForgeStudio's topic in How Do I Do That?

Hey Tom you are right! We are more interested in making sure you guys and gals are successful! @SilverForgeStudio Shoot me a PM and I will see what I can do to get you taken care of! -

Wanted to share this video with you highlighting the Highlead 318.

-

Here is some of the drum dyed we have...it will tool, but it just doesn't take water as well. https://www.springfieldleather.com/Leather/Hermann-Oak-Leather/By-the-Sq-Ft

-

I was like oh no what did we do now!! Heather was a great sport and she really does a great job as well as all the gatherers.

-

Did you find what you were looking for?

-

Here is just some information on how we cut leather and how we figure it. Would make it much easier if we could just find square cows.

-

They may have some different properties, but they are both acrylic and would serve the purpose here.

-

SLC and Hermann Oak **NEWS FLASH**

TonySFLDLTHR replied to TonySFLDLTHR's topic in Announcements and Administrivia

So the story behind why HO doesn't do double shoulders and double bends. They have always done sides since 1881. In their shop they hang the hinds down the spine and cut them into sides. Their racks to process are set up to do side. Its only been for sides. Because that's how they have always done it. In steps us and our customers asking for a double shoulder of HO...they don't do it...ask enough times and everyone sees that the customers would like something they don't do. How do they do it...Rusty and Kevin go up and talk with Shep and his people and they find a way to try it. This is where we are right now. They are learning to process their hides differently and that is going to take time. How to split and all the other that goes along with it. Double shoulders and bends tend to lead to higher yields for the end customer...so the numbers show. -

We have a guy here that has used it quite a bit. He said use a leather sheen (https://www.springfieldleather.com/Finish-Leather-Sheen-4oz). The thoughts he has on this is it is like anything with scales. You want to get them stuck down so that they aren't pulling up. He said he does no fewer that 2 coats when he does it. Getting the sheen under the scales and then pressing it down.

-

Leather News Flash When great companies work together, great things happen!!! And they happen for their customers as well. Those things are known as win-win situations, and the main beneficiary of these win-win situations is always the customer. The benefit to the companies comes later as it flows from happy customers to innovative companies. It’s well known that “Customer First” has been the long standing policy of great companies like SLC and Hermann Oak Leather. Having said that, leather crafters across the board have long desired a HERMANN OAK DOUBLE SHOULDER. And SLC and Hermann Oak feel that this would be a tremendous addition to the leather industry in this country for manufacturers, hobbyists, belt makers and all sorts of other leather crafters. But the production problems confronting the ability to actually create this seemingly simple cut of leather were far more daunting than the average person would realize. It would require a small book to explain them! So….recently, Hermann Oak and SLC have teamed up, and worked together extensively to try solve these difficulties. And, (amazingly enough) we feel that between us, we think we have it whipped!!! Another benefit of this production has been realized. Not only will we have a Hermann Oak double shoulder, but we’ll also have a double culatta!!! Initial research has shown that using double shoulders and double culattas can result in AS MUCH AS 40% YIELD INCREASES FOR VARIOUS END USERS! With all of these things having been said, production samples are in hand! Testing is in place. Grading and pricing are being discussed. We’re very excited to have a part in bringing this wonderful new product to our customers! And certainly want to express our gratitude and thanks to Hermann Oak for being willing to not only change the way that they think, but for making the time and effort required to make this colossal project a success. MORE NEWS SOON!!!

-

We have quite a few options...as well as something we really think is going to be exciting, but we can say anything about it yet. https://www.springfieldleather.com/search?keywords=belt blank https://www.springfieldleather.com/Leather/Belt-Blanks-Strips-Straps/Belt-Blanks https://www.springfieldleather.com/Leather/Belt-Blanks-Strips-Straps

-

This was what I was just about to post. Either a piece of string or lace with jewelers rouge on it. Pull it back through the red side.

-

This is what we do here as well. We take and lock the strips in a board so they stand on their edge and don't move. Plus easy storage.

-

We try and work as much as possible as we can with you. If you call in the phone order girls will put in the notes what you might be looking for. Also, some times we have been known to take a picture of what we are planning to send you and see what you think (just ask if they can help with that). Then if you get it and it's not up to par, we will send you out a return label. Hopefully this eases your mind a little, but I do understand the worry.

-

Alright here is the YouTube link.

-

Shouldn't be any problem. I will post it here when I get it added.

-

Page 47 talks about Twist-Loop Reins.

-

It is all good, I just want you to know how I felt too and then I don't blame you to get your monies worth. I went and checked and it looks like they only charge $15 in the cart for short order and not $30 which the price sheet states. That is where the convenience of being able to buy a half yard from us comes in. Don't feel bad at all for doing what you need to do. We really appreciate that you checked us out in your decision making process.

-

While we are more expensive that Fair Field. Make sure you are looking at the #8...which is what we carry. Their price is $18.61/yrd ours is $36/yrd. Also, for orders under 50 yards Fair Field charges $30 for handling. Honestly we just carry it out of convenience, for some. To be honest with you...our supplier is the same supplier as you are using. I can say I personally don't blame you for spending your money wisely. I don't think any other leather supplier even carries it.

-

That is correct! Here is the link. https://www.springfieldleather.com/black-friday-2018

-

Just wanted to drop the link to our scraps and remnants. https://www.springfieldleather.com/Leather/Scrap-Leather