kgg

Contributing Member-

Posts

3,343 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

I think this is a good point for discussion. I think if the top tension is to much then it puts to much strain on the the take up lever and parts and if the bobbin tension is to much then the bobbin assembly is at risk of damage particularly if the machine doesn't have a safety clutch. I usually just adjust the top tension first if I am assured that the machine is threaded correctly, the bobbin tension is correct for the thread and the needle is new and correct size for the thread size / material thickness. What I do is: i) change my needle for a new project or after eight hours of use or the needle seems dull / struggling whichever comes first ii) refill my bobbin with new thread and do a drop test iii) test seam If I have changed the thread size or changed thread manufacturers I will: i) cut the old thread at the spool and tie the old thread to the new thread ii) remove the thread from the eye of the needle and pull the old thread with the newly attached top thread through to the needle from the needle side of the machine iii) install a fresh bobbin with the new thread size and do a drop test. iv) test seam. If the test seam shows the bobbin thread on top then I first back off the top tension and if the bobbin thread isn't pulled up properly then I increase the top thread tension. Do another test seam and if that isn't correct I adjust the bobbin tension by an 1/8 of a turn. kgg

-

Very nice work. kgg

-

When selecting the right needle for the thread I would suggest sizing the needle to the thread. On CowboyBob's website there is a good guide ( https://www.tolindsewmach.com/thread-chart.html ). Depending on how thick / tough the leather is you may find that you may have to move up a needle size or two so the loop is formed properly so the hook can catch the top thread. The 135 x 17 can work in softer thin leather but the 135 x 16 is better as the tip cuts through the leather rather then punching through. The 135 x 17 is meant for fabric where you want to separate the fibers rather then cut them. kgg

-

I like this one from A&E : https://www.amefird.com/wp-content/uploads/2009/10/5-Thread-Size-Comparison-Chart-2-4-10.pdf kgg

-

This machine is a zig zag bottom feed tailor machine. Link: kgg

-

Piping foot for sailrite leatherworker machine

kgg replied to Thescandall's topic in Leather Sewing Machines

Try Aliexpress there are some aftermarkets stuff available. Search for 106-RP machines as they are the knockoff's ( https://www.aliexpress.com/item/1005002823365308.html ). kgg -

My opinion is that just increasing the torque and needle stroke isn't going to be enough. Getting basically 1/2" rope to be sewn properly isn't going to workout with the machine. I could be most definitely be wrong but I think you need a proper machine for this type of work. kgg

-

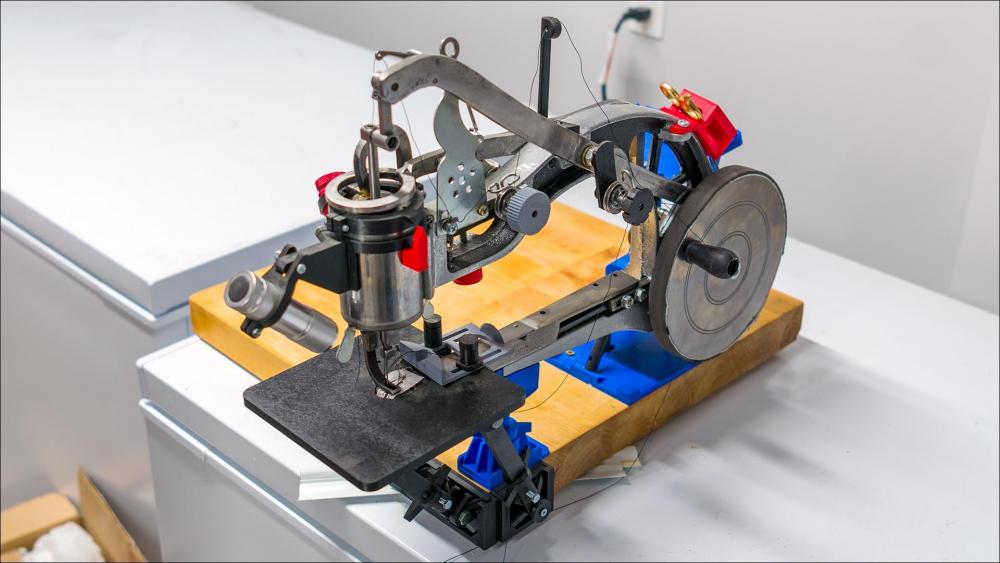

Thank you. I do a fair bit of 3d for all my machines as that is also another hobby of mine. All machines due have their place but.... kgg

-

Looking for a good middle weight machine

kgg replied to Michael Sheldon's topic in Leather Sewing Machines

Thanks, today the replacement model is a Cowboy CB2500. kgg -

More then likely as nylon is stiffer particularly in darker colors with black be more so. What size of needle are you using and what is the thickness you are sewing. kgg

-

Looking for a good middle weight machine

kgg replied to Michael Sheldon's topic in Leather Sewing Machines

I am not familiar with and couldn't find a photo / spec of the Cowboy Model 5. Do you have a photo? kgg -

The thread spool is the blue thing just to the left and under the red scissor scissors holder at the rear. kgg

-

Yes I moved the tensioners and the second tensioner I use for the bobbin winder. kgg

-

This is made with a fur / sheepskin sewing machine. Example: finished seam at 2:10 mark kgg

-

Thank you for posting the link. kgg

-

I think you should move up a needle size as the top thread loop isn't being properly formed and the hook is not catching it. Sometimes you need to move up a size or two depending on the how thick / tough / sticky the material is. A good chart for thread size to needle size: https://www.tolindsewmach.com/thread-chart.html I do have a question why are you not using the same size of thread in the bobbin as the top thread?? kgg

-

This what my "Tinkers Delight" looks like with 1) front and back side light attachment 2) Presser foot position indicator 3) folding table top attachment 4) adjustable and removable front arm support 5) rear 1 lb thread cone support 6) scissors holder 7) thread guide and the list goes on. Tinker On kgg

-

That is smart as the "Tinkers Delight" I have is actually the second one from Amazon as the first one arrived as a box of broken / cracked pieces of Chinese cast iron. kgg

-

If you mean the copper or brass rivets with burrs I use a dremel to grind the shaft off so the shaft of the rivet is below the burr but doing it slowly so as not to over heat the rivet or burr which would damage the leather. If you mean the double or single cap rivets I just wedge a screwdriver under the small cap end and pop it off the rivets shaft. kgg

- 12 replies

-

- how to remove rivets

- rivet removale

- (and 2 more)

-

The 135 x 16 or 17 needles will fit in the needle bar. This a fairly simple tinkering task of raising the needle bar up by about 5mm. That is about the length difference between the domestic needles that come with the machine and the system 135 needles. This is done by slacking the existing clevis attachment at the top of the needle bar and sliding the needle bar up. Just make sure you can just barely feel the tip of the needle at it's lowest point in the downward cycle on the bottom side of the cylinder arm. kgg

-

Yes the faster the slotted disc rotates the more it acts like a solid disc. kgg

-

I would suggest you consider something like a cylinder bed machine like Juki LS-341 or LS-1341 or clone with a table top attachment. The flatbed machines are good for wallets / belts but the bags are probably better done on cylinder bed. Having a cylinder bed machine with a table top attachment would cover all the bases. kgg

-

The constants you have as I understand them: 1. the size of the motor pulley for set 1 pulley is 2" 2. the size of the handwheel for set 2 pulleys and you want to use a 5" large pulley 3. the speed of the motor max to be 350 4. the rpm of the set 2 pulley to be 30 when sewing around corners What I would suggest according to the calculator to get 30 rpm is 1. set 1 small pulley 2" (motor pulley) with a 5" large pulley and set 2 would be a 1.5 small pulley alongside the 5" on the same shaft giving the handwheel a speed of 30 rpm with 150 rpm on the motor When you increase your motor speed up to 350 rpm (max setting) by fully depressing the foot pedal the handwheel rpm would be 70. The pulley alongside the 5" pulley has to be smaller then the handwheel pulley. kgg

-

Juki LU-563 needle / presser foot alignment

kgg replied to SewMuchToLearn's topic in Leather Sewing Machines

Slack the bolt holding the center presser foot to the shaft then move the presser foot so it lines up allowing the needle to be in the center of the presser foot hole and then retighten it on the shaft. kgg -

Those machines are for the true tinkers. I have one of those "Tinkers Delights " and it has given many hours of pleasurable tinkering or hours of pure frustration depending on how you look at it. Save your money and get one of the one armed bandits from Cowboy, Weaver or Tippmann if you want a hand operated machine that will do holsters without pre punching the thread holes. kgg