kgg

Contributing Member-

Posts

3,364 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

If I'm not mistaken: i) Techsew 4800 is a clone of the Juki LS-1342 costing about $ 2300 takes a #18 to #24 needle ii) Juki 1341 costs about $ 5000 takes a #18 to #24 needle manufacturer rated for V138 iii) I am assuming you meant Juki DSC-246 not Juki DS-246 costs about $ (unknown) takes an #18 to #23 needle manufacturer rated for V92 thread iv) Alder 669 costs about $ 5000 sewing thread manufacturer rated for up to V138 v) Parts and accessories for Juki and Juki clones are more available and less expensive then those for Alder machines. Please note the price I have shown doesn't factor in the cost of shipping or anything else. Since this is going to be an expensive purchase find a dealer, even if it means doing a road trip, and do a sewing test run with your items using the thread you want to use. Remember two things: 1) no one machine will do everything 2) BY ONCE, CRY ONCE kgg

-

The article dikman has suggested is an excellent starting point to help you narrow down your needs. If you need a walking foot with zigzag and your budget doesn't stretch to the portable walking foot Sailrite LSZ-1 then the only options that I know of are i) the used market market for either a used portable walking foot Sailrite LSZ-1, ii) used market for an industrial machine similar to the Consew 146 or iii) a new portable LSZ-1as there are a number of options like the Reliable Barracuda, Consew, Kobe, Rex, to name a few. Be aware that the portable walking foot machines are rated for V92 thread and were made to do repairs to sails. The zigzag feature is a nice add on but you could really open up your buying and machine options if this wasn't a must have for your type of sewing needs. kgg

-

The price maybe right but getting parts well that maybe questionable / expensive. If you can stretch your budget a bit I would look at the Tippman Boss for $1000 US. If you need parts they are readily available and if decide you need to later on move to a motorized machine you should be able to get most of your money back. kgg

-

I would suggest trying to add a secondary reservoir air tank alongside your skiver setup to extend the time interval that your air compressor kicks in. How big is your existing compressor tank, size of compressor motor and how long before you empty the tank before the compressor kicks in?? kgg

-

The Techsew 2750 is a clone of the older Juki LS-341 machine. The following link is to the page which shows "Adjusting the relationship between the feed dog and the needle bar" at the every bottom of the page. https://www.manualslib.com/manual/917750/Juki-Ls-341n.html?page=10#manual kgg

-

Dipping my toe into sewing; Advice requested

kgg replied to Sam83's topic in Leather Sewing Machines

A couple of quick notes for when you decide to order and the your machine arrives. 1. Have a second person to help you pickup, unpack, move, lift and place the machine. 2. Industrial sewing machines are heavy and clumsy to handle by oneself whether they are brand name or clone. Example: i) Juki DU-1181N head alone weights in at ------- 31 kg (~68.3 lbs ) ii) Juki DNU-1541 S head alone weights in at ---- 36.5 kg (~80.5 lbs ) iii) Juki LS-1341 head alone weights in at ---------- 37.5 kg (~82.7 lbs ) iv) Juki TSC-441 head alone weights in at --------- 56 kg (~114.6 lbs ) 3. They probably are going to have packing oil over their surfaces so they are also going to be slippery also. Clean all oil off before trying to move or lift them once they are out of the shipping box. 4. Cylinder bed machine and patchers are nose heavy and always wants to tip over until you get a couple of mounting bolts into the rear of the base and table. 5. Since shipping to your location is so outrageous I would suggest either building a table or getting a used industrial table locally. A industrial sewing table is going to be 1.2 m L x 0.5 m W (48"L x 20"W ) and with the weight of a motor weight in probably around the 35 kg mark. kgg- 45 replies

-

- sewing machine

- newbie

-

(and 1 more)

Tagged with:

-

Dipping my toe into sewing; Advice requested

kgg replied to Sam83's topic in Leather Sewing Machines

The prices they have quoted are nuts. Portable Walking Foot Machines: The Reliable Barracuda 200ZW sells for $579 US in North America and the Consew CP206RL sells for $549. These portable zig zag walking foot machines can be had from from China (without the name tag) for even cheaper off of places like Aliexpress. Those sellers would probably quote shipping to Dubia. Of the machines that you were quoted on what I think would work for your small items would be the portable walking foot machines. They may need some small modifications to the pressor foot and feed dog to do thin linings. The Sailrite portable walking foot is a better quality machine but comes at a much higher price tag. Those portable walking foot machines originally were made to repair sailboat sails while at sea. The other three you were quoted on are drop feed machines that would be best suited for your linings and the Juki TL-2000Qi is not a walking foot machine. For your linings you would be better off getting a used vintage Singer 99k type / style machine. A lot of these domestic manual sewing machines can be purchase from India if you can't find one locally. Remember no one machine will do everything. That is why a lot of us have a few different types (flatbed / cylinder bed / patchers / portable walking foot / etc) of machines with varying capabilities. I would suggest starting out with either a domestic sewing machine or a walking foot machine like the Juki DU- 1181N to do your linings and to learn on would be a wise move before jumping into the more capable machines. kgg- 45 replies

-

- sewing machine

- newbie

-

(and 1 more)

Tagged with:

-

Dipping my toe into sewing; Advice requested

kgg replied to Sam83's topic in Leather Sewing Machines

The first one you listed is a cylinder bed machine while the other two are flatbed machines. If you can afford a Juki and need / want a cylinder bed then seriously consider a Juki 1341 or a used 341. If a flatbed is what you need / want then buy the Juki 1541 but you should be looking at the Juki 1541"S" model which has a safety clutch. The cost difference is probably less then $100 but could save you an expensive repair if you jam up the machine. The 4-5mm thickness in leather would be approximately 12 - 13 oz and your 10mm would be equal to approximately 24 oz. I think if you want the ability to sew at 10mm or above consistently you probably should consider looking at cylinder bed machines in the Juki 441 ($10K) class and clones ($4k) and for flatbed machines in the Juki 1508 or better. Those machines are going to well exceed you $2,000 budget so that really only leaves the one arm bandits (Cowboy Outlaw ($1400), Tippman Boss ($1000), Master Tool Cub($2000)). kgg- 45 replies

-

- sewing machine

- newbie

-

(and 1 more)

Tagged with:

-

You never mentioned the size of the thread or the size of needle you are using. You may have to move up a size larger needle. I would replace the needle anyway first. kgg

-

A couple of quick notes: i) the top thread should be thread through the top hole in the top guide pin where you thread through the top hole and around so the thread comes out the bottom hole in the top thread guide pin ii) the spool of top thread should be placed so you have 2 1/2 times the height of the spool from the base of the spool to the thread stand guide arm hole. This will allow for better unwinding of thread from the thread spool. iii) Avoid having the thread stand guide arm hole too high so not to create a steep angle to the thread guide pin. The closer you can get it to being on a horizontal line to the thread guide pin the better. iv) If I'm not mistaken your machine is rated for a max needle size 100 (#16). A #16 needle is good for V69 thread. Using needles and larger sized thread may cause problems depending on the thickness / type of material being sewn and the hook to needle clearance. kgg

-

That is a really nice useful item. Excellent work. kgg

-

My first check would be to remove the needle and see if it then allows a smooth revolution by hand-wheeling. If so the needle is rubbing up against something. Have you: oiled the machine, removed the bobbin and checked to see there is no old thread wrapped around under the basket or noticed any signs of parts rubbing? A couple of photo's maybe helpful. kgg

-

From your sketch I would say it is a British Standard 3870 class 2 lapped seam. Look at the 2.05.02 in the Coats Reference Guide to Different Seam Types under Numerical Designations of Seam Types ( www.coats.com/en/information-hub/Seam-Types ) or ( www.coats.com/-/media/Coats/Information-Hub/Seam-Types_tcm35-155172.pdf?rev=ab977c6d9977486f8312d07387f20bf3 ) for a better / clearer view of the seam types. I would suggest changing to a 2.02.01 or for more strength a 2.04.01 that way you should be able to get an attachment to do the seam in one pass. I agree but not surprised at what the seller is suggesting. Speed reducer either by replacing the hand-wheel or an intermediate speeder reducer between the motor and the existing hand-wheel probably costs less then $200 or put an EFKA servo motor on for $1000 plus. I agree with Wiz that a good start would be to replace the existing servo motor with a good old fashion analog brush motor with the speed rheostat for about $150. My opinion is follow the KISS way, analog servo motor, drive belt, sewing machine. Once you put electronic controls in for the drive motor and needle positioning there are more things to go wrong. I don't use speed reducers, needle positioner's or electronically controlled servo motors on any of my machines. If I needed to lower the sewing speed I would seriously consider installing an intermediate speeder reducer but if I needed to add a speed reducer to get extra punching torque I would say I am using the wrong machine for the job. kgg

-

I normally use the same size thread on the top and in the bobbin. Sometimes you want to highlight your top seam but don't need the additional strength that will be provided by the same size thread in the bobbin. The main thing to remember is the strength of the seam will only be as strong as that provided by the smaller thread. I would turn off the needle positioning then add a speed reducer pulley between your servo motor and the machines hand-wheel or change the size of the machines hand-wheel pulley. There are pulley size calculators out there that would help with sizing the hand-wheel for a given motor and pulley speed. Are you binding the edges of the material?? If you were doing a lot of felled seams I would invest in a flat felled seam attachment. kgg

-

Juki PLC-1690 High Post Bed Thread Question

kgg replied to NickPol's topic in Leather Sewing Machines

Thread Sizing standards can drive you down the rabbit hole that is for sure. For the less commonly used thread sizing the easiest way to determine what the machine can handle is by the range of needle sizes a machine can accommodate and from there work backwards. A rule of thumb with Juki specifications is their machines are able to handle sewing thread of the same size in both the bobbin and the needle for sewing thick materials less one thread size of the max needle size. The needle specification for the Juki PLC 1690 is for a SCHMETZ 134×35R Nm100~Nm140 (Standard Nm120) with a 120 (#19) needle recommended and probably supplied. I used the spec from the Juki site for this machine ( www.juki.co.jp/industrial_e/products_e/lether_e/postbed_e/detail.php?cd=PLC-1690_PLC-1691_E). That relates to a needle range of a #16 to a # 22 needle so from that I conclude it will sew thick materials using V46 (T45) to V92 (T90) thread. For thinner materials the range would be V69 (T70) to V138 (T135). With it's sweet spot thread being V92 (T90). I guess it will depend on the toughness and thickness of what you want to sew. kgg -

Welcome to the forum. A good resource for selecting needles for your machine can be found at: www.tolindsewmach.com/thread-chart.html For your V138 thread you will need a larger needle from a #22 needle (140) to a #24 (180) depending on the type and thickness of material being sewn. The sizes of needles you have will cover off thread sizes V69 and V92. Also buy good quality brand name thread for consistent sewing results. I would invest in a servo motor before buying a reducer pulley. A servo will probably give you all the speed control / torque that you will need. Clutch motors have a steep sewing learning curve. What weight of canvas are you using. kgg

-

Nice job, I really like the nice clean servo setup. kgg

-

It is nice you are offering your patterns for free. Some people have very little interest in facebook while others prefer to stay away from it. I fall into the very little interest group. Maybe you could list them on your website. Thank you for the offer but I will pass. I wish you all the best. kgg

- 10 replies

-

- karlova

- free patterns

-

(and 1 more)

Tagged with:

-

Nice job. kgg

-

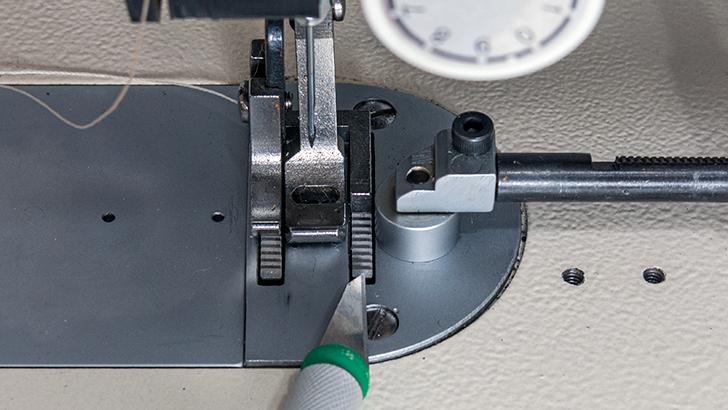

Thank all of you. Here is a closeup photo of the roller guide in relationship to both the double feed dog and presser foot with the roller set ever so slightly above the needle plate to allow it to spin. Where?? Damn I'm gotta have add some more stuff. Thanks kgg

-

The attachment that I figured, up until now, that was unavailable for portable walking foot machines is a drop down edge guide. So I designed and 3D printed a custom plate to accept an inexpensive Suspended Edge Guide I got off Aliexpress. Installation is simple requiring only the removal / re-installation of one existing screw in the LSZ-1 rear casting. This maybe of interest to those who wish to use a drop down roller guide or drop down flat edge guide on the portable walking foot machines. Photo's: Roller 2: View looking straight in with guide in the down position. The roller is extended to be alongside the feed dog opening in the needle plate. This what I would consider the closest usable position possible. Any closer and the presser foot will rub the roller as well as the feed dog. The dark piece of metal on the bed is a straight edge guide with can be interchanged with the roller. Roller 3: View with the guide in the up position with the roller guide in the extended position. This could go higher up if the roller wasn't extended to the max usable position. Roller 5: Overview with the drop down guide, straight edge guide and the binder and binder tape cup just moved to the side off the machine. The "Cup" is attaches to a C-clamp that I designed and printed for use on both the "Cup" and the Binder Spool Platter. All comments welcomed, good bad or indifferent. kgg

-

Have you tried winding the bobbin without the half moon shaped guide and guide stand removed then adding more tension on thread tension discs? A photo of the winder may also be helpful. kgg

-

Would be equal to about V130 so it is slightly smaller / weaker then V138 so I would move your needle size up to a #22 and see if that helps on a test piece. It may also be how you are making the turn that is causing the rogue stitch. kgg

-

What size of thread are you using? A good needle to thread chart would be https://www.tolindsewmach.com/thread-chart.html If you are using V138 thread you may have to move up to a size 22 or 23 depending on the thickness to give enough room for the thread not to be caught by the side of the needle hole when turning in the corner. kgg

-

Needle Hitting Shuttle Hook - Experienced Eyes Needed

kgg replied to adventureleather's topic in Leather Sewing Machines

I just watched the video and looked at the parts manual the RockyAussie was kind enough to share. I think another solution that may work if the OP has access to a 3D printer would be to print a flat thin shim in the circle shape of the ring that would set behind the ring and up against the body of the machine. The manual labels them as "Distance Piece" but doesn't say what thickness they are available in. A decent 3D printer should be able to print shims from 0.15mm up. I suspect a shim in the 1+mm range may solve the OP problem. Sorta kinda like what Alder done on some of their machines. kgg