nylonRigging

Members-

Posts

479 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by nylonRigging

-

Can you cut your pads, from Lamb Fleece hide to make your own ? .

-

1600-$ price is not on the high side for class-7 set-up . they pop-up around here once in while .I never see them below 1500-$ on a table & motor, and go up to 2500-$ on decent table set-up . Pretty over kill for what you want to do . And what 'constabulary' say's, they take up a lot of room (big table) and they are Big, not the machine Head you can just pick-up and throw around all by yourself . But they are a powerhouse for punching thread cord , I have sewn Para-harness container systems with class-7 and there about the only machine out there that can do the required 8-point stitch on the thick stack of webbing and confluence wrap doing the main lift of the harness . .

-

Shyster .....LOL , my grand parents and father Swiss. I guess that explain why you recognize it in German dialect, I use that word my whole life, as my oldman use to use the word all the time for the shady people description . yes i agree it not the host site, it the seller that using the Site to misrepresent items they selling and take advantage of people just for a few dollar profit. I wish the seller was only color blind, but the seller is premeditated in the act, as reason he strips all the ID. mill tags off bottom of cones identifying make/color/size ..etc There not worth wasting energy and time on. I got no time to waste and just throw the Cones on the thread shelves and move-on . It to bad there 'shysters' as I would have bought another 50 cones off them of that factory run if they were legit thread dealer and could snag more of it . They think there making a few dollars and laugh about it, but in reality they are screwing themselves out of sales . The legit dealers always deal straight and pull ahead with there good customer service for the long run . . edit add: . I never thought much about the word till you mentioned it, so I looked it up just a minute ago for it's original origin . https://en.wikipedia.org/wiki/Shyster -

-

Been so long since I bought off Ebay, ' I forget ' the Shyster's that roam around that place ....LOL . Was a real good reminder to stick with your usual distributors . & will make this a quick read . . Was browsing on-line for some more nylon #69 in a specific color/tone few weeks back. Was getting low on 1 color, and could use another 15-20 16oz rolls of it . I really like a good color of light-medium Tan/beaver in tone, as it a real good 'Chameleon' color with stitching certain items . I do have a few 'go-to' dealers I usually buy from ..but , I got a bright idea to just go on-line to do a quick random search anyway . So.., I see and clik-on this one add and it gets directed to Ebay seller . So I look at that picture of the Thread they are selling on the 16oz nylon in light-beaver, and I like the Dye tone of that color he selling in that Pic. So I play it safe . ( I not to stupid..LOL ) ..before blindly buying a large # cones . I log-in and I order just ( 1 ) Roll .. to take a look at, and string-up on a machine and check-out with throwing down a few stitches down . The Color/dye tone is great ! .. and it nice and smooth and tensions great .. I SOooooo Happy ...WuHhoo . So I look at there ebay-Score and it really good, and they been selling there a few years . I message the seller and ask ..." Hey . How many rolls do you have of this particular color I just bought, in 16oz. size 69 nylon Thread " ? They says ..." I only have 14 rolls left ". , and throws me a price that is fair ( 18-$/roll, and free ship ) for taking all remaining rolls in that color . So I pop over payment to seller, Co. ( ThreadXXXXXX ) out of NC. . a week later, I get this 20-Lb. box delivered . I open it up and there are ( 14 ), 16oz rolls of Tan/beaver #69 in there . .... BUT . here's my yearly life lesson in colorblind shyster's .. They are in Different ' color Tones' , different Manufactures, and all Rolls have there manufacture Mill-tag on the bottom removed . With one roll of the 14 actually size #92 that has a grease spot on it . ( in Pic. ) , I stacked the Rolls that did match each other . -- I had to take and save pic. of them to share my forgotten .. Ebay Love .. -

-

Plastic for Templates and Cutting Guides

nylonRigging replied to Riemer's topic in How Do I Do That?

What is your 'cutting table' top ? for running blade on for pattern template cutting . I like to use 4'x8' sheets 1/8" polyethylene sheets to cut/make all my permanent pattern templates . stays ridged , easy to cut even tight radius pattern designs . Just throw down on the material on the cutting table with weights on top, and trace, then cut . I buy plastics like abs in 4x8 ft. sheets from commercial warehouse in this area , and I use a nice size stack of 4x8' every years with internal stiff plates in items I sew/sell . For you to save money over a place like retail chain-store sales . Tap plastics (they are expensive) you have to buy from larger supplier . You are going to need at a minimum Acrylic hardness to run a blade around the edge . Sheet metal would be good for big large volume cutting with running a blade . . -

I don't like the way that looks either . It all mounted on a flat backing plate, so you would think it would all be closer to being in-line to each other than that . Can you screw-in or adjust inward the tension disk assembly any more on that flat mount plate ? .

-

Your check spring on tension assembly is down to far, and you already are starting out with to much slop . No expert.. edit add : ...BUT . now that I look at your assembly , do you have a back-tab on the check spring assembly . that you need take thread over at the end of the wrap on it. 'before' you route threw check spring ? If you not over and on backside of the tab . then you will start out with way to much slop for your check spring to handle . My old consew single needle model has 'check spring' on tension assembly and not resemble yours . . ( this Pic. ) is old singer . BUT it same as your assembly for example . route behind the tab, before check spring . - .

-

i think ? , this model same spec's./as older GA5-1 model . i had a ga5 head a long time back and it sews good, and will throw down solid stitching to about # 277 thread . but I would not use for fashion quality items like belts, it will leave dog tracks on anything that is softer .. It is a good learning machine that is good for rougher side of rigging on leather and nylon .

-

How to remove bobbin case from Consew 206RB-2

nylonRigging replied to Teslabolt's topic in Leather Sewing Machines

Just on a note about those top and bottom , gear, grease pack covers . There not for just making extended lubrication maintenance . Those covers make for making a 'much quieter' operating sew machine . I was sewing on a cheaper Mitsubishi model that has no helical gear covers packed in grease . that thing is Obnoxiously LOUD .Those grease pack covers dampen out a lot of noise . . -

How to remove bobbin case from Consew 206RB-2

nylonRigging replied to Teslabolt's topic in Leather Sewing Machines

Hinged corners heights and front corners . You can pull the rubber corner off . There probably a couple finish Nails or Staple, with the the head just buried below the surface . If it was routed a little to deep or the rubber bumper to low . pull it out and add a spacer under it to add little height 'till satisfied' , nail it back down and bury the the nail heads so the head not banging the head corners . . -

How to remove bobbin case from Consew 206RB-2

nylonRigging replied to Teslabolt's topic in Leather Sewing Machines

Can see much with your pic's but ( industry standard ) almost all cutouts same , and you got Felt or Rubber corner tabs (bumpers) in the routed-out corners for riding flush height with table top . I see rubber corners up front there in your Pic. in the cut routing . -

How to remove bobbin case from Consew 206RB-2

nylonRigging replied to Teslabolt's topic in Leather Sewing Machines

Yes, ..that be nice to have that drip pan, will be mess all over without . I don't see knee lift linkage there either for presser foot ? you can make some adjustments ( leveling ) to the way you Head height sits with table top cutout, by the felt pads bumpers in the corner cutouts up front . And there is a hole drilled on the table tops for a wood post back there somewhere to stick a post . . -

How to remove bobbin case from Consew 206RB-2

nylonRigging replied to Teslabolt's topic in Leather Sewing Machines

Yes.. there suppose to be spring tension on the flip lever . If you talking about a 'backlash' spring inside bobbin cover ? some do and some don't come with . If buy an aftermarket bobbin cover, I see most of them come with a backlash spring . Yes .. my Consew ( manual oil ) , has a ( tin, grease-pack cover ) top and bottom over the gears . I have some machines 'not consew' that don't have grease cans, but my old RB model does have them . You can probably lookup the part# of the grease covers and get a couple . they keep the table drip-pan a lot cleaner with having them , but can do without the grease packs and just lube when you go threw and lube on your regular maintain cycle . I just pack the tin covers with that juki grease in a tube, or just Vasoline/petroleum jelly good also, as you not running a high speed sweatshop . . -

How to remove bobbin case from Consew 206RB-2

nylonRigging replied to Teslabolt's topic in Leather Sewing Machines

those model bobbin cases are mass produced and plentiful . just grab one off amzon or ebay -10-$ . edit add : . . as long as your needle is ( Up ) and not sticking down into the bobbin assembly , your bobbin case should just pop in/out without a problem . takes quite a bit of force pulling on the lever to snap it off . Any idea why you had to pull so hard and the bobbin case would not slide out ? - https://youtu.be/SndtAjJ-pww?t=75 - -

I have never used one without drilling and tapping somewhere . Drilling and thread tapping a machine bed is really easy, and even 12 year old Chinese girl working in sweatshop for a bowl of rice and pack of Marlboro's with a R-angle drill and t-handle Tap does it fast and right . I doubt you find any sold retail that are mass produced to match holes on the bed of that machine . You will end-up drilling and tapping for a binder where ever you choose, just for the fact of getting the binder hardware in proper positioning to feed correctly . Most I see, all the usual generic straight and 90 deg. binding attachment sold have mounting base on the R-side of the feed and throat anyway for mounting. For mounting Seam binder to that machine, the most preferred/desirable position is on R-side on that slide plate . and also you can simply just slide that binder off when not needed to change to another attachment, or remove binder by just sliding it off, and put another plain flat slide-plate on and keep bed clean to sew like usual . . Side-Plate mount that seam bind attachment . Front mounting any attachment items is best done with a front slide-plate. most of the old singers 112/211 211/212 and the current copies have the front slide-plates . ( Here are couple quick pic's ) old singer/new juki, as this about the usual average everyday working binder for seam bind . Also is example of the common ( front slide-plate ) that is used to mount different attachments . - -

-

For mounting binding attachment to that singer model, and other similar . I always mount them to the right-inside slide plate . .

-

- That foot of japan Consew 146RB model of walker , your model Singer 153w103 high-shank feet are more common and better selection . that Consew model is good at what it does, but limited to feet selection . .

-

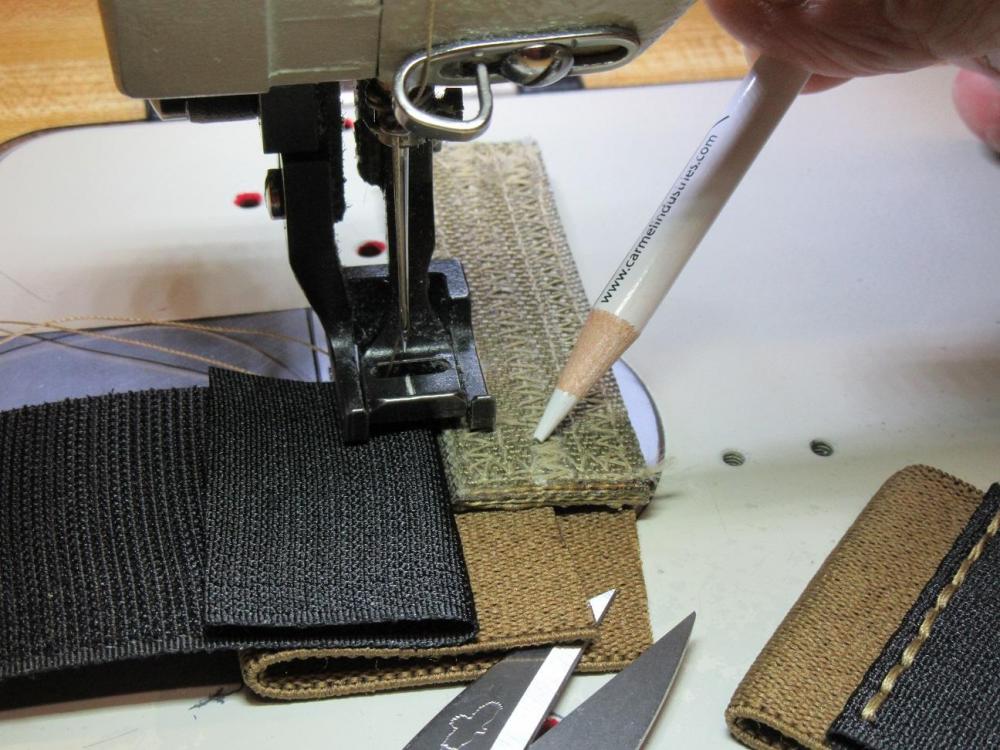

That knobby Elastic and the 'spongy' Hook all stacked together, look to be ' less than ideal ' for a nice stable surface for moving in between the feet and feed dogs . Stretchy Elastic with Knobs and spongy Velcro Hook ....LOL . . If you have a weird stack of unstable surface items together like that . It makes even tougher to do nice job, when you have a raised edge that your trying to sew the Needle close to the edge with your Presser-foot hanging half-On and Half-Off the material . Sometimes when you have a pile like this, you can put a spacer under one side of the Presser-foot that is exact width of the raised surface that your Presser-foot is on top of . That helps keep the uniformity your Foot to the the surface so you use all your Feed Dogs,and that makes far nicer stitching . ( for example) .. stacked ( 2 ) pieces thick heavy 2" Elastic, with fold-over Velcro Hook on top . then sew close to edge . For a spacer, take a piece of webbing that is same thickness of the folded Hook to . in the Pic. I pointing the pencil at the spacer . I using a walk foot here in Pic. but it really helps with all types of feed and presser foot . - -

-

It is said in the #2 post of this thread - ..."I would also place a sheet or two of regular paper ( on the feed dog side ) of what you are sewing". and I understand the concept that it possible to push materials being sewn thew a overly large Needle plate hole, by the needle itself or by using high amount of presser foot pressure . but I don't think the OP is saying is a problem he having ? . He not even saying what size# needle he using, or size of thread, mil thickness of Elastic, or if he has a huge needle hole that elastic is flowing ? He mainly was asking in #1 post about 'possible' getting/ using a rolled-edge foot attachment, for making a small 2" long fold on Velcro easier to and fast to do other than by hand . The 'silicon' bumps being described in #3 post from OP, on the Elastic is a little odd addition to that materiel ? , and he saying it ..." causes to much bulk ". ( I assume ) for him to sew threw ? I never have sewn Elastic with silicon bumps laminated to it's surface, that could be a learning curve ? . Never used lubrication ?. Don't know if I can add anything special as machine ?. I don't do anything special , I just sew many rolls of Elastic every year to Hook and Loop and other fabric using different machines daily with different machine feed types, without ever having problems . using majority of time a 135x5 and x17 and mostly E69 Nylon, but have used bigger threads and needles . the only bitch I ever have is maybe couple times a day I will get a little needle thread fray, from the sharp abrasiveness of the Hook side of Velcro . It also goes without saying you need to keep a new sharp fresh needle everyday for a nice smooth plunge up and down threw Elastic . OP never say's how long he been trying to smooth out his problems sewing on the project at hand ? . but repetitious practice never hurts to make things easier. .

-

Don't think you could make it more easy or faster or need a foot attachment for sewing rolled edge for just 2" of folded edge . As your just folding-over edge of a 2" edge of Velcro hook, sewing to topside piece of 2" Elastic . It pretty fast/easy to just use your hands to do this . also from other posts . I don't understand using paper under next to feed dogs ?, because material never gets sucked-in . or, Elastic stopping the loop forming that the Hook catches ? . I sew heavy Elastic and Velcro everyday with several different machines . your last post: ..." I am using a round point. I think I probably just have the wrong machine for the job ". A flat-bed machine or flat table attachment would be easier for you that doing on a curved surface needle plate on cylinder arm . .

-

- A good question on what Castor wheels ? . And I am slowly finding out there is a big difference in quality . Little wheel and the bigger wheels 2"-3"-4" . . Single-bolt post mount, or Flat-plate 4-bolt mount . . The cheap Castors you buy have a shitty friction brake lever, and the better one's have good quality friction-lever brakes that are more positive 'smooth lock/unlock , with better smooth tighter Bearings also . I use ( like using ) the 'flat base' ( 4-bolt ) , and I mount to 2"x4" and 2"x6" wood , between the machine table and Castors . I just use small lag bolts to secure castors to bottom side of wood . - -

-

You pretty much answered your own question ..." shorter table for better storage ". I keep 3 machines off to the side on castor wheels away from the rest, and one machine is on 1/2 flat-top table . 1/2 tables are great for saving space, or for machines that not your everyday workhorses at set stations . Also..I seen people put a hinged drop-leaf on the side of the 1/2 tables also, just swing leaf up for more sew table . .

-

UT3200: Flatbed attachment for the Cowboy CB-3200

nylonRigging replied to Uwe's topic in Leather Sewing Machines

he does nice work . I have a UT441, drilled and tapped to the arm of a 3200 artisan/Toro . His flat bed attachments are the best out there for, mounting , ruggedness ,and just pure aesthetics . . -

Why is the feed dog timing like this?

nylonRigging replied to Gymnast's topic in Leather Sewing Machines

You tuned it to your specific needs . You now advanced feed dogs, and you slow-speed stroke the needle plunge thew thicker materials . now with your new tune-up . For my curiosity, what I would like to see .. Try sewing with lighter thread and using lightweight fabric with 'speed ' on a straight run stitching, like the machine was built for . . -

hey, if you don't already know this . one more thing when you get around to dialing-in your tension release, with the lever/pushpin behind tension assembly . if you making a Pin or just cutting down a generic pin to length. 1st natural thing you going to do is make it all super tight ( but don't ) . You want to have a good amount of knee-lift play before it tops-out with push-pin engagement . and having a ( good amount ) , is having enough play to lift your presser-foot with your needle down and rotate your sewing materials under it, 'without releasing ' the thread tension on the partial foot lift . .