nylonRigging

Members-

Posts

477 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by nylonRigging

-

purchasing New ? or , Used . ? If I wanting something very specific, I just buy new . But for Used and you flexible like age, wear, specific model build .. I just keep an eye-out on my NW. area Craiglist for used machines if that the rout you choose, just keep steady eye on it once a week and look because around here are always at least a 100 random sew machines always up to dig threw . If you wanting/looking New and ( actually In-Stock ) that can go out the door now . I know that Artisan just got a new fresh shipment of Post Beds in this week, very common design that imported in and sold by a few different sew vendors . https://www.artisansew.com/postbedmachine.html .

-

Techsew 5100 Binding attachment?

nylonRigging replied to Runzeigrun's topic in Leather Sewing Machines

Total price for everything on that kH binder system , synchro Swingarm , raised Feed Dog , raised Needle Plate, and Binder . ( all shipped ) . is just under 240-$ That is just a killer price for the quality of mechanics that I received . I seen that and I could not walk by and pass that up, had to get one and mount it up and check it out . 'Same here' .. Shipping is 'surprisingly' super fast speed pack, for me on W. Coast it was ringing my doorbell in about 5 days after a email notice sent . I highly recommend to anyone on the fence and thinking about getting .. All hardware was true and correct in mounting . The Synchronized Swingarm mechanics, is about as simple as it gets, and works perfect . system is 'pin fit' and witnesses movement with the raised Feed Dog movement . . -

Well string it up, sew and see, figure out what he was doing ? . it;s interesting, he had something in-mind for taking an interest with doing that setup . looks like he is still keeping/using the the knee press-foot lift with factory tension unit . Did you ask previous owner what size thread he was trying to run on the top thread ? Did you ask previous owner what size thread he was trying to run on the top thread ? . was he trying to use 138 on top ? . I have very similar looking DB body , but I did not have to add that much extra tension on the machine to punch thicker and heavier, and to make good looking stitches top bottom . but I only using nylon #69 . The L-bobbins in my DB are pretty small but OK volume for using #69, but L-size is small and a lot of bobbin changing when sewing . .

-

I know my Mitsu.DB .. that was a weak point for sewing heavier and thicker . I put a heavier tension spring and new disks on it, with also using a Thread Post w/ tiny tension disk . 'interesting'.. So yours might have been MacGyver'ed even better approach, with that added tension setup put on it . Sew with it and let me know if that works well, I very well could be adding that to mine . .

-

Identify finding parts , Most wear parts for that machine are Mass produced common/plentiful and economical that cross over to many name branded machines that ALL SHARE Same Parts . I have no idea what the 1st Parent machine design was copied for the Mitsu.DB's . But Mitsubishi made many thousands of them in a lot of different model and then a crapload of DB-### re-branded name models . It's a VERY Common high shank foot bottom feed design machine . - - DB's don't get any respect on a leather forum , but It is, what it is .. DB's are good economical machines that sews pretty good for a ( bottom feed ) . it's a machine that uses it's primary feed with the bottom Dog Only . Sews great with 69E. has big selection of very narrow to Wide presser feet shapes, with dogs, needle plates ..etc. Main design was for light/Med. fabric weight and moving fast RPM . but you can easy slow them down for more precision stitching for little more heavier materials . The negative .. Your going to have 'Dog Tracks' on the bottom side of some soft leather, when using Presser foot or a roller foot . Sometimes that really matters, sometimes not , fabric never . But It a sewing machine that comes in handy for certain jobs, and handy one to keep around when you can have several machines in your stable . I see that you have a Roller Foot/dog/needle plate, on that Pic. and they sew good with roller when you 'slow them down' on the RPM with a nice servo . Roller foot good for certain jobs, and will delete the sliding/friction of a presser foot for a more fluid movement. .

-

You did not sew with it before buying ? . Only way your going to know if it's worth the price paid . You need to oil and manually cycle the machine. You need to plug it in, string it up, and lay down some stitches . If it a mechanically sound stitching machine, then 300-$ is a OK price. .

-

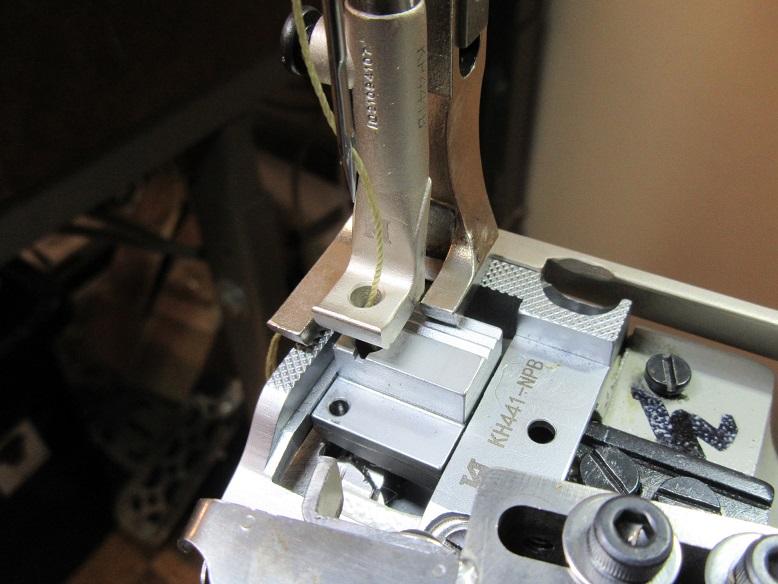

I was absolutely stunned by a refreshing slap in the face, from Craftsmanship ...LOL . . those KHsew 441 presser foot set in the Binder kit are, Sweet .. perfect in-spec. machine cut and finish, and along with there raised needle plate and feed Dog design, was absolutely Beautiful . I noticed they had other high-shank presser feet I am going to check-out, along with there needle gauge sets from there site. For majority of the ChiCom/china mainland products .. including 441 presser feet sets ... all bought off , ebay, amazon , and other online retailers . Have bought a dozen of the ( blanket foot/needle foot ) the full sized '441 ski's' for cut and grind . There really cheap-$ price, but all bought were disgusting, absolute ZERO craftsmanship and quality control . ALL have had over sized shaft hole, and All have 'never' been Square and Center . I was going to cut/grind and bastardize them anyway, so i used most of them, some I throw in the trash. . .

-

Finally got caught-up with orders and a couple hours to play with and do a little cut and fit on the new 441 binder this weekend .. and want to add: on the presser foot set with this Binder kit , this is ' Very 1st time ' that I have bought an aftermarket presser foot set, and it was perfectly cut to Spec. with the center needle foot shaft hole cut to correct size for a none sloppy fit to shaft . and centered perfect alignment between the outside presser feet . Also the whole kit looks pretty sweet on it's machine work and finish . Not finished yet with what I am doing now with the Binder, I just setting it up, and getting a good feel for what they sent me . Also waiting on an order of 1" nylon bias type2 to start in getting it appropriately dialed . The machine I am adapting the Kwon Hing kit to, is an ( Artisan model ) . So, No Way I cutting that nice Kwon Hing outside Press foot that I got with that Binder kit . So I cut/trimmed another cheap crappy Chicom foot that had laying around . I cut both sides of presser foot to appropriate lengths . Then I soldered extra Heal Plate to the Foot, to mate with the raised Needle Plate that has some nice knurled surface to mate with the foot's heal pressing down on materials .Then added a push bar off the Binder throat exit, for feeding the materials edge nice and snug to the Binding . also added a couple different mounting screw on mounting Binder to the swing-arm . - - I Just grabbed some scrap off the bench, and this is the 1st thing I Seam bound for a test . so I think the KH 441 Binding kit looks pretty promising for putting out some good results when people get it all tuned to there taste . -

-

Seiko stw 8 / consew 225 what to adjust?

nylonRigging replied to bigsig11010's topic in Leather Sewing Machines

edit to change .. thought it was bottom load . OHHhhh .. must be ( Top Load ) Bobbin ?. Your Tension is on the side ( staring up at you ) it's the 'spinning basket' you removed the Bobbin out of . just start looking around the side that is exposed to you, and you will see the tiny screw that adjusts the little leaf spring that the Bobbin thread is routed threw . . https://sewing.com/sewing-machine-parts/ . -

Zigzag 10mm wide machine questions

nylonRigging replied to Montybrown's topic in Leather Sewing Machines

Wow.. Nice .. you went and pulled the trigger on a new 146 RB . That Consew is a strong puncher, lay's down nice stitches, and well design machine, will last you minimum of a few decades .... LOL Like all sewing machines . ALL have there plus/minus's . ( IMHO ) I think the only minus with this line of Consew, is limited design/selection of presser feet . But if looking for a combo-straight stitch/zigzag, That one is 'proven' to be a strong everyday workhorse machine . I bought a new 146RB1A over 20+ years back and have no regrets, I jump behind that thing at least once every day for something, was a good investment . I run ( 2 ) combo/Straight/zigzag stitch machines . setup heavy and one setup light . the 146RB for a 'thumper' and a old Swiss. 217 Bernina for more finesse . Keeping a ZigZag in your arsenal comes in SOoooo handy to jump behind for even doing a quick Butt seam, and even use it for quick (hidden) Tacking to hold together layered panel items,when putting things together . . -

Zigzag 10mm wide machine questions

nylonRigging replied to Montybrown's topic in Leather Sewing Machines

Flat Bed zigzag and walk foot . The Consew 146RB-1 models, ZigZag /straight stitch, are pretty common in use and dependable workhorse machine . . -

On the thinner material you should have no problems . I did Bind some thinner 4mm thickness and was all good, and I did some test sews on different thicknesses after getting it all together and working out some of the bugs . I am pretty swamped this week on getting some orders finished and out the door, Then I will put more time into fine tuning there binding kit . ------ The KHsew parts kit, I am pretty impressed with . This IS NOT the normal that I am used to when getting aftermarket sew parts off the mainland PRC . KHsew parts Quality Control look really Nice, the Fit to machine is spot-on, and tool and finish is really good . This parts kit is a well thought-out piece of kit, and it's great starting point with the 441 machine to get yourself Binding . I have ZERO regrets on the KH 441 Binder parts kit, it is a keeper for me, ( IMHO ) It is 98% all there for your Binding needs, and I will build and modify off of it, to make a kickass binder set-up for my personal needs. ------ OK .. The KW 441 kit, will and does seam bind right out the box . It is plug-in and play parts kit . This Is a Nice Seam Bind 441 kit .. But it can and Will do better, and I have never bought even a high-dollar seam binder that I have never had to put some work into, to get that professional finish look I am after . If this is all the work I have to do get the end results needed with the purchase of a new Seam Binder. Then I feel like one lucky SOB .... LOL . Couple things that I am going to modify . change and shape/cut a different outside press foot . And am going to add-on an extension off the throats exit, for material and binding guide/edge to push against feeding out . ( for me ) .. when doing some test runs . That is only negative I see, 'You Will' , be constantly fighting to keep the Binding Tape's rolled edge 100% consistently tight against your materials edge when sewing. The Bindings finished rolled edge will have some soft hollow feel if not getting some added push surface leading into the machines feed . .

-

I really Jones'ing to get these parts-in, and for giving them a going over, and mount them on the Artisan 441 clone . . On the ( KHF 441 ) part . . 9mm opening and a 26mm binder fold, is the smallest option on that part # . but that is GTG and satisfactory for me for some heavy bag binding. Great looking website with a lot of nice looking accessories . easy Log-in, and I have had all the items in my Cart trying to order the 441 Binder parts . Was Easy to get it all together , But... I got an item by mistake in Cart twice ( X 2 ) , and For some reason I can not delete , ( Site Glitch wont delete follow threw command and update Cart change ) . I have tried many times to delete the item in cart. and pay for ( x1 ) . I still waiting for a return contact back by email so I can get some new play toys . ....thanks for the heads-up on the Parts in this Thread . . .

-

Most anytime you want to drill/tap a hole on the Flatbed. The Machine body overhangs blocking your average pistol grip style Drill from anywhere near getting your Bit Plumb. A small R-angle drill will get you into the places with little workable headroom clearance . You particular model Consew is single-needle, and does offer very affordable and wide selection of Presser feet. You might get lucky and not have to Modify your R-side of your presser foot at all . It all depends on model type machine you are putting a Binder to, and it's offered selection of Feet, and just how close you have to get to that Needle for your feed. .

-

what Don and Wizcrafts is saying .. . You will be picking up a lot of small facts in a fast,short time . so don't feel overwhelmed and stay relaxed. Mounting brackets and direct deck mounts, Drilling and Tapping is no biggie and is all but expected, .. PLUS your going to want to get more Presser Feet... LOL .. fitting/cutting/file/trimming Feet, to fit your need is all part of Binders . All tools you will get good at using . small R-angle Drill , Thread Taps . Then Cut/Dremel , Grinder and a File. a small Vice. To shape Feet for a mounting Binder into a workable slot . You spend many Hundreds-$ on a top-shelf Binder, or folders, Or just spend 20-$ for generic Binder off EBay . But all have one thing common in the end everyone deals with . YOU Alone have to make this happen . For a fact, you all by yourself ( will spend Many Hours ) . in finding that, perfect Spot to mount, with just the right Distance, correct Height and perfect angle of Feed . All set in that perfect slot set into the side of your Presser Foot, That most times you have to make. Your picking up and building a lot of good knowledge to have. 1st time new Binder Set-up, It's always Pain in the Ass, but it does get way easier after you do it a couple times and get your head wrapped around the basics . This 1st trip your now taking. You will be gathering a lot of little details and store them away in your head, that you will come in pretty handy latter down the road. Because if you are sewing for any amount of time. You will have 'want' more Binders setup on this same machine, or Binders on a different machines. .

-

My ego eye can't tell what brand of binding you are using by the Pic. ..LOL . I was just saying that I have had real bad issues with a lot Import, NonUS milled binding Tape, especially in the mil.spec.typelll . Me If I buying binding, Usually buy from Bally Ribbon, but If I have bought from other suppliers I make it a point to ask where they bought it from because until you run a lot of good quality and bad tape, it hard for you to really see the differences . I see on-line generics that say and list different options of throat widths . If you don't see listed, You need to email or call them and ask for an answer of sizes available . but If a company can't tell you what the simple feed opening of a binder is, then you should have nothing to do with them . You live in Canada, so I don't know if you have any Shops that build to order . If you want 'one' of the Best for custom soldering made to your specific wants, I go to Tenn. attachment . Just expect to spend a few hundred $ minimum, and you can easy get up to about 600-$ pretty quick . but you get something that will last and give quality results. Right Angle Binder, is feeding your tape into the throat at a 90deg. off to the side, and not straight in front of you . Your binding then makes turn and folds into the Throat, running into your machine feed . ( me ) , I like a swingarm bracket for a top load bobbin machines, with the Binder system mounted on the slide plate covers . .

-

Sailrite binders are still pretty generic and are nothing special . Your going to want a Right angle to do corners and negotiate radius proper . So Ask Sailrite if they build a R-angle 3/4" binder with an adjustable mounting bracket for your Consew . Also take into consideration your foot setup on your machine . Your going to want to adapt the Binder side of the press foot, so the Binder can slip in there close as possible for good position . - ...edit add: . I Mic'ed both my Single Needle, and Double Needle binders and they both are around the ( 5.5mm ) in mouth openings . Your upper post say's you are using a 2.6mm opening, and you were getting tight on negotiating over transitions of thickness of added seams ..etc with the flow of your binding. Your 2.8mm sounds ideal for thin edge and a nice finish, but you need bigger for thicker material with good flow up and over spots . Also, I just checked with the single needle and 3/4" tape . and ( for me ) the thickest I would Bind with 3/4" tape with single needle is about 4.5mm thick of material stacked to look good . You can only push 3/4" so far for a wrap and look nice . This also .. ( Just my opinion ) Use GOOD Quality binding . Your using 3/4" bias weave and type lll binding . The day I quit buying subpar Import crap binding trying to save a Dollar, and 100% moved to good US milled product, was the smartest thing I ever did . The majority of import is hideously out of Spec. it's CRAP that does not track and flow , it causes more headache that the worth of saving a few dollars over Quality binding. .

-

Binding is always a BIG PIA to learn , 'everyone' has Lot's Of Headaches at first...LOL . and is a pretty in-depth study throughout your entire time sewing . Single Needle . You should be able to get by with most what your binding with 3/4" tape with, 5.5 or 6 mm mouth/throat on the Binder. Your using bias weave tape, and that is good flexible for doing tighter radius . ( Just my feeling ) probably your biggest problems with the way your tape is tracking and feeding to sew, might be the way your Binder is set-up to your machine to materials used. . and just your lack of technique built up doing it . like negotiating the thicker seams or sections that your passing over. Also .. Not to say that you cant do decent binding with a generic . but there a BIG difference in end product quality, between using generic Binders bought off the internet, and buying custom soldered binding throats . I have always got best results using hand built/soldered setups and the Tape/Binding always tracks the best threw there throats. But generics are Good Learners to build technique. - On that link posted of ( ngosew ) . I always got positive dealings with them for several years. if you call or Email NGO sew , they always get back to you. They are down a little S. of me in Salem OR. mail --> ( info@ngosew.com ) ... Jack or Liam are the 2 contacts that I have dealt with. .

-

Much appreciate the Info, and also the time you are taking putting it to Pics. and Posting . It really helps cutting down on some of the modification headaches that are always there when your getting new 'sight unseen' hardware for a machine . .

-

- Damn .. saying that is .."very reasonable price". is understatement on that hardware kit receipt you just posted . Those Pic's you posted, sell themselves . & Very affordable price to purchase and have a wide selection of different Throat sizes. to have on hand for binding different thicknesses of materials. .

-

Suggestions on freeing frozen vertical shaft?

nylonRigging replied to rlevine's topic in Leather Sewing Machines

Good deal, that a little stress that you clear of now.. If I cant get old metal free and moving with heating, that when I start to get worried . Hope your staying warm to ' It's Cold ' . I noticed your profile in Portland . I over west past of Hillsboro and the Ice is coming down here pretty steady now . seriously thinking of chaining up the 4x in morning to even get wife to work. . -

Suggestions on freeing frozen vertical shaft?

nylonRigging replied to rlevine's topic in Leather Sewing Machines

Hot air Heat it maybe ? , with direct heat, I have loosened up a lot of 'old' screw that have been torqued down for ages with soldering iron tip and direct small flame . But larger area, like you describe . maybe just pump some heat to it for a time with a hair dryer on high-heat, or a heat gun set on low setting . then manually working back-forth slowly try to turn shaft . . -

How to identify when my consew was made

nylonRigging replied to Don Ayres's topic in Leather Sewing Machines

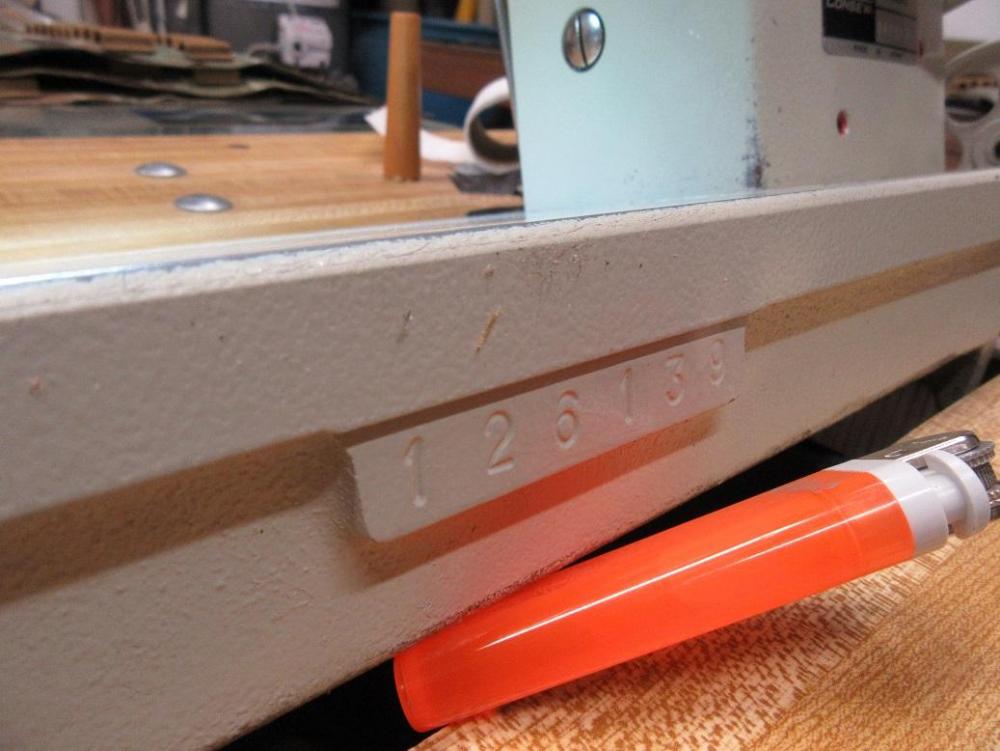

That japan/Consew serial# Head, I bought new back in May of 2001. still have receipt in the drawer . But I know the wholesale outfit I bought it from was sitting on it for more than 2 years before I bought it. I was eyeballing it for sometime, whenever I would go into Portland for parts or supplies . So I thinking ( guessing ) it is about a 98 -1999 production. . -

How to identify when my consew was made

nylonRigging replied to Don Ayres's topic in Leather Sewing Machines

I have never seen an on-line Consew serial#'s and date of manufacture archive to look that up, Like you can easy do with Singer manufactured machines with factory serial#'s cross reference open direct to the public. Does your Consew machine have the serial# cast on the underside front of the machine ? . You might give call or email Consew, and ask if there is a way, or if they even do publish there date of manufacture info . .