-

Posts

599 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Brokenolmarine

-

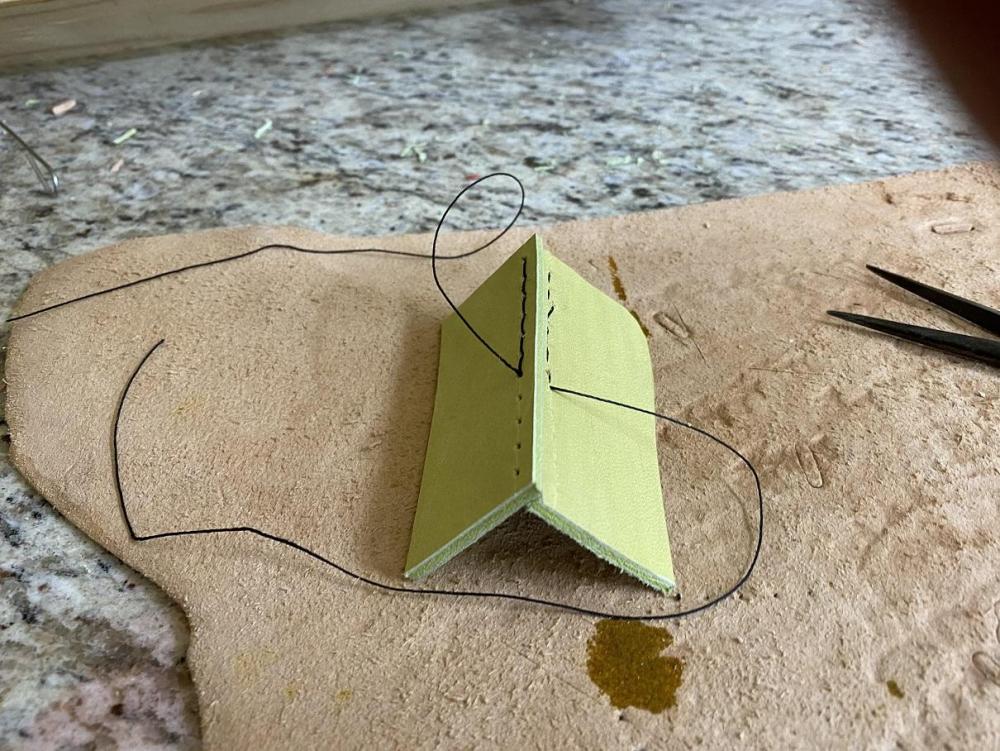

Almost time to hand stitch the piece together. A new technique for me. Box stitch. Time to practice. Mark the spacing and use the fork on the top piece to punch the holes. Butt the side piece to the top and align them, then mark the holes with the fork, but don't punch them thru. They are angled thru with the awl. The side piece is butted up from the bottom at 90 degrees. Once they are butted, you sew them together using a standard saddle stitch method. I didn't align my spacing correctly, but that's what practice is for, to learn the spacing and angles. I'll practice a couple more times before attempting the stitching on the actual pouch.

-

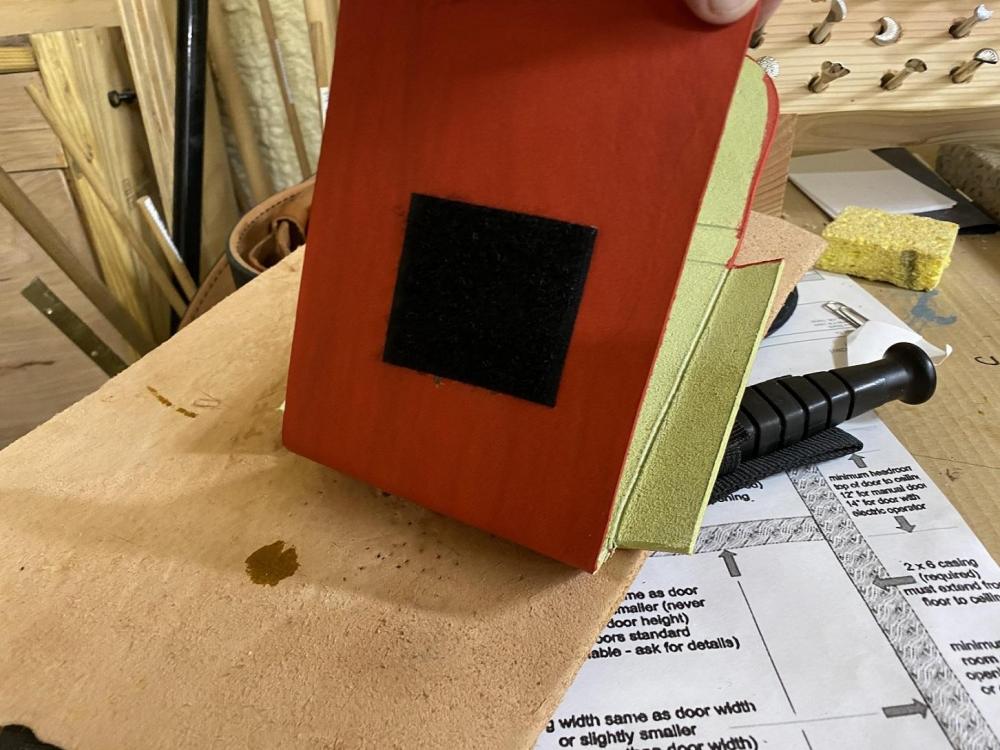

Got out yesterday and sat down at the machine to sew down the D-rings. Small space to sew, but got er done. We are getting close to the end here. Things left to do, but close. I started with the Red pouch because the kid liked the green one better. This was my first, so it was practice as well as a pouch she would be able to use if it worked. I have learned some valued lessons. Don't treat the edges with dye, it bleeds badly on chrome tan. I can only say that the sewing was harder than I expected, but it's getting there. I had the edges still to burnish and the patch arrived and I sewed that on, pics to follow. I treated the panel with mink oil after dying the thread where appropriate.

-

Now that the sewing on the flats is completed, I can attached the D-Ring assemblies. I waited as I didn't want them to interfere with sewing on the flap or more importantly the front panel. I marked their position and coded each one to the marking in case of (BECAUSE OF) minor differences. I then added a dab of contact cement to the pouch panel and the assembly. Clamped them, and left them to cure. I'll sew them tomorrow. Once that is completed, I will sit this part aside, while waiting for the RED CROSS patches due Wednesday, and either start on the green one or work on other projects around the farm.

-

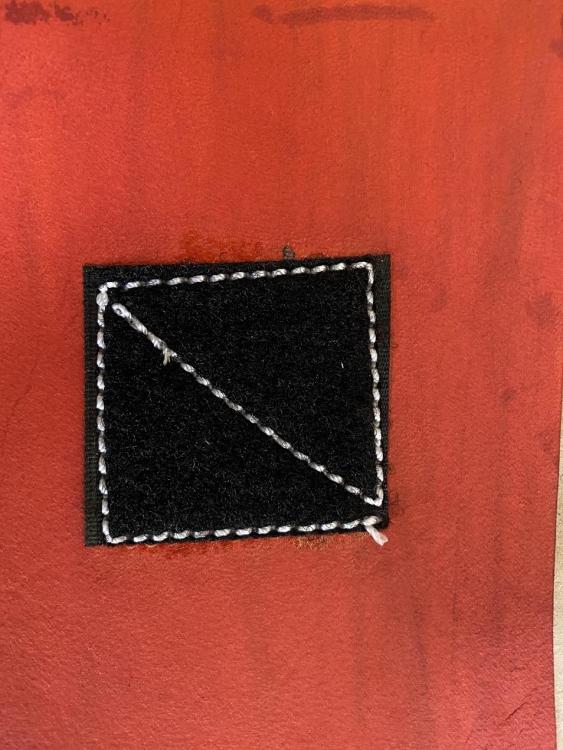

Next was sewing the velcro loops on the outside of the front panel. Again, the thread will be dyed to match when I am done with all the sewing. Inside stitches. Not too bad, but not perfect. Things I need to learn. I'll burn and trim and all when all the sewing is done. I did stain portions of the inside of the front panel, and all the edges. I didn't stain all the way down. When I am staining the holes punched for hand sewing, I may finish the inside or not. You won't see the inside but ... I have normally finished the insides.

-

Well, I waited all day for the call, but nothing. NO idea what might have happened. At about 3pm I gave up and went out to the shop to work. I started by sewing the velcro HOOKS on the flap portion of the pouch. This way if they get weak they can be cut off and replaced. It's unlikely they will wear out before she wears out the pouch itself. This is really only the second time using the new machine... so I don't feel like it was too bad. Here is a view of the inside of the flap. You'll note that I dyed the inside of the flap as well. Once I have finished all the sewing to be done, I'll dye the stitches. I have ordered a Red Cross Medical Patch for the flap To cover the outside stitching. Once that is sewn on, I'll dye this thread black. This will be covered with a Red Cross Patch that Glows Green in the Dark to help Jess Find Pouch in an Emergency.

-

My daughter picked up a dozen reptile skins for me at a good price. Some are as soft as suede, some are a bit stiff, the two rattlesnake skins are stiff as cardboard. How do I condition them so I can work with them as inlays on a sheath, holster, and gunbelt? Then keep them pliable.

-

BlackJack,Sap, what ever

Brokenolmarine replied to Bert03241's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I remember the first year COPS was on the air, the officers are dispatched to a dispute in a bar. Redneck is acting stupid at the pool table, and the patrol boys are trying to get him under control. Drunks can be as slippery as cats. To make it more difficult, his four eyed forty ish drunk gal pal keeps trying to interfere. The female Sergeant warns her two or three times to stop the slick as snot the sap appears from her slash pocket on her right uniform trouser leg, pop, perfect. Woman's glasses fly off she drops like a stone. The Sergeant returns the sap to the slash pocket without looking as smooth as a Doc Holiday shuffle. you'd think she had done it before. Then, remembering, she shoots an "Oops" look over her shoulder directly into the camera. Can't take it back, so she turns to her guys: "Charge them both," she says. -

I like the second one better, the crown on the first did look off to me too, but then, I'm more traditional. Very nice.

-

Hopefully will work on this tomorrow. Watched vids on box stitching if I get that far. The Cowboy and I will sew the D-Rings and velcro at least. First, I have to wait for my mechanic to call. I am in the process of building my private shooting range. The berm wall is done, it will contain the dirt berm. The dirt berm will have a base of dirt filled interlocking used tires. None of the tires will be exposed, they will be covered with dirt, but will help strengthen the base. I'll go pick up a trailer full of used tires tomorrow. No charge. Drop the trailer back by the berm. Then, back to the leather.

-

Next I refold the pouch and mark where the flap hits so I can apply glue to the two pieces of velcro, AND the locations on the pouch. Yeah, good luck with that. I make my marks and hope for the best. I will glue the squares down now, and when I sew on the D-rings, I'll sew down the velcro as well. This way I don't have to try and HOLD the velcro with pins nor worry about it pulling or shifting if it was only sewn. Of course, I glued the front panel as well. This was enough for now. I shut down the shop and let the work set up. I got some inspiration from my pup, Princess Fiona when I went inside. She had a great idea.

-

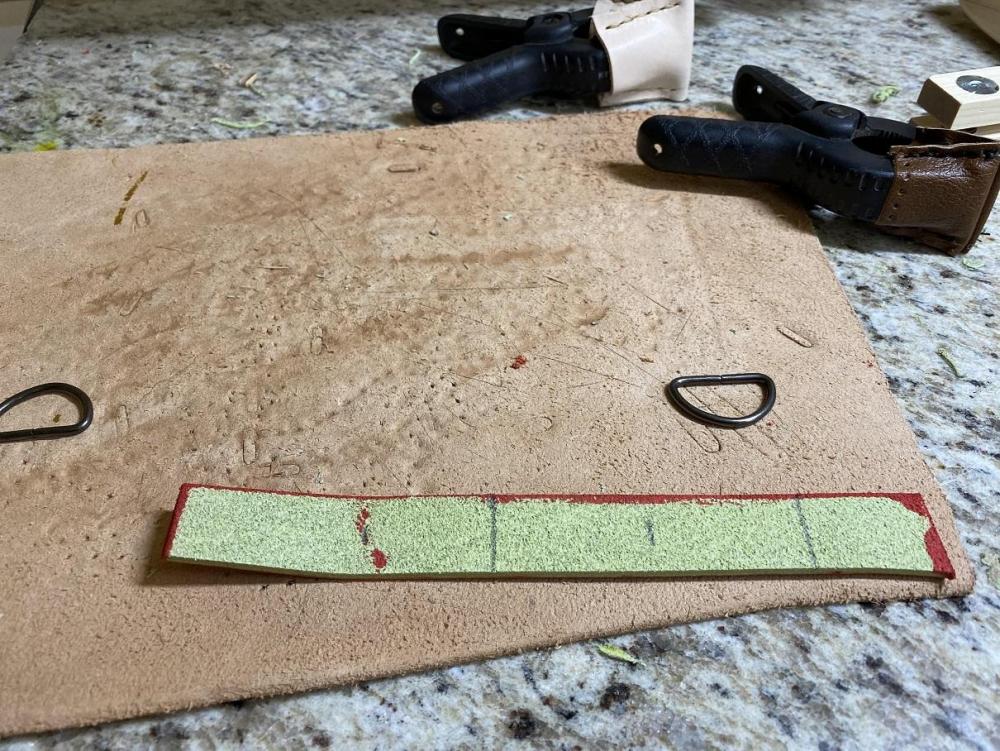

Next I was going to build the strips to hold the D-rings which I'll sew at the upper edge of the back of the pouch. That is how the kid wants them. It's the way she wears the pouch, like a messenger bag. So, I gather up the tools I need. I measure the inside of the D-ring, 7/8 of an inch, and set the strip cutter. Cool little deal. Nothing fancy. Make sure I have the clamps, and the contact cement. Zip, I make the cut and then mark the back of the strip for cutting across to make to loops and then applying the contact cement. I need to leave the area for the D-rings glue free so they will move freely, and have glue on both ends of the two 3" strips. Git R Done.

-

Once all the grooves were cut, I wet the grooves and then attempted the fold. It actually worked pretty well, and allowed me to see I wasn't going to be able to use the extra 1/8" sewing area, so I trimmed it off. I cut a notch for the bottom and will definitely be sewing the bottom and sides by hand with a curved needle. Ignore the bruise on the back of my hand. For some reason a light touch bruises me up. Sucks being old. I got that taking shirts out of the dryer.

-

Back at it to begin the build. First step is to try and fold. Groovy.. yup, use the grooving tool. This cuts the V shaped tool to allow the fold, but have to wet the leather to keep it from cracking. I make several passes to prevent tearing. Don't ask me how I know this... It takes a lot of grooves to allow the test folds to see the pouch. A LOT of grooves.

-

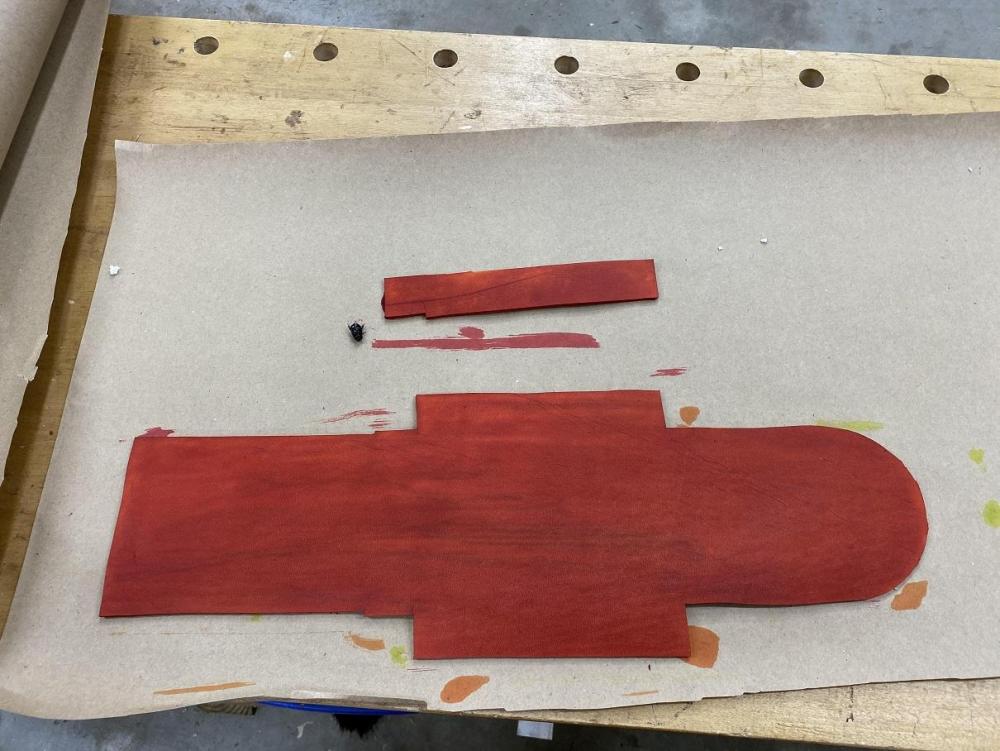

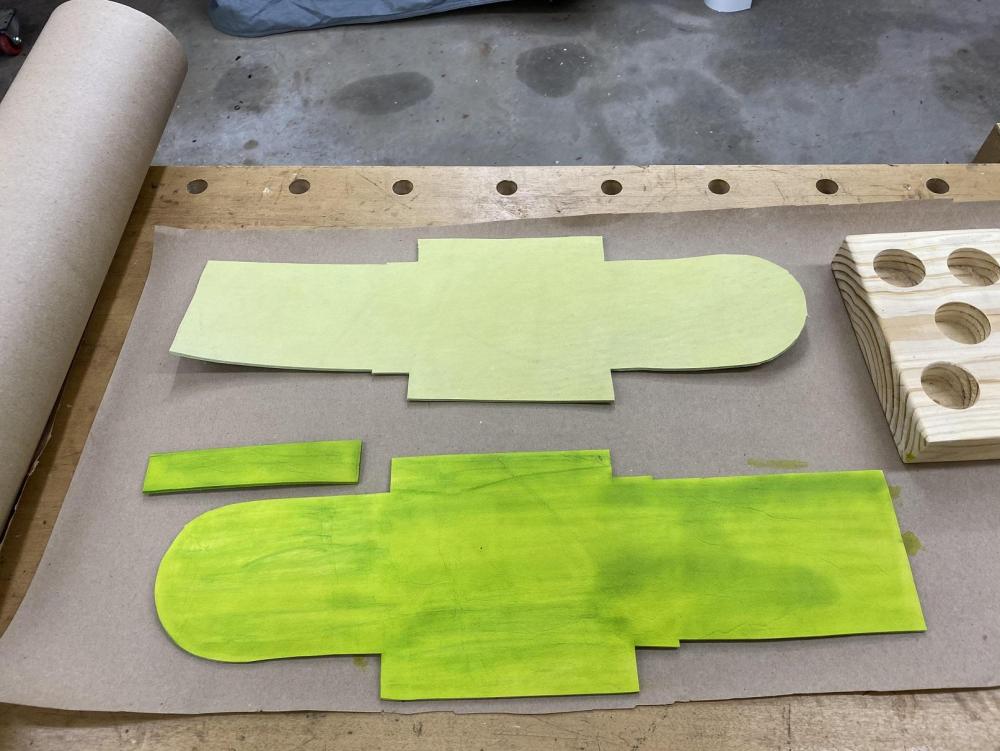

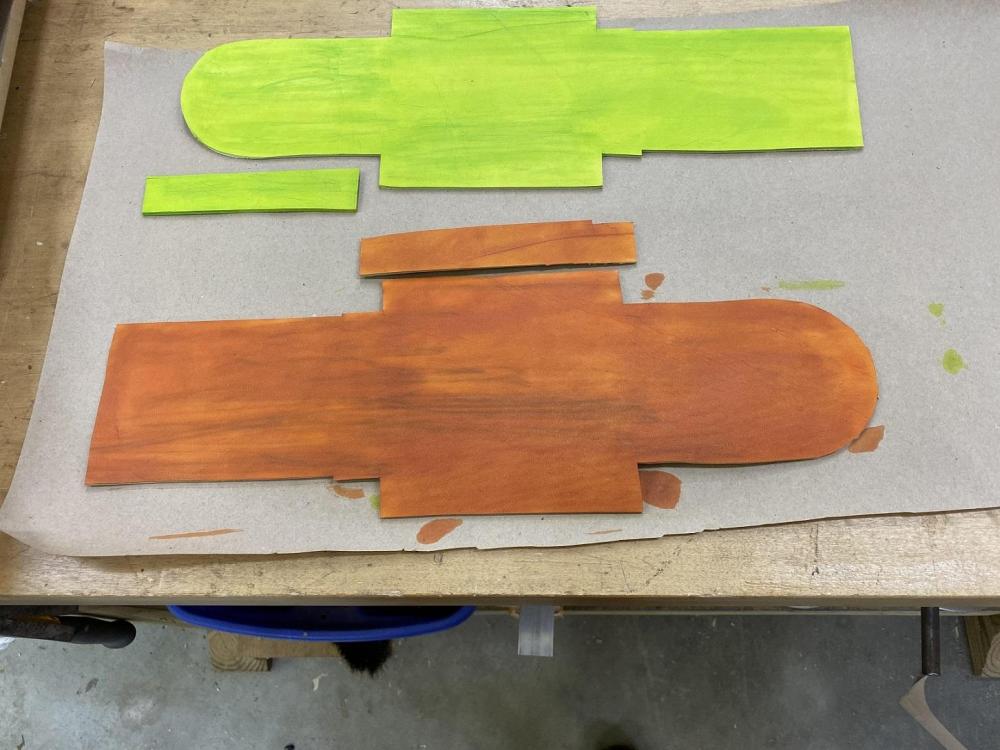

I sent the pics to my daughter after the dye was done and she loved the improved green, agreed that it really popped and was thrilled. The orange however... blech. She didn't like that at all. I sent her a new pic this morning when both of the dye'd pieces had dried fully and she said, still looks like dried baby.. um. She still didn't like the color. I told her I'd dye it red, and if that didn't work, black. I sent her the pic of the piece dyed red. She loved it. "Like the blood of my enemies," she texted back. That's my girl! I may dye the red again tomorrow to get a darker deeper red, we'll see. I am looking forward to starting on the actual assembly. Never done it before. This type of build will be a learning process. Fail, and count it as practice and start over with Veg Tan.

-

Oh, in case someone was wondering. The wood block in the upper right of the lime green pic holds pill cups. THEY hold the dye. PILL cups turn over EASY and can ruin a project. (They also hold mixed paint, Watco Oil and other things that ruin projects.) I saw the cup block on a you tube video and made one the next morning. I think I might add a couple small holes in the block that will hold a couple paint brushes and an acid brush vertically. You know, stick the NON bristle end in the block...

-

So, I dyed the first piece of leather and a 1" wide scrap to use as the loops for the two D-Rings. Important to thing thru the project, or I'd either TRY to match the color or say I planned to use black loops to match the velcro. You can really see the difference in the green between the newly dyed piece and the original undyed leather. The new piece POPS. Should be easy to see when Jess is looking for it. When the dye dries, hopefully it will be even. If not, I planned it that way. Now to the orange..... Same thing, dyed the leather pattern piece plus the extra for the D-rings. Ah... planning ahead. It's okay, the orange, but I think the green base subdued the orange rather than enhanced it. Again, I'm hoping it dries even. In both cases, I tried to apply the dye evenly, but the leather had been previously dye, and it's chrome tanned, which I have never worked with. Flying blind. Almost ready to start sewing the D-rings and velcro....

-

My next step in this pouch was to test dye colors. I intended to dye ONE pouch a BRIGHT green. The other an orange color, so I pulled a piece of the cutoff and sat down at the workbench. From left to right: A dark green mixed with 1/3 yellow. Not bright enough. The center? The dark green mixed 1/3 green and 2/3 yellow. Pops! The end? Red mixed with 2/3 yellow. Works.

-

Miss Tina has gone to Hobby Lobby for the D-Rings this morning. We drove to Duncan Yesterday. Her twenty year old Bernina started to waiver in Straight Stitch Mode. She was in the middle of a beautiful quilt with 1" blocks. The 1/32" waiver in straight stitch might not have been so noticeable with bigger squares, but seemed glaring to her with the small blocks. Duncan is about two hours each way, but the Bernina Service center is there. She has other machines, but doesn't like to use the embroidery machine for basic sewing, and the antique machines are noisy and rattle, but do sew a nice tight line. He said two weeks, but doesn't hold much hope, that machine has a VERY high stitch count. She uses them a LOT. With our history there, he said he'd make her a good deal on a replacement. If that's what it takes to keep mama happy.

-

Yup, I cut out panels for two. Hopefully they'll both turn out, or one will. If not, I got in some practice and will have learned a few things. I'll dye both pieces, try to brighten the green, and turn the other either yumm tumm orange or red. I have scraps to work with. Thought I had D rings. Hobby Lobby... Here I come.

-

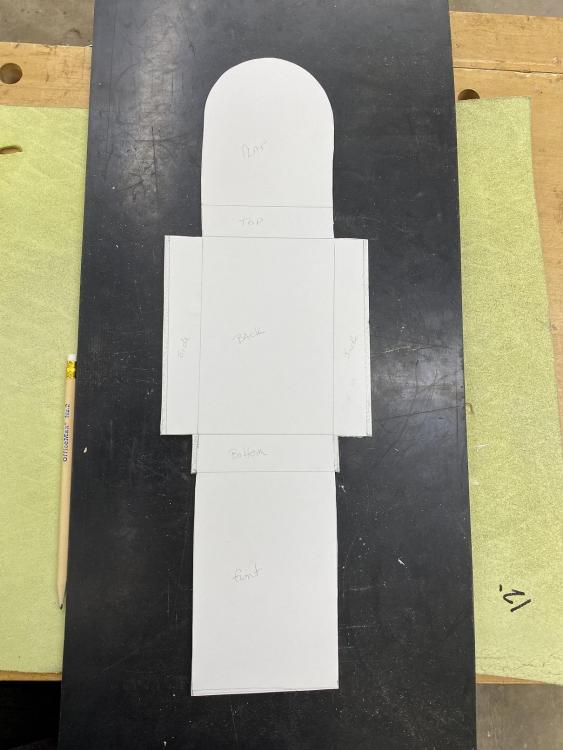

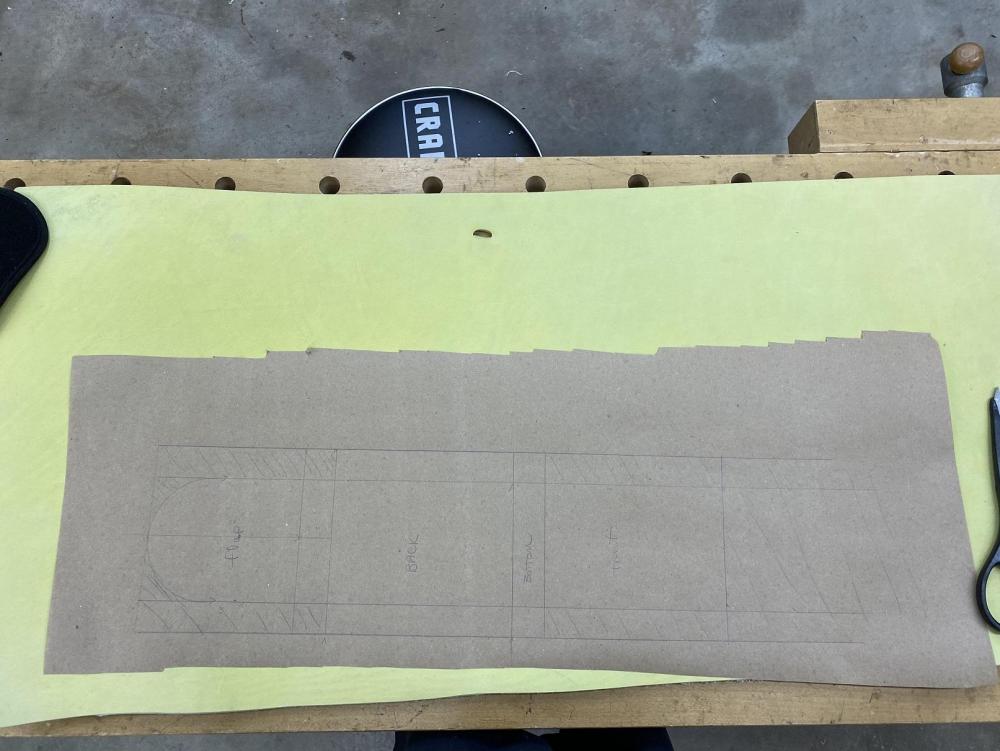

After I had the pattern drawn out, I cut it out very carefully and folded it. I wanted to check the size against the original pouch and look for sewing patterns and routes. Ah, size was good, but no... the sewing wasn't going to work. Back to the butchers paper and I added an 1/8 inch to the side and bottom panels to allow for easier sewing. I also figured out that I'll be sewing those panels by hand. I can use my machine to sew the velcro patches on the flap and front panels with the machine and attach the D-Rings for the lanyards prior to sewing it together by hand. Satisfied after folding the new paper pattern, I cut a hard pattern on poster board.

-

My Daughter has a medical condition that is pretty dangerous and always carries two epipens, and uses a Service Dog. HE has started to have seizures. Cruel World isn't it? So she has to carry his meds as well. She found a little pouch to hold both and has worn them out. She asked me to make her one, rather than buy another. It didn't have to be exactly like the other, just similar in size and shape as the dog is trained to bring it to her if she goes down. If rescue approaches her, he will pick up the pouch and "Give" it to them. Jess had brought some Chrome Tanned leather and said the lime green was fine. She wanted a bright color. I started by measuring the original pouch and transferring the design. Using the measurements, I created one of those fold it, patterns. I did that on butcher paper, actual size, I took my time and was very careful. I wanted the pattern to be as neat as possible, as I know she loves the design of the pouch and has been using it for years. I imagine I'll be making them for a while.

-

I just practice stamping and carving on scraps if I don't have a project, or make an extra sheath for an existing knife for practice, or for a new knife. Working toward making the western gunbelt.

-

As I said, I was going to make a nice leather handle, even cut it out, just knew I would never carry the case and take a chance of scratching it. A friend of mine bought a very nice shotgun in one of those wooden/leather carved cases. He bought a nice aluminum case to take the shotgun to the skeet range in. That really nice case never left his gun room. (Guest Room)