-

Posts

1,502 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by AlZilla

-

Soon as I read "... reached up ..." parts of my anatomy sucked up into my abdomen. My beard is long enough that I tuck it in my shirt if I'm using a dremel or other spinny thing in my hands.

-

Will you ship worldwide? Or just US? We have members everywhere.

-

Development of best servo motor for leather sewing machine

AlZilla replied to CowBoyOUTLAW's topic in Leather Sewing Machines

I've got a machine with a servo that does 100RPM startup and a speed reducer. Today I counted 14 stitches in 30 seconds. 50RPM would give me 7! But, I'm slow enough. -

Development of best servo motor for leather sewing machine

AlZilla replied to CowBoyOUTLAW's topic in Leather Sewing Machines

This is usually such a friendly place. He's made no secret that he's the marketing guy, not the tech guy. Would torque increase the same way speed reduces? As in 3:1 on speed equals 1:3 on torque? I'm definitely skeptical that a motor in this size range can achieve the same increase as 750 Watts with a 1:3 speed reducer. -

I appreciate the rundown on airbrushes. I definitely learned some things, but for the few times a year I'd use one, I'm not buying, maintaining and trying to remember where I put, an airbrush. I'll post back here if I get passable results. Overspray and spatter might make me happy. Perfection is just terminally boring.

-

That armored tee-shirt saved you. Sucked up the energy of the spinning bit. EDIT: 7th grade wood shop teacher was missing a couple of fingers and had a scar on the same wrist, having almost lost the hand. Years earlier his necktie got caught in a wood lathe. Maybe that's why I don't have all the great war stories you guys do ...

-

Yeah, I knew somebody would spot that I burnished before I glued ... Normally, I would glue/sand/burnish. It also would have flattened that edge and avoided the little stitching hiccup on the back. Appreciate the comments ...

-

Yeah, mine also take a bit before that servo light blinks out. All of them. If I watch, they all flash "err 2". For me, "Off" means lights out. Especially on that 441 clone! EDIT: I forgot we were talking about those torque monster clutch motors. Absolutely, if that bad mother is spinning, it's "ON".

-

Thanks, guys. In the harsh light of pictures, it looks like I could decrease my presser foot pressure.

-

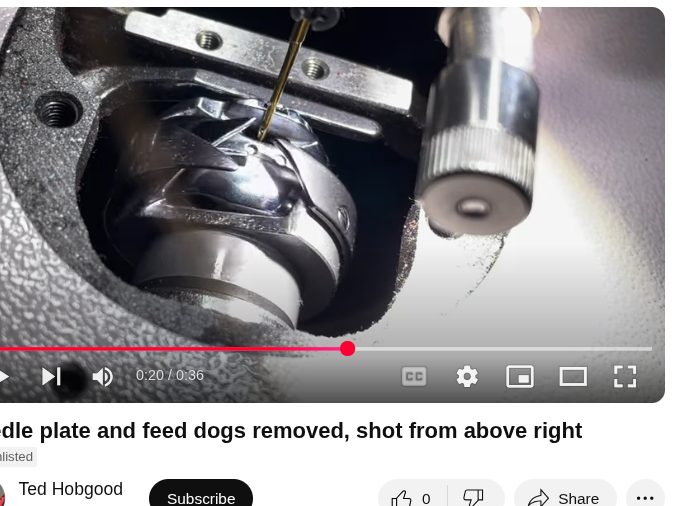

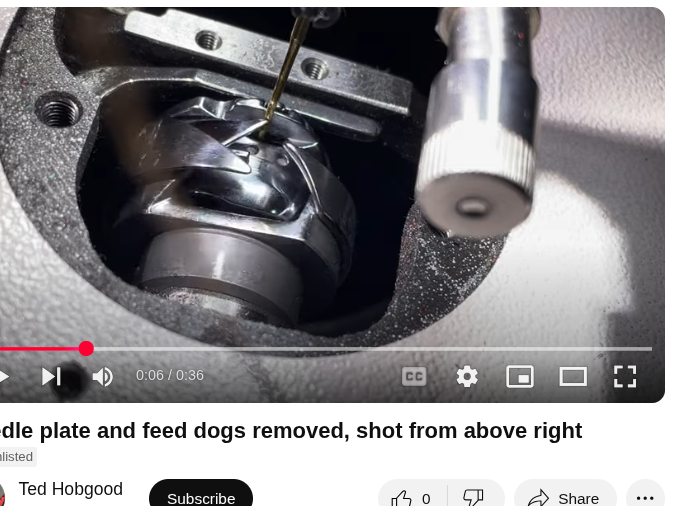

Juki 5550N experiencing problem in the bobbin area

AlZilla replied to thobgood's topic in Leather Sewing Machines

Have you looked at everything the thread touches and slides across to be sure there's not a burr somewhere? Come to think of it, have you looked to be sure the thread is feeding smoothly from the spool? -

I think my next project is going to be fabricating a couple of hinges out of angle iron. It is a genuine PITA trying to work on this thing, flopping around on the bench ...

-

Juki 5550N experiencing problem in the bobbin area

AlZilla replied to thobgood's topic in Leather Sewing Machines

That whole post should be a sticky entitled "When Your Sewing Machine Skips Stitches". I'm going to print it out and go through all my overlooked check springs the next time I have to work on my machines. Thanks for the time and effort putting that together. -

Generally I just make functional things, including this one. But I thought I'd post it anyway. I bought a cheap Tractor Supply knife, put a razor edge on it, cut the junk sheath apart and used it for a template. Here's the result. Machine sewn, for the curious.

-

This was my concern, that this is going to devolve into a string of DND links. If the members want to have this conversation, no problem with me. But we have enough trouble with the Minecraft spamers. No need to add DND to the list.

-

Let's move this to Off Topic. I'd use a firearm to kill a cow, skin it and tan the hide, then cut the strips I need. Unless your realm has a leather store like Tandy.

-

You could put a binding on the edges to hide and contain the interface between the liner and exterior. It's a folded over piece of your material of choice, folded over the edge and sewn. Pretty common on all sorts of things - clothes, gear, carpet and so on. You've seen it a million times. The rest of it, I don't have a clue.

-

Is that a very long strap, doubled over around the buckle to give you 2 layers? Very tedious work. The overlapped stitching isn't noticeable until you look for it. Very fine work!

-

Is that a clutch motor?

-

Replacing the Hook (and Bobbin Shuttle) on a Juki LS-341N

AlZilla replied to Yoshi888's topic in Leather Sewing Machines

You'll be glad you did this repair. It's not nearly as difficult as it seems. I think your machine uses Allen screws, if I remember right. If it's slotted screws, you'll want good, hollow ground screw drivers in the right size. Let us know your it goes. Maybe you'll inspire the next person.- 5 replies

-

- sewing machine repari

- juki ls1341

-

(and 2 more)

Tagged with:

-

I wrestled a little with this post yesterday and decided not to respond further. To me, giving (whether a brand new car or answering a question like the OP presented) is done without expectation of any return or even a thank you. So, I wouldn't boot someone for not checking back in. An acknowledgment and thank you would certainly encourage more dialog, but people seem to be pretty self focused these days. Maybe he forgot where he posted the question ... It was really kind of a fragment of a question anyway, not really enough info to give a coherent, specific answer. I think Chuck nailed it - pretty much any information a person needs is somewhere here.

-

I'm pretty cavalier with the domestics, but the industrials I (usually) shut off. A good reminder,

-

Yep, that is a lot of work. Very nice work, too. You would be doing all of humanity a favor if you uploaded your images directly here. Unless you plan on leaving them on that 3rd party site for all of eternity and saddling your descendants with maintaining them in perpetuity, they'll disappear at some point in time. Imagine how disappointed someone is going to be 400 years from now, not knowing what that ancient belt looked like ...

-

Development of best servo motor for leather sewing machine

AlZilla replied to CowBoyOUTLAW's topic in Leather Sewing Machines

Exactly. And people will spend long money for the latest and greatest. Thousand dollar cell phones when a $40 phone does the same thing, handgun optics that cost more than the handgun they're attached to, the list goes on. I believe what OP was saying is that they already have a 50 RPM start speed, so no need for a 5:1 gear reduction. I also think there's a language barrier involved. I don't know any more than the rest of you how sincere he is, but it's a worthwhile discussion. Definitely got me rethinking some of my choices. Wiz's comments above have made me wish I hand't turned my nose up at those outdated brushed servos! EDIT: Let's not forget leather stamps. Look how many people buy $50 big name stamps when a $7 Hobby Lobby stamp is pretty close.

.jpg.d60258221c476480a6e073a8805645bb.jpg)

.jpg.442ba33f0e0a6b457c45387319bd5ed1.jpg)

.jpg.35750c11062811f63a3e4718c037f11d.jpg)

.jpg.246afc3c10d815290fd489dbaec85f3f.jpg)