All Activity

- Past hour

-

Yes you are. I have been following your progress and it is damn good. kgg

-

Thank you all so much for the replies, really appreciate it.

-

Oh, you're buying it 'retail" - that's different indeed. I generally get HO ..FROM H.0. This means buying 10 sides, but I figger I'll use it so it's fine. Just going through it a bit slower than the saddle makin' crew. The ONLY place I ever recommend for buying HO in smaller quantities is GOLIGER LEATHER. Cheryl has always shipped great leather (when you order "A" you GET "A") and the service is just as good. Only thing I could possibly not like about it is the shipping CA to the midwest is a bit spendy,... but unavoidable. So AGAIN - Goliger has never sent me a piece of leather I wasn't happy with. I have TRIED to work with others over the years, with little to praise for it. YEARS ago I could walk into The Leather Factory (before it was "tandy leather factory - I don't know if they bot it or if they already owned it back then and were running under a different name), pick out some hides, and be tooling GOOD leather at a GOOD price in an hour. That place is still in Des Moines, IA ... now called TANDY leather factory... and largely filled with JUNK (and the manager last time I was there is a jerk - if they know what's good for them they've got rid of him by now). Back when, you could just call and in a couple days you had a solid chunk of leather that was 90% good stuff (and 10% of the less firm edges for testing dye and stain colors is fine). Now, I won't buy anything there unless I find time to go hand pick it. And HOW MANY times did I order at SLC and get ... EWWWW. I explained to them that I buy from Hermann Oak, but sometimes I just need one or two sides of a different weight. Usually I would order a "back", cuz i don't care for the belly leather. More than once they cut it the wrong way (seriously, not a joke). And SO many times the leather I got was FAR from being the "B" grade i ordered. I'd call and explain to them again that I HAVE "B" from HO and yours looks nothing like that. Honestly, I think they're SO geared at retail sales that they don't really "grasp" that somebody would actually know the difference (and they're counting on that). ANY RATE, they'd always apologize, offer to send me a different piece... not charge me shipping for returning the doormat they called leather.... BUT I finally just had to tell em that while they'd never "stuck" me with a piece they refused to take back, the time I was having to spend straightening it out just made it not worth the trouble. I have purchased some good leather from S-T Leather (st louis), but it has been hit and miss, not consistent. I ordered leather from Weaver Leather. Once. Never again. Some of the worst hides I've ever seen. And you've already seen my vomiting up ALD above. And the W/C I generally order FROM W/C as well. I think the smallest piece they sell is backs, so like 17-18 sq ft. But it's good leather. I use the "holster" leather for what it sounds like, though it TOOLS very nicely. I'M not sure how it's different from their "tooling" hides, which are quite nice. As I mentioned before, it's a bit less "firm" than HO leather, assuming the same treatment. The hides are generally quite clean - not a lot of waste. I think like twice (or was it 3) over the years I had an issue worth discussing over there, and was always met with an acceptable outcome. My "pitch" to the places I buy leather is simple. I don't mind PAYING premium price, long as I'm GETTING premium leather. I tell em right on the phone.... send me the best piece you have and charge me accordingly. IF the leather is good, and the service is good, you won't hear me complain about the cost. Other side of the coin is... free shipipng is no favor if you're shipping me landfill material.

-

Good morning Guys. moved this "topic" to the used machines for sale forum. I need to move this machine along to a new caretaker.

- Today

-

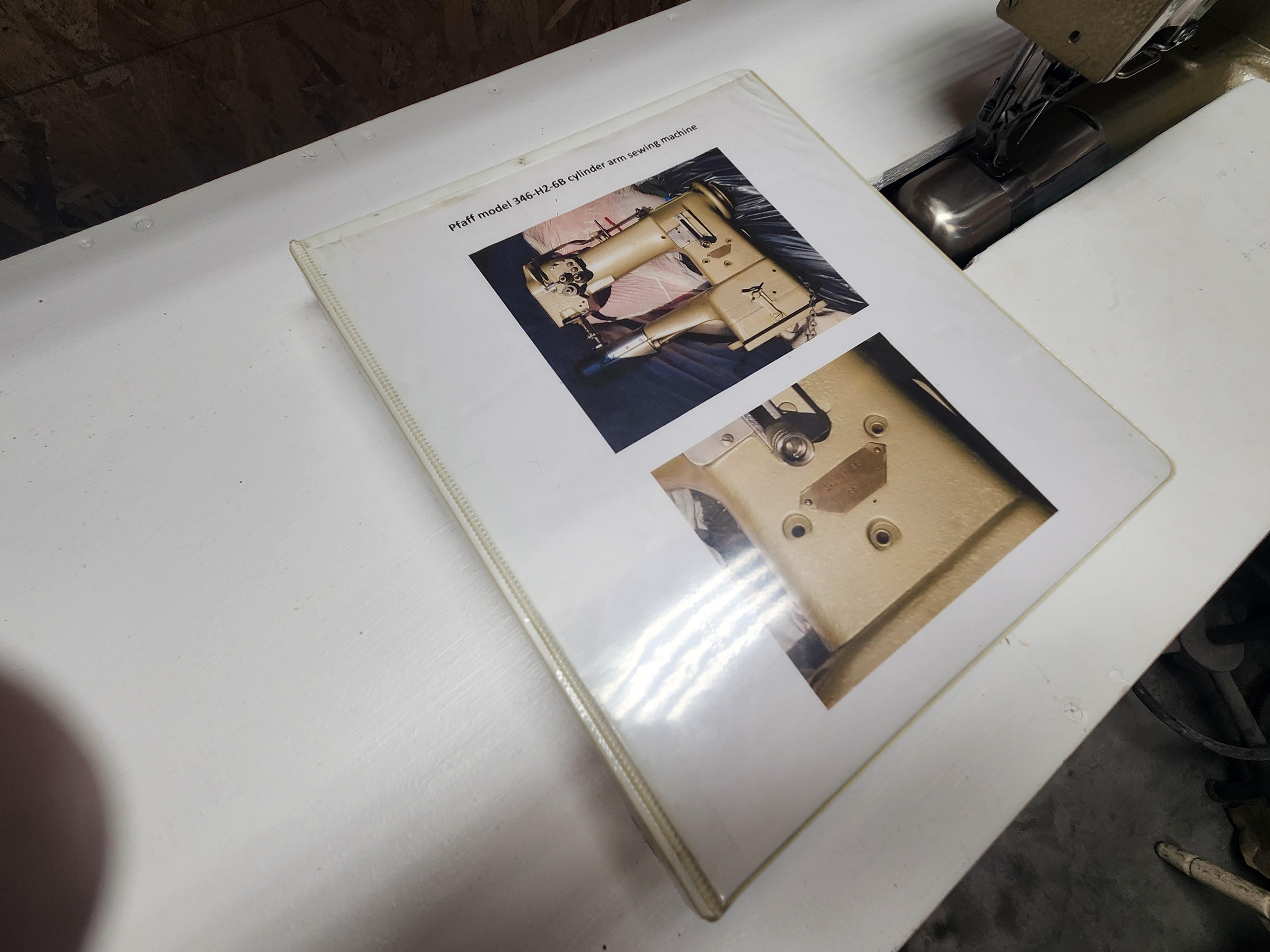

Time to move my 346 along to a new caretaker. I picked up this cylinder arm machine about three years ago and have had it in dry storage since. While recommissioning it recently, I found that it does not reliably pick up the bobbin thread. This adjustment is beyond my skill set. Buyer gets the machine, table and clutch motor. A table/insert to provide a flat surface, a 3-ring binder with useful info such as manuals and parts list. Pickup on west central Connecticut. $400.00. test reply by gary

-

Welcome to the forum from Denmark. The Singer patchers are fantastic machines. Have fun restoring yours. Brgds Jonas

-

Just finished up an axe sheath for my son-in-law. Probably the last time I sew something that thick, but I had an idea and wanted to see if it would work. It did, but my fingers are sore. Lol

-

I would knock as much rust off as you can with a wheel or brush. Then soak in EvapoRust or Metal Rescue - WD-40 makes a similar product I have not tried. Wire wheel off the residue, use what ever abrasives are indicated to work out deep pitting, oil dip and work the hinges some, oil again until it comes out clear. Might end up OK. Here are a few I have had through here with the cast bells. The #10005 is a Barnsley.

-

And I'll echo those ^^^^ words . . . May God bless, Dwight

-

I'm going to be the outlier on the edges. While admitting they might be more attractive if polished and concealed, I think they look fine as they are. To me, edges that are totally concealed and finished to hide the seams just look like cheap vinyl that could be spit out of any factory, 10,000 before lunch time. To each, their own.

-

Welcome from SW Missouri, USA. You are now joined! Lots of knowledgeable folks on here regarding sewing machines.

-

Skiving tip to get an even surface

Loft Leather replied to DoubleKCustomLeathercraft's topic in How Do I Do That?

I have a cordless electric Ryobi wood planer. I can shave down a 2x4 nicely with it. I wonder if a stiff piece of veg tan would be "plane able." Running it over softer leather sounds like a recipe for a tangle up in the blade and might be unsafe. Maybe if I skive perpendicular to the edge instead of trying to run it lengthwise it might stand a chance of allowing for a nice rolled edge? The heavy veg tan this would likely work well on seems like the type I have the best chance of doing a decent job with a knife skive by hand anyway. The softer chrome tans are where I think I'll make a bad skive and screw it up. -

Looks really clean! Love the stitching. It appears that the laminated edges could use a bit more sanding so they look like a single piece of leather instead of 3. It takes a bit more time, but the results are fantastic after burnishing the edges. I would also help to really press down on the pieces after gluing to ensure there are no gaps between the leather.

-

Looks good. Did you put edge paint on it?

-

A quick internet search turns up a lot of hits for Geo Barnsley. I didn't follow the rabbit trail but it seems Barnsley is pretty well known. https://duckduckgo.com/?q=Geo+Barnsley+lasting&t=brave&atb=v430-1&ia=web

-

I Used an Automaker's Emblem on a Key Fob. Did I Do Wrong?

billybopp replied to Gosut's topic in Leatherwork Conversation

Remember back in the day, when you'd get a keyfob with your license # on it, and an address where you could mail them for free return service? Times have changed! LOL - Bill -

I Used an Automaker's Emblem on a Key Fob. Did I Do Wrong?

Handstitched replied to Gosut's topic in Leatherwork Conversation

@Gosut I don't think you have much to worry about. I use beer logos in leather, and I also sell beer bottle tops as fridge magnets. Some years ago , I spoke to a rep for a company that covers many beer brands etc. here in Oz , he told me ' as long as I don't modify the logo they are fine' . There's a thread regarding copyright on this site. HS -

@lhow I would take a punt and say they are pre 1900's. The later models with a bell shaped hammer had screw in hammers ,the one pictured is cast as a whole piece .The earliest reference catalogue i have is from 1910 and it shows the screw in bell style . In fact that is the first one by any maker that i have seen with a cast bell hammer . With a rust converter treatment and a going over with a wire wheel they could become serviceable again .

-

How to add needle positioner on adler 669

HarrySingh replied to HarrySingh's topic in Leather Sewing Machines

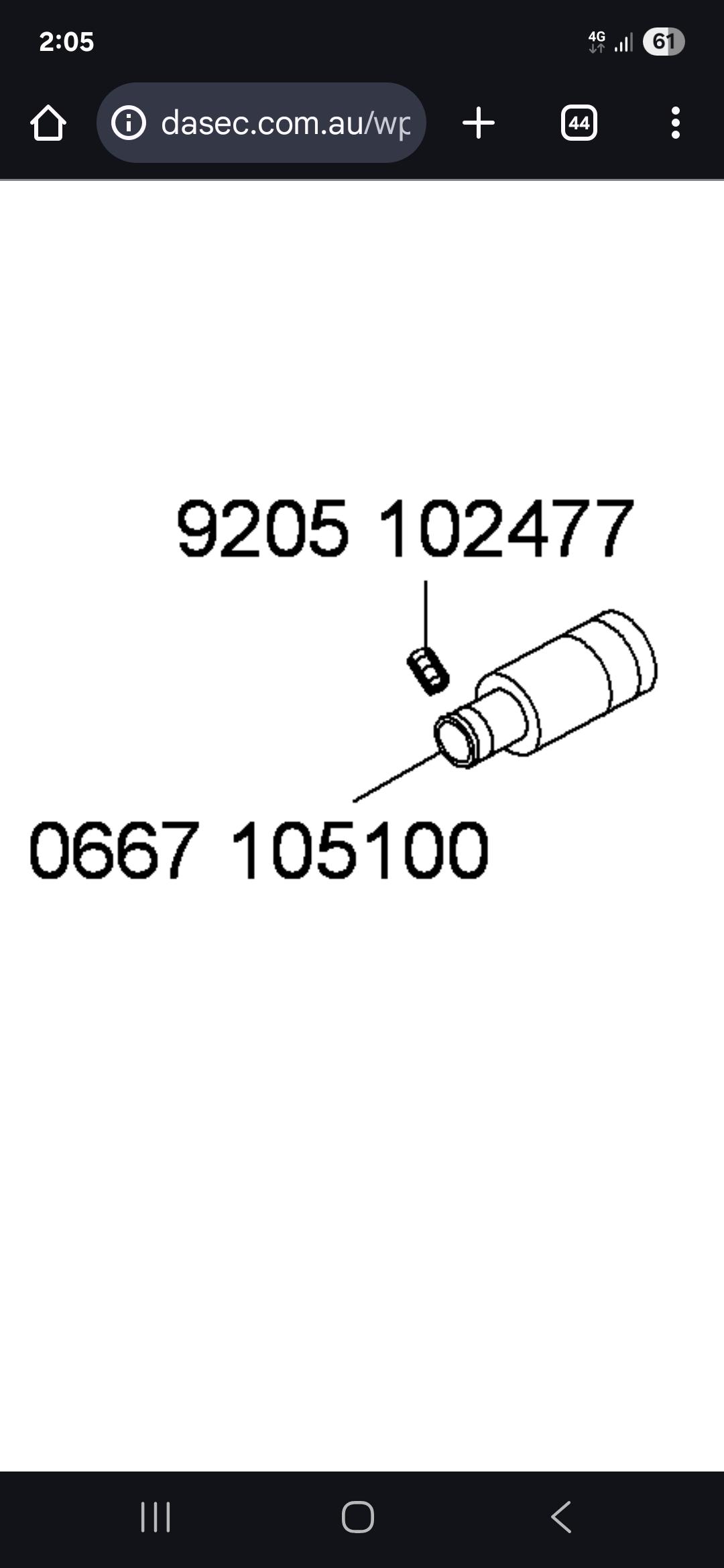

Hi Glenn, Thanks alot for the reply. Just checked on google the part no mentioned and find on 867 manual and the screen short of the part is this... Do it's needed to screw , I think their is no hole in Shaft or i may need to recheck. Do 600 watt [Hohising g60] in enough for 669? -

SwampyCar joined the community

-

Had a go at making some dies for a fellow shooter and leatherworker. It's not as easy as it looks and there's an element of luck in trying to match the shapes on two sides. Part of the process is figuring out which combination of tools works best to get a desired result - sometimes it's not what you think. I had to make up another tool because nothing I had would let me get the bend I wanted! I tacked the die together with the MIG, and after I'd taken the photos I put a sharpened bevel edge on one, using a worn 120 grit belt (that reduced the risk of grinding too much and also polished the edge). I put it under the Vevor press with some thick scrap and heaved away, very satisfying when it went clunk! It worked!! The banding works well and is surprisingly tough, although being 1 1/2", compared to the 1" of the steel rule, means it's just a bit harder to work with. Damn, I'm good!

-

That's a bright idea. If you turn on the drill press slow you could use the punch for mixing batter too.