All Activity

- Past hour

-

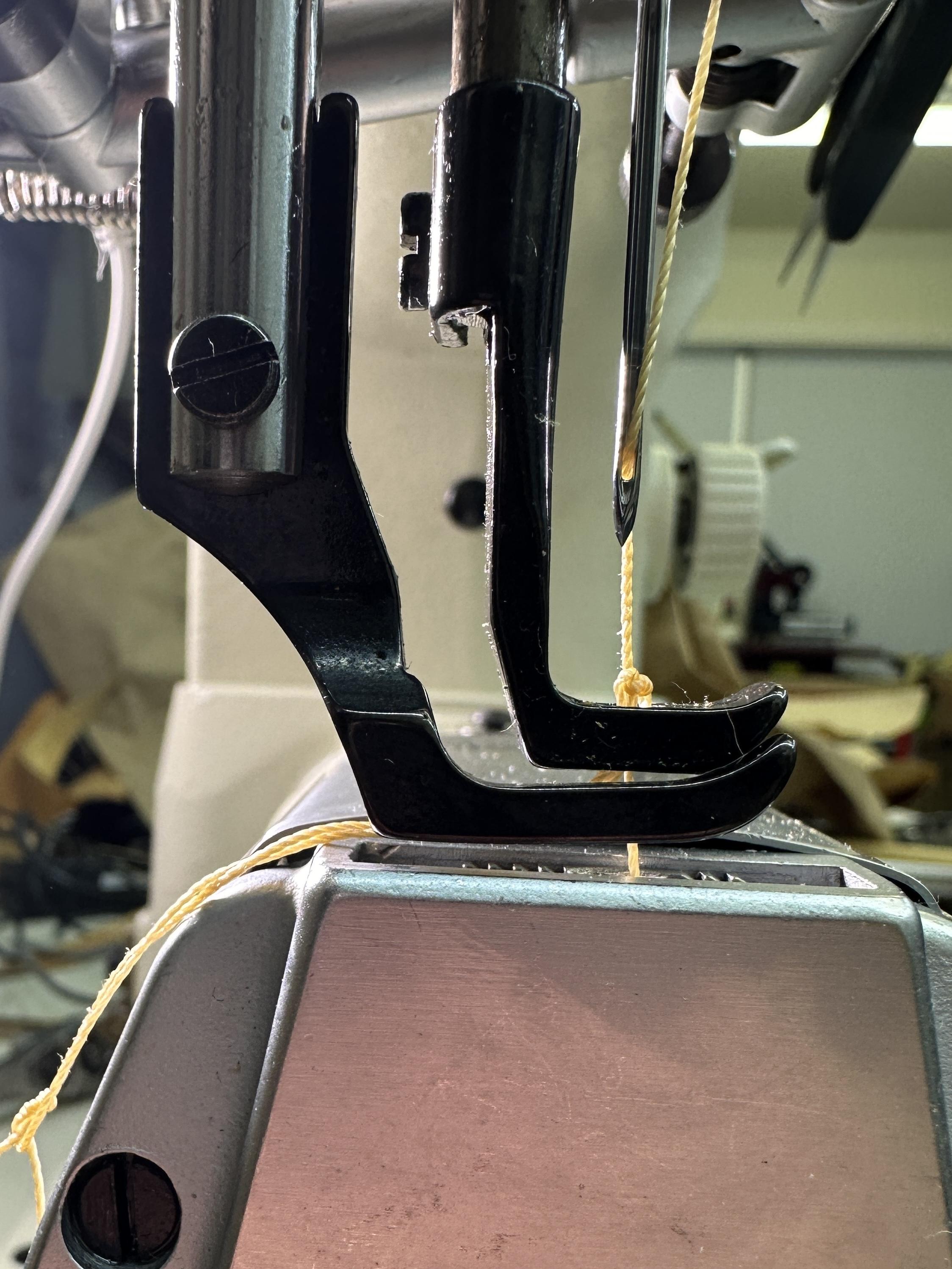

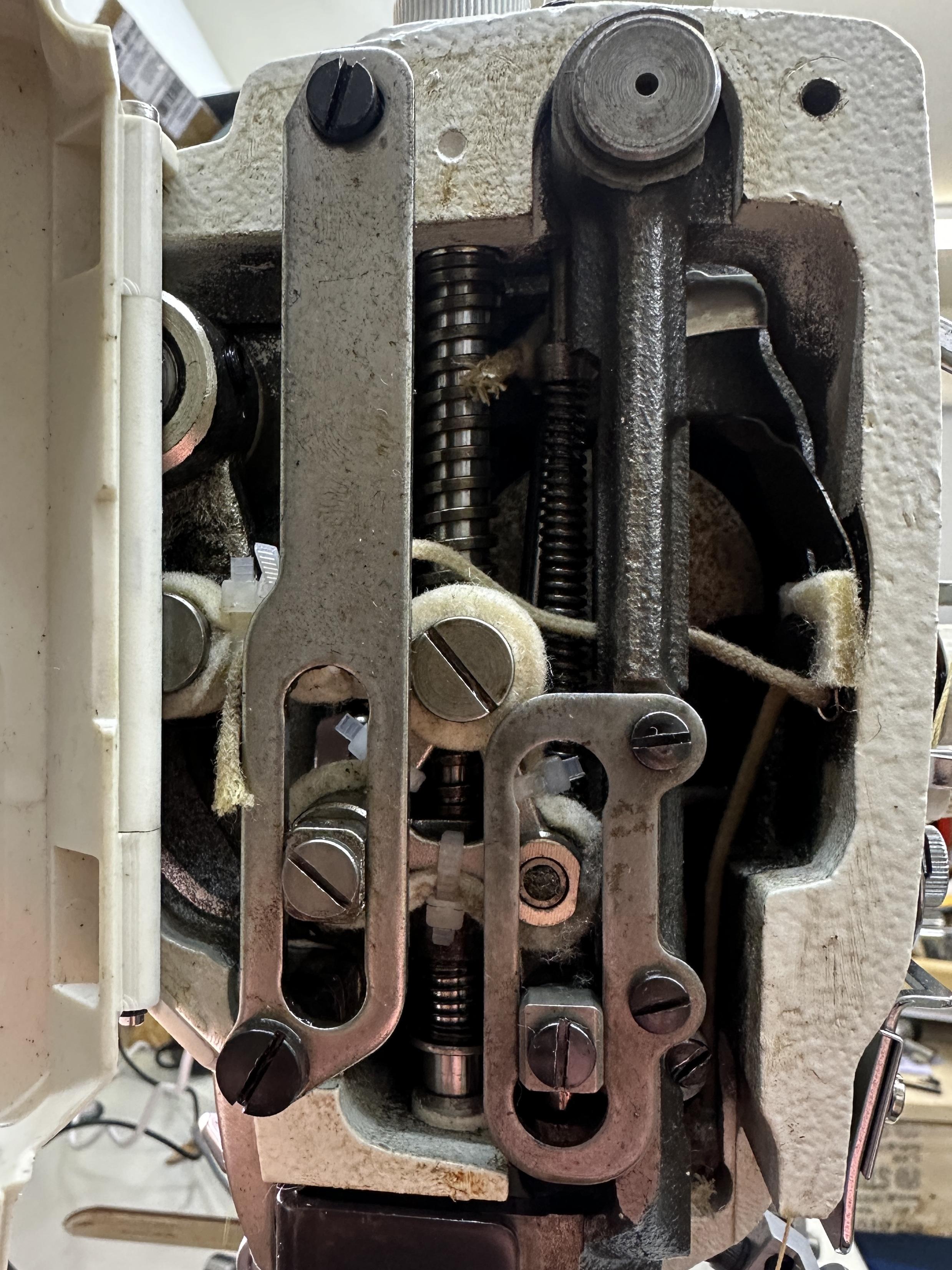

I just picked up a used 1341 and noticed some of material slightly slips while sewing. When the needle reaches the top most, shouldn't the presser foot go all the way down to the throat plate? If so, can anyone help me and explain how to adjust the presser bar to go down?

-

A few thoughts from my first time applying tools or finish to leather... Workspace is important! Everything must be clean! And I understand why I've seen people wearing gloves working with leather. My pieces look thoroughly manhandled, which of course they. I felt like a fingernail scratched some surface every time I moved. I already know what I'd do different. I beveled the edge. Smooth, even passes are critical. I presume I'll get a feel for the right angles and pressure. I sanded with 240. I tried to go "one way" but again, I'll figure out the grain. More like wood? Or steak? 😉 I did one pass with tokonole. Clearly I used to much. But I see what one application did and how to make it better. Even for a first time, I think it looks better than it was. This weekend I teach myself saddlestitch!

- Today

-

Recommended Source for Hermann Oak Tooling.

PastorBob replied to Latigo Smith's topic in All About Leather

KC is a great guy and have done business with him multiple times at Traditions. The Live Oak leather they have tools nicely. It just doesn't seem as "sturdy" or have as much density as HO. Almost kind of floppy. But after tooling and dyeing, it firms up pretty nice. I have been pleased with it. It seems to be cheaper too. -

' How do men in Australia find sheep in long grass?' Very enjoyable indeed HS

-

i think it came out pretty darn good!

-

Yes, you can notch the life out of the first fold because no one will see it. More careful with the second. Skiving might help as well.

-

I didn’t really stretch them that much, they always shrink tight. I started off using dental floss on some of the more delicate wallabies to attach them to the frames until one day I was in a hurry and tried the pneumatic staple gun and found it heaps quicker and neater. The cows were strung with builders string onto a makeshift raw dogwood frame. My place is surrounded by dogwood so that was easy to grab at the time! im not 100% sure what the timber is on the cat frame, my neighbour has a Lucas mill which I help with from time to time and gave me a lot of the off cuts - he says it’s American redwood. But this is the outer sapwood. I like the look of it so have left the cat on it! last night I took down the cow hides off their frames, I have heaps more room now! Im in tassie, love it here.

-

I trying to find new rocker to order and new screw for sure the thread is damaged in there, so will replace for new thank you

-

Taylormm joined the community

-

My daughter needed a gift for the buyer of her project at our county stock show. Since her buyer happens to be my boss’s wife I was able to customize a purse for her. I used 5/6 oz Hermann Oak skirting for the panels, and for the gusset some chrome tan that I found at Tandy on clearance I thought look nice. The pattern I used was from Tandy’s purse pattern pack that I modified to have an interior pocket and have a wider gusset with a shoulder strap instead of the wrist strap it called for. I used the tooling pattern that came with it slightly modified to incorporate the brand. I gave it a couple coats of neats foot oil and used mahogany antique and finished with tan-kote. Sewed it together with Maine Thread .040 twisted thread. Here are some pictures, let me know what you think.

-

spring flowers and good food

Darren8306 replied to chuck123wapati's topic in All About Us and Off Topic

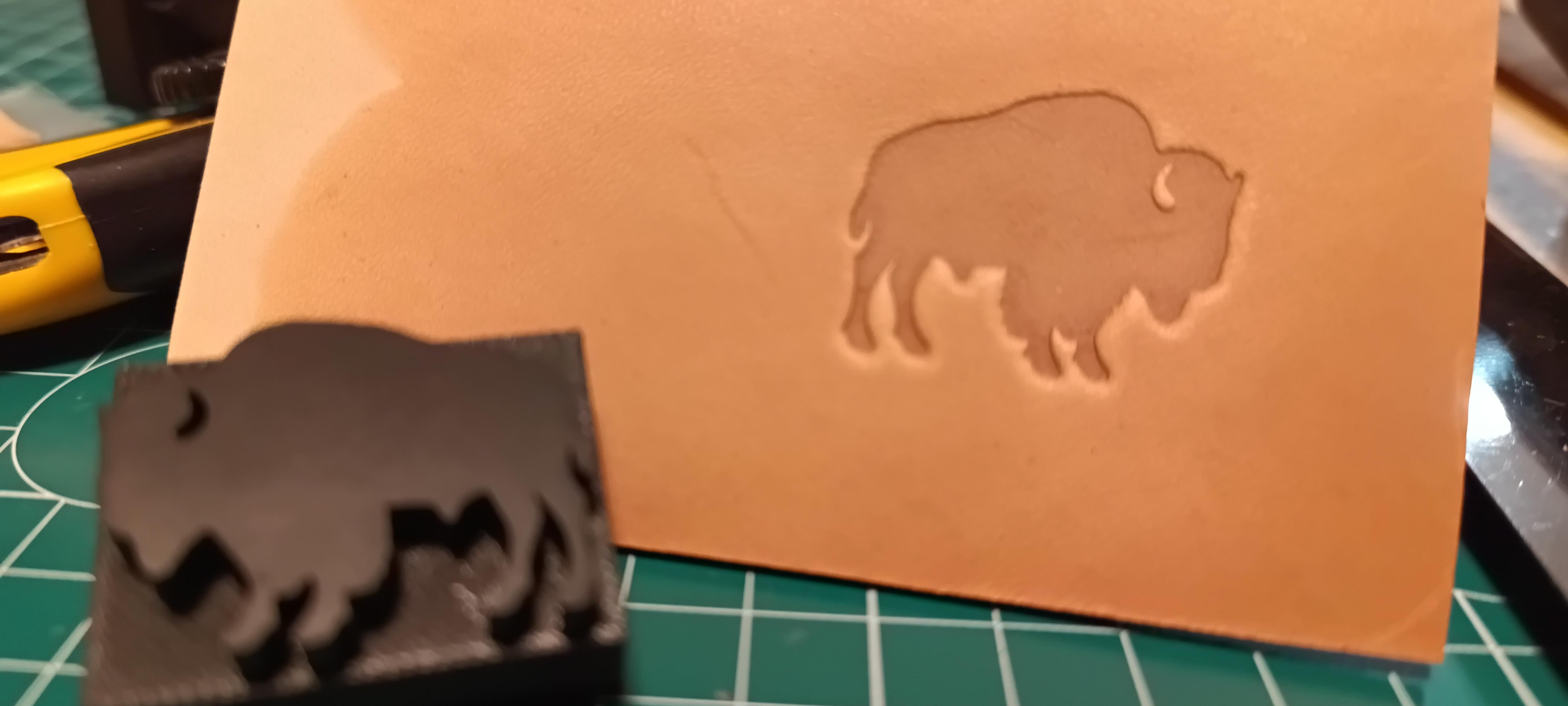

My friend just got into the 3d printing hobby. The other day, it was his birthday. In true hobbit fashion, he gave me gifts. several animal stamps, 3d printed with carbon fiber plastic. When I tried the previous stamps, a texture from the printing became visible after finishing. This time I sanded it a bit and got rid of that. So now stamp production is so cheap, it almost isn't worth considering buying a metal stamp for these. He has also made some rollers, which are for impressions on clay, which is a hobby his sweetheart loves. (I sense some motivated learning there) If you want a stamp, it is now shockingly inexpensive and easy to have. I may devise a durability test, but the one I tried last went over a dozen uses with no visible wear. -

neverwill joined the community

-

dikman, I thank you again for your feedback. I’m presently working on purchasing the machine which would be my first industrial machine. As you mentioned, it should be a good machine and is reportedly in working order. If the shipping comes in reasonable I’m ready to, and excited to get it as it’s looking like a fair deal. I was trying to see if someone was familiar with this no further letters/ numbers following the 211 identifier. I have heard that it is a machine for which spare parts are not too rare and that it is the precursor to many other reliable machines. All in all things seem to be promising. It will take me a while to get her online but I’m looking forward to get it, inspect it, clean it and eventually having it working as well as I can. I’m excited. Thanks

- Yesterday

-

Recommended Source for Hermann Oak Tooling.

bladegrinder replied to Latigo Smith's topic in All About Leather

I was buying from Springfield in the past until both of my last two orders got sent back. In my eyes what they sent to me should never have left their door. It’s sad to think that they lost a good customer by obviously trying to pull the wool over my eyes and hope that someone somewhere will just not send it back and just bite the bullet on accepting inferior leather. I’ve since bought two sides directly from Wickett and Craig and was absolutely happy with both the quality, price, and shipping. -

Forgot could do a ranger belt style buckle set-up, I want to try this.

-

Thank you, I use a soft tape to measure the circumference of it and and some if using a concho, on my first one made a connector strap for the back to fit it. This way it will fit different hats with a new backstrap. On the one with the concho you could make some extra hole on the bottom piece for adjustment. For fit try to make it snug so it stays on the hat, be careful if to snug it will make the hat tight, could use a dab of hot glue for added security or a stitch. For me being able to remove it easily for cleaning or changing bands cause I made a different one. Added photos to show, hope this helps.

-

Pm Sent

-

G'day cobber, good to see another Aussie on here. Which State are you in? The 132K6 is a good solid machine but be warned, an interest in sewing machines can lead to a very deep rabbit hole!

-

Those came out well. heck all your stuff is looking good! I've always wanted to make some hat bands, but I've always wondered how to make them if you don't know the size of the hat it will end up on, and how they are attached to the hat. Any pointers?

-

Top photo is of an Osborne six inch round knife. I bought this when I was in the Navy Circa 1954. Number embossed in blade doesn't come up on Google. It has been ground professionally and cuts leather like butter. There is a slightly flat spot at the top of arch. I do not remember why that is there. $50 plus shipping Round knife at bottom of photo was custom made for me by Terry Knipshield. Three and a quarter inches tip to tip. This is a top of the line blade. I used it to skive leather and cut intricate pieces of leather. Blade is scary sharp. $200 -=SOLD=- plus shipping. I will not take less for this blade PayPal or Postal Money order

-

Makersleathersupply.com

-

If you get the 1/2" leather tape that can act as a guide.